Posts made by Guyaros

-

RE: Issues after updating Firmware from V3.0 to V3.3posted in Firmware installation

Ok, I think I have figured what was wrong with the X-axis homing, and I can solve it.

But I still need help for the other issue with PanelDue not displaying informatin at all and stuck on "Connecting"

-

Issues after updating Firmware from V3.0 to V3.3posted in Firmware installation

Hi all,

Its been a long time sinch I have visted here (few years..).

My printer was runing very good, and I didnt had the time and the need to update the firmware.Now after I replaced hotend components (Heatbreak to Titanium), I wanted to do a PID tuning , and I have read that FW 3.3 has some benfits, so I went and updated from V3.0 to V3.3 by uploading the ZIP file through DWC.

After the update has completed I encounter several issues:

- Home X axis does weird stuff and keep crashing to the endstop. (prior to the update it worked flawless)

- PanelDue 4.3 (FW 1.24) does not show any information, and stuck on Connecting..

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.3 (2021-06-15 21:44:54) running on Duet WiFi 1.0 or 1.01 Board ID: 08DAM-999TL-MQ4S8-6JKD2-3SJ6K-94BVW Used output buffers: 3 of 24 (17 max) === RTOS === Static ram: 23876 Dynamic ram: 75352 of which 156 recycled Never used RAM 12176, free system stack 134 words Tasks: NETWORK(ready,13.3%,225) HEAT(delaying,0.0%,330) Move(notifyWait,0.1%,319) MAIN(running,85.7%,441) IDLE(ready,1.0%,29), total 100.0% Owned mutexes: === Platform === Last reset 00:01:42 ago, cause: power up Last software reset details not available Error status: 0x00 Step timer max interval 0 MCU temperature: min 32.7, current 36.9, max 48.9 Supply voltage: min 24.1, current 24.2, max 24.5, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/0, heap memory allocated/used/recyclable 2048/4/4, gc cycles 0 Driver 0: position 27765, standstill, SG min/max 0/186 Driver 1: position 0, standstill, SG min/max not available Driver 2: position 0, standstill, SG min/max not available Driver 3: position 0, standstill, SG min/max not available Driver 4: position 0, standstill, SG min/max not available Driver 5: position 0 Driver 6: position 0 Driver 7: position 0 Driver 8: position 0 Driver 9: position 0 Driver 10: position 0 Driver 11: position 0 Date/time: 2021-08-27 00:54:02 Cache data hit count 3709949299 Slowest loop: 6.48ms; fastest: 0.15ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 5.0ms, write time 0.0ms, max retries 0 === Move === DMs created 83, maxWait 85539ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 3, completed moves 3, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 18.96ms; fastest: 0.00ms Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.26 WiFi MAC address a0:20:a6:16:e6:1a WiFi Vcc 3.31, reset reason Turned on by main processor WiFi flash size 4194304, free heap 24072 WiFi IP address 192.168.1.207 WiFi signal strength -37dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0Here is my config,g

