@Phaedrux

I tried both of the versions listed here: https://docs.duet3d.com/User_manual/RepRapFirmware/Updating_firmware

I seem to have gotten it to work from the command line. It says it's writing the firmware as I type this now

@Phaedrux

I tried both of the versions listed here: https://docs.duet3d.com/User_manual/RepRapFirmware/Updating_firmware

I seem to have gotten it to work from the command line. It says it's writing the firmware as I type this now

Thanks @Phaedrux ! I got it back up n running

@OwenD said in Best way to do extra tricks on tool change & retraction?:

I wonder if using M571 to control a solenoid or servo to move a plate across the nozzle would be suitable?

Not sure if it would close during retraction or whether you could get a solenoid or servo that would work fast enough if it did.

I think I could solve the speed problem with some creative thinking. The trick will probably be keeping whatever solution I come up with light enough, since it's traveling with the extruder.

I'm sure some combination of slicer settings and firmware retraction will give me a way to add the gcode I ultimately decide on. If nothing else I can probably make a post-processor of some kind, maybe a plugin in DWC.

My debate is how to implement the idea in my gcode. M280 seems the more flexible option and would be simple to tune in, with adjustments to the servo angle just requiring a change in gcode. M571 seems more straightforward, just by assuming the wiper/servo position covering the nozzle as home. When the extruder is running, make M571 actively move and hold the wiper away from the nozzle. It's more of a binary choice in the gcode and would probably have to be physically tuned, but bending a lil thin steel and iterating a few parts is easy enough.

@gloomyandy said in Best way to do extra tricks on tool change & retraction?:

@curtisb1986 Perhaps some sort of micro servo (as used in model aircraft etc.), easy to control from RRF.

Can you point me to the documentation for this? Is it handled as another axis as I suspected? It would be lovely if I could simply add it to the firmware retraction gcode instead of going through the additional hassle of creating axes, which I can only assume would require endstops and a stepper.

This feels like a bit of a n00b question, but does a microservo not require a driver in the same way a stepper does?

The pebble wiper is very similar to what I'm thinking, but I don't have a tool changer per se, just two hot ends that home at either end of the X axis on an otherwise pretty traditional cartesian printer. The pebble wiper seems to be a solution to a different problem, but full of useful tricks to accomplish my end goal. You can all count on me being back with lots of questions haha

As far as passive solutions, I have these steel wipers that sit at either end of the X axis:

https://www.tronxyonline.com/h-product-detail.html?goods_id=1977303

They are better than the original brass brush solution, and the inspiration for my active solution, but their stationary position can only help so much.

Ideally that steel sheet would quickly rotate into place simultaneously with a retraction and Z hop, effectively eliminating any stringing or oozing (in my idealized version anyway)

I work with a lot of flexibles on IDEX printers, with two color models. Stringing keeps me up at night, but I had a vision of a way to solve my problems. I need to add a microstepper to actuate a lil steel wiper onto the nozzles at tool change and maybe during retractions as well.

I'm not sure where to start with this idea tho, can I add an axis for the aforementioned microstepper and some gcode to move that axis during firmware retraction? Or is there a simpler gcode command I could include to accomplish this without having to set up whole new axes about it?

Any ideas or pointers or suggested readings would be much appreciated!

@droftarts said in Endstop documentation clarification:

@curtisb1986 on the I/O Mapping tab, you need to choose an I/O connector for the Z axis. For the endstop wiring, I guess your micro switch boards are like the Makerbot Mechanical endstops, so look a little further down the page: https://docs.duet3d.com/User_manual/Connecting_hardware/Sensors_endstops#makerbot-mechanical-endstop-v12

Ian

Yep, there's that simple solution. Maybe I'm too tired lol

Thanks @droftarts

I'm trying to connect some pcb-mounted endstops for a twin z motor leveling.

The documentation says specifically "This applies to a bare microswitch, not to a microswitch on a board with a LED"

Is this a matter of power draw from the LED? My switch PCBs have pads for an LED, but nothing soldered there. Can I safely use them? Should I configure them differently, or are they just not gonna work in this context?

