Fly-RRF-36 RP2040 Based CAN-FD Toolboard

-

@jay_s_uk It's working now on io2 without pullup; I'll leave it there for the time while I move on with the rest of the setup.

thermistor doesn't work on io1; it can't do digital readI have another issue now while trying to drive my extruder (a LDO Orbiter with a modest LDO36STH20-1004AHG, driven at 0.85A)

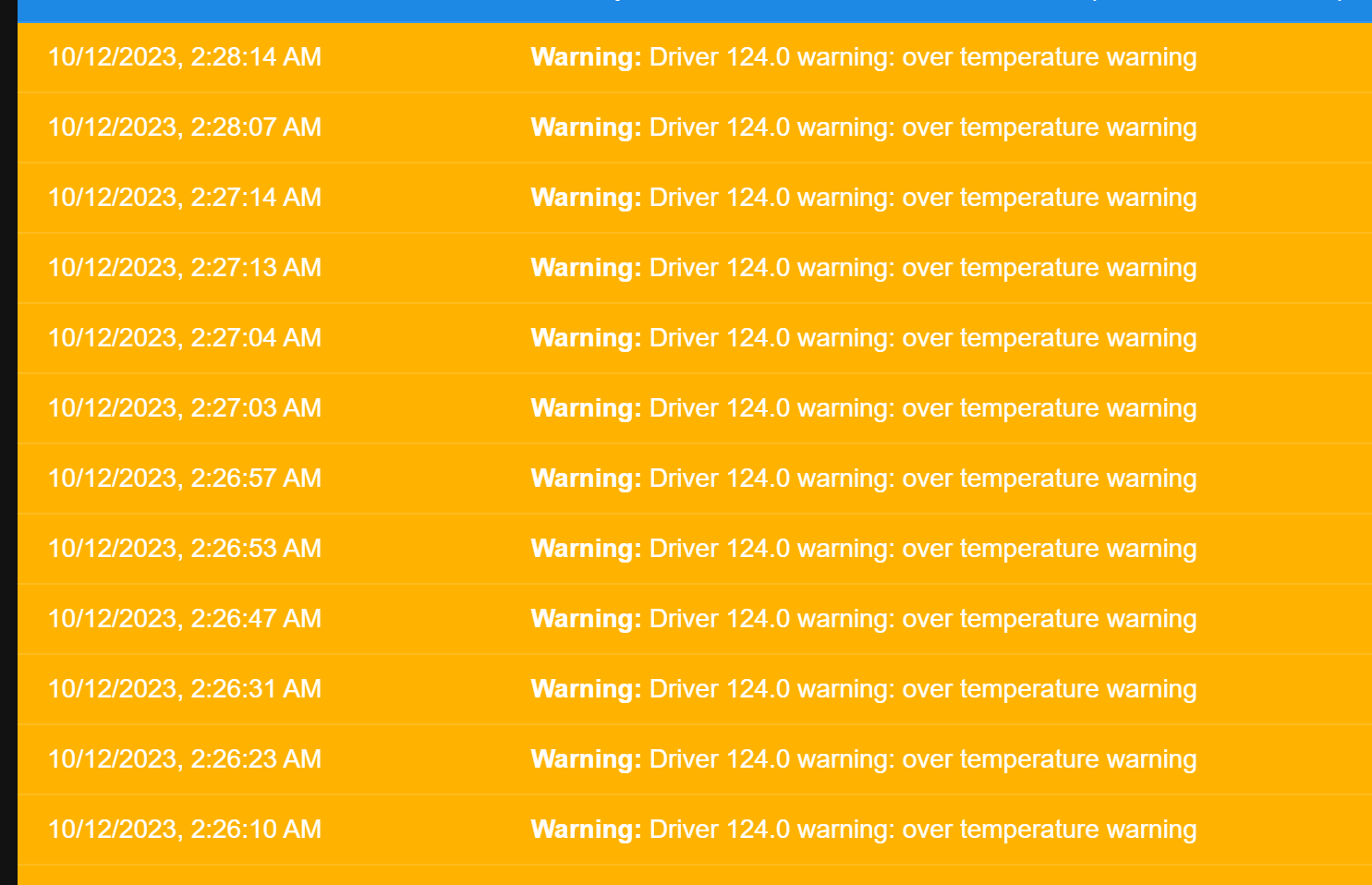

I'm getting a series of over temp warnings, as the driver seem to get in a drive/reset loop for the duration of the move.

Measuring the board with my IR cam reveals 60 to 70c tops package temp on the TMC.

Any tips?