; Configuration file for Duet WiFi V1.0 ; Executed by the firmware on start-up ; Board ID: 08DAM-999TL-MQ4S8-6JKD2-3SJ6K-94BVW ; General preferences G90 ; Set absolute coordinates M83 ; Set relative extruder moves M550 P"Guyaros Creator Pro" ; Set printer name ; Network M552 P"F16D" S1 ; Set SSID of network to connect to (P) ,Enable networking as a client (S1) M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Motor Drives M569 P0 S1 ; Physical drive 0 goes forwards M569 P1 S1 ; Physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; Physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; Set drive mapping M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X94.12 Y94.11 Z400.00 E409.00 ; Set axis steps/mm (Z axis 8x8 TR, XY Pulley 10.82[mm]) M566 X840.00 Y840.00 Z600.00 E120.00 ; Set maximum instantaneous speed changes (Jerk) (mm/min) M203 X9000.00 Y9000.00 Z720.00 E1200.00 ; Set maximum speeds (mm/min) M201 X4000.00 Y4000.00 Z300.00 E600.00 ; Set accelerations (mm/s^2) M204 P1200 T1800 ; Set print and travel accelrations [mm/s^2] M906 X750 Y750 Z400 E1000 I20 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout to 30[sec] ; Axis Limits M208 X-115 Y-70 Z0 S1 ; Set axis minima M208 X137.6 Y67 Z175.50 S0 ; Set axis maxima (Previous Z175.0) M564 H0 ; Allow axis movement before homing ; Endstops M574 X2 S1 P"xstop" ; Configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"^!ystop" ; Configure active-low endstop for high end on Y via pin ystop, Pull up resistor, Invert pin, M574 Z2 S3 ; Configure sensorless endstop for high end on Z M915 P2 Z S10 F0 ; Configure motor stall detection, Z motor, Stall detection threshold, Stall detection filter mode disabled ; Z-Probe ;M558 P0 H10 F120 T5400 ; Disable Z probe but set dive height, probe speed and travel speed ;M557 X-100:130 Y-50:60 S20 ; Define mesh grid ; Heaters ; Bed M308 S0 P"bedtemp" Y"thermistor" T94573 B4230 ; Configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; Create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; Map heated bed to heater 0 M307 H0 A242.2 C901.9 D1.5 S1.0 ; Set heating process parametersheater, Heater0 (H0), Gain (A242.2), time Constant (C901.9), Dead time (D1.5), maximum PWM 100% (S1.0) ; Extruder E0 Hotend (E3D Hemera) M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; Configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; Create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S286 ; Set temperature limit for heater 1 to 285C M307 H1 B0 A417.4 C229.8 D3.5 S1.0 ; Set heating process parameters, Heater1 (H1),Gain (A), time constant (C), Dead time (D), Max PWM 100% (S1.0) ; CPU Temp M912 P0 S-16.1 ; Calibrate CPU temp sensor ; Fans M950 F0 C"fan0" Q250 ; Create fan 0 on pin fan0 and set its frequency M106 P0 C"BlowerLayerCooling" S0 H-1 ; Set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q250 ; Create fan 1 on pin fan1 and set its frequency M106 P1 C"HemeraExtruderFan" S1 H1 T40 ; Set fan 1 name and value. Thermostatic control is turned on M950 F2 C"fan2" Q250 ; Create fan 2 on pin fan2 and set its frequency M106 P2 C"DuetBoardFan" S0 H-1 ; Set fan 2 name and value. Thermostatic control is turned off M950 F3 C"e1heat" Q250 ; Create fan 3 on pin Heater E1 and set its frequency M106 P3 C"RearCoolingFans" S0 H-1 ; Set fan 3 name and value. Thermostatic control is turned off ; Resurrect routine (Power failure) M911 S23 R25 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss ; Tools M563 P0 S"ExtruderE0" D0 H1 F0 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C T0 ; Select first toolHere is my homex.g

; homex.g ; called to home the X axis ; Edited by Guyaros on 25.04.2020 G91 ; Set Relative positioning M913 X30 ; Set X motor current to 30% of its normal current, to avoid ramming in case of crash ; First pass (Corse movement) G1 H1 X290 F3600 ; Move quickly to X axis endstop and stop there (first pass) G1 H2 X-5 F600 ; Go back a few mm ; Second pass (Fine movement) G1 H1 X10 F300 ; Move slowly to X axis endstop once more (second pass) ; Finish G90 ; Set absolute positioning M913 X100 ; Reset X motor current to normal current 100%Youe help is appreciated.

-

RE: Installing E3D Hemera Extruder on FFCP (+Duet WiFi)posted in Third-party add-ons

As requested, here is an update, with the new config file, to match RepRap Firmware V3.0

Note: I completely removed the Z-axis endstop, and I am using Stall detection to home the Z axis.

