hey all together

I have a weird moving / shaking when driving curves (especially when driving slower- see video)

I tried different jerks, accelarations and microstepping.

The Influence of the printing was very small...

may anyone has an idea what I can change?

R.

WhatsApp Video 2021-08-30 at 12.05.39.mp4 WhatsApp Video 2021-08-30 at 12.10.34.mp4

WhatsApp Video 2021-08-30 at 12.10.34.mp4

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Aug 02 2021 16:15:35 GMT+0200 (Mitteleuropäische Sommerzeit)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M552 S1 P192.168.2.108 ; Wifi

G4 S4

M574 C1 S3

M574 C0 Z0 ; No C Z endstop

M915 P1.2 C S0 F0 R1

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes forwards

M569 P0.3 S0 ; physical drive 0.2 goes forwards

M569 P0.4 S0 ; physical drive 0.2 goes forwards

M569 P0.5 S0 ; physical drive 0.2 goes forwards

M569 P1.0 S0 ; physical drive 0.2 goes forwards

M569 P1.2 S0 ; physical drive 0.2 goes forwards

M569 P121.0 S0 ; physical drive 121.0 goes forwards

M569 P122.0 S1 ; physical drive 122.0 goes forwards

M569 P123.0 S1 ; physical drive 123.0 goes forwards

M584 X1.0 Y0.0:0.1 Z0.2:0.3:0.4:0.5 C1.2 E121.0:122.0:123.0 ; set drive mapping

M350 X32 Y32 Z16 E16:16:16 I1 ; configure microstepping with interpolation

M92 X320.00 Y320.00 Z640.00 C91.022 E409.00:409.00:409.00 ; set steps per mm

M566 X100.00 Y100.00 Z60.00 C3000 E3.00:3.00:3.00 ; set maximum instantaneous speed changes (mm/min)

M203 X15000.00 Y15000.00 Z800.00 C5000 E6000.00:6000.00:6000.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z1000.00 C400 E2500.00:2500.00:2500.00 ; set accelerations (mm/s^2)

M906 X1300 Y1300 Z2500 C400 E1000:1000:1000 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M671 X-80:-80:930:930 Y-80:930:930:-80 S20 ; leadscrews at front left1 and n´back2. back rigth3 and front4

; Axis Limits

M208 X-10 Y-81.4 Z0 S1 ; set axis minima

M208 X860 Y890 Z850 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"^io3.in" ; configure active-high endstop for high end on X via pin ^io3.in

M574 Y2 S1 P"^io1.in" ; configure active-high endstop for high end on Y via pin ^io1.in

; Z probe

M558 P5 C"io2.in" H50 F360 I0 T1100 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds

G31 P200 X5 Y30 Z0 ; Set Z probe trigger value, offset and trigger height; Z probe

