@patrickwjoyce , try starting your macros (homex.g, homey.g, homez.g) with command

M400 S1 ; wait until motion stops, do not release any axes or extruders

Posts made by EagleB3

-

RE: Z-Homing Race conditionposted in Duet Web Control

-

RE: Last update - 3.5.3 - File simulation runs infinitelyposted in Duet Web Control

@dc42 , After installing the new MB6HC binary from the link you provided, the problem was completely resolved. THANK YOU SO MUCH!

-

RE: Last update - 3.5.3 - File simulation runs infinitelyposted in Duet Web Control

@chrishamm , Thank you! Here is a link to my config file and Gcode file

The process of printing the part is carried out absolutely normally, the process is completed without any errors.

-

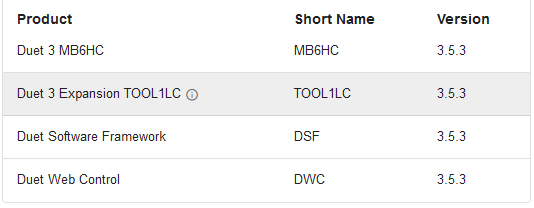

Last update - 3.5.3 - File simulation runs infinitelyposted in Duet Web Control

After upgrading from version 3.5.2 to version 3.5.3, the file simulation process runs infinitely. My configuration after upgrade:

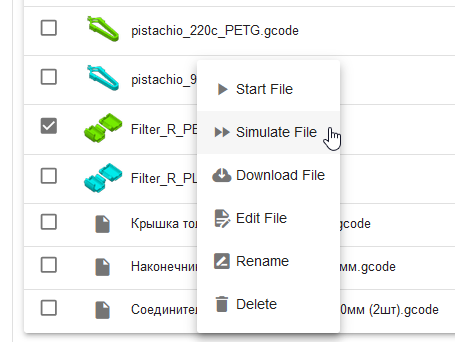

As usual, I start the simulation process for a part that was previously successfully simulated in version 3.5.2:

