@dc42 Sorry, I forgot post my config file.

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"duet" ; set printer name

M669 K1 ; select CoreXY mode

; Network

;M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

;M586 P0 S1 ; enable HTTP

;M586 P1 S0 ; disable FTP

;M586 P2 S0 ; disable Telnet

; Drives -

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.3 S0 ; physical drive 0.3 goes backwards

M569 P0.4 S0 ; physical drive 0.4 goes backwards

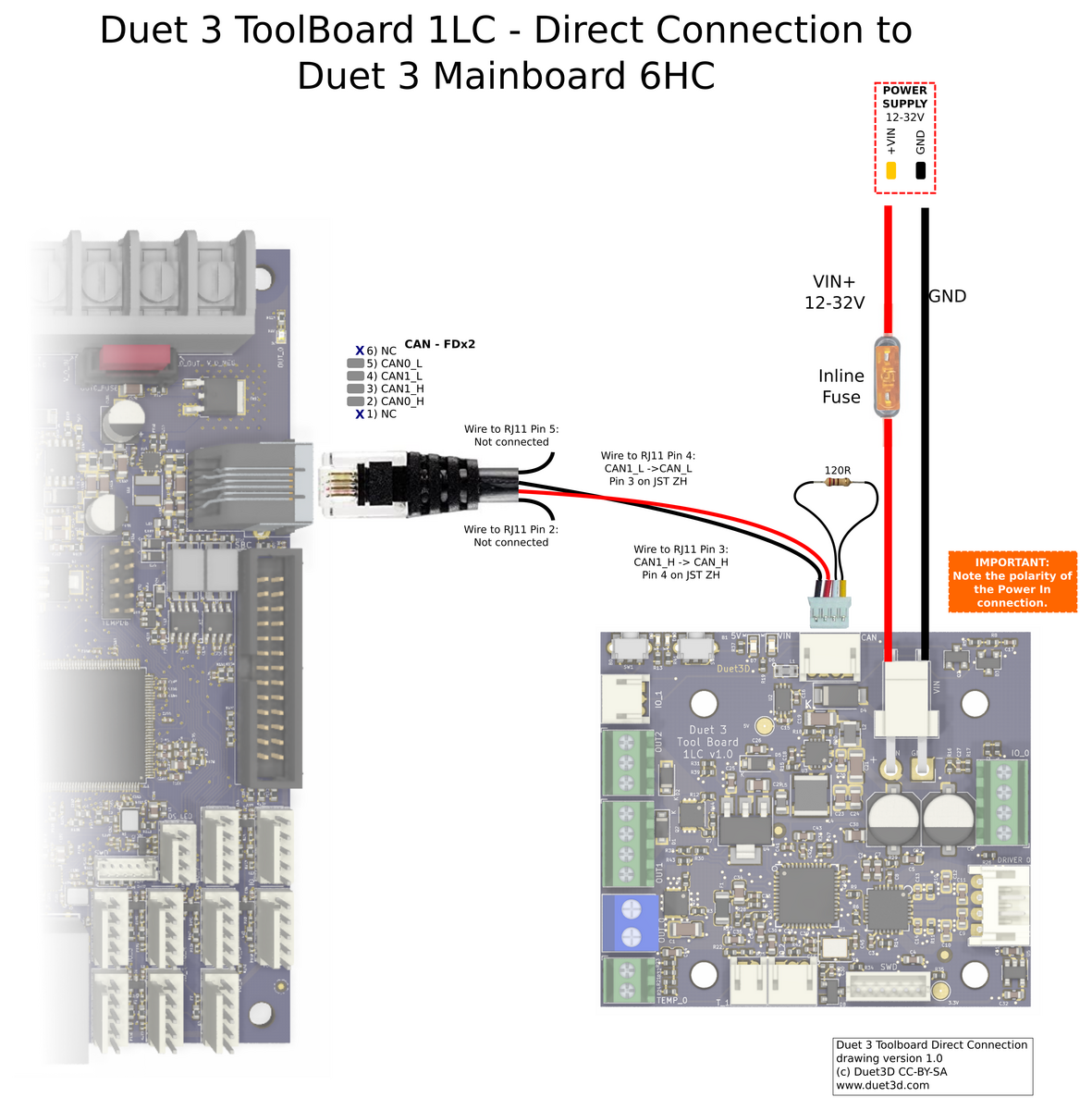

M569 P1.0 S0 ; physical drive 1.0 goes backwards

M584 X0.0 Y0.1 Z0.2:0.3:0.4 E1.0 ; set drive mapping

M350 X32 Y32 Z64 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z1600.00 E409.00 ; set steps per mm

; Calculated values from https://www.3dblog.cz/nastaveni/akcelerace-jerk-a-junction-deviation/

M201 X3200.00 Y3200.00 Z100.00 E2000.00 ; set accelerations (mm/s^2)

M203 X12000.00 Y12000.00 Z300.00 E10000.00 ; set maximum speeds (mm/min)

M204 P1400 ; Set printing acceleration

M205 X12.00 Y12.00 Z12.00 E12.00 ; set maximum instantaneous speed changes (mm/min)

M906 X1773 Y1773 Z1773 E940 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X-4:270 Y-4:270 Z0:270 ; set axis minima/maxima

; Endstops

M574 X1 S1 P"!1.io1.in" ; configure sensorless endstop for low end on X

M574 Y1 S1 P"!io1.in" ; configure sensorless endstop for low end on Y

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M950 S0 C"1.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"^1.io0.in" H1.5 F240 T12000 ; set Z probe type to bltouch and the dive height + speeds

