Dashboards as of now - mostly focussing on filament monitor Vs charts to diagnose extrusion issues [TL;DR - it was pressure advance]

I'll upload the source code to a github repo next week

Dashboards as of now - mostly focussing on filament monitor Vs charts to diagnose extrusion issues [TL;DR - it was pressure advance]

I'll upload the source code to a github repo next week

@zapta Thanks for the links - I'll check them out. I already managed to problem solve my under/over extrusion issues so the dashboards are unlikely to change without needing more information displayed for diagnostics.

I love the level of detail Vector3D goes to - I definitely hope to be able to optimise my printer further with something like this - my next optimisation needs to be print quality

The acceleration/speeds were of commanded moves of all motors - it's not very useful - this is typically always the way when designing these visualisations - you think you know what you want but when you actually look at the outcome achieved - something very different provides the insight you need

@T3P3Tony Thanks for the kind words - and thank you for your patience on my reply

I really do prefer the pull approach - the action of collecting is offloaded to a dedicated tool and configured elsewhere - this has it's own resources which ensures the service that is under observation sees minimal load [and doesn't have to worry about dealing with errors such as `I can't send my metrics anywhere]

It also ensures that the systems stay loosely coupled - can be monitored by multiple systems and if these systems move - is easy to reconfigure in a decentralised way.

What I'm tempted to do is wrap the DSFNode logic into a dedicated runnable so there is minimal footprint - running NodeRed is quite heavy for just this logic.

I use NodeRed to notify me on Discord of errors or problems so I can attend to the printer so it's fine for now - one for the future

I've upgraded the dashboards a little so will add some new examples below and when time permits - put it all into my Github for others to use - I can imagine this would be really useful for commercial/industrial clients.

Hi Duet3D Forum!

I recently completed a proof of concept using Node-red, the brilliant DSFNode project, Prometheus, and Grafana. My goal was to gain deeper insights and troubleshoot issues with my delta printer, which originated as a Think3dPrint3d Kossel XL kit.

I'm reaching out to see if anyone else has undertaken a similar project. I'd love to either reuse existing insights or, if there's interest, share more details about what I've developed.

Outcome achieved: Ability to visualise properties of the printer over time:

Using this dashboard, I was able to understand how the filament monitor performed during a print. I could contrast the configured sensitivity with the measured one and see that the measured min/max values were nearing the set limits, causing the printer to pause.

I aim to further enhance this to observe how different changes, corresponding to the measurements provided by the filament monitor, manifest. For instance, I'd like to plot acceleration or temperature against max and min values, adjusting them throughout a print. I'm keen on gathering evidence to understand the effect of each tweak I make on the quality.

However, several challenges remain. Currently, measurements are taken every 250ms. This frequency might cause aliasing in acceleration/speed measurements, as they might change more rapidly than the metrics are imported into Prometheus & Grafana

How it works: I employ a slightly modified version of DSFNode (in Node-red) that integrates additional queries to the object model to fetch the filament monitor's calibrated attributes. Node-red polls the printer every 250ms, then translates the JSON payload into Prometheus format metric strings. Node-red hosts an HTTP endpoint, delivering the Prometheus format metric strings for Prometheus to scrape. Every 250ms, Prometheus retrieves these metrics. I've configured Grafana to extract data from the Prometheus datasource, and I've set up a dashboard to display the data.

The entire process took only a few hours [so there is much room for improvement!]

Looking forward to hearing if anyone has done something similar!

Dave

Just a quick note to say that the fan has had no issues once rotated away from the Magnetic Balls.

I also have to say I'm a big fan of the Magentic filament sensor, its readings are really helping me understand if the printer is well calibrated all around (including extruder and hotend distance)

Thanks for the help all.

Dave

Thank you @jay_s_uk and @blt3dp for such quick response, think you are both on the mark here:

I am indeed using Hayden Magball arms

Currently, the stickers do not alternate, I thought I had assembled them with alternating poles going round but I paid no attention to the stickers.

Also, the fan is facing more towards a set of magballs (short edge) more than it is the long edge. The only issue with this is the cooling fan assembly that I've chosen, I cannot rotate the hot-end fan any more with it attached.

Pictures of current set up before I change:

With respect to config, I don't believe I have anything for the hot-end fan as it's the always on fan?