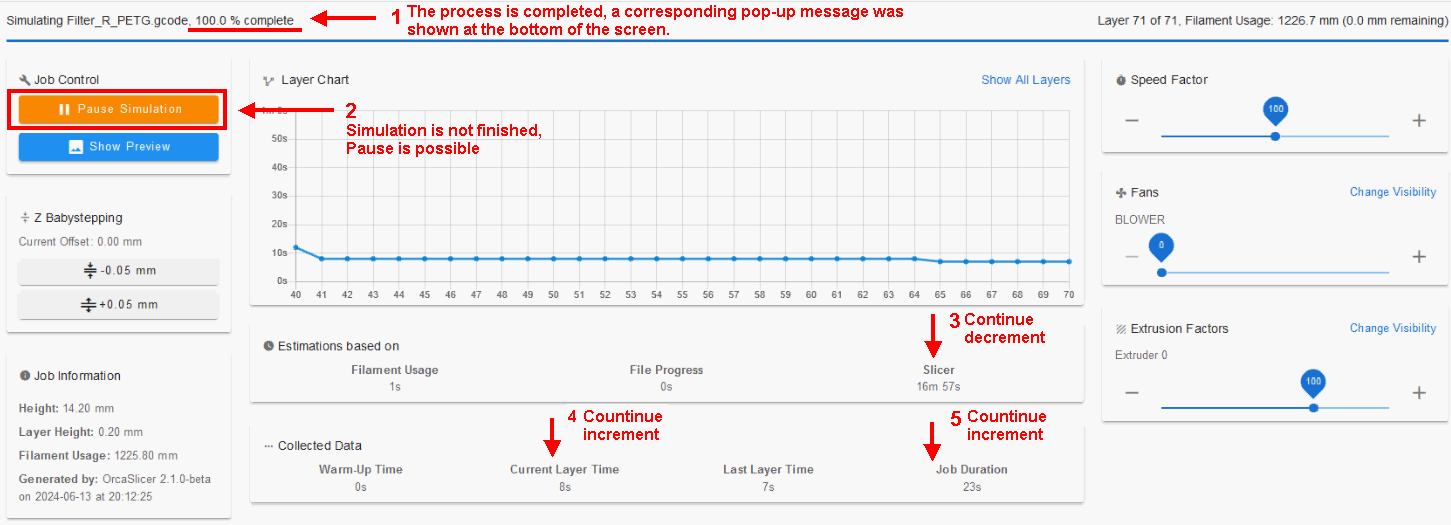

After a while, a pop-up window about the end of the simulation process with information about the results is shown at the bottom of the screen.

After a while or by clicking the mouse, the window is hidden - up to this point, everything works correctly.

But after that:- The screen says that the simulation is 100% complete

- The "Pause Simulation" button is still displayed, which should only be displayed during the simulation process.

- The "Slicer" counter continues to count down, its value continues to decrease.

- The "Current Layer Time" counter continues to count, its value continues to increase.

- The "Job Duration" counter continues to count, its value continues to increase.

If you go to the "Jobs" section at this time, you cannot start the simulation of another part by right-clicking.

-

RE: ExecOnMcode + 3.4.6, sudo commands are not executedposted in Plugins for DWC and DSF

@Falcounet , thank you very much for your quick response! Please tell me what changes should be made to DSF config and how this can be done? Maybe there is a link to the description?

Is it possible to give the plugin the necessary rights by changing the manifest of the ExecOnMcode plugin before installing it in the DWC interface (https://github.com/Duet3D/DuetSoftwareFramework/blob/master/PLUGINS.md#list-of-permissions, "SuperUser" )?

P.S. I have extensive experience in IT, but practically no experience with *nix systems...

-

RE: ExecOnMcode + 3.4.6, sudo commands are not executedposted in Plugins for DWC and DSF

@jay_s_uk , many thanks! I didn't know about this possibility.

I tried it and it worked!

-

ExecOnMcode + 3.4.6, sudo commands are not executedposted in Plugins for DWC and DSF

Re: ExecOnMcode

Hello!

I'm using Duet3HC + SBC Raspberry Pi3

I deployed the Duet3-Lite image (v.3.4.6 from 09/06/2023, taken from https://github.com/Duet3D/DuetPi) to MicroSD, configured the network, and restored the configuration files of my printer.

Then I installed the ExecOnMcode plugin (ExecOnMcode-0.5.zip) in DWC exactly according to the instructions https://plugins.duet3d.com/plugins/DSF_ExecOnMcode_Plugin.html,

including creating the file /etc/sudoers.d/010_dsf-nopasswd and writing dsf ALL=(ALL) NOPASSWD: ALL in itRestarted Duet3HC+SBC

Launched the ExecOnMcode plugin in DWC

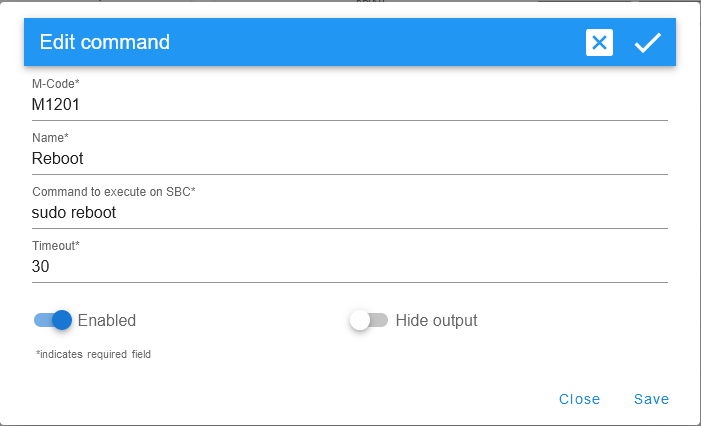

I edited the M1201 command and specified 'sudo reboot' in it

In the console DWC I executed commands M1200 and M1201 sequentially.

