First 2 prints after updating; all goes well until the end where I find the head:

- Stopped on the print (didn't park)

- However with heater Off

- And weirdest of all, stuck retracting (wheel spinning endlessly)

- Machine stuck in "busy" state (needs powercycle to reset)

My slicer end script is just M0; see the last few lines of that example print:

;TYPE:WALL-INNER

G1 F2925 X153.975 Y152.548 E0.84064

G1 F1500 E-0.3

G0 F7200 X106.719 Y152.548

G0 X106.313 Y152.548

G1 F1500 E0.49956

G1 F2836.4 X104.964 Y152.548 E0.10883

;TIME_ELAPSED:1108.150049

G1 F1500 E-0.3

M82 ;absolute extrusion mode

M107

M0

M83 ;relative extrusion mode

M104 S0

;End of Gcode

My stop.g looks as follow:

; /sys/stop.g

; Clean up and shut down after a print

; M0 in slicer to invoke

M400 ; wait for moves to finish

M104 S0 ; turn off temperature

M140 S0 ; turn off heatbed

M107 ; turn off fan

G1 E-3 F300 ; retract 3 mm to reduce pressure in the nozzle

G91

G1 X2 Y2 ; Wipe nozzle

G90

; Drop Z, being careful near the max

if move.axes[2].machinePosition + 10 < move.axes[2].max

G1 Z{ move.axes[2].machinePosition + 10 }

else

G1 Z{ move.axes[2].max }

G0 X-30 Y100 F3000 ; move to purge bucket

Seems like the printer may freeze right at line 9 of my stop.g?

However and that's where I'm at a loss, the issue does not appear when aborting a print with pause/stop.

Any ideas on what could that be?

Here is a M122 (after restarting because unresponsive when the crash occurs)

M122

=== Diagnostics ===

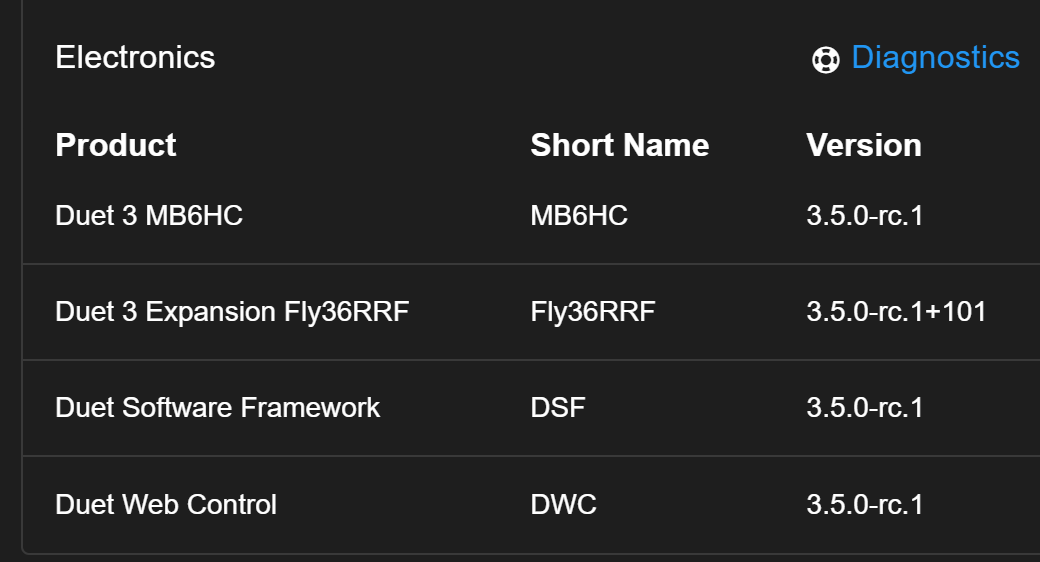

RepRapFirmware for Duet 3 MB6HC version 3.6.0-beta.3 (2025-01-16 19:09:36) running on Duet 3 MB6HC v1.0 or earlier (SBC mode)

