I am also having a similar issue on the duet2 and rrf 2.05

Layer one is perfect on tool0, but tool1 is too high. Changing my G10 Z offset for the second tool has no effect on the first layer, but it will be accounted for in subsequent layers.

I am also having a similar issue on the duet2 and rrf 2.05

Layer one is perfect on tool0, but tool1 is too high. Changing my G10 Z offset for the second tool has no effect on the first layer, but it will be accounted for in subsequent layers.

I didn't quite find what I was looking for, but I figured it out.

What I did was start a 20x20 cube print, with different color infill and hit print.

I watched the layers, and guessed how much it was off by.

I paused the print, sent the G10 P1 Yx.x offset code with my new number for Y, and a M208 Ux.xx for offsetting the second extruder in X.

Then I homed X, and resumed the print. I would let it run a couple layers, then look at what needed adjustment. Then I repeated this process until I was happy with the result.

It was as "Live" tuning as I could figure out. It wasn't so bad.

Is there a way to babystep one axis while printing to align both extruders on an IDEX system?

For instance, mid print I could see that the extruders are misaligned. If I were to babystep X while printing I would be able to change the offset of the active extruder and take note, to then offset it in the config file.

I'd rather not do this longhand if I don't have to.

Hello! I am about to undertake a huge project for myself, and will be wiring a few printers with both the Duet Wifi/Duex5 and the Duet3 with tool boards and all that jazz.

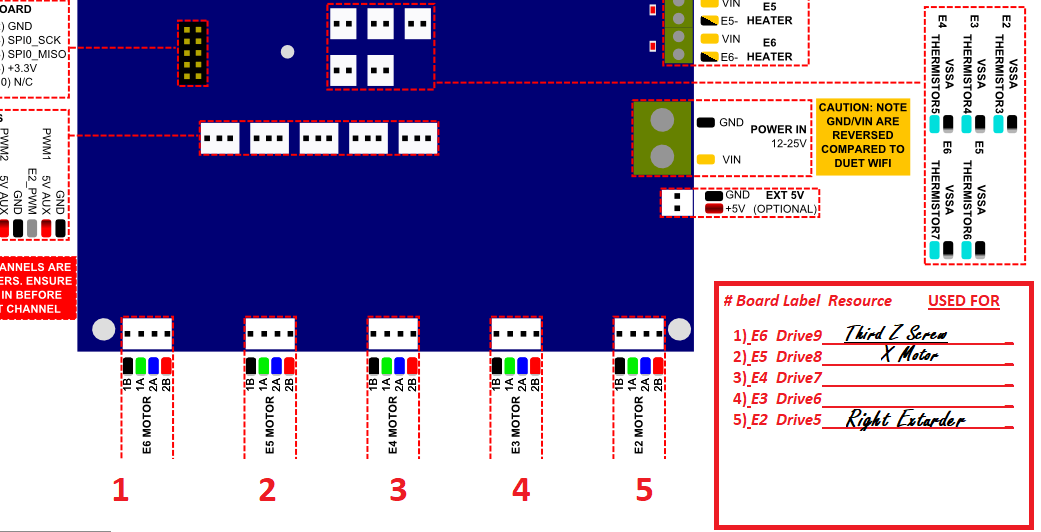

My question is, Is there a blank wiring diagram available that I can just fill in as I wire?

I would love a diagram that is numbered, with a resource key and blank lines for my notes.

Then the key would be labeled the resource that I need to use when configuring the hardware. For instance on the Duex 5, the board is labeled E2 in real life. The current wiring diagram shows it is Drive 5. That is all good. But PWM4 is not very straightforward. Same with other smaller IO's. Having an input legend with a notes section would make things very easy to keep a record of both your wiring for future troubleshooting, and keeping what you have plugged into what straight when writing the firmware.

It's very hard to describe what I want to see, when the existing diagrams are still very good, and I know many will find my request silly.

Like most of my ideas, someone usually has beaten me to it. So I figured I'd ask if this already exists.

Thanks for the help guys.

