That is what I was hoping to hear!

So I only need the H parameter?

EDIT: Worked like a champ! Thank you so much for the help.

That is what I was hoping to hear!

So I only need the H parameter?

EDIT: Worked like a champ! Thank you so much for the help.

So I am tweaking and tuning on the FK-1 and I have run into a problem that likely does not plague many people.

I am using a Duet2Wifi and a Duex5 to allow auto tramming of the Z. I have my bed.g file running:

M561 ; clear any bed transform

G28 ; home all axes

G30 P0 X5 Y395 Z-99999 ; probe near a leadscrew Left Rear

G30 P1 X5 Y5 Z-99999 ; probe near a leadscrew Left Front

G30 P2 X1180 Y5 Z-99999 ; probe near a leadscrew Right Front

G30 P3 X1180 Y395 Z-99999 S4 ; probe near a leadscrew Right Rear and calibrate 4 motors

G30 P0 X5 Y395 Z-99999 ; probe near a leadscrew Left Rear

G30 P1 X5 Y5 Z-99999 ; probe near a leadscrew Left Front

G30 P2 X1180 Y5 Z-99999 ; probe near a leadscrew Right Front

G30 P3 X1180 Y395 Z-99999 S4 ; probe near a leadscrew Right Rear and calibrate 4 motors

G28 ; home all axes

G29 ; probe the bed and enable compensation

This runs through the "Auto Bed Leveling" twice and adjusts the motors each time. (I may think about a third time, but for now is gets REALLY close.)

Then it runs the G29 to map the bed for mesh bed leveling.

My config.g contains:

; Z-Probe

M950 S0 C"duex.pwm1" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H10 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-24.5 Y18.5 Z0.15 ; set Z probe trigger value, offset and trigger height

M557 X0:1150 Y50:400 S50 ; define mesh grid

Here lies my issue/question:

As you can see in my M558, I use a dive height of 10mm. This is excessive, but necessary on a printer that is 1200mm wide as it is very easy to knock it out of level pretty extremely. When I had an H of 5, I would frequently get errors as out of range.

As you can see from my M557, I have a "FEW" probe points for the mesh leveling. With a dive height of 10mm, it adds a significant amount of movement to the process.

I am curious if there is a way to have a different dive height for each part. Example, could I call the M558 in my config.g as normal, but then call it again using an H5 between the last G30 and the G28/G29 and then call it again after to set it back to the H10 in case I level again without reboot?

Hope this all makes sense.

Thanks in advance.

Just wanted to drop in with a quick update:

Joe from Project R3D (https://www.projectr3d.com/) has jumped on board with sponsoring the FK-1! He has provided a DueX5 so that I can run 4 independent Z motors and setup auto leveling on the carriage that carries the X and Y axes. He also provided a Duet Maestro so I can design an enclosure in case someone wants a cheaper option when building a FK-1.

So with this, the next step is getting the 4 ball screws and getting them mounted. My plan is to have this done, tuned, and functioning by ERRF!

Thanks for reading!

The FK-1 has done it's first print and it did not go well. I should preface it with the fact that I am still learning a lot of new things, but more so, I did not do any initial calibrations. I had decided quite a while ago that I would be printing a 3DBenchy as my first print because it is a model I am familiar with.

So during a live stream, I printed this:

Yes, that is a complete and total mess. But the point was for the printer to push filament for the first time.

Yesterday during a stream, I attempted another benchy and was having a consistent layer shift in about the same spot every time. I moved away from the benchy and printed a calibration cube and ended up with this:

Not the greatest, but not bad. Size wise, it was very, VERY close to 20x20x20.

So as a last ditch effort last night, I dialed in a few more slicer settings and upped my X motor current a bit more and printed another benchy. Here is the outcome:

Not perfect by any means, but the closest I have to a good print.

This has all been on a temporary bed. I am using the leaf out of an Ikea kitchen table until my sheet of MIC-6 aluminum gets here (today.) Once I get it drilled and mounted, I should be able to get it dialed in much better and have more consistent results.

Thanks for reading and Print On!

I want to give a HUGE shout out to our latest sponsor to join the FK-1 project... Printed Solid has stepped up to supply a PEI sheet! But not just a PEI sheet, a custom laser cut 16"x48" (Just slightly larger than 400x1200mm!) Thank You Printed Solid!

Well last night the printer finally moved under it's own power!!!! (video link below.)

I am going to admit something here... I am pretty stubborn and set in my ways. Most of the time I blame it on my OCD, but that is not always true. LOL! When I first thought about the Duet board, I told myself it would be fine and I would just hook a Raspberry Pi to it and use Octoprint just like the rest of my printers. But after playing with it last night, I love the interface! It is amazing to me that there is a console with keyboard on there! (Now I need to figure out how to tweet from there. LOL!