-

@fractalengineer weird; somehow increasing the current to 1A resolved it?

-

you must use TEMP0 for thermistor. IO will lack the 4k7 resistor.

-

@fractalengineer 1A is a lot for this stepper, I run it at 650mA.

-

@oliof stepper is rated 1A, I normally run it at .85 but since less current didn't improve the issue, I tried more.

Extruder is recommended to run at 1.2A in the instructions (runs hotter but more torque)

TMC2209 Driver is rated 2A.

Speaking of, I did manage to get one print of it at 1A,

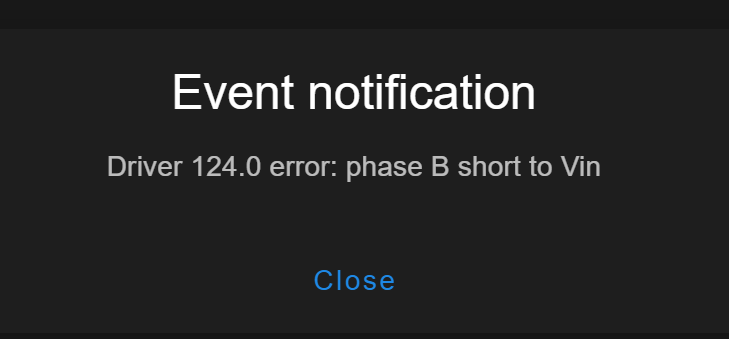

But on the 2nd one I got this message

I checked the driver and ye I got a dead short between B phase and GND...

Will pull the board out and investigate further

-

Ye something's definitely wonky; I took the board out, checked again out of circuit, no mo short.

Reinstalled it, extruder spun nicely again.

Homed, heated up and started a new print, first one ran well,

2nd one gave me the over temp error again.

Idk what I'm doing wrong with it; here's my whole config file, if anyone would be kind enough to look through it and help me point out at any funky stuff