Raspberry did not restart.The lines appeared in the log:

Duet3 kernel: audit: type=1400 audit(1701354925.815:8):apparmor="DENIED" operation="capable" profile="/opt/dsf/plugins/ExecOnMcode/" pid=820 comm="sudo" capability=7 capname="setuid"

Duet3 kernel: audit: type=1400 audit(1701354925.815:9): apparmor="DENIED" operation="capable" profile="/opt/dsf/plugins/ExecOnMcode/" pid=820 comm="sudo" capability=6 capname="setgid"What should I do to be able to use the plugin to run "sudo reboot" and "sudo poweroff" with M-Code commands?

P.S. IMHO, it would be useful for many users if you added one more example to the two existing example commands that appear after installing the plugin: a command using sudo. For example, "sudo reboot".

-

RE: PSU dedicated temperature control channel?posted in Tuning and tweaking

@engikeneer said in PSU dedicated temperature control channel?:

I think it defaults to 100% (I've never specified the x parameter before) but can't hurt to define it like that

Many thanks! I think even such a configuration will be enough for most applications.

In any case, it is much (MUCH!) better than what is offered by the manufacturer in PSU industrial standards! -

RE: PSU dedicated temperature control channel?posted in Tuning and tweaking

@engikeneer , THANKS A LOT! How do you think it is necessary to use the "X" parameter in the M106 command? For example,

M106 P3 L0.40 X1.00 T40:65 B1.0 -

RE: PSU dedicated temperature control channel?posted in Tuning and tweaking

@engikeneer ,

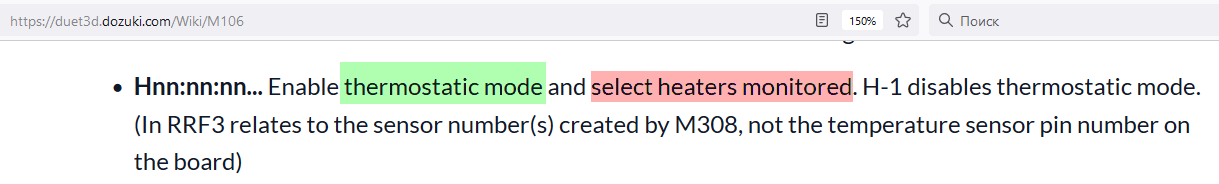

As far as I understand it, the M106 command does not make it possible to create a thermostatic channel without assigning some kind of heater to this channel.

But there is no heater in PSU. Besides:- I do not want to take a single release channel with a heater even without real heater connectivity to this output;

- I do not have the confidence that the thermostat channel will be flicked correctly without adjusting the PWM control (M303) of the heater used in it. And how to perform it, if there is no real heater?

Of course, perhaps I understand something wrong to apply the command M106 ...

That is, I understand perfectly, how can you create a temperature measurement channel with the M308 command. But I absolutely do not see the way to create a thermostatic channel for this sensor:

- without heater

- with a three-stage control characteristic that I need.

If I create a fan S3 command M108:

M308 S3 P"io.whichever" A"PSU_temp" Y"thermistor" T100000 B3950 ; define PSU temperature sensorI will get if using the M106 command

