I sounds like motors not correctly wired to the board. Make sure that the coils are correctly paired...

Best posts made by FelixH

-

RE: Need some help with workbee cncposted in CNC

-

RE: True Bed Leveling (G32) leads to "inconsistent Z probe readings"posted in General Discussion

@gloomyandy yeah, got you! As I already checked, by setting the tolerance to 0.004 it did already the trick.

thanks a lot!

-

RE: Trigger height not taking effect on Delta printer.posted in Tuning and tweaking

Well, I did change the trigger height to 16.25 and re-run the delta calibration. The Delta Height changed by 0.2mm (or so). I approached the nozzle to the bed until Z=0 and, sure enough, I got nice paper grab...

Thanks a lot, everybody

-

RE: CNC style Pendantposted in Hardware wishlist

Yesterday I noticed something weird while using the pendant. The multiplier knob was set at x10 and, not thinking about it, I tried to move the Z axis. Because I turned the wheel too much, I got a message on the display telling me to chill out (paraphrasing here) because I wanted to move more than the axis allows. So far, so good. However the X axis moved a little bit instead, even though the Z axis was selected on the axis knob. Now that's weird. Once I switched to x0.1 multiplier, the Z axis moved ok.

Knowing that, I'll be more careful from now on, but I am really curious if this is a "global" bug or it is just me.I am using an Arduino Nano and I changed the resistor on it in order for the bypass of the display to work. The Arduino Pro Micro I ordered came when the Pendant was already assembled, so I saw no reason to open it up again. Also, I did not update the firmware to the latest version, as I understood it was only Pro Micro related and I didn't see a point on doing it.

Cheers!

-

RE: CNC and Coordinate Systemsposted in CNC

Well, I finally got the time to do some experimenting. If I understood that correctly, I was mistaken regarding the G10 command. It seems it's like this:

P1 is G54 (WCS #1)

P2 is G55 (WCS #2)

etc. -

RE: Do we need ABL (Auto Bed Leveling) devices anymore?posted in General Discussion

The closest thing I‘ve seen similar to what would be using Stall detection as a Z probe is the Smart Effector on a Delta. It is not the same, as it is based in some other phenomenon, but you effectively use the nozzle tip a sensor. Maybe one could design a carriage for a cartesian printer this this technology??

BTW, buying the Smart Effector for my Delta was one of the best decisions I‘ve done (3D Printing related, that is).

-

RE: Famous error :Warning: motor phase A Drive1posted in Duet Hardware and wiring

aren't you missing something?. The error tells you exactly what is happening. Instead of looking to your config files, check the continuity of you motor cables. I got this error once and it pop up because one of the motor cables was pinch by the printer's frame and eventually was severed. I repaired the cable and everything was fine.

-

RE: Sensorless homing tuning on cartesian printerposted in Tuning and tweaking

Well, i mixed the code on the 3 independent homing files into one homeall.g file (see below). It appears to work without any issues...

I hope this post helps somebody else with similar issues.

Thanks a lot, everyone.

; homeall.g ; called to home all axes ;M98 Phomex.g ;M98 Phomey.g ;M98 Phomez.g G91 ; set relative mode G1 S2 Z5 F1200 ; lift Z G29 S2 ; to clear the height map before Z homing M561 ;reset bed compensation ; homex.g G1 S2 X0.2 ; Move X by 0.2 mm, clear stall status M400 ; make sure everything has stopped before we make changes M913 X60 ; X motor % current M915 X S2 R0 F0 ; set X sensitivity, do nothing when stall, unfiltered M574 X1 S3 ; set endstops to use motor stall G1 S1 X-220 F3600 ; move X back, stopping at the end stop M400 ; make sure everything has stopped M913 X100 ; XY motors to 100% current M915 X S30 R0 F0 ; set X sensitivity high, do nothing when stall, unfiltered M400; ; make sure everything has stopped ; homey.g G1 S2 Y0.2 ; Move Y by 0.2 mm, clear stall status M913 Y75 ; Y motor % current M915 Y S3 R0 F0 ; set X sensitivity, do nothing when stall, unfiltered M574 Y S3 ; set endstops to use motor stall G1 S1 Y-220 F3600 ; move X back, stopping at the end stop M400 ; make sure everything has stopped M913 Y100 ; XY motors to 100% current M915 Y S30 R0 F0 ; set Y sensitivity high, pause when stall, filtered M400; ; make sure everything has stopped homez.g G90 ; absolute positioning G1 X110 Y110 F6000 ; go to first probe point G30 ; home Z by probing the bed -

RE: SuperPID Spindle Controller with Duet WiFi v2.xposted in CNC

So, as promised the following is what I've done to get my SuperPID working flawlessly with my Duet Wifi 2.