; Configuration file for Duet WiFi V1.0 ; Executed by the firmware on start-up ; Firmware Version 3.0 ; Duet Web Control 2.1.4 ; Last edited on 26.04.2020 by Guyaros ; General preferences G90 ; Set absolute coordinates M83 ; Set relative extruder moves M550 P"Guyaros Creator Pro" ; Set printer name ; Network M552 P"ABCD" S1 ; Set SSID of network to connect to (P) ,Enable networking as a client (S1) M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Motor Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X94.12 Y94.11 Z400.00 E409.00 ; Set axis steps/mm (Z axis 8x8 TR, XY Pulley 10.82[mm]) M566 X840.00 Y840.00 Z600.00 E120.00 ; set maximum instantaneous speed changes (Jerk) (mm/min) M203 X9000.00 Y9000.00 Z720.00 E1200.00 ; set maximum speeds (mm/min) M201 X5000.00 Y5000.00 Z300.00 E600.00 ; set accelerations (mm/s^2) M204 P1200 T1800 ; Set print and travel accelrations [mm/s^2] M906 X750 Y750 Z400 E1000 I20 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout to 30[sec] ; Axis Limits M208 X-115 Y-70 Z0 S1 ; set axis minima M208 X137.6 Y67 Z175.6 S0 ; set axis maxima M564 H0 ; Allow axis movement before homing ; Endstops M574 X2 S1 P"xstop" ; Configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"^!ystop" ; Configure active-low endstop for high end on Y via pin ystop, Pull up resistor, Invert pin, M574 Z2 S3 ; Configure sensorless endstop for high end on Z M915 P2 Z S10 F0 ; Configure motor stall detection, Z motor, Stall detection threshold, Stall detection filter mode disabled ; Z-Probe ;M558 P0 H10 F120 T5400 ; disable Z probe but set dive height, probe speed and travel speed ;M557 X-100:130 Y-50:60 S20 ; define mesh grid ; Heaters ; Bed M308 S0 P"bedtemp" Y"thermistor" T94573 B4230 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M307 H0 A242.2 C901.9 D1.5 S1.0 ; Set heating process parametersheater, Heater0 (H0), Gain (A242.2), time Constant (C901.9), Dead time (D1.5), maximum PWM 100% (S1.0) ; Extruder E0 Hotend (E3D Hemera) M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S285 ; set temperature limit for heater 1 to 285C M307 H1 B0 A346.2 C189.8 D4.3 S1.0 ; Set heating process parameters, Heater1 (H1),Gain (A), time constant (C), Dead time (D), Max PWM 100% (S1.0) ; CPU Temp M912 P0 S-16.1 ; Calibrate CPU temp sensor ; Fans M950 F0 C"fan0" Q250 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"BlowerLayerCooling" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q250 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"HemeraExtruderFan" S1 H1 T40 ; set fan 1 name and value. Thermostatic control is turned on M950 F2 C"fan2" Q250 ; create fan 2 on pin fan2 and set its frequency M106 P2 C"DuetBoardFan" S0 H-1 ; set fan 2 name and value. Thermostatic control is turned off M950 F3 C"!e1heat" Q250 ; create fan 3 on pin Heater E1 and set its frequency M106 P3 C"RearCoolingFans" S0 H-1 ; set fan 3 name and value. Thermostatic control is turned off ; Resurrect routine (Power failure) M911 S23 R25 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ; Tools M563 P0 S"ExtruderE0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C T0 ; select first tool; homex.g ; called to home the X axis ; Edited by Guyaros on 25.04.2020 G91 ; Set Relative positioning M913 X30 ; Set X motor current to 30% of its normal current, to avoid ramming in case of crash ; First pass (Corse movement) G1 H1 X290 F3600 ; Move quickly to X axis endstop and stop there (first pass) G1 H2 X-5 F600 ; Go back a few mm ; Second pass (Fine movement) G1 H1 X10 F300 ; Move slowly to X axis endstop once more (second pass) ; Finish G90 ; Set bsolute positioning M913 X100 ; Reset X motor current to normal current 100%; homey.g ; called to home the Y axis ; Edited by Guyaros on 25.04.2020 M913 Y40 ; Set Y motor current to 40% of its normal current, to avoid ramming in case of crash ; First pass (Coarse movement) G91 ; Set Relative positioning G1 H1 Y165 F3600 ; Move quickly to Y axis endstop and stop there (first pass) G1 H2 Y-5 F600 ; Go back a few mm ; Second pass (Fine movement) G1 H1 Y10 F300 ; Move slowly to Y axis endstop once more (second pass) ; Finish G90 ; Set Absolute positioning M913 Y100 ; Reset Y motor current to normal current 100%; homez.g ; called to home the Z-axis ; Edited by Guyaros on 25.04.2020 M98 P"homeZMaxUsingStallDetection.g"; Call to script; Script homeZMaxUsingStallDetection.g ; Edited by Guyaros on 25.04.2020 M913 Z70 ; Reduce current of Z motor to 70% G91 ; Switch to Relative positioning G1 H1 Z200 F1200 ; Lower bed all the way down, untill motor stalls M913 Z100 ; Reset motor currents back to normal 100% -

RE: RRF 3.01-RC9, DWC 2.1.4 and DSF 2.1.0 releasedposted in Beta Firmware

Thanks.