M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters

M557 X200:650 Y200:650 S45 ; define mesh grid

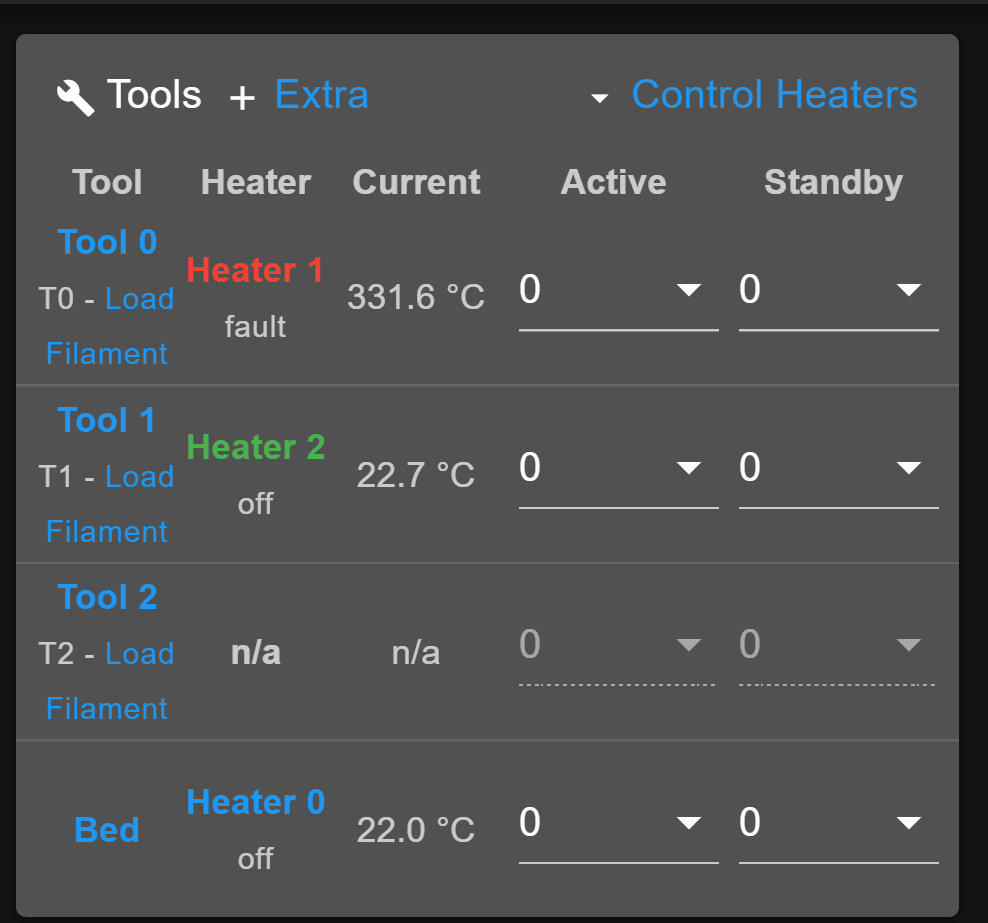

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 R0.243 C586.2 D33.87 S1.00 V0 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as PT1000 on pin 121.temp0

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S250 ; set temperature limit for heater 1 to 250C

M308 S2 P"122.temp0" Y"pt1000" R2200 ; configure sensor 2 as PT1000 on pin 122.temp0

M950 H2 C"122.out0" T2 ; create nozzle heater output on 122.out0 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S250 ; set temperature limit for heater 2 to 250C

M308 S3 P"123.temp0" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin 123.temp0

M950 H3 C"123.out0" T3 ; create nozzle heater output on 123.out0 and map it to sensor 3

M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H3 S250 ; set temperature limit for heater 3 to 250C