; ; ___________ __ .__ ; \_ _____/___________ _____/ |______ | | ; | __) \_ __ \__ \ _/ ___\ __\__ \ | | ; | \ | | \// __ \\ \___| | / __ \| |__ ; \___ / |__| (____ /\___ >__| (____ /____/ ; \/ \/ \/ \/ ; ___________ .__ .__ ; \_ _____/ ____ ____ |__| ____ ____ ___________|__| ____ ____ ; | __)_ / \ / ___\| |/ \_/ __ \_/ __ \_ __ \ |/ \ / ___\ ; | \ | \/ /_/ > | | \ ___/\ ___/| | \/ | | \/ /_/ > ; /_______ /___| /\___ /|__|___| /\___ >\___ >__| |__|___| /\___ / ; \/ \//_____/ \/ \/ \/ \//_____/ ; General Setup - RailCore RRF on an SBC for Duet3 ; General G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M564 S1 H1 ; No movement before homing, no out-of-range G4 S2 ; wait for expansion boards to start ; Debugging M111 S0 ; Debug (S0 is off; S1 is on) M929 P"eventlog.txt" S1 ; start logging to file eventlog.txt M915 X Y S10 F0 R1 ; log motor stalls ; Stepper Configuration and Trinamic Drive Tuning M569 P0.0 S1 D3 V5 H5 ; X / Rear - LDO-57STH56-2804MACRC M569 P0.1 S0 D3 V5 H5 ; Y / Front - LDO-57STH56-2804MACRC M569 P0.2 S1 D3 V5 H5 ; Z / FL - LDO-42STH47-1684MAC M569 P0.3 S1 D3 V5 H5 ; Z / RL - LDO-42STH47-1684MAC M569 P0.4 S1 D3 V5 H5 ; Z / MR - LDO-42STH47-1684MAC ;M569 P5 S0 D2 V5 H5 ; E / Extruder - LDO-42STH25-1004AC ;M569 P5 S1 D2 V5 H5 ; E / Extruder - Biqu H2 ;M569 P5 S0 D2 V5 H5 ; E / Extruder - Orbiter 2.0 M569 P124.0 S1 D3 V5 H5 ; E / Extruder - SmorbV3 Toolboard ; Axis configuration M669 K1 ; Corexy mode ;M584 X0 Y1 Z2:3:4 E5 ; Map X to drive 0 Y to drive 1, Z to drives 2, 3, 4, and E to drive 5 M584 X0.0 Y0.1 Z0.2:0.3:0.4 E124.0 ; Map X to drive 0 Y to drive 1, Z to drives 2, 3, 4, and E to toolboard drive 0 M208 X270 Y290 Z325 ; Set axis maxima and high homing switch positions (adjust to suit your machine) M208 X-35 Y0 Z0 S1 ; Set axis minima and low homing switch positions (adjust to make X=0 and Y=0 the edges of the bed) ; Stealthchop parameters M915 P0:1 S3 F1 H153 T20000 R0 M915 P2:3:4 S3 F1 H1652 T1 R0 ;M915 P5 S3 F1 H540 T1 R0 M915 P124.0 S3 F1 H540 T1 R0 ; Steps/mm (for the default 1/16 microstepping) M92 X160 Y160 Z1600 ; Axis Steps/mm ;M92 E4206 ; FLEX3DRive ;M92 E932 ; Biqu H2 M92 E690 ; Orbiter 2.0 ; Microstepping (independent of M92 above) M350 X64 Y64 Z16 I1 ; Set 32x microstepping for axes with interpolation ;M350 E8 I0 ; Set 16x microstepping for Flex3Drive extruder interpolation OFF ;M350 E16 I1 ; Biqu H2 M350 E16 I1 ; Orbiter 2.0 ; Motor current M906 X{2800 * 0.65} Y{2800 * 0.65} Z{1680 * 0.65} I30 ; Set PEAK motor currents (mA) and motor idle factor ;M906 E420 I30 ; Flex3Drive ;M906 E800 I30 ; Biqu H2 ;M906 E1000 I10 ; Orbiter 2.0 (rated 1 amp, recommended 1.2) M906 E850 I10 ; Smorb3.0 (rated 1 amp, recommended 1.2) M84 S30 ; Idle timeout 30s ; Speeds M203 X15000 Y15000 Z600 E7200 ; Maximum speeds (mm/min) // XY15000(250mm/s), Z600(10mm/s)), E7200 (120mm/s) ; Accelerations and Jerk M201 X2500 Y2500 Z100 ; Accelerations (mm/s^2) ;M201 E120 ; Flex3Drive ;M201 E5000 ; Biqu H2 ;M201 E3000 ; Orbiter 2.0 M201 E3000 ; Smorb 8000mm/s recommended M566 X800 Y800 Z100 ; Maximum jerk speeds (mm/min) ;M566 E6 ; Flex3Drive ;M566 E300 ; Biqu H2 ;M566 E300 ; Orbiter 2.0 M566 E300 ; Smorb ; Leadscrew locations M671 X-10:-10:333 Y22.5:277.5:150 S7.5 ; End Stops M574 X1 S1 P"io0.in" ; Map the X endstop to io1.in ;M574 Y1 S1 P"io3.in" ; Map the Y endstop to io2.in M574 Y1 S1 P"124.io2.in" ; Map the Y endstop to toolboard io1.in ; BLTouch ;M558 P9 C"io7.in" H5 R1 F120 T6000 A5 S0.02 B1 ; Define the bltouch input on io7.in ;M950 S0 C"io7.out" ; Define the bltouch servo on io7.out ;G31 X0 Y25 Z2.00 P25 ; Set the offsets for the bltouch Flex3Drive ;G31 X-25 Y0 Z1.814 P25 ; Set the offsets for the bltouch Biqu H2 ;G31 K0 P25 X0.0 Y20.0 Z2.924 ; Set the offsets for the bltouch Orbiter 2.0 ; Euclid Probe M574 Z1 S2 ; configure Z-probe endstop for low end on Z M558 K0 P8 C"124.io0.in" H8 F300 T9000 A3 S0.01 ; Define Euclid input G31 K0 P500 X25.0 Y0.0 Z1.63 ; Set offset for Smorb V3 Euclid ; Thermistors M308 S0 P"temp0" Y"thermistor" A"Keenovo" T100000 B4240 H0 L0 ; Bed