Upgrade PanelDue Frimware ............... Done

Upgrade Duet Web Control ................... Done

Edit sys files using RepRep Configurator Tool .............. Done

Upgrade to Duet Firmware 3.0 ............ Done; Configuration file for Duet WiFi V1.0 ; Executed by the firmware on start-up ; Board ID: 08DAM-999TL-MQ4S8-6JKD2-3SJ6K-94BVW ; Firmware Version 3.0 ; Duet Web Control 2.1.4 ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sat Apr 25 2020 01:01:46 GMT+0300 (Israel Daylight Time) ; Last edited on 25.04.2020 by Guyaros ; General preferences G90 ; Set absolute coordinates M83 ; Set relative extruder moves M550 P"Guyaros Creator Pro" ; Set printer name ; Network M552 P"F16D" S1 ; Set SSID of network to connect to (P) ,Enable networking as a client (S1) M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Motor Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X94.12 Y94.11 Z400.00 E409.00 ; Set axis steps/mm (Z axis 8x8 TR, XY Pulley 10.82[mm]) M566 X840.00 Y840.00 Z600.00 E120.00 ; set maximum instantaneous speed changes (Jerk) (mm/min) M203 X9000.00 Y9000.00 Z720.00 E1200.00 ; set maximum speeds (mm/min) M201 X5000.00 Y5000.00 Z300.00 E600.00 ; set accelerations (mm/s^2) M204 P1200 T1800 ; Set print and travel accelrations [mm/s^2] M906 X750 Y750 Z400 E1000 I20 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout to 30[sec] ; Axis Limits M208 X-115 Y-70 Z0 S1 ; set axis minima M208 X137.6 Y67 Z175.6 S0 ; set axis maxima M564 H0 ; Allow axis movement before homing ; Endstops M574 X2 S1 P"xstop" ; Configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"^!ystop" ; Configure active-low endstop for high end on Y via pin ystop, Pull up resistor, Invert pin, M574 Z2 S3 ; Configure sensorless endstop for high end on Z M915 P2 Z S10 F0 ; Configure motor stall detection, Z motor, Stall detection threshold, Stall detection filter mode disabled ; Z-Probe ;M558 P0 H10 F120 T5400 ; disable Z probe but set dive height, probe speed and travel speed ;M557 X-100:130 Y-50:60 S20 ; define mesh grid ; Heaters ; Bed M308 S0 P"bedtemp" Y"thermistor" T94573 B4230 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M307 H0 A242.2 C901.9 D1.5 S1.0 ; Set heating process parametersheater, Heater0 (H0), Gain (A242.2), time Constant (C901.9), Dead time (D1.5), maximum PWM 100% (S1.0) ; Extruder E0 Hotend (E3D Hemera) M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S285 ; set temperature limit for heater 1 to 285C M307 H1 B0 A346.2 C189.8 D4.3 S1.0 ; Set heating process parameters, Heater1 (H1),Gain (A), time constant (C), Dead time (D), Max PWM 100% (S1.0) ; CPU Temp M912 P0 S-16.1 ;Calibrate CPU temp sensor ; Fans M950 F0 C"fan0" Q250 ; create fan 0 on pin fan0 and set its frequency M106 P0 C"BlowerLayerCooling" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"fan1" Q250 ; create fan 1 on pin fan1 and set its frequency M106 P1 C"HemeraExtruderFan" S1 H1 T40 ; set fan 1 name and value. Thermostatic control is turned on M950 F2 C"fan2" Q250 ; create fan 2 on pin fan2 and set its frequency M106 P2 C"RearCoolingFans" S0 H-1 ; set fan 2 name and value. Thermostatic control is turned off ; Resurrect routine (Power failure) M911 S23 R25 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ; Tools M563 P0 S"ExtruderE0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C T0 ; select first tool -

RE: RRF 3.01-RC9, DWC 2.1.4 and DSF 2.1.0 releasedposted in Beta Firmware

Hi,

Using Board: Duet WiFi 1.0 or 1.01

Running Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 2.03RC5 (2019-06-05b5)

Duet WiFi Server Version: 1.23

Duet Web Control 2.0.2Do I need to upgrade to 3.0 first and then to 3.01-RC9 ?

If so, could you please share a link to download RepRapFirmware 3.0Also, currently running PanelDue-V2-4.3 , Firmware version: 1.21-3

Should I upgrade to 1.24?Thanks,

-

RE: RepRapFirmware 3.01-RC3 releasedposted in Beta Firmware

I'm using Board: Duet WiFi 1.0 or 1.01

Running Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 2.03RC5 (2019-06-05b5)

Duet WiFi Server Version: 1.23

Duet Web Control 2.0.2Printer is running perfectly, with no issues at all.