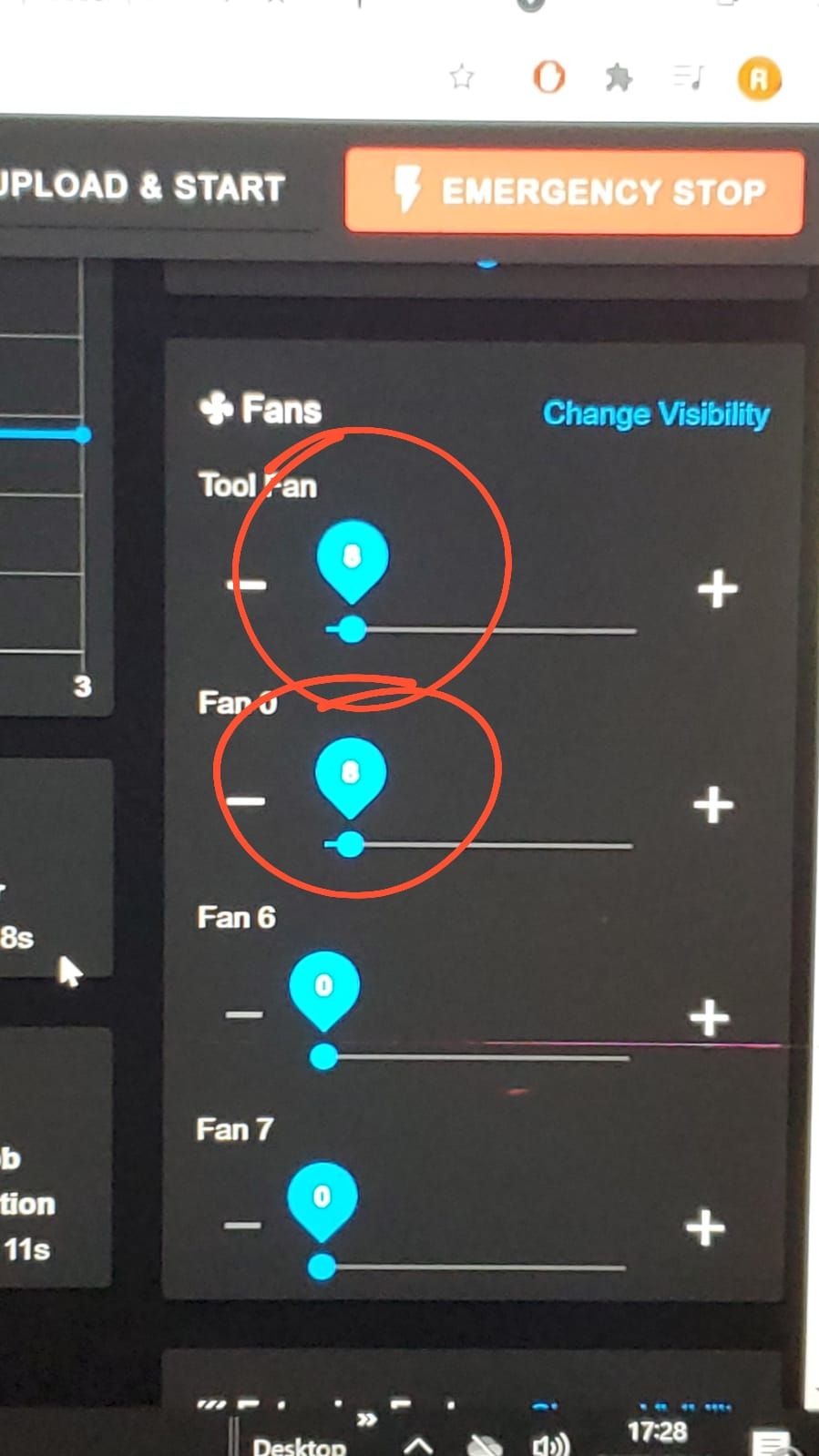

; Fans

M950 F0 C"121.out1" Q25000 ; create fan 0 on pin 121.out1 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M563 P0 D0 H1 ; tool uses extruder 0, heater 1

M950 F1 C"121.out2" Q500 ; create fan 1 on pin 121.out2 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M563 P0 D0 H1 F1 ; tool uses extruder 0, heater 1

M950 F2 C"122.out1" Q500 ; create fan 2 on pin 122.out1 and set its frequency

M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off

M950 F3 C"122.out2" Q500 ; create fan 3 on pin 122.out2 and set its frequency

M106 P3 S1 H2 T45 ; set fan 3 value. Thermostatic control is turned on

M950 F4 C"123.out1" Q500 ; create fan 4 on pin 123.out1 and set its frequency

M106 P4 S1 H-1 ; set fan 4 value. Thermostatic control is turned off

M950 F5 C"123.out2" Q500 ; create fan 5 on pin 123.out2 and set its frequency

M106 P5 S1 H3 T45 ; set fan 5 value. Thermostatic control is turned on

M950 F6 C"out4" Q500 ; create fan 6 on pin out4 and set its frequency

M106 P6 S1 H-1 ; set fan 6 value. Thermostatic control is turned off

M950 F7 C"out5" Q500 ; create fan 7 on pin out5 and set its frequency

M106 P7 S1 H T45 ; set fan 7 value. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X30 Y28.25 Z-39.75 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 F2 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 D2 H3 F4 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

but if I really need them... I'm not sure, yet.

but if I really need them... I'm not sure, yet.