@droftarts thanks for the last link I didnt see it. Connecting some break out boards to the expansion header is really viable option for me that is not messing with my existing setup. I will go that way.

Posts made by daninet

-

RE: Need suggestion regarding quad Z setup with duet 2posted in Duet Hardware and wiring

-

RE: Need suggestion regarding quad Z setup with duet 2posted in Duet Hardware and wiring

@droftarts thank you for your answer. Considering the friendly price of the BTT expansion module it seems like a good option. Am I losing the paneldue on my printer if I choose this?

-

Need suggestion regarding quad Z setup with duet 2posted in Duet Hardware and wiring

Hi,

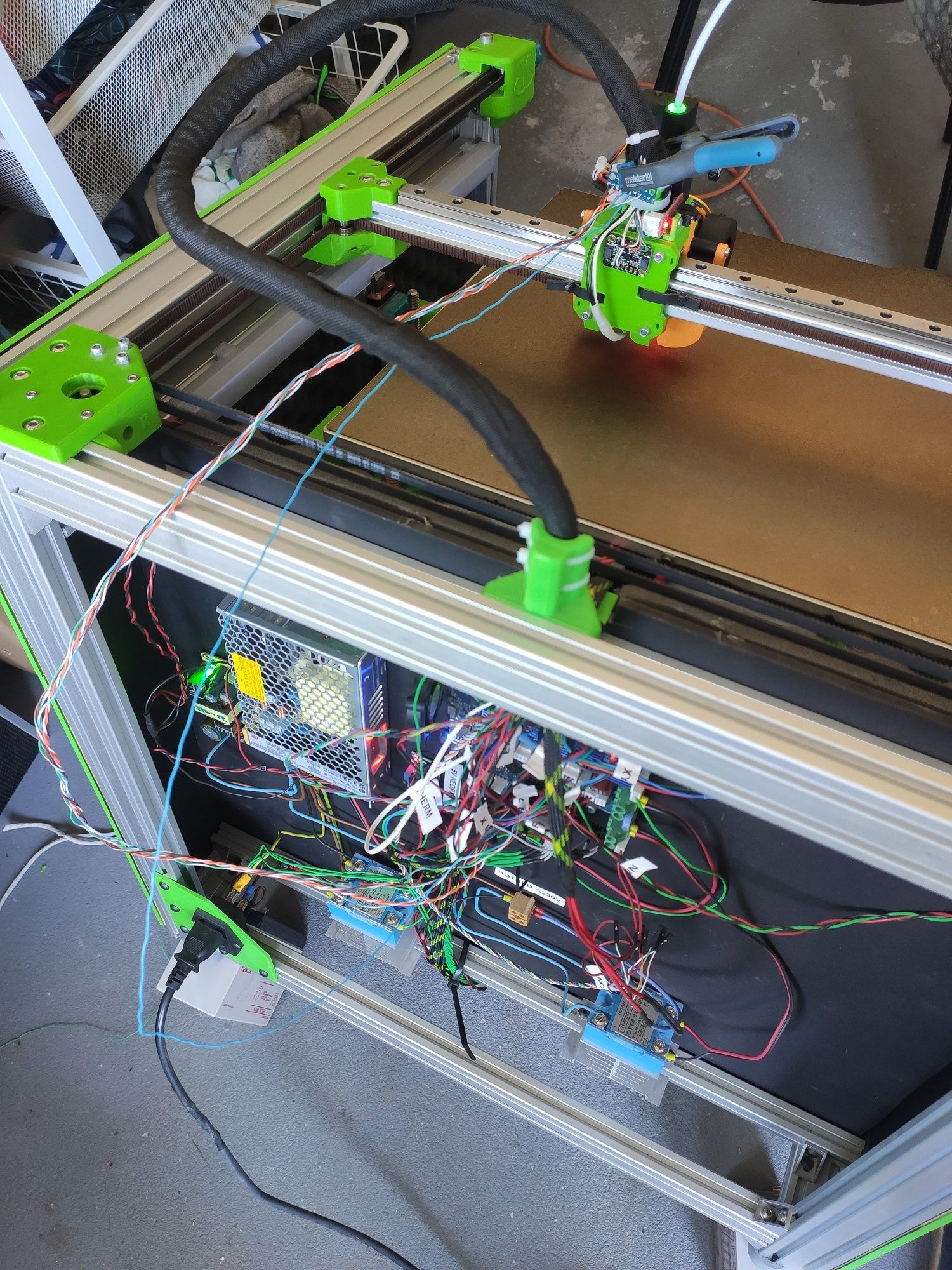

i have built a fully custom core xy machine with duet 2. It is the style of core xy printer where the bed moves down (not like on the voron where the printhead moves up).

This printer is built with a big 350x350mm build plate of thick machined aluminium. Currently I'm using two steppers with lead screws for the Z but it is extremely hard on the screws because of the weight. I need to convert it to a quad Z and I want to do that type of fixture when the bed is just resting on 4 pivot points.

my issue is the additional 2 steppers, the duet2 currently is maxed out. If I buy an expansion board for the duet can I still use the unused pins for things like buttons and other gpio? I have a lot of stuff connected to my expansion header at the moment and I dont fully understand how the expansion board works. I need 2 extra steppers and another 5ish gpio for my trinkets around the printer. -

RE: Inconsistent z-offset too high on new printsposted in General Discussion

@Phaedrux

i took the big gun, took apart the Z and checked manually for any mechanical error, there was none. restarted all the calibration for movement and now it seems to be ok. I have no idea what was the problem tho. I consider it solved. Thank you for your help. -

RE: Inconsistent z-offset too high on new printsposted in General Discussion

@Phaedrux you mean mechanically? i didnt notice such a thing. When it gets going it works perfectly

-

Inconsistent z-offset too high on new printsposted in General Discussion

Hello!

I have a problem since some time. I thought I'm seasoned on 3d printer issues but this one got me.

Printer: blv mgn based custom core xy, I made a lot of part for it myself. It is running on duet2 wifiSymptom:

I'm leveling the bed on the 4 corners manually then starting a print. Even tho I have mesh bed leveling seemingly I still have to do it. Print goes ok. Printer turns off, I don't need the printer for a week.

I turn on the printer, need to print small stuff on the center so I skip the manual leveling. I have mesh leveling anyway. Mesh level goes down, print starts and it prints 2-3mm above the bed after successful mesh leveling. Huge margin of error. It is not the "height is slightly off" it literally prints in the air. The deviation in my 350mmx350mm bed is something like 0.7mm, even if my -i don't know- mesh axes are wrong the height difference is still too much.This is completely beyond me how can it happen because the bltouch measurements are consistent. It is an original one.

Best I can do is share as many settings and data with you as I can and please if anyone has any idea what is happening share it with me.config.g

sample gcode

homeall.g

mesh.g

imgur gallery with images and video -

New pause stateposted in Firmware wishlist

It would be nice if state.status returns different pause state for manual (including gcode pause) and pause initiated by error or filament sensor.

This would enable running special macros, for example unload the remaining filament when the filament sensor triggers during print and print is paused. Something that you might only want to do if you are in an error state. If this can be solved with the current reading of the pause state and I'm just missing something please let me know

-

RE: Orbiter filament sensor setupposted in Third-party add-ons

@droftarts I need some brainstorming here.

I thought about it a lot and the following scenario is working while the printer is idle:idle && no filament -> press button to start loading filament

idle && filament present -> press button to start unloading filamentI think this is clear so far and working in the macro.

However there are two tricky situations need to be covered:- Print paused manually for filament change so filament is present but status is paused

- Filament runs out and print is paused

For case 1 we can use the original macro as filament is present, but I'm not sure how I could handle when print is paused with error. I have looked up all the available statuses and printer status is same when manually paused and when paused with error. I'm wondering what other parameter we could use this case to determine if the print was halted by error or manually.

