Posts made by gabi68

-

RE: Filament Frenzy script used on prusa slicer scratch bedposted in General Discussion

@oliof Sorry for late reply (family problems). Here is a test file sliced with Prusa slicer. There is a G32 from that Frenzy script and I am thinking if that is read it properly by PS since there is no bed.g file. Thoughts ...

test.gcode -

RE: Filament Frenzy script used on prusa slicer scratch bedposted in General Discussion

@fcwilt Strange. Same script run fine in S3D. Something is different in Prusa. Maybe PS doesn't read the G29 or G32 properly. I asked in their forum, but I did not get any answer. I will keep looking. If anyone has another ideea I am all ears...

-

RE: Filament Frenzy script used on prusa slicer scratch bedposted in General Discussion

Any other opinions, please?

-

RE: Filament Frenzy script used on prusa slicer scratch bedposted in General Discussion

@fcwilt Here it is

; bed.g ; called to perform automatic delta calibration via G32 ; ; generated by RepRapFirmware Configuration Tool on Thu Jul 12 2018 20:54:00 GMT-0500 (Central Daylight Time) M561 ; clear any bed transform ; bed.g file for RepRapFirmware, generated by Escher3D calculator ; 16 points, 6 factors, probing radius: 114, probe offset (0, 0) G30 P0 X0.00 Y114.00 Z-99999 H0 G30 P1 X73.28 Y87.33 Z-99999 H0 G30 P2 X112.27 Y19.80 Z-99999 H0 G30 P3 X98.73 Y-57.00 Z-99999 H0 G30 P4 X38.99 Y-107.12 Z-99999 H0 G30 P5 X-38.99 Y-107.12 Z-99999 H0 G30 P6 X-98.73 Y-57.00 Z-99999 H0 G30 P7 X-112.27 Y19.80 Z-99999 H0 G30 P8 X-73.28 Y87.33 Z-99999 H0 G30 P9 X0.00 Y57.00 Z-99999 H0 G30 P10 X49.36 Y28.50 Z-99999 H0 G30 P11 X49.36 Y-28.50 Z-99999 H0 G30 P12 X0.00 Y-57.00 Z-99999 H0 G30 P13 X-49.36 Y-28.50 Z-99999 H0 G30 P14 X-49.36 Y28.50 Z-99999 H0 G30 P15 X0 Y0 Z-99999 S6 ; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors ; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed) -

RE: Filament Frenzy script used on prusa slicer scratch bedposted in General Discussion

@jay_s_uk Is doing what is suppose to do (scan the bed with the nozzle, show the old and new value). When is starting the first part of arc I can see the head is going down incrementally, meaning the further is going the distance is smaller and smaller until start scratching the bed. The only way out of this is to stop the printer and rehome it. Strange...

-

Filament Frenzy script used on prusa slicer scratch bedposted in General Discussion

I have an heavily (Haydn rods, Duet wifi, smart effector, Hiwin rails, Gates belts, Berd air) modified Anycubic Kossel delta and I am a long time user of S3D, but now I looking to change to Prusa slicer. I followed the wizard and configure my printer to use Prusa slicer. All went good, but when I tried to print something the nose scratch the bed. In S3D I have a script (Filament Frenzy) to help to prime the hot end. I ported that script over Prusa with all the settings (speeds, retraction, cooling, ...).

At the start up I have a G28 and G29 command with a 9 points followed by that Frenzy script. The Duet reports 0.01 correction, but the nose still dive into bed and the only thing to do is to stop the printer and rehome. I really what to understand why this is happening since everything is working properly in S3D.