- Should I consider upgrading to RRF3.01-RC3? What are the benefits?

- What is the upgrade procedure?

- In case I will upgrade to RRF3, is it possible to bind Heater E1 as a Fan output?

Thanks,

-

Installing E3D Hemera Extruder on FFCP (+Duet WiFi)posted in Third-party add-ons

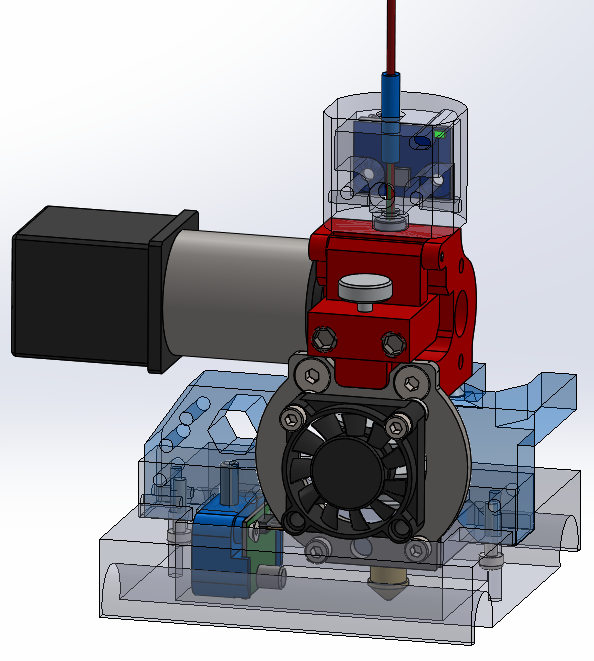

Sharing my Extruder installation.

Hope it will helps others who are considering to install Hemera extruder.Custom designed parts:

https://www.thingiverse.com/thing:4165038

https://www.thingiverse.com/thing:4173393Original Box

Extruder out of the box

Included parts

!

!