I will clean the blockage and then re-assemble with the stickers alternating. I am also printing PETG next so I won't need the cooling fan, I'll leave it off and look for a re-designed version that does not need the hot-end fan to be rotated.

Thanks

Dave

Following on from a post about a Magnetic Filament Sensor Issue I raised here:

https://forum.duet3d.com/topic/14018/no-angle-reported-by-magnetic-filament-sensor

Problem:

Hotend fan starts with the printer normally, continues to run normally while printing, but at random points fails mid-print and stops. Manually spinning the fins gets it going again but by this point, it's too late and plastic has melted above the melt zone and the filament cannot be extruded.

This has not happened every time I've printed, I have managed to print a part for several hours without any issue, the print finishes perfectly, then 15 minutes into the next print, the fan stops.

I've already dismantled and cleaned the entire hot-end using a hot air gun a number of times to unblock and am very hesitant to try it again

I am running a Smart Effector with an official E3D V6

I have already replaced the 30x30x10 24v fan with one from the E3D site and have even gone as far as to replace all connectors (as in, cut off old connectors, re-crimped and re-attached) The fan currently attached has it's original crimps from the factory.

There are no other issues with the smart effector, the LED's stay lit, it's working superbly well in terms of calibration, I simply have the hot-end fan fail randomly mid-print.

Can any recommend what I can check? The Smart effector is new, I had this issue the first time I used it but assumed it was down to my assembly, however, now I've iterated several times I'm not sure what else to do differently.

Any help would be greatly appreciated!

Thanks,

Dave

I've had to tweak my sensor configuration mid-print to ensure it doesn't pause incorrectly during printing, I haven't yet confirmed it's working as expected or at a good tolerance level as unfortunately by hot-end fan stopped again mid-print; I once again need to dismantle as heat has crept up and created a blockage.

On the plus side, the filament sensor did pause the print when the filament blockage occurred, which is great, unfortunately, this doesn't cut the power to the heater and I can't see any way to configure this.

I'm happy to start a new thread with the other issues unless @dc42 you are able to help me here:

[Q] I have a smart effector and while I've managed to print for several hours at one time (and get very good parts out of it) the hot end fan randomly stops and I need to manually spin the fins to get it going again. How can I work out what's happening here? I'm not sure it's ever been correct, the first print I made with the smart effector was perfect, the second was the first one where the hot end fan failed, and this has now happened 3 times and I've already replaced the hot-end fan with parts direct from E3D.

[Q] Is it possible to adjust the behaviour of the pause from the filament sensor without code modification? if I can get it to turn off the tools, this may be better for me while it currently has issues with the hot-end fan.

As always, thanks in advance for any assistance!

Ok, Thanks for the help. After a print, running the M591 D0 reports calibration parameters.

M591 D0

Duet3D magnetic filament monitor on input 4, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, version 2, measured sensitivity 26.21mm/rev, min 93% max 104% over 208.0mm

I'd be happy to update the documentation, It seems to be editable but thought I would ask if you would like/accept community contributions for review

I ran a print job which lasted 15 minutes but then failed due to the hotend fan failing, I know, sod's law right!

I had to strip down completely to repair, the Bowden tube had to be replaced and I had to use a hot air gun to clean the heat break.

I've now re-assembled with a new fan direct from E3D however I am somewhat hesitant to run without the filament monitor as I'm concened the fan wasn't the root cause.

I'm going to jump to the assumption that the print job has to finish for calibration data to take effect? The instructions didn't expliclty say print first, they say test first, see the angle, then go and print

I'll start a print when I get home and report back. I've left the printer on (not printing, so no load) for several hours and the hotend fan has not failed.

Thanks!

Dave

Yes, as soon as filament passes through, the led flashes green continuously

Hi All,

I am having an issue getting started with a magnetic filament sensor ordered directly from Duet3D. I purchased this back in September 2019 and have only just added it to my printer.

Instructions Reference: https://duet3d.dozuki.com/Wiki/Duet3dFilamentMonitor_RotatingMagnetVersion

Problem:

Issuing a M591 D0 never shows the current sensor angle, only a message stating no calibration data

Connect the filament monitor to an endstop connection on the Duet 2 (normally E0 or E1), using a straight through 3 wire cable with a molex KK on either end.