;M190 S{print_bed_temperature} ;Uncomment to add your own bed temperature line ;M109 S{print_temperature} ;Uncomment to add your own temperature line G21 G90 M107 G28 ; Lower extruder G92 E0 G1 E-6 F1800 G32 G0 Z200 F7200 G0 X-97.666 Y35.740 Z1.000 G1 E0 F1800 ; Extrude about 40 mm by printing a circular arc and FF Branding M117 Purging Extruder ; First part of arc G1 X-97.666 Y35.740 Z0.300 F1200 G1 X-100.644 Y26.205 E0.751 G1 X-102.694 Y16.430 E1.502 G1 X-103.797 Y6.502 E2.252 G1 X-103.942 Y-3.485 E3.003 G1 X-103.128 Y-13.441 E3.754 G1 X-101.363 Y-23.272 E4.505 G1 X-98.663 Y-32.888 E5.255 G1 X-95.053 Y-42.202 E6.006 G1 X-90.566 Y-51.126 E6.757 G1 X-85.244 Y-59.578 E7.508 G1 X-79.135 Y-67.481 E8.259 G1 X-72.296 Y-74.761 E9.009 G1 X-64.791 Y-81.352 E9.760 G1 X-56.688 Y-87.192 E10.511 G1 X-48.062 Y-92.228 E11.262 G1 X-38.993 Y-96.414 E12.013 G1 X-29.564 Y-99.710 E12.763 G1 X-19.862 Y-102.086 E13.514 G1 X-9.977 Y-103.520 E14.265 ; First F G1 X-9.000 Y-104.000 E14.347 G1 X-9.000 Y-95.000 E15.023 G1 X0.000 Y-95.000 E15.700 G1 X-1.500 Y-96.500 E15.859 G1 X-7.125 Y-96.500 E16.282 G1 X-7.125 Y-98.000 E16.395 G1 X-1.125 Y-98.000 E16.846 G1 X-2.625 Y-99.500 E17.005 G1 X-7.125 Y-99.500 E17.343 G1 X-7.125 Y-102.875 E17.597 ; Second F G1 X1.000 Y-104.000 E18.214 G1 X1.000 Y-95.000 E18.890 G1 X10.000 Y-95.000 E19.567 G1 X8.500 Y-96.500 E19.726 G1 X2.875 Y-96.500 E20.149 G1 X2.875 Y-98.000 E20.262 G1 X8.875 Y-98.000 E20.713 G1 X7.375 Y-99.500 E20.872 G1 X2.875 Y-99.500 E21.210 G1 X2.875 Y-102.875 E21.464 ;Second part of arc G1 X9.977 Y-103.520 E22.000 G1 X19.862 Y-102.086 E22.751 G1 X29.564 Y-99.710 E23.501 G1 X38.993 Y-96.414 E24.252 G1 X48.062 Y-92.228 E25.003 G1 X56.688 Y-87.192 E25.754 G1 X64.791 Y-81.352 E26.505 G1 X72.296 Y-74.761 E27.255 G1 X79.135 Y-67.481 E28.006 G1 X85.244 Y-59.578 E28.757 G1 X90.566 Y-51.126 E29.508 G1 X95.053 Y-42.202 E30.259 G1 X98.663 Y-32.888 E31.009 G1 X101.363 Y-23.272 E31.760 G1 X103.128 Y-13.441 E32.511 G1 X103.942 Y-3.485 E33.262 G1 X103.797 Y6.502 E34.012 G1 X102.694 Y16.430 E34.763 G1 X100.644 Y26.205 E35.514 G1 X97.666 Y35.740 E36.265 ; Retract and move nozzle up G92 E0 G1 E-1.5 F1800 G0 Z0.5 G1 E0 F300 ; Branding M117 Filament FrenzyThank you

Gabi

-

RE: Berd-air pump connectionposted in General Discussion

@infiniteloop Try it your solution, but for whatever reason it doesn't work. At the startup the pump starts.

Version

RepRapFirmware for Duet 2 WiFi/Ethernet

Firmware Electronics: Duet WiFi 1.02 or later

Firmware Version: 2.03 (2019-06-13b2)

WiFi Server Version: 1.23

Web Interface Version: 1.22.6

Not a big problem,Thank you for taking time to answer and help.

-

RE: Berd-air pump connectionposted in General Discussion

I had time today and installed the pump with the flyback diode. I choose to use Fan0 instead an unused heater. Everything is working properly and the pump is not noisy (used F25500) which is recommended by more experienced members. The only annoying thing is when I start my printer the pump starts also and I need to shut it down from the fan button.

I used M106 P0 F25500 L60 B0 C"cool" and changed L60 to L0, but no effect. What should I do to make the pump not to start at the printer start up?Thank you

-

RE: Berd-air pump connectionposted in General Discussion

@infiniteloop I read a post from David saying I can use a heater output to connect the pump. It will be easier than a fan? I have a flyback diode and I think I still need one. Thoughts?

-

Berd-air pump connectionposted in General Discussion

Hi just took a delivery (9 days from China to UK) for a 12V berd air pump. What and where do I need to connect and use (safely) the pump with a Duet wifi ver 1.04c?

Thank you

-

Pt100 alternativeposted in Duet Hardware and wiring

Hi to all,

I need a PT100 sensor because the old one failed (one wire detached from the barrel) . I found one on 3djake, quite expensive, but I bought it. My questions to more knowledgeable people:

- can some other sensors be used (same family PT100)?

- where I can find that type of "replacement" sensors?

- there is a way to reinforce the sensors from e3d or other vendors?