This has been an epic journey so far and it is only going to get better!

I have a little bit of cable management to do and then I will get the bed installed. After that, it will be time to lay down some plastic!

Thanks for following along so far!

Here is the link to the stream last night where it finally powered up and moved: https://youtu.be/9YczLdAs_zw (Motion is around 8 minutes in.)

Again, HUGE THANK YOU to

Duet3D

IC3D Printers

E3D

Bondtech

Antclabs

OpenBuilds

Kuntry3D

Scott McLellan

Uncle Ron

All of the other friends of the channel who donated and supported

And very importantly, my wife for dealing with all of this!

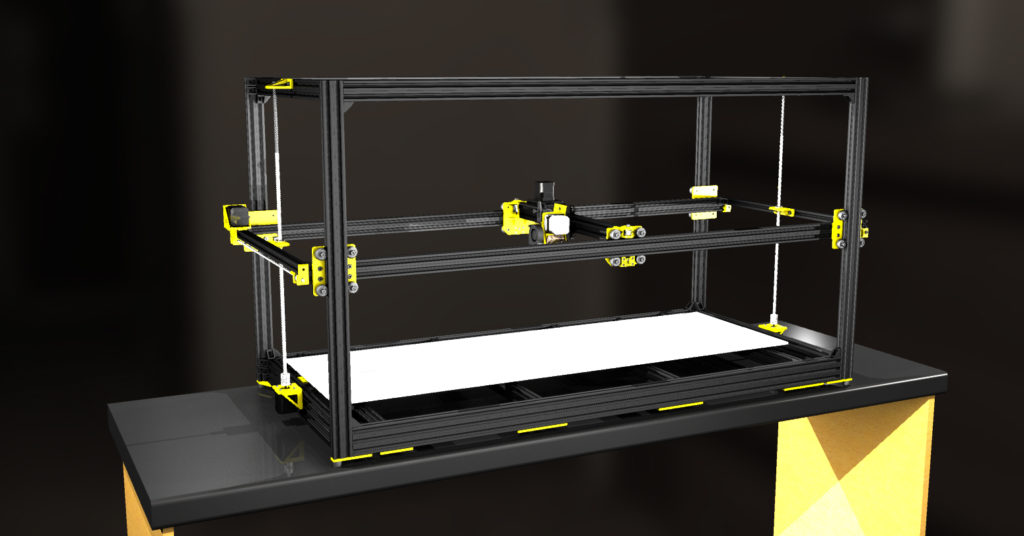

So just another quick update. Sometimes I forget that the public has not seen the latest progress as I have been recording stuff, but have not edited/released it yet.

The entire frame is built. Next comes belts and motors to begin to get ready to make stuff move.

But the crowning jewel so far is the extruder assembly.

There is so many beautiful parts making up the extruder on this printer and I look forward to seeing what my DuetWifi will do with it.

Frame is built and the movement on this thing is incredibly smooth!

I could not upload the gif here due to size, so if you would like to see it, then you can check out this tweet:

https://twitter.com/FunKing3d/status/1033090700122968064

There has been a couple of the printed parts that I needed to address due to clearance issues, but things are really coming together.

The last of my stepper motors have arrived and now I am just waiting on the power supply and a few pieces of hardware.

I will start setting up and testing the electronics very soon.

Just a quick update as to the progress:

My DuetWIFI and PanelDue have arrived. I have also received my BondTech extruder and BLTouch sensor.

These, of course, are some major players in the build.

Last night I took the time to cut all of the aluminum v slot (openbuilds.com) and brought them back to the studio. If you have never cut aluminum, I will tell you that it creates a massive amount of "glitter" and I will be cleaning my shop of it for months to come. LOL!

(This photo was before I cut it to square the ends.)

Here it all is cut and waiting to be tapped.

So, now I start to assemble the frame! It is going to take longer than I want as I need to film the entire process for our YouTube channel, but it will be worth it!

Stay tuned!

@emily said in Build Log: Fun King 3D FK-1 3D Printer:

Looks like it could be fun. (Pun very much intended). As someone that can't look at any printer without wanting to tinker, I see some things I would want to change.

Honestly, I had to finally just put my foot down and call it good. There are still things I will change, but if I did not just stop this thing would be in the design phase forever!

Obviously such a large printer is going to have to be built with some compromises without cost getting insane. Otherwise we end up with a $500,000 milling machine.

One of those compromises may be printing primarily with a large diameter nozzle, and tall layer heights. I would rule out printing with a .4mm nozzle. (Might work ok within a smaller portion of the bed), unless it turns out to be rigid enough. Tall layer heights could be more forgiving here.