Checked: Wiring - Sensor image attached which shows connection to sensor

The filament monitor will flash the green LED 3 times to indicate the magnet is detected. The green LED will then flash periodically indicating communication to the Duet. If the magnet is rotating the LED will flash more frequently. For other LED flashing codes see the troubleshooting section below

Checked: LED flashes 3 time on startup and then flashes Green, Red, Green, Red continuously etc as expected to show transfer of position and sensor status data (as stated in troubleshooting section)

Important: the production version of the filament monitor requires 2.03 or later firmware running on the Duet.

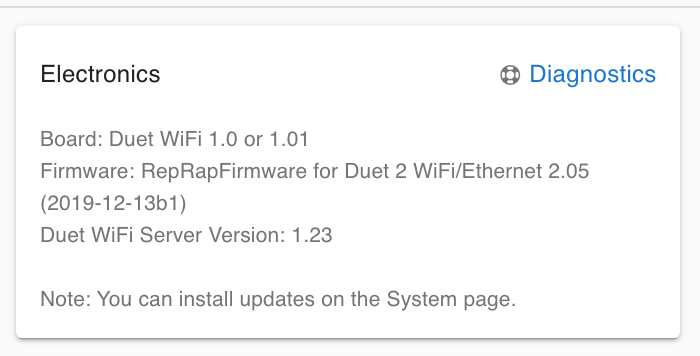

Checked: Screenshot - Firmware Version attached, running version 2.05

from config.g

M591 D0 P3 C4 S1 R70:130 L24.8 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E1 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length

Please note: The above states C4; I initially used C3 as sensor was attached to E0 end stop but as a test I switched to E1 and thus it currently reads as C4, I have not moved this back to E0

Run M591 D0 returns:

M591 D0

Duet3D magnetic filament monitor on input 4, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, version 2, no calibration data

I have repeated this step after:

Extruding some filament with M302 P1 enabled (cold extrusion) with bowden out of hotend

Extruding some filament with hotend at required temperature

Printing a test print

At no point does the output of M591 D0 change, it always states no calibration data and never reports a sensor angle.

If I change the configuration so that E0 is set to have the sensor, and leave the sensor connected to E1 (so no sensor connected), the output changes to the following:

M591 D0 P3 C3 S1 R70:130 L24.8 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E1 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length

M591 D0

Duet3D magnetic filament monitor on input 3, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, no data received

This indicates that when no sensor is detected, the output is different and that the setting of C4 is correct and the sensor is detected

Another check, have I got the right Extruder Drive D index... Screenshot - Status - Drive 0 as Extruder attached showingExtruder 0 in status pane but thought I would try it anyway:

M591 D1 P3 C4 S1 R70:130 L24.8 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E1 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length

M591 D1

Duet3D magnetic filament monitor on input 4, enabled, sensitivity 24.80mm/rev, allow 70% to 130%, check every 3.0mm, version 2, no calibration data

I've also included a picture as an attachment (Printer) which shows the overall assembly as as an image Wiring - Duet which shows the connection to the Duet,

Additional Checks:

Connectivity test between all pin outs on cable using multimeter (Attach buzzer to one end, ensure that this activates if touching the corresponding pin at the other end of cable); Therefore cable ok

Switch to E1 instead of E0 endstop input - as highlighted in above

Attachments:

Wiring - Sensor - Shows image of sensor with wiring, also confirms version -

Grey -> Ground

White -> 3.3v

Black -> Output

My apologies for the confusing colours, I never thought anyone else would see this

Wiring - Duet - Shows image of Duet 1.01 with wiring

Wiring - Duet Closeup - Shows colours of wires, the Black wire in this photo looks white-black but is in fact the Black wire

Printer - Shows how the sensor is mounted and its overall attachment, indicates wire length for example (not sure this is an issue though!)

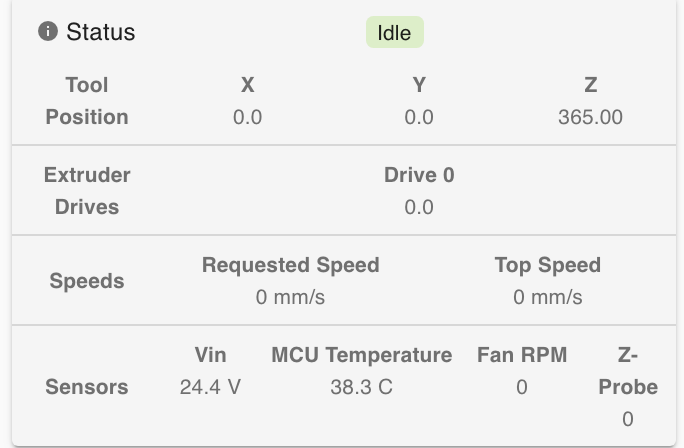

Screenshot - Status - Drive 0 as Extruder - Shows Status panel showing Drive 0 as only extruder

Screenshot - Firmware Version - Shows version as 2.05

Any help would be greatly appreciated!