thermistor - connected to temp0 ;M308 S1 P"temp1" Y"thermistor" A"Mosquito" T4606017 B5848 C5.548428e-8 H0 L0 ; Dyze 500c thermistor - connected to e0_heat ;M308 S1 P"temp1" Y"thermistor" A"BiquH2" T100000 B3950 C0 H0 L0 ; Biqu H2 Chinesium HT-NTC100K thermistor - connected to e0_heat M308 S1 P"124.temp0" Y"thermistor" A"Smorb" T100000 B4138 C0 H0 L0 ; Smorb ATC Semitec 104NT-4-R025H42G ; M308 S3 P"124.io1.in" Y"thermistor" A"Extruder Temp" T100000 B4092 ; Smorb extruder temp (not supported) ; Define Heaters M950 H0 C"out0" T0 ; Bed heater is on out0 ;M950 H1 C"out1" T1 Q10 ; Hotend heater is on out1 M950 H1 C"124.out0" T1 Q250 ; Hotend heater is on toolboard out0 ; Heater model parameters M307 H0 A158.5 C366.7 D2.1 S1.0 V24.0 B0 ; Keenovo duet 3 configuration ;M307 H1 R3.573 C131.3:99.7 D5.74 S1.00 V29.4 ; Mosquito 205deg 29.4V ;M307 H1 R3.368 K0.543:0.000 D7.05 E1.35 S1.00 B0 V29.3 ; Mosquito new model 215c 29.3V ;M307 H1 R4.724 C172.5:109.0 D7.70 S1.00 V29.4 ; Biqu H2 205deg 29.4V M307 H1 R5.101 K0.652:0.000 D5.68 E1.35 S1.00 B0 V29.3 ; Smorb temp 215c 29.3V ; Heater Fault Parameters M570 H1 P10 T15 S180 ; Hotend allows 10sec for anomaly, permits 15deg excursion, abandons print after 180s M143 H1 P1 S350 A0 ; raise a heater fault if it exceeds 350C ; Define Bed M140 H0 M557 X5:275 Y25:310 P10:10 ; Sets mesh leveling probing area /!\ Accounts for probe offset ; Fans ;M950 F0 C"out5" Q250 ; Hotend fan on "out5" connector ;M106 P0 C"Hotend Fan" H1 X0.8 T75 B0.3 ; Enable thermostatic mode for hotend fan - 0.8 to compensate for 29.4V ;M950 F1 C"out4" Q250 ; Layer fan on "out4" connector ;M106 P1 C"Layer Fan" X0.8 S0 ; Layer Fan M950 F0 C"124.out1" Q500 ; Hotend fan on "out5" connector M106 P0 C"Hotend Fan" H1 T75 X0.8 ; Enable thermostatic mode for hotend fan - 0.8 to compensate for 29.4V M950 F1 C"124.out2" Q500 ; Layer fan on "out4" connector M106 P1 C"Layer Fan" H-1 S0 X0.8 ; Layer Fan ; Tool definitions M563 P0 S"Smorb v3" D0 H1 F1 ; Define tool 0 G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures ; Duet3 Cooling M308 S2 Y"drivers" A"DRIVERS" ; Configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet M308 S3 Y"mcu-temp" A"MCU" ; Configure sensor 3 as thermistor on pin e1temp for left stepper M950 F2 C"out6" Q250 ; Create fan 2 on pin fan2 and set its frequency ;M106 P2 C"ElectroBox" H1 S0.8 T75 ; Set fan 2 value M106 P2 C"ElectroBox" H1 X0.7 T30:75 ; Set fan 2 value M308 S4 P"124.temp1" Y"thermistor" A"Chamber Temp" T100000 B4092 ; Toolboard temp ; LED M950 F3 C"out8" Q1000 M106 P3 C"Enclosure Light" X0.6 S0 M950 C"124.rgbled" E0 T1 M950 F5 C"124.io0.out" Q1000 M106 P5 C"Hotend Light" X0.6 S0 ; Filament Sensor ;M591 D0 P7 C"io6.in" S0 E51 L2.1 R85:115 ; Fractal Encoder filament sensor ; Mesh Bed Compensation ;G29 S1 ; Load height map from SD card - Disabled in config.g, moved after startup routing probing M376 H3 ; Set taper height 3mm ; External Triggers M950 J1 C"io1.in" ; Green Button on io1 M950 J2 C"io4.in" ; Red Button on io4 M950 J3 C"io2.in" ; Black Button on io2 M950 J4 C"io5.in" ; Blue Button on io5 M581 T2 P1 S1 R2 ; Green button trigger 2 only when not printing (Load filament) M581 T3 P1 S1 R1 ; Green button trigger 3 only when printing (Raise Z) M581 T4 P2 S1 R2 ; Red button trigger 4 only when not printing (Unload filament) M581 T5 P2 S1 R1 ; Red button trigger 5 only when printing (Stop) M581 T6 P3 S1 R2 ; Black button trigger 6 only when not printing (Resume) M581 T7 P3 S1 R1 ; Black button trigger 7 only when printing (Lower Z) M581 T8 P4 S1 R2 ; Blue button trigger 8 only when not printing (LED strip on/off) M581 T9 P4 S1 R1 ; Blue button trigger 9 only when printing (LED strip on/off) ; Accelerometer ;M955 P0 I21 C"spi.cs3+spi.cs2" ; LIS3DH removable on Orbiter 2 M955 P124.0 I10 ; Onboard toolboard ;M593 P"mzv" F42 ; Dynamic Acceleration Adjustment (DAA) ;M593 F52 ; Logging M929 P"eventlog.txt" S1 ; start logging to file eventlog.txt T0 ; Select first hot end ; Global Variables global hotend_timer_started = false global hotend_timer = 0Cheers