The wiring schematic is as follows (please don't mind the inaccuracy of standard symbols):

The ON/OFF is accomplished using the FAN0 (-) pin to ground the RUN port on the SuperPID.

The router RPM of the router is controlled by the (-) pin of the FAN1.On the config.g file on the Duet a file named customconfig.g is called in which customizations are done without modifying the main config.g file. On this file I added the following lines, which configure the FAN1 as the "Tool 0" pin and set the RPM for a max PWM signal (255). It also inverts the PWM signal, so that the more PWM the more RPM:

M106 P1 I-1 H-1 A21 ; disable FAN2 & allocate Tool 0 to pin 21 M563 P0 S"Spindle" ; M453 S"Spindle" P21 I1 T0 R30000; , Tool 0 = Spindle, invert PWM, 30000 RPM at max PWMTo turn ON the router:

M106 P0 S255To turn OFF the router:

M107 P0To set the RPMs:

M3 S15000 ; Set the router speed at 15000 RPM (PWM aprox 128)References:

-

RE: Tool missing after update to firmware 3.3posted in General Discussion

@JoergS5 thanks, T0 is at the very end of the config.g file, not shown on the snippet above.

@jay_s_uk that seems to have been the issue, apparently. I added the example line shown on the wiki and it appears to work ok:

M584 X0 Y1 Z2:3 E4:5:6I wonder why did it work without that line previously...

-

RE: Help troubleshooting after upgrade to RRF3 (sensorless homing)posted in Tuning and tweaking

So, the printer has undergone several Y-homings since I changed the speed and has suffered 0 fails, so I would say the issue is solved. Thanks again!

-

RE: Fusion 360 post processorposted in CNC

I modified my Duet-powered Ooznest Workbee last year with a SuperPID, with which I can control a modified a router (DeWalt in my case). You can see some infor here:

After many liters of coffee and documentation reading, I was able to modify the Post-processor that the folks back on Ooznest provide for their Workbee machines. With it I am able to turn on and off the spindle via GCode as well as control the RPM.

It is not perfect, since my understanding of how post-processors are coded is extremely limited, but maybe it could be a good starting point. I am happy to share it with whomever needs it:

WorkBee - Duet_with_router_control.cps

Have fun!

-

RE: Tool missing after update to firmware 3.3posted in General Discussion

@phaedrux ... I guess I should start reading the release notes from now on... thanks!

-

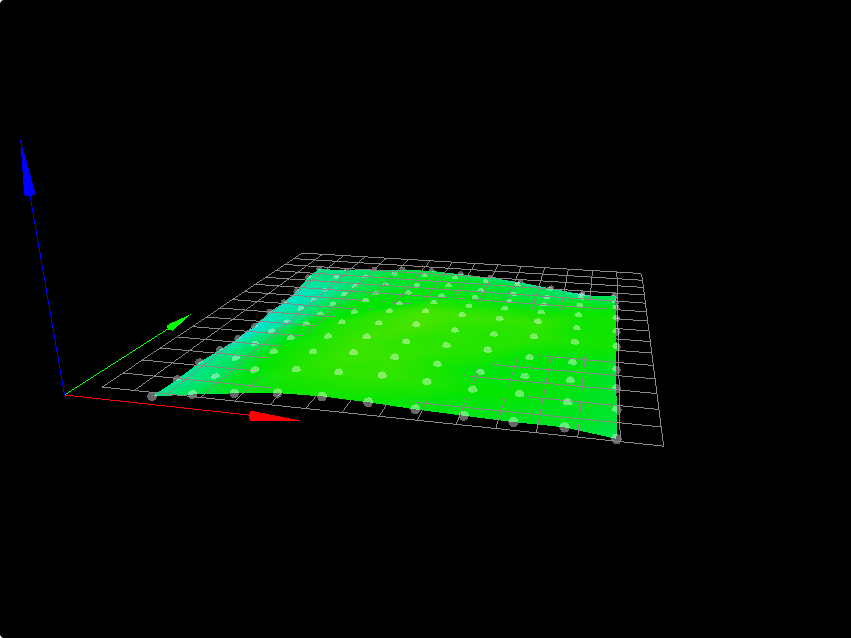

RE: Mesh leveling height map seems mirroredposted in Tuning and tweaking

@phaedrux well... I promised I would report back...

Thanks a lot! At the end of the day it was just the simple "level it the old fashioned way before..."