Thanks,

Dave

Success!

I modified my config.g to not start the WiFi at startup and the M997 S1 was successful in uploading the firmware. This wasn't listed in any of the documentation sites but am very happy that all firmware is now upgraded. Might be worth adding to documentation somewhere?

Thanks!

I've tried a few variations based on your suggestions, I've tried it this way before and is listed above but wanted to follow up on any advice given.

Manually Moving update files to SD and issuing M997 S1 from Web UI requires power cycle to access again

Manually moving update files to SD and issuing M997 S1 from PanelDue results in the same error. Have tried this 4 times without any luck.

I have now also downloaded the necessary files for 2.05RC1 and can confirm that my board is now running the main firmware at this version with the latest version of DuetWebControl.

I attempted all the various upgrade mechanisms again but alas, still the same error.

@Dougal1957 Hi, thanks for posting so quickly!

The only reason for this was caution over compatibility between versions. Due to the naming convention change in the firmware files, the instructions differ between 1.20 and 1.21 and therefore I decided to follow step by step there first before going to a higher number.

If advised, I would jump straight directly to 2.05RC1, although, if the same problem occurs the WiFi server may stop functioning altogether as the firmware versions would be incompatible (2.05RC1 requires 1.23 DuetWifiServer)

Hi all,

I am having issues upgrading DuetWifiServer on my Duet Wifi (Reported as version Duet WiFi 1.0 or 1.01).

Any help would be greatly appreciated!

The printer is going through an upgrade, I've installed linear rails and am also upgrading to a Smart Effector.

Before re-wiring to meet the connector needs of the smart effector, I decided to upgrade the main board to a recent version of the firmware

The main issue: The main firmware has upgraded but the Wifi Server always fails to upgrade