-

RE: If statement for macro trigger in RRFposted in Gcode meta commands

I didnt know about this tool, it's cool. Makes this so much easier. Thanks

I think this is solved lets continue any discussion in the other topic: https://forum.duet3d.com/topic/34132/orbiter-filament-sensor-setup/9

-

If statement for macro trigger in RRFposted in Gcode meta commands

Hello,

I need help with syntax. I have duet 2 board with RRF.

I have a button that calls trigger2.g

So far this is ok.I have a filament runout sensor switch connected to zstop.

Depending on the state of the sensor I either want to start filament loading or filament unloading on button press triggering trigger2.g

The sensor is right at the extruder so it is a good indication of which gcode to start upon button press.M591 D0 returns this:

Simple filament sensor on pin !zstop, enabled, output low when no filament, filament present: yesHow is my if statement will look like?

if sensors.filamentMonitors[0].filamentPresent = true ;unload gcode else ;load gcode endifError: in file macro line 1 column 4: meta command: unknown value 'filamentPresent'

Thank you

-

RE: Orbiter filament sensor setupposted in Third-party add-ons

@droftarts thanks, this will get me started. If I have a working solution I will post it here for anyone in the future.

-

RE: Orbiter filament sensor setupposted in Third-party add-ons

@droftarts Ok I never thought of this. So:

I do something like this in a macro and call this in the trigger2.g:; Macro to check printer status and load filament or pause print M408 S0 P"status" ; Retrieve the status information ; Check the status response - I'm just assuming here the reply is printing or idle, needs to be checked IF {[state.status] = "printing"} M98 P"pause.g" ; Execute pause.g to pause print ELSEIF {[state.status] = "idle"} M98 P"loadfil.g" ; Execute loadfil.g to load filament ENDIFAm I thinking about this the right way?

-

RE: Orbiter filament sensor setupposted in Third-party add-ons

@droftarts this sounds like a possible workaround. How do I undefine a config entry in my start gcode?

-

Orbiter filament sensor setupposted in Third-party add-ons

Hello,

I have orbiter sensor setup with my duet2 board. The orbiter sensor has 2 trigger switches, one inside the sensor and a button on the top. The intended operation is pressing the button unloads a filament and while there is no filament putting filament in the sensor starts loading the filament. The problem with this is there is no filament sensing defined, this is no more than just a faster way to load and unload filament.

So the logical way to do is to define the filament sensor switch with M591.So this is how the settings look like:

M591 D0 P1 C"!zstop" S1 ; set filament sensor switch for extruder 0 M950 J1 C"!zstop" ;define logical input for filament auto load M581 P1 T2 S0 R0 ;define trigger for filament auto load triggers trigger2.g M950 J2 C"^connlcd.encb" ;define logical input for filament unload M581 P2 T3 S0 R0 ;define trigger for filament auto unload triggers trigger3.gBut once you do that you no longer have the option to load the filament. M591 invalidates the M950 line.

I believe the orbiter sensor was mainly designed for klipper, so there they might be able to use the sensor switch for sensing and loading.

As a workaround now I'm simply doing filament loading with a macro from panel due and not use the filament load feature. Question is: would there be a way to use the M591 and M950 at the same time with conditions? For example if the switch is not triggered (no filemant) and becomes triggered start the filament load macro? But when triggered and becomes untriggered (filament runs out) pause the print like it should?

If this could not be done can we define double or long press triggers on buttons? So single press on the button would unload filament, double press would load the filament. -

RE: Help Connecting accelerometer to duet2 wifiposted in Duet Hardware and wiring

@droftarts

This must be some different issue.

I have ordered a new adafruit accelerometer, soldered the cables and connected it to the board.

Same thing, "accelerometer not found"

Ok, then it might be the cabling, right?

I have cut a set of absolutely short cable, the shortest length that can reach the hotend from the board.