Installation process begins

Thermistor

Heater

Fan threads

Thermal paste

Installing Hotend - Heat block and Nozzle

Mounting the extruder on teh XY carrige

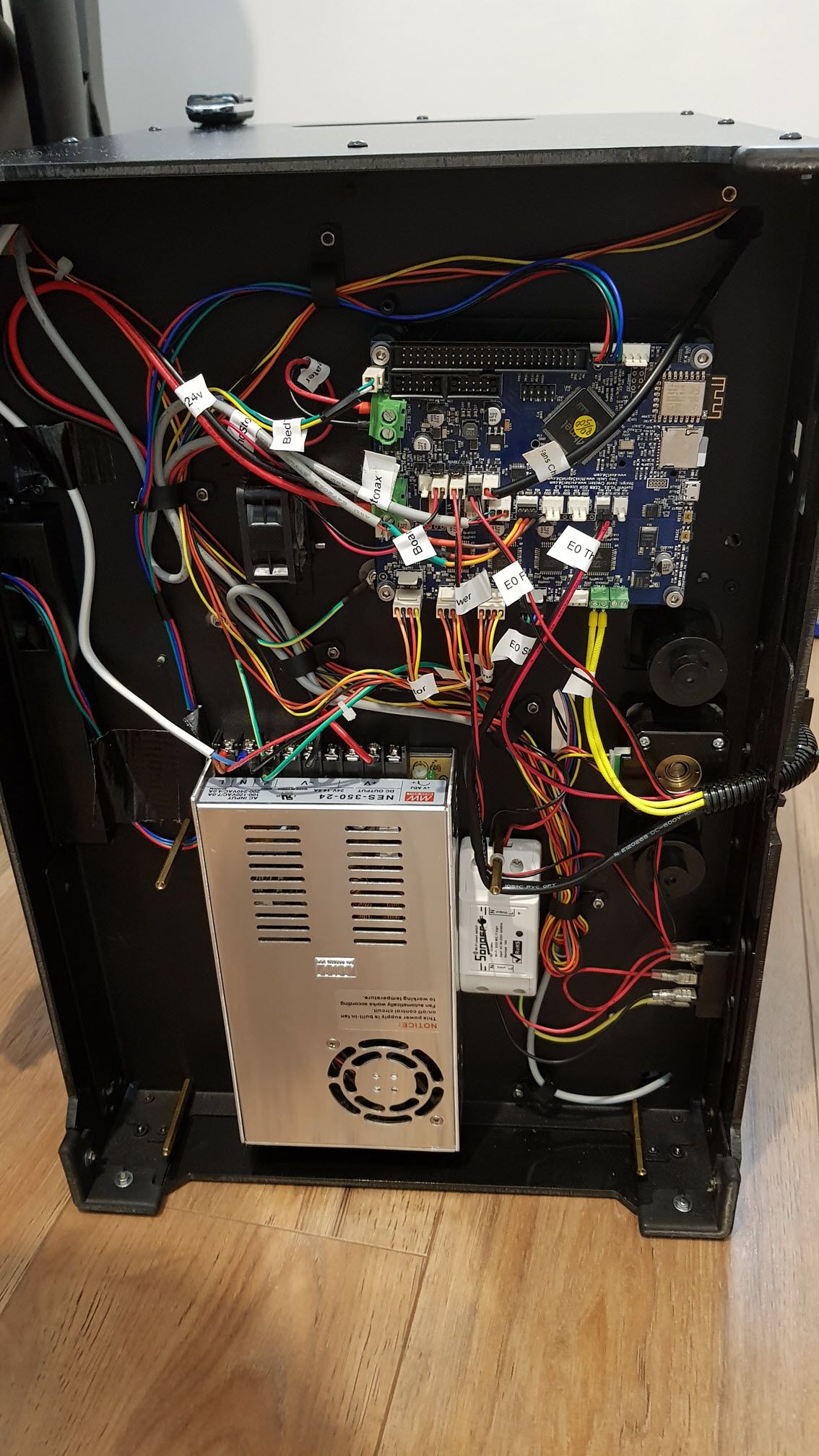

Wiring the extruder to Duet board

Finally, all set

Editing config file:

(showing only relevant commands, not the entire config file)M569 P3 S1; Set (E0) motor drive 3 (P3) goes Forward (S1) M350 E16 I1; Set microstepping to x16 step, Interpolation enabled (I1) M92 E409; Set axis steps/mm M906 E1000 I20; Set motor currents [mA] and motor idle factor in percent (20%) M84 S30; Set idle timeout to 30[sec] (S10) ; Axis kinematics M201 E600; Set axis maximum accelerations [mm/s^2] M566 E120; Set axis maximum instantaneous speed changes [mm/min] M203 E1200; Set axis maximum speeds [mm/min] ; Heaters & Thermistors M305 P1 T100000 B4725 C7.06e-8; Set thermistor and ADC parameters M143 S285; Set maximum heater temperature to 285C M307 H1 A346.2 C189.8 D4.3 S1.0; Set heating process parameters, Heater1 (H1),Gain (A), time constant (C), Dead time (D), Max PWM 100% (S1.0) ; Fans M106 P1 S0 I0 F250 H1 T35 L1; Set fan 1 value, PWM signal inversion and frequency, Thermostatic control is turned on (Extruder0 Fan) ; Tools M563 P0 D0 H1 F0; Define tool 0 (P0), uses Extruder 0(E0) (D0), uses Heater 1 (Actually Heater E0), uses Fan 0 (F0) -

RE: Original FlashForge Creator Pro Dual Extruder upgradeposted in General Discussion

Hi,

I have converted my FFCP to DuetWifi, a few years ago (2017), and the results are great.

The printer is super quiet now, and overall the performance are great.

I love using the Duet, I think its the best upgrade you can make to a 3d printer.I am using E3D Hemera extruder, but you can also use the original extruder.

Why do you consider to replace the original PSU? I am using the original MeanWell 350[W]

You can search the forum for posts about the converting FFCP to use DuetWifi.

here is one result:

https://forum.duet3d.com/topic/3553/converting-a-flashforge-creator-pro-to-use-duet/5 -

RE: Laser Filament Monitor - test resultsposted in Filament Monitor

@fma In my sensor housing design, the sensor window can be completely closed using M4 screw.

Its also make it easy to check if the IR from the surrounding is interfering with the sensor. -

RE: Laser Filament Monitor - test resultsposted in Filament Monitor

Hi all,

Thanks for your feedback.