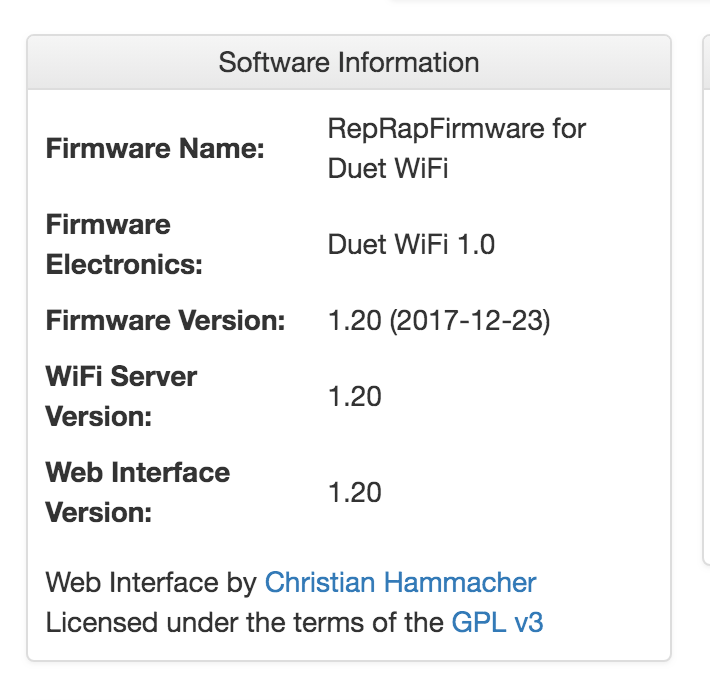

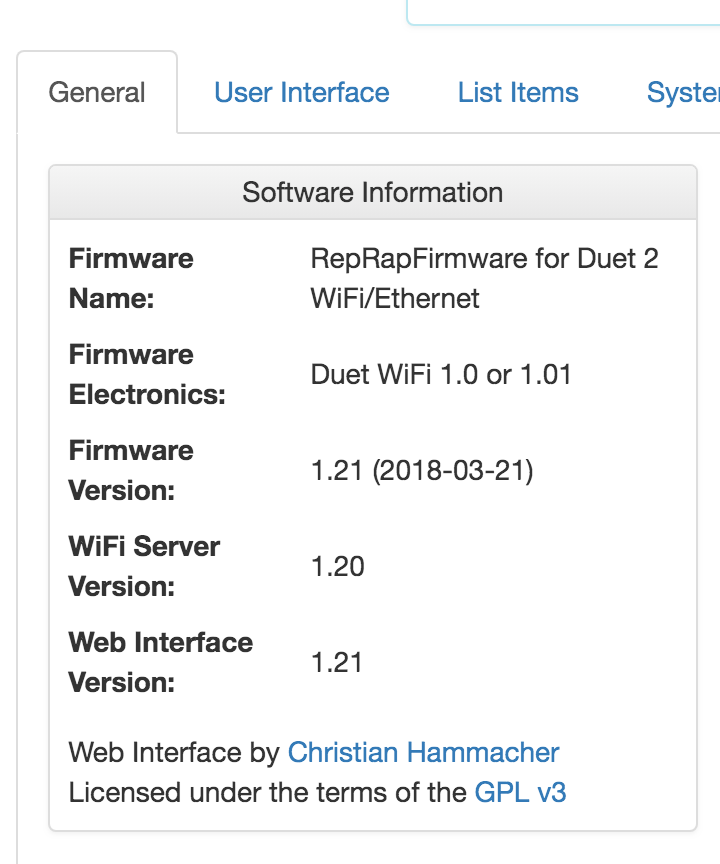

Initial Versions:

DuetWifiFirmware = 1.20

DuetWifiServer = 1.20

DuetWebControl = 1.20

Planned Upgrade Path:

1.20 -> 1.21 -> 2.04 (OR 2.05RC1)

Also, I have read through all of the whats new section and can confirm no changes would impact the upgrade path for my printer

Upload iap4e.bin (57.6 KiB) from 1.21 release page

Upload DuetWifiFirmware 1.21 (DuetWiFiFirmware.bin, 371.6 KiB)

Noted from 1.21 installation instructions that DuetWifiServer can be installed before or after main firmware so updating main firmware first

Allow UI/upload to kick off update

Update completes successfully for 1.21 Duet WifiFirmware

Upload DuetWifiServer 1.2.1 (DuetWiFiServer.bin, 289.9 KiB)

Allow UI/upload to kick off update

Disconnects, Wait 3 minutes, cannot reconnect via UI

Cannot refresh page, connection time out

Power Cycle Printer

Reconnect to UI and check version

DuetWifiServer version still shown as 1.20

Repeat above process: same result

Initiate upgrade using PanelDue with M997 S1

PanelDue shows error at end of process and power must once again be cycled to access the UI

Attempt upgrade of DuetWebControl via UI

Upload DuetWebControl (DuetWebControl.zip, 561 KB)

Update completes succesfully for 1.21 DuetWebControl

Repeat above tests to see if this has made a difference

Result -> All fail

https://forum.duet3d.com/topic/5646/duet-wifi-not-updating-firmware-when-installing-2-0/4

For the above, I have confirmed I have updated the iap4e.bin file

https://forum.duet3d.com/topic/9807/failed-to-add-ssid-to-remember-list/2

From the above, even though not directly related, I've used the commands to do the following:

1 - Put WiFi into IDLE (M552 S0)

2 - Activate WiFi (M552 S1)

Retry update - Failed with same error

Power Cycle

1 - Put WiFi into IDLE (M552 S0)

Retry update - Not started because its in idle mode?

Power cycle

https://forum.duet3d.com/topic/2340/upgrading-duet-wifi-to-v1-19/3

For the above, suggests I have an early version of the product and this may continue to always fail?

Using the suggestion of running only over 5v (as above was all at VIN Power of 24v)

Same result 2 times

1 - DuetWifi - Initial Version Information - Duet3D System Information screen showing versions prior to upgrade steps

2 - Duet2Wifi - Post Upgrade Version Information - Duet3D System Information screen showing versions after upgrade steps

3 - PanelDue Error - Picture of PanelDue reporting update error

4 - Uploaded Files - Screenshot of uploaded files to UI