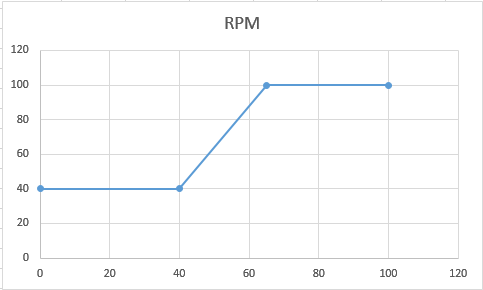

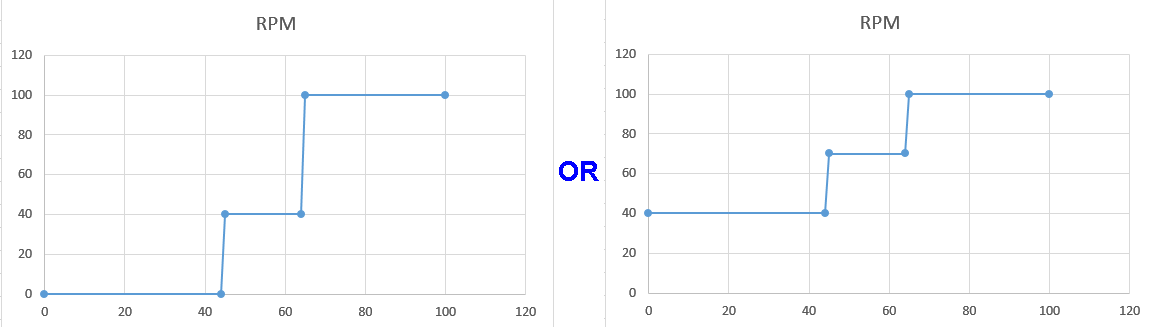

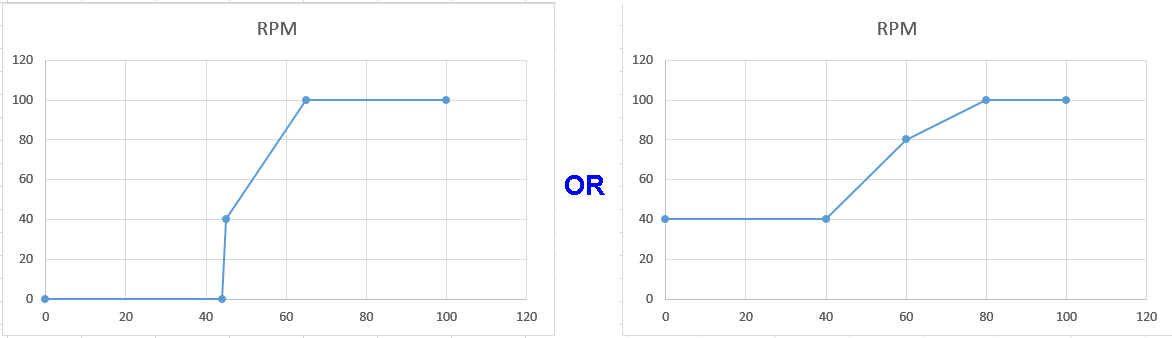

M106 P3 L0.40 X1.00 T40:65 B1.0Here is a rule of control:

I would not like to burn my power supply or DUET when experiments ...

-

PSU dedicated temperature control channel?posted in Tuning and tweaking

The temperature control circuits built into the PSU are far from ideal.

- They rarely have more than one fan speed switching limit (only two set values are supported - the minimum rotation speed and the maximum rotation speed when the boundary temperature is exceeded).

- Even the minimum speed is set so that the fan is guaranteed to start, and even at these speeds the noise from the fan can be quite strong.

- When replacing the fan, these parameters are difficult to correct without replacing parts in the PSU.

I myself was ready to formulate my question as follows: I have a Duet 3 MB6HC (with firmware version 3.3, DATE: 2021-06-15 21:45:56 stable), which has several free channels for measuring temperature and outputs suitable for controlling a fan. I would like to add a temperature sensor (B3950 or PT1000) to my PSU and control the fan speed in my PSU. At the same time (in order to reduce the priority of requirements):

- It is imperative to implement at least a minimum control characteristic (fixed fan speed in three sections, determined by two boundary temperature values) - otherwise the idea generally loses its meaning.

- Optional: It is highly desirable to be able to turn on 100% fan speed for some time after turning on from the "off" position (analogous to parameter "B" in command M106; for example, M106 B0.5).

- Optional: It is highly desirable that not a single output channel for heater control, which is not in the PSU, is occupied. PSU heats itself up.

- It is almost not necessary: It would be ideal if there was a way to realize a proportional increase in the fan speed in some areas, for example, from a temperature of 45 to a temperature of 65:

Tell me, is there a way to implement what I want in the current RRF implementation? If it is described somewhere, please give a link to the description!