Board ID: 08DJM-956L2-G43S4-6JTDA-3SS6L-1B76H

Used output buffers: 1 of 40 (17 max)

=== RTOS ===

Static ram: 136892

Dynamic ram: 95960 of which 5464 recycled

Never used RAM 105740, free system stack 200 words

Tasks: SBC(2,ready,0.6%,747) HEAT(3,nWait 6,0.0%,369) Move(4,nWait 6,0.0%,333) TMC(4,nWait 6,2.8%,377) CanReceiv(6,nWait 1,0.0%,794) CanSender(5,nWait 7,0.0%,334) CanClock(7,delaying,0.0%,353) MAIN(2,running,94.5%,139) IDLE(0,ready,2.0%,29) USBD(3,blocked,0.0%,149), total 100.0%

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 00:03:32 ago, cause: power up

Last software reset at 2025-01-21 01:41, reason: User, Gcodes spinning, available RAM 105956, slot 2

Software reset code 0x2003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a

Error status: 0x00

MCU temperature: min 35.9, current 37.6, max 38.7

Supply voltage: min 29.4, current 29.5, max 29.5, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.0, current 12.1, max 12.1, under voltage events: 0

Heap OK, handles allocated/used 99/14, heap memory allocated/used/recyclable 2048/792/592, gc cycles 0

Events: 0 queued, 0 completed

Date/time: 2025-02-02 00:51:54

Slowest loop: 193.96ms; fastest: 0.06ms

USB interrupts 2

=== Storage ===

Free file entries: 20

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00

Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00

next step interrupt due in 68 ticks, disabled

Driver 0: standstill, SG min n/a, mspos 2, reads 31387, writes 25 timeouts 0

Driver 1: standstill, SG min n/a, mspos 2, reads 31387, writes 25 timeouts 0

Driver 2: standstill, SG min n/a, mspos 8, reads 31388, writes 24 timeouts 0

Driver 3: standstill, SG min n/a, mspos 8, reads 31388, writes 24 timeouts 0

Driver 4: standstill, SG min n/a, mspos 8, reads 31389, writes 24 timeouts 0

Driver 5: standstill, SG min n/a, mspos 8, reads 31402, writes 11 timeouts 0

Phase step loop runtime (us): min=0, max=20, frequency (Hz): min=1889, max=2118

=== DDARing 0 ===

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x80000003, drives owned 0x80000003

Code queue is empty

=== DDARing 1 ===

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000

Code queue is empty

=== Heat ===

Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1 -1 -1 -1 -1, ordering erHeater 1 is on, I-accum = 0.0

=== GCodes ===

Movement locks held by null, null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

=== CAN ===

Messages queued 1730, received 3816, lost 0, ignored 0, errs 607, boc 0

Longest wait 2ms for reply type 6031, peak Tx sync delay 31346, free buffers 50 (min 49), ts 1007/1006/0

Tx timeouts 0,0,0,0,0,0

=== SBC interface ===

Transfer state: 5, failed transfers: 0, checksum errors: 1

RX/TX seq numbers: 6457/6457

SPI underruns 0, overruns 0

State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x27c70

Buffer RX/TX: 0/0-0, open files: 0

=== Duet Control Server ===

Duet Control Server version 3.6.0-beta.3 (2025-01-17 10:25:30, 64-bit)

HTTP+Executed:

> Executing M122

Trigger+Post:

> Executing M409 K"network" I1 (31 more codes pending)

>> Macro config.g: Idle

Trigger:

>> Finishing macro config.g, started by system

Code buffer space: 4096

Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0

Full transfers per second: 25.28, max time between full transfers: 1660.9ms, max pin wait times: 328.1ms/7.1ms

Codes per second: 0.32

Maximum length of RX/TX data transfers: 4508/872

And my Config.g

;