It's mostly a matter of convenience as they have the correct spacing to mount on the aluminum extrusion

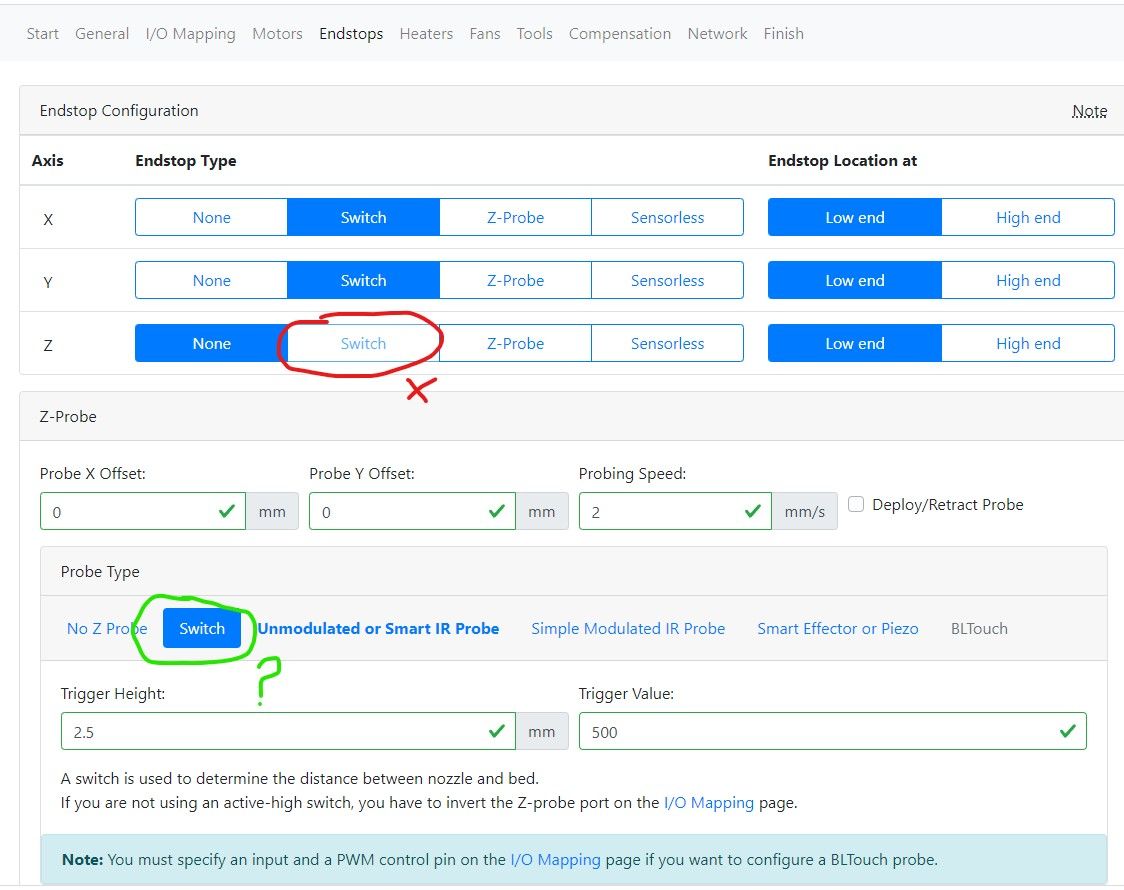

On a related note, when I try to select "switch" in the z probe section of the reprap configurator, it seems to be un-clickable no matter what I try. I can't specify the pins/IO port correctly in the configurator either, but when I select io3in for input pin and IO3out for modulation pin, I have the option to select "switch" in the lower pane and input some values.

What am I missing? Is it supposed to be like that? Why have an option for "switch" if it can never be clicked? And why can I only choose the lower option for "switch" when I have the IO pins mapped in a way that doesn't make sense?

Should I just select "none" for Z probe in the configurator and put it into config.g manually??

Let me know if I sound crazy here, but it seems like I'm having a problem that should (hopefully) have a simple solution

TIA for any help

Thanks @Phaedrux ! I got it back up n running

@Phaedrux

I tried both of the versions listed here: https://docs.duet3d.com/User_manual/RepRapFirmware/Updating_firmware

I seem to have gotten it to work from the command line. It says it's writing the firmware as I type this now

Thanks for the quick reply!

I switched USB cables, and got a samba port (COM7) and tried to use bossa to connect, but the only COM port it lets me choose is COM3 (intel active management technology)

So that's where I'm stuck now.

Still no diag light tho