-

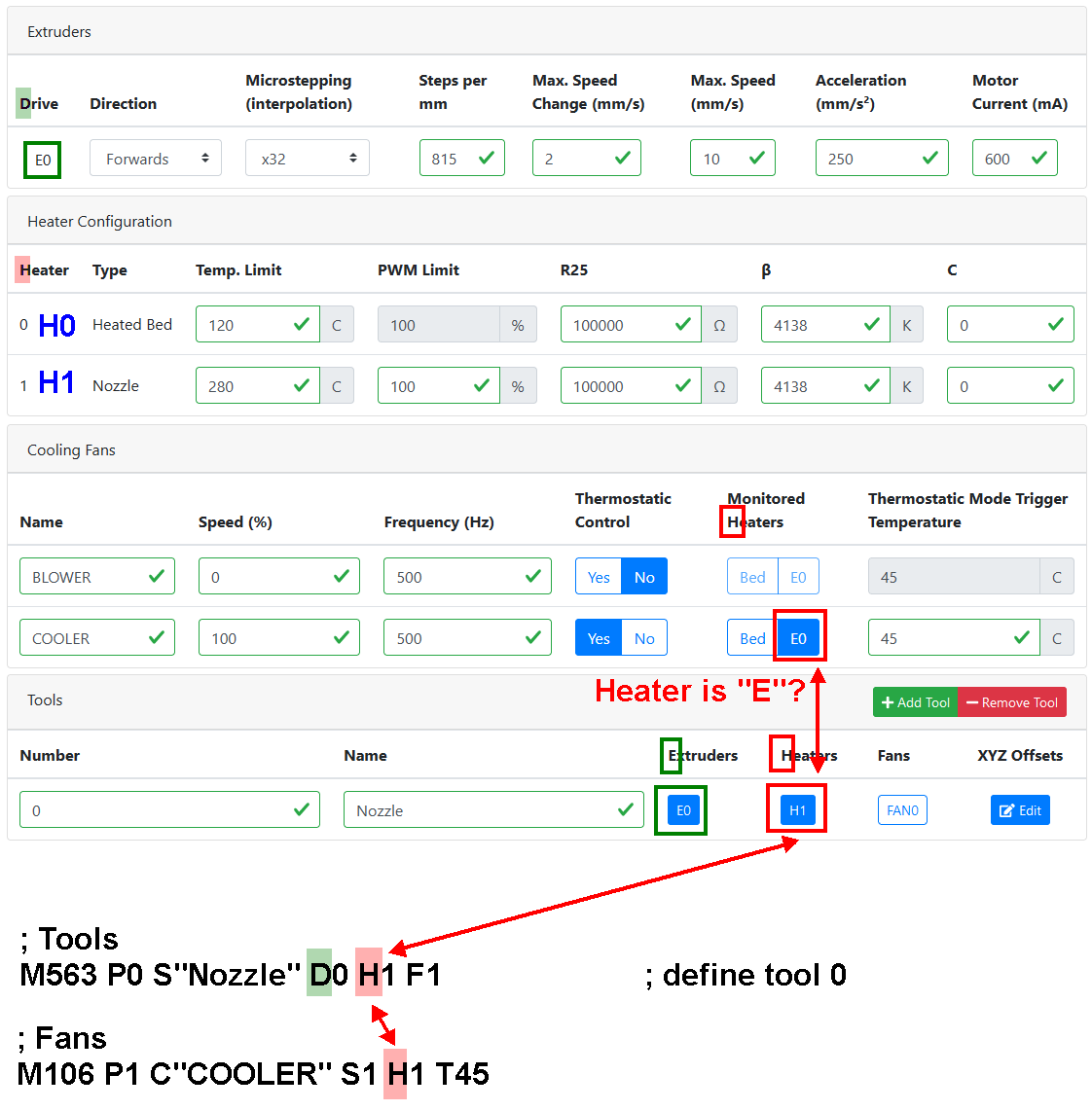

RE: Why are heaters marked with the letter "E"?posted in Config Tool

@t3p3tony , It's clear. Thanks!