G31 P1000 X36 Y-44 Z4.50 ; set Z probe trigger value, offset and trigger height

M557 X32:270 Y0:226 P8 ; define mesh grid

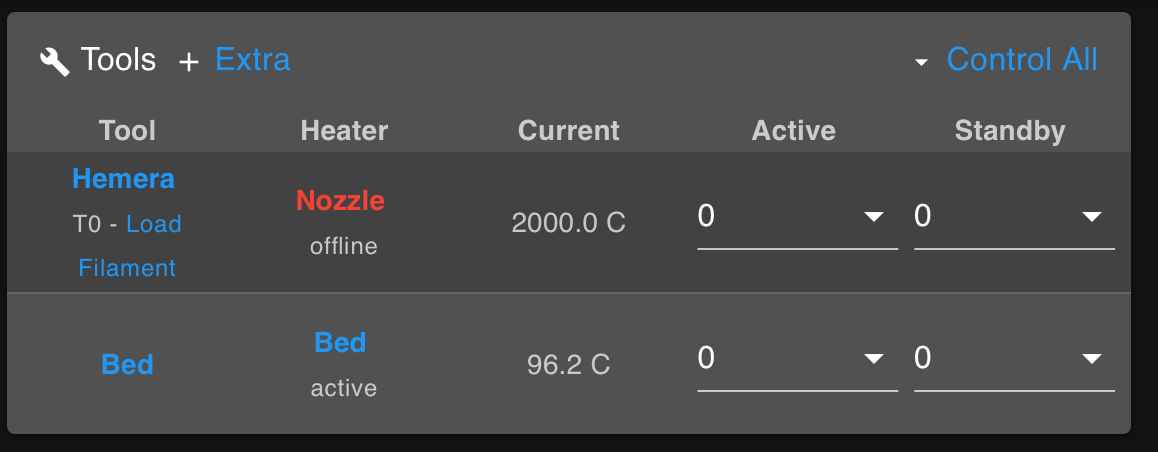

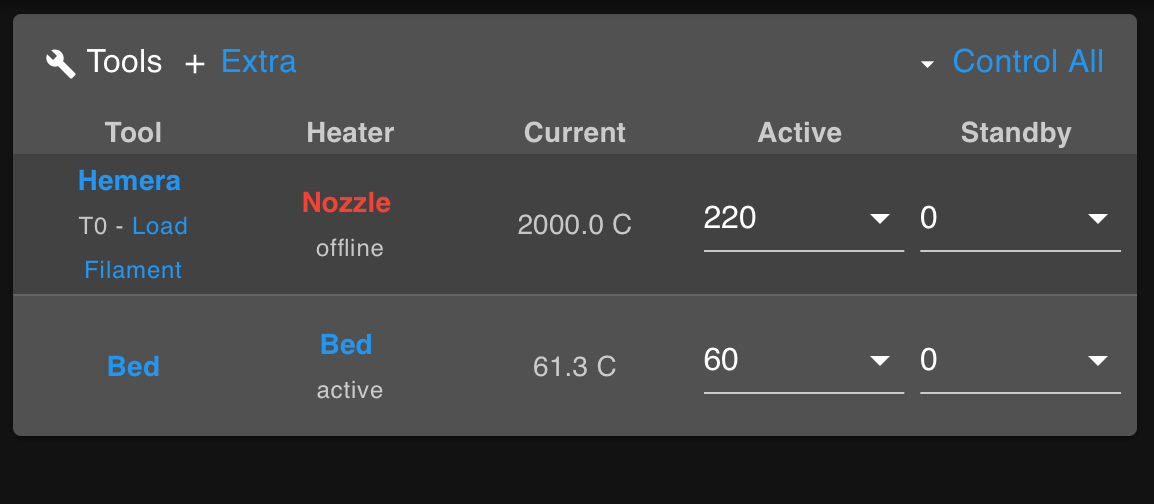

; Heaters

M308 S0 P"temp0" Y"thermistor" T90000 B4000 A"Bed" D600 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out1" T0 ; create bed heater output on out0 and map it to sensor 0

M140 H0 ; map heated bed to heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M308 S1 P"1.temp0" Y"pt1000" A"Nozzle"; configure sensor 1 as PT1000 on pin 1.temp0

M950 H1 C"1.out0" T1 ; create nozzle heater output on 1.out0 and map it to sensor 1

;M950 H1 C"out0" T1 ; (TUNING PURPOSES - M303 only) create nozzle heater output on out0 and map it to sensor 1

M143 H1 S285 ; set temperature limit for heater 1

; Fan

M950 F0 C"!1.out1+^out1.tach" Q1000 ; create fan 0 on pin 1.out1 and set its frequency (Blower)

M106 P0 S0 H-1 B0.2 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"1.out2+^out2.tach" ; create fan 1 on pin 1.out2 and set its frequency (Heatsink)

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 S"Hemera" ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

; Resetting Z-probe

M280 P0 S160 ; Alarm Release and Push-Pin UP

M280 P0 S90 ; Send PWM channel 0 the S90 (angle) command

;M290 M290 R0 S-0.040 ; Baby Z-offset

M572 D0 S0.025 ; Configure pressure advance

;M564 H0 ; allow movement of axes that have not been homed

M501 ; Set the active parameters to those stored in sys/config-override.g on the SD card.