I had tested continuity of the heater wires once while tapping and shaking the cable chain and the rest of the harness, and they checked out. I decided to check them again, but this time while moving the carriage around. There was a dead spot towards the back and middle of travel, where I would loose contuinity.

I've replaced the heater wires and hopefully that is that.

I was using that red reinforced silicone heater that comes on the heaters. I have never had that stuff burn before, but I am thinking that has to have been what that smell was. I know what motors, and circuit boards, and regular wires, and plastic smell like when they are burning. But not that stuff. Maybe now I do.

The regained connection is a result of me resetting the heater fault, turning the heater back on, and resuming the print.

The wires are ran through a cable chain. The only connector for the heater wires is an XT30 connector, near the heater. The wires are flowing nicely, and nothing is sharply bent other than the heavier wires going into the cartridge itself (they have to be).

I will attempt to get a couple pictures.

https://ibb.co/gFTkSMv

I have no idea how to upload images, on my list of things I don't know.

Ok, I have thrown out nearly a spool of filament, and this is getting old.

The other day, I was printing a long print over night, and noticed an unusual burning smell in the morning. It was something new I haven't smelled before and I really couldn't figure out what the smell was, or where it was coming from. Sniffing up close... I couldn't find it. I've been cautiously babysitting my printer during shorter runs, and everything has been working fine...

I had a print just stop, and seen a print cancelled warning due to heater fault. I figured that had to be related to the smell. I happily swapped my heater cartridge. While I was at it, I installed my PT100 I have been putting off.

So with a new heater, heater block, nozzle and heat break I felt confident that my problem was solved. That is until I had another long print fail for heater fault. I need these parts, and cannot babysit a 20 hr print, so I have no choice to run them over night. (They are at work, not in a residential building).

I have changed the heater, again, investigated my wiring and connectors, and everything seems to check out.

I am not running a fan at all (this seems to be a common issue).

I have ran the autotune a couple times now.

Firmware Electronics: Duet WiFi 1.02 or later + DueX5

Firmware Version: 1.21 (2018-03-21)

WiFi Server Version: 1.21

Web Interface Version: 1.21

This last time it faulted while I was nearby. I was able to snag a screenshot after I resumed printing.

What should I look into now?

Thanks for the reply.

It is something in the Duex board itself. If I take a known good axis/motor, plug it into the faulty driver, and remap it in the firmware, the problem will happen on the bad driver only. Come to think of it though, it could possibly be any of the components... The WifI main board, or even the ribbon cable connecting them. I'm just not sure.

As for diagnosing the circuit and components, I just don't have those skills. I do know how to hit a board with some hot air and pluck a chip off though.

I purchased my board from Fillastruder, back in Feb 2018. I did inform them at the time of the issue, and they said to send it back within 6 months. Here I am 17 months later haha. I wouldn't expect warranty service at this point.

Ok, Back to back pent up questions. My duex 5 board arrived with a driver that doesn't work correctly. The motor moves, but it stalls super easy. No matter the current settings, it will easily stall. Nothing visually looks bad.

Would replacing the 2660 itself fix my problem? I've been messing with surface mount repairs, and feel that I can do it myself.

Unfortunately I was a bit impatient when I received my board. I knew it was bad, but I wanted to use it. I didn't need all of the channels at the time so I decided not to send it back for warranty. Kinda wishing I did.

And then I found the answer after making this post. That's my life haha.

The answer is 12, in case someone searches the exact questions I did and couldn't find the info they wanted.

Reading is tough for me for some reason. I can find the stats of each board individually but I'm having a hard time adding up the actual usable outputs when using both the DuetWifi and Duex 5 toghether. I know that you get 10 total stepper drivers, but how many external drivers can you also add?

I figure if I'm going to go through all the work to set up a tool changer, Might as well plan for as many tools as I can wire.

Hi, I'm just curious what the maximum amperage I can run through the board for servos and the aux outputs.

Is it a big deal to leave a hobby servo powered for days on end?

I also had the idea to use the extra fan outputs to be able to control the power to my servos.

