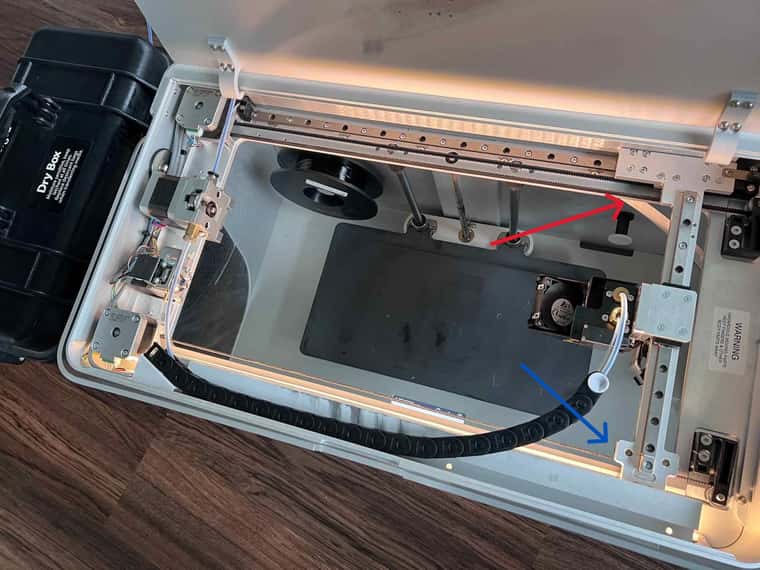

@droftarts That is why I'm really looking into Core-XY. I can at least get the XY motors out of the build chamber. The heat-break and extruder motor will be water cooled.

I think the toolboards are great, but I have never used them because all of my other machines are enclosed. I usually just run one or two multi-conductor cables (Either Igus or Molex) to my tool head to keep the clutter down. Currently my highest temp machine is 90C chamber. However the kinematics are Cartesian so the motors are inside the chamber. I haven't had any issues yet and honestly the motors aren't that expensive and I'm willing to write them of as Somewhat-consumable.

However at over 120C it becomes a reliability issue so that's why I want em out! As well as the fans. Thankfully most E-Motors are so short that a well made water cooling block can do well enough to keep the heat down.

This has been and excellent replacement for a BL-Touch in a heated chamber too:

https://mandalaroseworks.com/products/strykepoint-probe