I have plans to start with a .4 as that is what is already on the hotend and what I run on all of my other printers, but I also have plans to play with other sizes in the future. I want to be able to print larger objects quicker, so the larger diameter is a must. The hotend will be swappable, so I am also planning a 3mm option.

I figure you are already aware of this. Joining the extrusions with blind screw method here would be best. The corner brackets won't do much (Don't ask me how I know this).

All connections with the Openbuilds v-slot will be blind screwed as well as adding the brackets. I built an AM8 from the Anet A8 and it is only bracketed. While it is fairly rigid, I plan to disassemble it and blind screw it as well. (One day. It prints really well and I hate to mess with it. LOL!)

As mentioned earlier. I would go with either 3 or 4 lead screws on the Z axis. 3 is preferable if it works, but I would probably do 4. At this point you probably don't have to worry much about weight with 4 z motors.

I have looked into this and have a couple ideas for options.

Out of curiosity, why would you think it would need more than the 2? (What is the concern?) I won't tell you my thoughts yet, I would like to hear yours to see if we are on the same page.

This design relies a lot on the 20x40 extrusions being perfectly straight with minimal deflection. So maybe this isn't a concern, deflection is acceptable and the extrusions you got are really straight. But this is something I would test.

I would consider going with a 20x60 extrusion on the long axis. More costly option would be to add a linear guides to that. A possible budget oriented solution if the current design is just not working would be to add a second narrower extrusion on the inside of each side with holes drilled regularly along its length for adjustment. This would be kind of tedious to get adjusted but it could work.

The bottom "box" is 2060 which I did to allow the additional fastener to the uprights. (It also allows me 20mm under the cross members that the bed attaches too to allow wires and such to pass.) I did a few (very non scientific) tests and with the length it is running the deflection "shouldn't" be an issue. LOL! 2020 had too much deflection though.

It will be fun to see this progress.

It has been fun to this point for sure and is now getting really exciting.

Thank you for this post. These are all great points.

@brunofporto The 1200mm came from the fact the bed material comes 48" wide (1200mm) and it makes the bed larger than the gCreate big which is what caused this project to start. The Big has a 42" wide bed so I had to one up Gordon from gCreate. LOL!

We want to print things like skateboard decks, street signs, etc.. It is really more of a Fun thing. Hmm Fun King Fun Thing. LOL! (I am the Dad BTW.)

As for warping, where exactly are you thinking the issue will be? In the print or in the bed? (This is a legit question.) The bed will be made of Mic-6 Cast Aluminum Tool Plate which is cast in a way to resist warping even when heated. It will also have 8 mounting point to the frame. The entire service will be heated with a 120V silicone heater.

Thank you for the input. I have not concentrated on design for making the frame rigid as I want to have the frame built for testing. But your suggestions are good.

As for the CoreXY, the premise is understood and if I need it as a plan B that is where I will likely go. Again, the point of this was to try to be different. To think outside the box in the hopes of stumbling upon something great.

I will absolutely share the cost when I know. The issue currently is that during the prototyping stage, more money is spent than needed as I test things. My best guess is $1500 at this point. The aluminum for the frame was $330 alone.

The whole project is being sourced so that others will be able to build one eventually.

Thanks all!

Space reserved for future expansion.

Hello everyone! I am Glenn from Fun King 3D and a few months ago I decided to design and build my own 3D Printer from the ground up.

This printer will have a 400x1200X475mm build volume and will feature a Duet Ethernet/PanelDue, Bondtech Extruder, E3D V6 Hotend, and all printed parts will be done in IC3D PETG that was custom colored for us. (Available from their website for purchase.)

Quick Note: I intentionally did not research other printers/ways to do what I have done here. I have had a few people give me advice to go look at this and that. I am always open to suggestions, ideas, criticism, etc.. but please note that I am not looking to build this like someone else's design. This is for the purpose of educating myself and my son, as well as trying to do things outside the box. I just feel it is in my best interest to not copy current designs in the hopes of stumbling upon something new, better, different, etc.. Again, I am not saying that I don't want input. I have had some great input from people. I just want it to be known that I am not looking to (intentionally) copy any current designs. (I hope this paragraph does not make me sound like a jerk! That is not my intentions.)

With that said, there is information available on our website at:

https://www.funking3d.com/FK-1

And a teaser trailer video available at:

https://youtu.be/YxHpcLYmU1I

A huge THANK YOU to the following companies for working with us on this! In no particular order:

Duet3D

IC3D Printers

E3D

Bondtech

About Us: Fun King 3D is a joint venture between a father and a son to learn and teach things about 3D Printing and Electronics Projects. Fun King 3D is not a business. We are here to have fun and learn something new every day. You can find us most places @funking3d and twitter is our main place of contact.

If you have questions or comments, let it rip. We love to have dialog with other people in the 3D Printing community!

Thanks for the space.