-

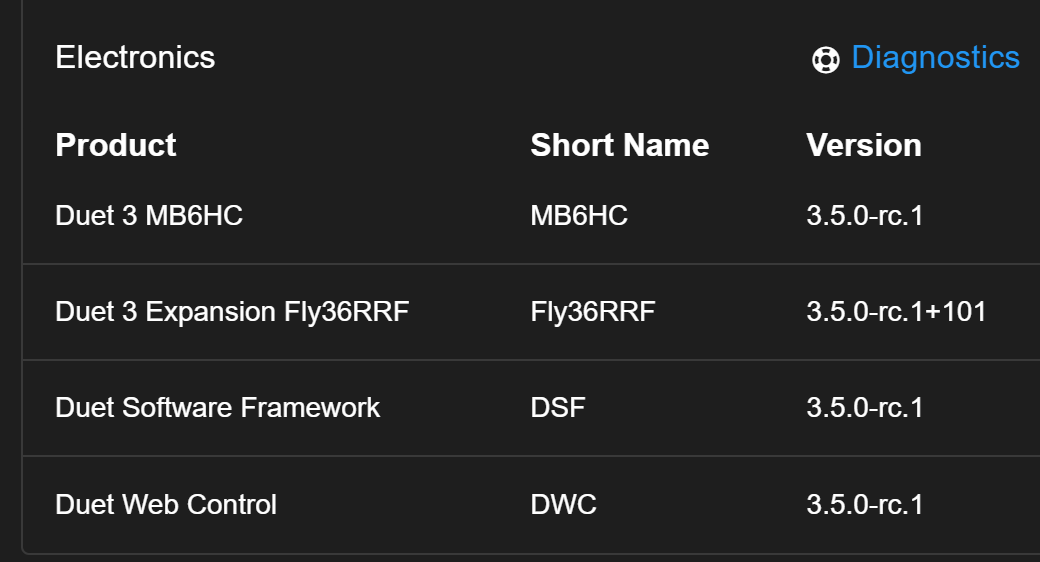

@KenW yep everything on 3.5.0 RC1

-

@jay_s_uk any thoughts on this?

-

@fractalengineer maybe try without the stealthchop parameters

-

@jay_s_uk Well I'd be damned; didn't think of removing them but these were indeed tied to my TMC5160 tuning

Also somehow missed that I had M569 set to D3...

Set it back to D2, disabled M915 and it seems to be running like a champ now, thank you very much!

Let's push some plastic now

-

@KenW ah yes, the update thing should be fixed in RC2.

To get round it at the moment, create/upload a file calledDuet3Firmware_Fly36RRF.binin the firmware folder

It doesn't matter what the file is or what it contains. This will trick RRF into updating the toolboard -

@jay_s_uk Just to clarify, you will also need to use this trick to install RC2 (when it is available) as there are changes in both the main RRF and in the toolboard code. Once everything is on RC2+ then you should not need the trick again.

-

@KenW yes, the 101 to 102 change only affect mainboard firmware

-

Just a heads up, the fw file names appear to be case sensitive, but the https://github.com/gloomyandy/RepRapFirmware/releases repo produces wrong case (Duet3Firmware_FLY36RRF where M997 expects Fly)

This is also erroneous on the docs: https://teamgloomy.github.io/fly_rrf_36_general.html

I've figured simply correcting the case on both .bin and .uf2 made the flash successful

Perhaps have GitHub produce case correct filename and reflect it in the docs for further reference?

Apart from that still happy with the board,

thank you!

thank you! -

@fractalengineer thanks, I'll update it once I'm home

-

@fractalengineer Posted this problem back when I was not able to update the firmware and was told to create a bin file. I had to correct the case to Fly on the .uf2 to match the .bin like you did. But for some reason all my postings on the board vanished. Never found out why that happened. Asked if I had done something wrong and was told no so?

Not had them vanish since.

-

@KenW @fractalengineer That's interesting. I fixed the names in the latest rc2 version (the filenames are now uppercase). But I've never actually seen this issue when updating. Are you by any chance running an SBC configuration?

-

@gloomyandy This was my first time updating from the Duet; RC1 was a fresh flash from USB, but yep I'm on Duet3 MB6HC + SBC