If I can get away with not running an extra voltage regulator that would be great. But if I do, I would tie the positives to the board for reference right?

OMG. Sometimes going to lunch and having a beer fixes all of the problems.

I just realized that all of the pictures i've been looking at, the board is in the oppisite orientation. I had my wiring backwards. It was backwards every time I checked it.

Goes to show you that sometimes you just need to retrace all of your steps, sometimes with fresh eyes.

Hello! Here's my obligitory "New member who has a pressing issue" post!

I have fumbled through most of my firmware setup, however I just cannot get my BLtouch to do ANYTHING beyond the startup cycle. When I apply power, it does it's blinky check routine. I cannot get any response through the gcode terminal.

I am using the PWM1 servo plug on my Duex5. I have the H2 disabled, and everything references H2 for signal. I have tried value and H3 as well. At one time I tried PWM2, but I'm unsure if I had any other settings correct. My wiring will not allow me to reach any other servo ports.

I've read as much as I can bear to. Here's what I've done.

Cut the LOGIC trace on my AUTHENTIC Smart BLtouch

Verified the wiring is correct (multiple times).

Verified I have no broken wires

Checked voltage at the sensor is 5v (4.92 actually)

I have set up deployprobe and retractprobe, both without inversion

I think there is something I'm blatantly missing.

Here's my config…

; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Wed Mar 28 2018 10:37:18 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; Send absolute coordinates…

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmareM667 S1 ; Select CoreXY mode

M564 H0 ; shut off homing

; Network

M550 PX5s ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Drive 0 X goes forwards

M569 P1 S1 ; Drive 1 Y goes forwards

M569 P2 S0 ; Drive 2 Z and W goes Backwards

M569 P3 S0 ; Drive 3 E0 goes Backwards

M569 P7 S0 ; Drive 7 goes Backwards

M569 P6 S0 ; Drive 6 goes Backwards

M915 P0:1:2:6:7 S2 R0 F0 ; set Selected drives to enable stall detection sensitivity 2, do nothing when stall, unfiltered

M584 X0 Y1 Z7:6:2 U7 V6 W2 P6 E3 ; three Z motors connected to driver outputs 2 becomes left screw, 6 becomes Rear screw and 7 becomes Right screw. P is how many show up on webpage

M350 X16 Y16 Z16 E16 U16 V16 W16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z400 U400 V400 W400 E527 ; Set steps per mm

M566 X300 Y300 Z12 U300 V300 W300 E120 ; Set maximum instantaneous speed changes (mm/min)

M203 X102000 Y102000 Z5000 E4000 U10200 V10200 W10200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z250 E250 U1000 V1000 W1000 ; Set accelerations (mm/s^2)

M906 X1300 Y1300 Z800 E800 U1000 V1000 W1000 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 U0 V0 W0 S1 ; Set axis minima

M208 X380 Y370 Z390 U410 V410 W410 S0 ; Set axis maxima (Each Z screw (U V A) has more max travel than the Z to allow room for sensorless homing)

; Endstops

M574 X3 Y3 U3 V3 W3 S3 ; Set endstops controlled by motor load detection

M574 Z2 ; Set Z endstop; Z-Probe

M574 Z2 S2 ; Set endstops controlled by probe

M558 P9 X0 Y0 Z1 H2 F100 T2000 ; Set Z Probe to type Switch or Digital output where Z probe connector is used. Used for z only.

G31 P50 X-30 Y0 Z1.5 ; Set Z probe trigger value, offset and trigger height

M557 X15:365 Y15:335 S20 ; Define mesh grid; Heaters

M301 H0 S1.00 P10 I0.1 D200 T0.4 W180 B30 ; Use PID on bed heater (may require further tuning)

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S300 ; Set temperature limit for heater 1 to 300C

M307 H2 A-1 C-1 D-1 ; Disable Heater2 for BLTouch; Fans

M106 P0 S1 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F200 H1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F800 H1 T30 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic power saving

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings are not configured

Many thanks to anyone who offers their time to help me out!