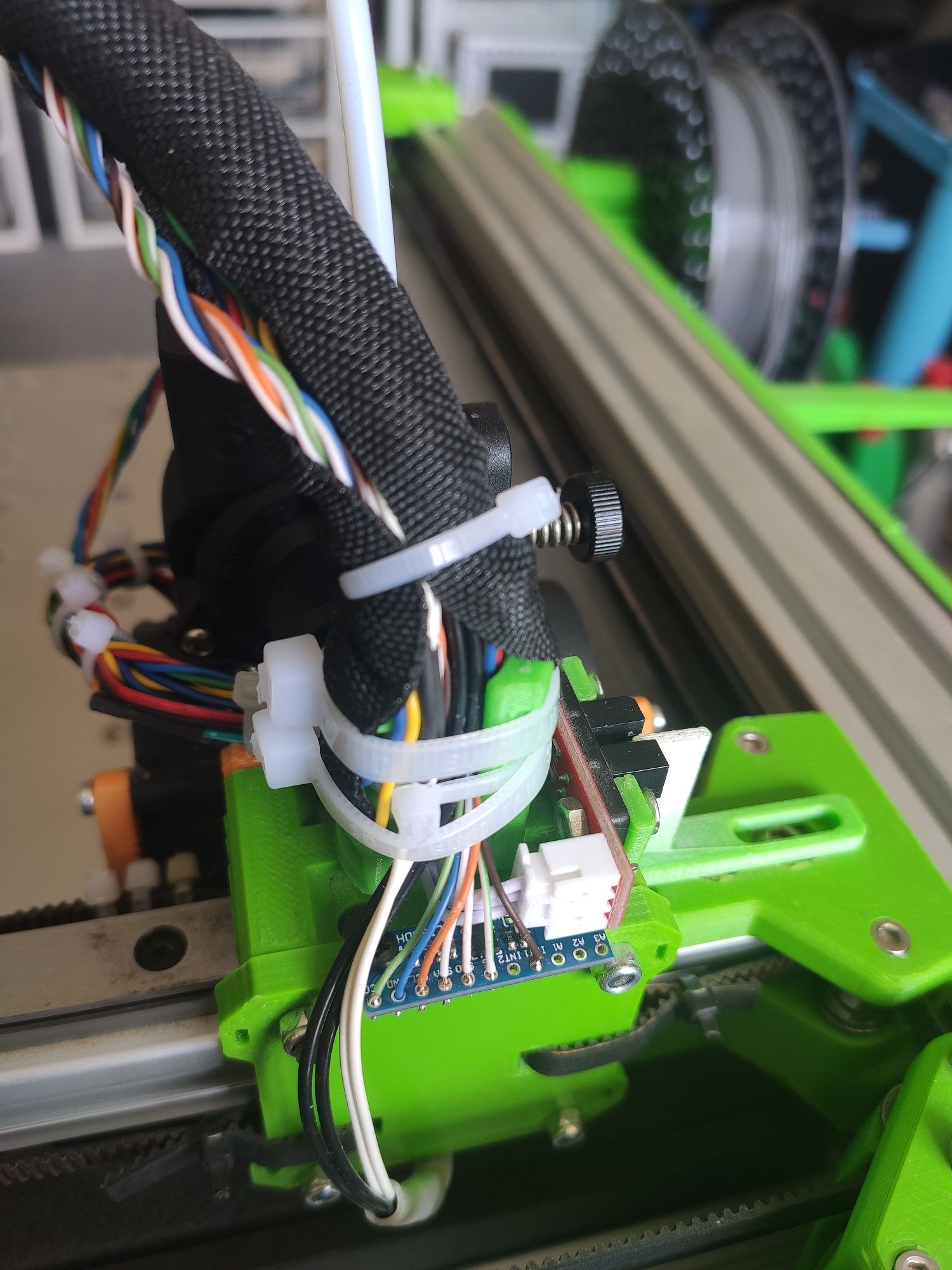

I have connected my original accelerometer to it and the results are the same. As the photo below shows the blue wire is the CS separated away from the rest of the cables and the accelerometer temporary held there with a clamp. The other accelerometer is the adafruit one I have tried earlier.