It seems to me that the time has come to make a change. After all, this is just a designation (visualization) in the "Config Tool" interface. It's probably familiar to old controller users, but it can be confusing for newer ones. -

RE: Why are heaters marked with the letter "E"?posted in Config Tool

@fcwilt said in Why are heaters marked with the letter "E"?:

Do they normally have an associated cooling fan?

I do not know. I have a printer without a thermal camera; I just gave an example that the heater is not always an extruder.

Thermal chamber fan - it is possible that it is necessary. Hot air rises, and the temperature must be equalized throughout the chamber, so I think the air will have to be mixed, especially in printers with a large working volume. I have seen printer designs with a heat chamber and a fan embedded in the top panel. -

RE: Why are heaters marked with the letter "E"?posted in Config Tool

@fcwilt said in Why are heaters marked with the letter "E"?:

In the place where you see the E0 what is being specified is what is being heated, the bed or an extruder.

It is possible. But it doesn't have to be related to the extruder.

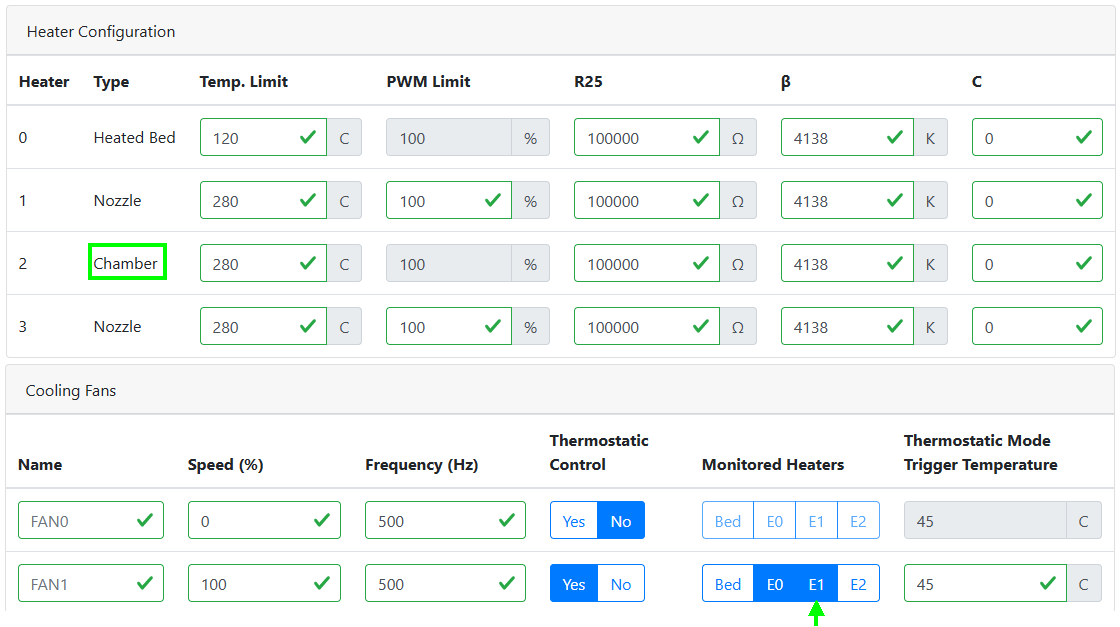

All heaters except BED are designated "E". Even if it is a chamber heater:

"BED", "E", "C"? ..

In my opinion, the use of the letter "E" for the heater is incomprehensible and brings certain inconveniences. -

Why are heaters marked with the letter "E"?posted in Config Tool

Why the heaters are indicated by the letter "E" in the "Cooling fans" interface? Indeed, in all other places in the interface and in the associated G-code commands, the heaters are designated by the letter "H"...

Is there any logical mnemonic for this?