Thank you

-

RE: Help with settings...posted in Tuning and tweaking

@Danal

The machine is calibrated, I think. I will do it again today after work. PT 100 don't give any warnings. Thermal tuning saved with a M500.

On both attempts I saw the same behaviour, the first 15 layers are laid down beautifully. Starting with layer 16 where the infill is almost finished the gaps appear. It looks like the filament don't stick anymore on the previous layer.

Why is that? -

RE: Help with settings...posted in Tuning and tweaking

Hi David,

I was thinking about that and actually tried, but the extruder start skipping like the PLA was not melted properly.

I will try tomorrow with a lower temp. -

RE: Help with settings...posted in Tuning and tweaking

- Any advice for doing a better calibration besides the measurement method?

- "Nimble (biggest crap ever)". Why is that?

-

RE: Help with settings...posted in Tuning and tweaking

Nimble is on the way. I still use the original extruder with Capricorn tube.

config AKL.g -

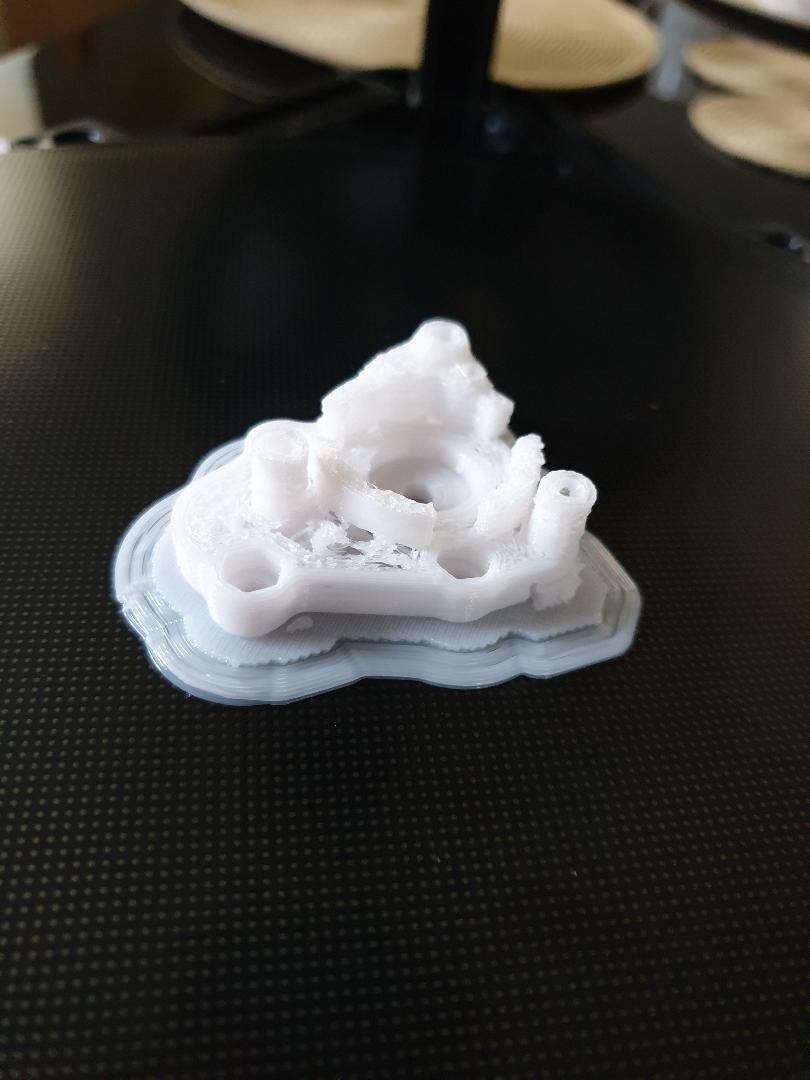

Help with settings...posted in Tuning and tweaking

Hi to all,

I have a Anycubic linear plus with:

- duet 2 wifi board;

- hayden rods;

- smart effector;

- PT100;

- ultrabase;

- on order a Zesty Nimble V2.

I fight with this crappy prints for over a month. I really need help with some settings.

I use Simplfy3D and a have: - bed temp. 70C;

- hotend temp. 210C;

- nozzle 0.4mm (brass);

- extrusion multiplier - 0.95;

- retraction 5mm;

- speed retraction 3000 mm/min;

-layer height 0.15mm; - first layer - height 110 - width 100 - speed 55;

- raft;

- no fan.

Printer is calibrated (I think, maybe not). No warnings. Z probe working properly.

Why I have this terrible results? See photos

-

RE: AKLP ckeckposted in Firmware installation

@bricor I just measured. The multimeter stays 0. Agree I will close this.

Thanks for your help

Gabi