So for me it seems it is not an issue with the accelerometer, not an issue with the cabling.. so what remains? I have no idea.

For the record: I have continuity tested all cables multiple time, I myself put the dupont connectors on the cable and have verified they make contact and have used the pinout diagram on the docs to verify the cabling order many times.

This is my full config: pastebin

-

RE: Help Connecting accelerometer to duet2 wifiposted in Duet Hardware and wiring

@droftarts I do believe my wiring is correct, i have quadruple checked it by now with the pinout diagram. The CS cable runs in the umbilical cord of the print head very tightly packed with many other wires data and power as well. I have around 30-35 cable running in the cord.

hotend, thermistor, bl touch, orbiter filament sensor, extruder motor, optical endstop, 3 fan and the accelerometer. I do have a screen with SD card reader on the front of the printer and that does not have this issue, that has a CS cable as well.

I don't know how I could run it away from other cables. I put a resistor on the end as it was advised.

I have ordered a second accelerometer from adafruit (this one is from aliexpress) as I have no way to verify if the unit is working or not (seemingly not if this is not a cable issue).

If it is the cabling I have no idea how to manage it... Maybe I need a grounded shielded cable for the CS only? Really not sure. -

RE: Help Connecting accelerometer to duet2 wifiposted in Duet Hardware and wiring

@droftarts

Hi Ian, thank you for your reply.I did reconnect it to the temp daughterboard connector but I have the exact same issue.

Here is my setup: LIS3DH sensor on the printhead connected with twisted pair ethernet cable

Other end has dupont connectors and now connected to daughterboard pins:

I have checked for cable continuity as well as triple checked the pin layout. It is as per the docs.

In my config G I have setup the accelerometer: M955 P0 C"spi.cs4+spi.cs3"

I have enabled accelerometer plugin in the web interface.

When I run acceleration test (G1 X-50 G4 S2 G1 X50 F20000 M400 M956 P0 S1000 A0) the head moves 50mm to the positive direction then I get the following error: Error: M956: Accelerometer not found -

Help Connecting accelerometer to duet2 wifiposted in Duet Hardware and wiring

Hi,

My board is loaded and I could not use the pins in the tutorial. I have paneldue with SD card taking up SPI_MOSI/MISO/SCL pins. So I have used the SPI1 pins instead.

I did the following setup:

Wire# Accelerometer signal Duet signal

1 not connected not connected

2 GND GND

3 not connected not connected

4 SCL SPI1_SCK_BE

5 SDA SPI1_MOSI_B

6 SDO SPI1_MISO

7 INT1 SPI.CS3

8 3V3 +3V3

9 CS SPI.CS4

10 not connected not connectedI have used stranded UTP cable and have added a 250ohm resistor to CS pin.

In my config G I have setup the accelerometer: M955 P0 C"spi.cs4+spi.cs3"

When I run acceleration test I get the following error: Error: M956: Accelerometer not foundHelp me how to do the setup.

-

RE: Inverting Y direction swaps X and Yposted in Using Duet Controllers

@dc42 Thank you, I had to swap the motor connectors.

-

RE: Inverting Y direction swaps X and Yposted in Using Duet Controllers

@engikeneer thanks, now i understand the issue but still don't have the solution

So when I go the original way:

M569 P0 S0

M569 P1 S0

+X moves to the right -OK

+Y moves forward - not OKM569 P0 S0

M569 P1 S1

axes are invertedM569 P0 S1

M569 P1 S1

+X moves to the left - not OK

+Y moves backwards - OKM569 P0 S1

M569 P1 S0

axes are invertedso... Do i need to invert the wiring in one of the motors?