Can't thank you enough, it was bothering me for a while...

-

Laser/CNC macros for RRF3 on Workbeeposted in CNC

Hi all,

yesterday I updated the firmware of my Ooznest Workbee. Last year I upgraded her with a SuperPID and a Laser. It took a while, but I was able to create some simple macros for switching between CNC and Laser modes.

However now the firmware runs FFR3 and these macros do not work anymore and I am having a hard time adapting them, so I would appreciate some help here.

Before the upgrade this was my setting:

customconfig.g (which is called at the end on config.g)

; ADD ANY CUSTOM SETTINGS BELOW ;New Steps=(mm requested*current steps)/mm actual M92 X399.03 Y398.49 Z400 ; Set steps per mm M574 X2 Y2 Z2 S1 ; Set active low endstops M106 P1 I-1 H-1 A21 ; disable FAN2 & allocate tool 0 to pin 21 M563 P0 S"Spindle" ; M453 S"Spindle" P21 I1 T0 R30000; , Tool 0 = Spindle, invert PWM, 30000 RPM at max PWMSwitch to Laser.g (macro to switch from CNC to Laser modes)

M106 P2 S255 ; turn on 12v PSU M307 H3 A-1 C-1 D-1 ; Disable Heater output on H3 M452 P3 S1 R255 F200 ; Enable Laser mode, on output 3 (heater 3), with max intensity being 255, and a PWM frequency of 200Switch to CNC.g (macro to switch from Laser to CNC modes)

M106 P2 S0 ; turn off 12v PSU M453 ; Put the machine into CNC Modes M140 H-1 ; Disable heated bed M208 X800 Y770 Z94 S0 ; Set axis maxima M98 Pcustomconfig.g ; Execute custom config settingsAs far as I remember I used the output on FAN1 to control the Spindle speed.

The FAN2 was used to control a SSR to turn on/off a 12v PSU, for the laser.the new config.g provided by Ooznest, simply calls different config files:

config.g (by Ooznest)

; Configuration file for Duet ; executed by the firmware on start-up ; WorkBee Firmware Version 1.1 global systemSettingsVersion={1.2} ; Configuration files M98 P"config-network.g" M98 P"config-drives.g" M98 P"config-axes.g" M98 P"config-axes-limits.g" M98 P"config-axes-calibration.g" M98 P"config-axes-endstops.g" M98 P"config-probe.g" M98 P"config-spindle.g" M98 P"config-laser.g" ; Other Settings M453 ; Put the machine into CNC Modes G90 ; Set absolute coordinates M140 H-1 ; Disable heated bed M564 S1 H1 ; Disable jog commands when not homed M911 S21.0 R23 P"G91 G1 Z3 F1000" ; Configure power loss resume ; User Configuration files M98 P"config-user-settings.g" M501 ; Load Stored ParametersThe instructions provided by the folks at Ooznest seem a little bit superficial, in my opinion:

https://learn.ooznest.co.uk/Guide/How+To+Update+WorkBee+Firmware+V1.0.7+>+V3.3.0-1.2/240#s1128

I asked for help on their site, but they came back to me twice providing solutions for something I was not having an issue with...

So I would appreciate any help somebody would give me in adapting my old macros to the new paradigm...

Thanks in advance!

-

RE: NEJE-like Laser as CNC upgradeposted in Laser Cutters

@Phaedrux thanks a lot for your help. Actually shortly after I posted the question I found where the problem was. The command disabling the heated bed was being called twice. I cleaned it up and now everything seems to be working just fine. Thanks a lot again!

-

RE: Macro not sent from PanelDue (but works ok from Web interface)posted in PanelDue

well, I just made a short test in which I unplugged the Pendant and plugged the PanelDue as usual. The Macro in this configuration works just fine. So, apparently, it is a problem with the Pendant. I will post the problem over the Pendant post.

-

RE: Request Cartesian with cyclops system: 2 extruders and 1 hotendposted in Example setups and prints

If somebody lands on this thread looking for the same info as I was, here you have it. This is what did it after some headaches:

; Configuration file for Duet WiFi (firmware version 3.11) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool on Mon Feb 04 2019 17:03:09 GMT+0100 (Central European Standard Time) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ;Panel Due Setup M575 P1 B57600 S1 ; Network M550 P"FH-Dual" ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S0 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes backwards M569 P4 S1 ; Drive 4 goes backwards M584 X0 Y1 Z2 E3:4 ; Driver 0 controls the X motor, 1 controls Y, 2 controls Z motors, 3 and 4 control E motors M350 X16 Y16 Z16 I1 ; Configure microstepping with interpolation M350 E16:16 ; Configure microstepping with interpolation M92 X100.00 Y100.00 Z400.00 ; Set steps per mm M92 E408:408 ; Set steps per mm M566 X600.00 Y600.00 Z18.00 ; Set maximum instantaneous speed changes (mm/min) M566 E300:300 ; Set maximum instantaneous speed changes (mm/min) M203 X10000.00 Y10000.00 Z1000.00 ; Set maximum speeds (mm/min) M203 E3600:3600 ; Set maximum speeds (mm/min) M201 X1500.00 Y1500.00 Z100.00 ; Set accelerations (mm/s^2) M201 E10000:10000 ; Set accelerations (mm/s^2) M906 X650.00 Y800.00 Z800.00 I30 ; Set motor currents (mA) and motor idle factor in per cent M906 E800:800 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Axis Limits M208 X0 Y-49.0 Z0 S1 ; Set axis minima M208 X220 Y209 Z200 S0 ; Set axis maxima ; Endstops M574 X1 S3 ; Motor Stall X Endstop M574 Y1 S3 ; Motor Stall Y Endstop M915 X Y S30 F0 R0 ; Stall guard config when not homing M574 Z1 S2 ; Set endstops controlled by probe M558 P5 C"zprobe.in" I1 H5 F300 T6000 ; Set Z probe type to switch and the dive height + speeds G31 P500 X-23 Y7 Z0.35 ; Set Z probe trigger value, offset and trigger height ; The larger the number the closest it gets to the bed ; i.e. 1.50 puts the nozzle closer to the bed than 1.20 M557 X40:210 Y5:190 S20 ; Define mesh grid ; Bed Heaters/Thermistors M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 C0 R4700 ; Define thermistor M950 H0 C"bedheat" T0 ; Link pin name with heater M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; Links everything on the GUI M143 H0 S95 ; Set temperature limit for heater 0 to 95C ; HotEnd Heaters/Thermistors M308 S1 P"e0temp" Y"thermistor" T103944 B3943 C1.658e-7 R4700 ; Define thermistor M950 H1 C"e0heat" T1 ; Link pin name with heater M143 H1 S290 ; Set temperature limit for heater 1 to 290C ; Bed / HotEnd Autotunes M307 H1 A1048.7 C250.3 D10.3 V24.1 B0 ; Hotend Autotune //Changed M307 H0 A112.6 C601.0 D1.0 V24.1 ; Bed Autotune //Changed ; Fans M950 F0 C"fan0" Q500 M106 P0 S0 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M950 F1 C"fan1" Q500 M106 P1 S1 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 M563 P1 D1 H1 ; Define tool 1 G10 P0 X0 Y0 Z0 ; Set tool 0 offsets G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures G10 P1 X0 Y0 Z0 ; Set tool 1 offsets G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures ; Automatic power saving M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss ; Custom settings are not configured T0 T1 -

RE: Weird Laser Modeposted in Laser Cutters

well, just as usual after I posted something I myself come up with an improvement...

I changed the macros as follows:

Laser focus ON

M106 P2 S255 ; turn on laser's 12v PSU M453 ; Enable CNC Mode M950 P0 C"!exp.heater3" Q1000 ; assign laser pin to a pin number M42 P0 S0.01 ; set 1% PWM on GPIO port 0 ; do the focusing stuffLaser Focus OFF

M42 P0 S0 ; disable laser M950 P0 C"nil" ; free heater3 again for use in laser mode M106 P2 S0 ; turn on laser's 12v PSUAnd I changed my "switch to CNC macro to:

M5 M106 P2 S0 ; turn off 12v PSU M452 C"nil" ; free "exp.heater3" pin M453 ; Put the machine into CNC Mode M550 P"WorkBee CNC Machine" ; Set machine namein which I added the M452 C"nil" line.

This seems to work, although when I go back to CNC mode the console throws a red warning:

Error: DueX fan or GPIO pins may not be used to control lasersbut well, it looks like I will have to live with it. On a positive side, I think that the M42 command lets me control the power of the laser somehow better. Yesterday I used it "the old way" with a Fan port and even a M106 P3 S0.001 would start burning the plywood after a couple of seconds.

-

RE: Macro not sent from PanelDue (but works ok from Web interface)posted in PanelDue

well, if anyone is following this thread, I just want to mention that it has been solved.

The issue was the name of the macro together with the firmware version of the Paneldue. I changed the name of the macro to be just text and it worked fine. And just for the sake of it, I updated the firmware to the latest version. Everything works just fine now.