; ___________ __ .__

; \_ _____/___________ _____/ |______ | |

; | __) \_ __ \__ \ _/ ___\ __\__ \ | |

; | \ | | \// __ \\ \___| | / __ \| |__

; \___ / |__| (____ /\___ >__| (____ /____/

; \/ \/ \/ \/

; ___________ .__ .__

; \_ _____/ ____ ____ |__| ____ ____ ___________|__| ____ ____

; | __)_ / \ / ___\| |/ \_/ __ \_/ __ \_ __ \ |/ \ / ___\

; | \ | \/ /_/ > | | \ ___/\ ___/| | \/ | | \/ /_/ >

; /_______ /___| /\___ /|__|___| /\___ >\___ >__| |__|___| /\___ /

; \/ \//_____/ \/ \/ \/ \//_____/

; General Setup - RailCore RRF on an SBC for Duet3

; General

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M564 S1 H1 ; No movement before homing, no out-of-range

G4 S2 ; wait for expansion boards to start

; Debugging

M111 S0 ; Debug (S0 is off; S1 is on)

M929 P"eventlog.txt" S1 ; start logging to file eventlog.txt

M915 X Y S10 F0 R0 ; log motor stalls

; Stepper Configuration and Trinamic Drive Tuning

M569 P0.0 S1 D3 V5 H5 ; X / Rear - LDO-57STH56-2804MACRC

M569 P0.1 S0 D3 V5 H5 ; Y / Front - LDO-57STH56-2804MACRC

M569 P0.2 S1 D3 V5 H5 ; Z / FL - LDO-42STH47-1684MAC

M569 P0.3 S1 D3 V5 H5 ; Z / RL - LDO-42STH47-1684MAC

M569 P0.4 S1 D3 V5 H5 ; Z / MR - LDO-42STH47-1684MAC

;M569 P5 S0 D2 V5 H5 ; E / Extruder - LDO-42STH25-1004AC

;M569 P5 S1 D2 V5 H5 ; E / Extruder - Biqu H2

;M569 P5 S0 D2 V5 H5 ; E / Extruder - Orbiter 2.0

M569 P124.0 S1 D2 ; E / Extruder - SmorbV3 Toolboard

; Axis configuration

M669 K1 ; Corexy mode

;M584 X0 Y1 Z2:3:4 E5 ; Map X to drive 0 Y to drive 1, Z to drives 2, 3, 4, and E to drive 5

M584 X0.0 Y0.1 Z0.2:0.3:0.4 E124.0 ; Map X to drive 0 Y to drive 1, Z to drives 2, 3, 4, and E to toolboard drive 0

M208 X270 Y290 Z325 ; Set axis maxima and high homing switch positions (adjust to suit your machine)

M208 X-35 Y0 Z0 S1 ; Set axis minima and low homing switch positions (adjust to make X=0 and Y=0 the edges of the bed)

; Stealthchop parameters

M915 P0:1 S3 F1 H153 ;T20000 R0

M915 P2:3:4 S3 F1 H1652 ;T1 R0

;M915 P5 S3 F1 H540 T1 R0

;M915 P124.0 S3 F1 H540 T1 R0

; Steps/mm (for the default 1/16 microstepping)

M92 X160 Y160 Z1600 ; Axis Steps/mm

;M92 E4206 ; FLEX3DRive

;M92 E932 ; Biqu H2

M92 E676 ; Orbiter 2.0

; Microstepping (independent of M92 above)

M350 X64 Y64 Z16 I1 ; Set 32x microstepping for axes with interpolation

;M350 E8 I0 ; Set 16x microstepping for Flex3Drive extruder interpolation OFF

;M350 E16 I1 ; Biqu H2

M350 E16 I1 ; Orbiter 2.0

; Motor current

M906 X{2800 * 0.65} Y{2800 * 0.65} Z{1680 * 0.65} I30 ; Set PEAK motor currents (mA) and motor idle factor

;M906 E420 I30 ; Flex3Drive

;M906 E800 I30 ; Biqu H2

;M906 E1000 I10 ; Orbiter 2.0 (rated 1 amp, recommended 1.2)

M906 E850 I10 ; Smorb3.0 (rated 1 amp, recommended 1.2)

M84 S30 ; Idle timeout 30s

; Speeds

M203 X15000 Y15000 Z600 E7200 ; Maximum speeds (mm/min) // XY15000(250mm/s), Z600(10mm/s)), E7200 (120mm/s)