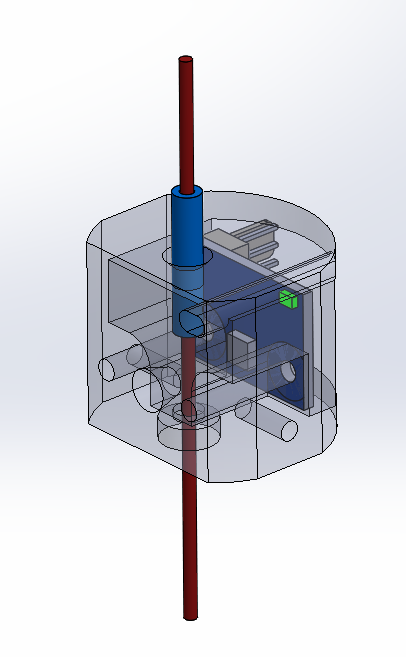

I designed an improved sensor housing (V2).

I have printed it and tested the sensor fit, but I didn't have time to test the sensor yet.If anyone wants to print and test this, please go ahead.

I designed this to be a very fast and simple print and should be universally easy to mount because I included top and side holes.Here is a link to download the STL file:

Laser Filament Sensor Housing - Thingiverse -

RE: Laser Filament Monitor - test resultsposted in Filament Monitor

Hi all,

I designed a housing for the sensor, which will enable me to install the sensor on top of the Extruder, to eliminate undetected movment during retractions and improve reading accuracy.

The enclosure will be printed using a black filament to minimize IR reflections.

Currently, the distance between the sensor to the filament is set to 8[mm], because that what David recomneded.Here are some images:

The housing is still under development, so it would be beneficial to read the feedbacks before printing and testing the first version.

As soon as I will print and test it, I will share and upload the CAD files to Thingiverse.

-

Mesaure distance to Endstopposted in General Discussion

Hi,

Is there a method to measure the distance from current tool position to endstop trigger point?

For example:

Let's say I position the tool (Extruder carriage) at some point on the X-axis (Manually, by hand), and I want to send a gcode command that moves the carriage to the X-axis endstop, and report the travel distance.Is that possible?

if does, I would like to take it step forward, and use this script to measure the distance from coordinate to endstops between layer changes so to detect layer shifting.

-

RE: DuetWiFi with external antenna connectorposted in Order discussion

Alternatively, you can buy Duet Ethernet and connect it to an access point, so the Duet could be accessed through Wifi. so basically the access point acts as an antenna.

-

RE: GCode file upload with GZIPposted in Firmware wishlist

@dc42 said in GCode file upload with GZIP:

I get 800kbytes/sec to 1Mbyte/sec. Here are some tips:

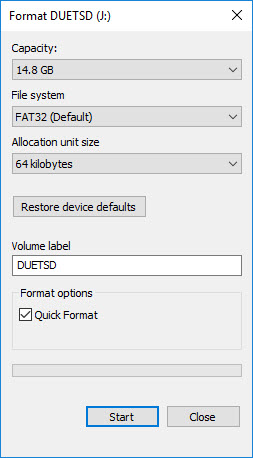

- Use a branded Class 4 or better SD card

- Format the SD card with 64K clusters

Is it ok to format the SD card using windows 10 format tool?

The memory card is Sandisk Ultra Class 10 16GB -

RE: G92 not working for E axisposted in General Discussion

Thanks for the very informative reply, now it makes sense to me.

Personally, I don't need the extruder position in M114, but it may be useful for others.When I had the need to control the extrusion absolute position - for example for a "syringe extruder" which has maximum travel (syringe max stroke), I configure W-axis that act as an extruder.

-

RE: Cancel.g doesn't do what I want :-)posted in Tuning and tweaking

M25executes macro filepause.g

M24executes macro fileresume.g

M0executes macro filestop.gI know that after I press ""pause print"" in DWC and press cancel, its executes macro file

stop.g, which in my case includes these commands:;Stop Printing (M0) G10 P0 S0; Turn off extruder heater M140 S0; Turn off bed heater M106 P2 S0; Turn off cooling Fan M300 S100 P500; Sound beep using PanelDue buzzer, frequency Hz (Snn), Duration (Pnn)I don't have

cancel.gfile in my sys folder,

What am I missing? -

RE: DuetRFF Cura plugin - not working/recognizing in cura?posted in General Discussion

Thank you very much!

now it's working.

-

RE: Laser filament monitorposted in Filament Monitor

I am looking forward to purchasing Duet3D laser filament monitor when it will be out for sale.

Thanks,