@Phaedrux @PaulHew @dc42 @Danal

OK Figured it out....FINALLY!!

Just so you know, the motors are louder than the creality stock board. I plan on replacing them, once I have found a "better" version of stepper motors that are more compatible with the Duet 2 Maestro board. (Anyone have any suggestions? What's the best on the market?)

The stepper motor for the Z axis needs to be set to 800, not 400 steps. It seems the stock motors of Ender 3 and 5 Pro are different. The lead screw is "TR4" with a 4mm pitch and set to 1:1 ratio. You can then set whatever microstepping you want. 16 works fine for me.

Also, make sure you set your extruder to run 'Backwards' not forwards (another difference between Ender 3 and 5).

If you want higher resolution you can set your extruder to 128(on) microstepping. Whatever you choose, make sure that you set your "Hob Diameter" in the reprap config tool to 10.9 and 1:1 gear. That will set the calculation to the correct value.

The rest of the settings that you see below are directly from the Marlin board, so I am sure they are right and I'm getting some decent prints now. Louder, mind you! At this point, I don't mind.

To be honest, I am still not convinced I have the right settings for the motor currents. I couldn't find any conclusive info on this. I will do some more digging and update if I find anything.

Attached is my config file.

Bear in mind that I added an additional 5015 blower to my filament blower. Thus the tool to make sure they are running in-sync.

***Pro tip: if you have a brand new board, it seems they ship the jumper for the "FAN2" to 5V. Make sure you change it to "VIN".

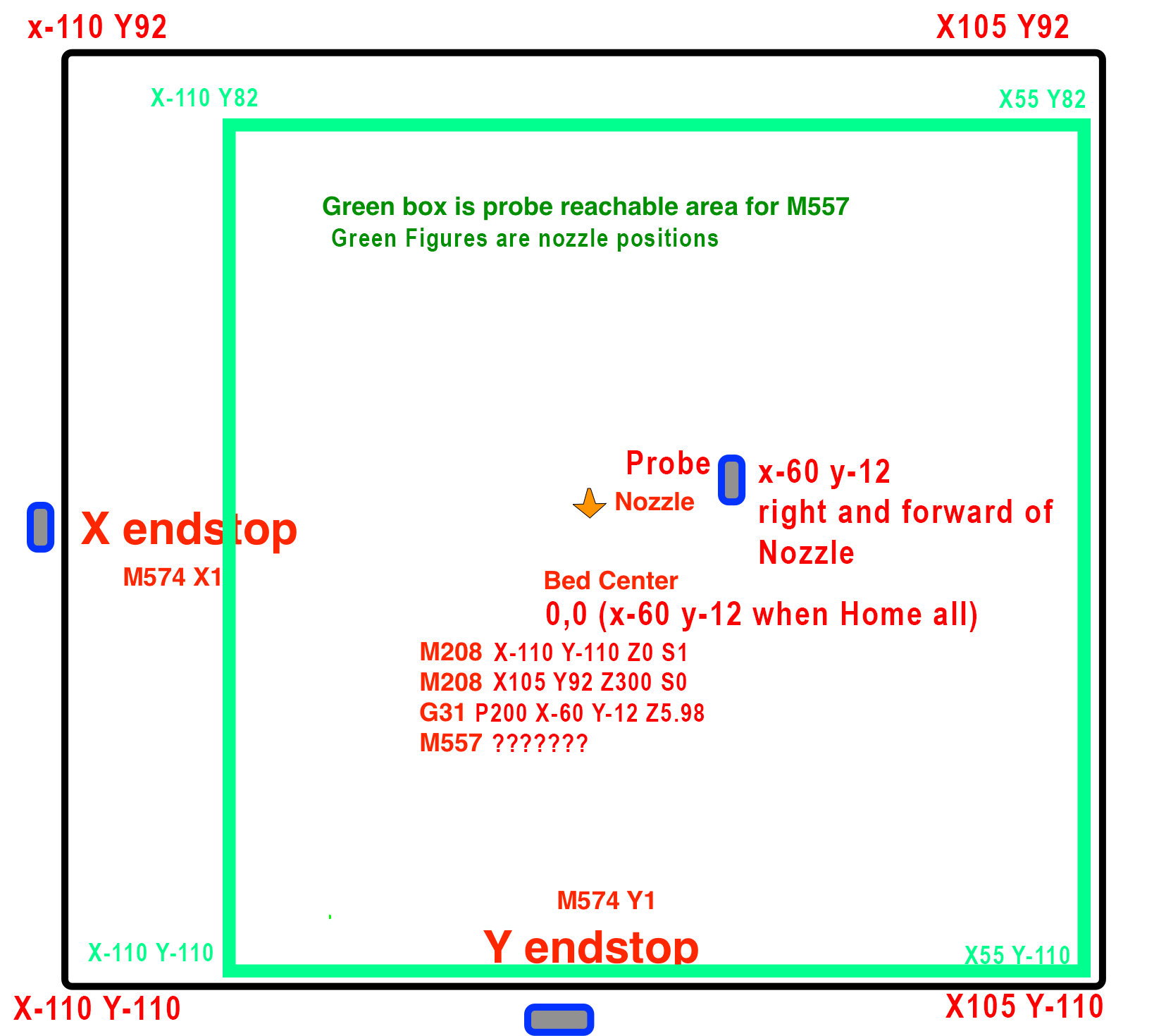

I also have a Hero Me Gen3 cooling duct attached, thus the offsets, Mesh grids, etc. If you plan to copy-paste, make sure you calibrate these to your machine.

I also google and found the correct settings for the heaters of the hotend and bed. the ones here are safe to use. I have not done a PID tunning yet though...never done before, will try that to see if it works out for me.

; Configuration file for Duet Maestro (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun Apr 05 2020 20:04:18 GMT-0500 (Colombia Standard Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Damien's Ender 5 Pro" ; set printer name

M918 P1 E4 F2000000 ; configure direct-connect display

; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

I

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E128 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E747.59 ; set steps per mm

M566 X600.00 Y600.00 Z60.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z300.00 E1500.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X-110 Y-110 Z0 S1 ; set axis minima

M208 X110 Y102 Z300 S0 ; set axis maxima

; Endstops

M574 X1 Y1 S1 ; set active high endstops

M574 Z1 S2 ; set endstops controlled by probe

; Z-Probe

M558 P9 H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-48 Y-17 Z2.761 ; set Z probe trigger value, offset and trigger height

M557 X-138:14 Y-127:60 S20 ; define mesh grid

; Heaters

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B3950 R2200 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100000 B3950 R2200 ; set thermistor + ADC parameters for heater 1

M143 H1 S250 ; set temperature limit for heater 1 to 250C

; Fans

M106 P0 S0 I0 F20 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S0 I0 F20 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S0 I0 F20 H-1 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off

; Tools

M563 P0 D0 H1 F0:2 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings

M918 P1 E4 ; Enable 12864 LCD with 1 menu item per encoder click

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

It took me a while to find all of this in various places on the internet.

Hopefully, this starts you off well.

Happy Printing!