; Accelerations and Jerk

M201 X2500 Y2500 Z100 ; Accelerations (mm/s^2)

;M201 E120 ; Flex3Drive

;M201 E5000 ; Biqu H2

;M201 E3000 ; Orbiter 2.0

M201 E3000 ; Smorb 8000mm/s recommended

M566 X800 Y800 Z100 ; Maximum jerk speeds (mm/min)

;M566 E6 ; Flex3Drive

;M566 E300 ; Biqu H2

;M566 E300 ; Orbiter 2.0

M566 E300 ; Smorb

; Leadscrew locations

M671 X-10:-10:333 Y22.5:277.5:150 S7.5

; End Stops

M574 X1 S1 P"io0.in" ; Map the X endstop to io1.in

;M574 Y1 S1 P"io3.in" ; Map the Y endstop to io2.in

M574 Y1 S1 P"124.io2.in" ; Map the Y endstop to toolboard io1.in

; BLTouch

;M558 P9 C"io7.in" H5 R1 F120 T6000 A5 S0.02 B1 ; Define the bltouch input on io7.in

;M950 S0 C"io7.out" ; Define the bltouch servo on io7.out

;G31 X0 Y25 Z2.00 P25 ; Set the offsets for the bltouch Flex3Drive

;G31 X-25 Y0 Z1.814 P25 ; Set the offsets for the bltouch Biqu H2

;G31 K0 P25 X0.0 Y20.0 Z2.924 ; Set the offsets for the bltouch Orbiter 2.0

; Euclid Probe

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

M558 K0 P8 C"124.io0.in" H8 F300 T9000 A3 S0.01 ; Define Euclid input

G31 K0 P500 X25.0 Y0.0 Z1.486 ; Set offset for Smorb V3 Euclid

; Thermistors

M308 S0 P"temp0" Y"thermistor" A"Keenovo" T100000 B4240 H0 L0 ; Bed thermistor - connected to temp0

;M308 S1 P"temp1" Y"thermistor" A"Mosquito" T4606017 B5848 C5.548428e-8 H0 L0 ; Dyze 500c thermistor - connected to e0_heat

;M308 S1 P"temp1" Y"thermistor" A"BiquH2" T100000 B3950 C0 H0 L0 ; Biqu H2 Chinesium HT-NTC100K thermistor - connected to e0_heat

;M308 S1 P"124.temp0" Y"thermistor" A"Smorb" T100000 B4138 C0 H0 L0 ; Smorb ATC Semitec 104NT-4-R025H42G

M308 S1 P"124.temp0" Y"thermistor" A"Smorb" T100000 B4681 C6.483003e-8 H0 L0 ; Smorb ATC Semitec 104NT-4-R025H42G

; M308 S3 P"124.io1.in" Y"thermistor" A"Extruder Temp" T100000 B4092 ; Smorb extruder temp (not supported)

; Define Heaters

M950 H0 C"out0" T0 ; Bed heater is on out0

;M950 H1 C"out1" T1 Q10 ; Hotend heater is on out1

M950 H1 C"124.out0" T1 Q250 ; Hotend heater is on toolboard out0

; Heater model parameters

M307 H0 A158.5 C366.7 D2.1 S1.0 V24.0 B0 ; Keenovo duet 3 configuration

;M307 H1 R3.573 C131.3:99.7 D5.74 S1.00 V29.4 ; Mosquito 205deg 29.4V

;M307 H1 R3.368 K0.543:0.000 D7.05 E1.35 S1.00 B0 V29.3 ; Mosquito new model 215c 29.3V

;M307 H1 R4.724 C172.5:109.0 D7.70 S1.00 V29.4 ; Biqu H2 205deg 29.4V

M307 H1 R4.017 K0.408:0.270 D6.28 E1.35 S1.00 B0 V29.4 ; Smorb temp 215c 29.3V

; Heater Fault Parameters

M570 H1 P10 T15 S180 ; Hotend allows 10sec for anomaly, permits 15deg excursion, abandons print after 180s

M143 H1 P1 S350 A0 ; raise a heater fault if it exceeds 350C

; Define Bed

M140 H0

M557 X30:295 Y5:285 P15:15 ; Sets mesh leveling probing area /!\ Accounts for probe offset

; Fans

;M950 F0 C"out5" Q250 ; Hotend fan on "out5" connector

;M106 P0 C"Hotend Fan" H1 X0.8 T75 B0.3 ; Enable thermostatic mode for hotend fan - 0.8 to compensate for 29.4V

;M950 F1 C"out4" Q250 ; Layer fan on "out4" connector

;M106 P1 C"Layer Fan" X0.8 S0 ; Layer Fan

M950 F0 C"124.out1" Q500 ; Hotend fan on "out5" connector

M106 P0 C"Hotend Fan" H1 T75 X0.8 ; Enable thermostatic mode for hotend fan - 0.8 to compensate for 29.4V

M950 F1 C"124.out2" Q500 ; Layer fan on "out4" connector

M106 P1 C"Layer Fan" H-1 S0 X0.8 ; Layer Fan

; Tool definitions

M563 P0 S"Smorb v3" D0 H1 F1 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

; Duet3 Cooling

M308 S2 Y"drivers" A"DRIVERS" ; Configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet

M308 S3 Y"mcu-temp" A"MCU" ; Configure sensor 3 as thermistor on pin e1temp for left stepper

M950 F2 C"out6" Q250 ; Create fan 2 on pin fan2 and set its frequency

;M106 P2 C"ElectroBox" H1 S0.8 T75 ; Set fan 2 value

M106 P2 C"ElectroBox" H1 X0.7 T-30:50 ; Set fan 2 value

M308 S4 P"124.temp1" Y"thermistor" A"Chamber Temp" T100000 B4092 ; Toolboard temp

; LED

M950 F3 C"out8" Q1000

M106 P3 C"Enclosure Light" X0.6 S0

M950 C"124.rgbled" E0 T1

M950 F5 C"124.io0.out" Q1000

M106 P5 C"Hotend Light" X0.6 S0

; Filament Sensor

;M591 D0 P7 C"io6.in" S0 E51 L2.1 R85:115 ; Fractal Encoder filament sensor

; Mesh Bed Compensation

;G29 S1 ; Load height map from SD card - Disabled in config.g, moved after startup routing probing

M376 H3 ; Set taper height 3mm

; External Triggers

M950 J1 C"io1.in" ; Green Button on io1

M950 J2 C"io4.in" ; Red Button on io4

M950 J3 C"io2.in" ; Black Button on io2

M950 J4 C"io5.in" ; Blue Button on io5

M581 T2 P1 S1 R2 ; Green button trigger 2 only when not printing (Load filament)

M581 T3 P1 S1 R1 ; Green button trigger 3 only when printing (Raise Z)

M581 T4 P2 S1 R2 ; Red button trigger 4 only when not printing (Unload filament)

M581 T5 P2 S1 R1 ; Red button trigger 5 only when printing (Stop)

M581 T6 P3 S1 R2 ; Black button trigger 6 only when not printing (Resume)

M581 T7 P3 S1 R1 ; Black button trigger 7 only when printing (Lower Z)

M581 T8 P4 S1 R2 ; Blue button trigger 8 only when not printing (LED strip on/off)

M581 T9 P4 S1 R1 ; Blue button trigger 9 only when printing (LED strip on/off)

; Accelerometer

;M955 P0 I21 C"spi.cs3+spi.cs2" ; LIS3DH removable on Orbiter 2

M955 P124.0 I20 ; Onboard toolboard

;M593 P"mzv" F42

; Dynamic Acceleration Adjustment (DAA)

;M593 F52

; Logging

M929 P"eventlog.txt" S1 ; start logging to file eventlog.txt

T0 ; Select first hot end

; Global Variables

global hotend_timer_started = false

global hotend_timer = 0

couldn't figure it out still

couldn't figure it out still