@fcwilt Hi Frederick,

You were spot on! Hadn't realised that RRF3 changed the way that H was utilised.

Works a treat now.

Many thanks,

Tom

@fcwilt Hi Frederick,

You were spot on! Hadn't realised that RRF3 changed the way that H was utilised.

Works a treat now.

Many thanks,

Tom

@jay_s_uk said in Duet 3 3HC Expansion board firmware update.:

M997

@jay_s_uk You've done it again! Cheers chap!

Thanks for the suggestions all! I've updated the boards to 3.3 and will try @deckingman 's solutions tomorrow and let you know!

Many thanks,

Tom

@droftarts Hi!

Thanks for your reply.

I have set the CAN addresses, I can communicate with them using M115 B20, B21 and B22. I can heat up the three hotends as well as operate the PCF on each but I can't get the motors to turn.

I originally had one extruder which I could extrude plastic fine. I wired up the other motors the same and added what I thought would be correct to the config however none of them seem to turn now.

Many thanks,

Tom

Our printer runs the E3D toolchanger. I had the first extruder/tool working no problem however when I added the next two tools and added them (following the wiki) the extruders no longer works.

I'm aware that it's probably something tiny that I need to change however I'm a bit lost.

Any help appreciated! Config below.

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Mon Aug 03 2020 17:11:06 GMT+0100 (British Summer Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

G4 S1 ; Wait for expansion boards to start

; Drives

M569 P0.0 S0 ; X

M569 P0.1 S0 ; Y

M569 P0.2 S1 ; Z1

M569 P0.3 S1 ; Z2

M569 P0.4 S1 ; Z3

M569 P0.5 S1 ; Z4

M569 P1.0 S1 ; C

M569 P20.0 S1 ; E0

M569 P21.0 S1 ; E1

M569 P22.0 S1 ; E2

M584 X0.0 Y0.1 Z0.2:0.3:0.4:0.5 C1.0 ; set drive mapping for motion system

M584 E20.0:21.0:22.0 ; set drive mapping for tools

M350 X16 Y16 Z16 E16:16:16 I1 ; configure microstepping with interpolation

M350 C8 I0 ; configure microstepping with no interpolation

M92 X80.00 Y80.00 Z817 C100 E350 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 C2 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X36000.00 Y36000.00 Z500 C5000 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z20.00 C400 E250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z2000 C450 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Leadscrew locations for bed tramming

M671 X590:-70:-70:590 Y-40:-40:670:670 S10

; Axis Limits

M208 X0 Y0 Z0 C0 S1 ; set axis minima

M208 X515 Y464 Z1000 C500 S0 ; set axis maxima

;Stall Detection

M915 C S3 F0 H200 R4700

; Endstops

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y2 S1 P"io2.in" ; configure active-high endstop for high end on Y via pin io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

;M558 P5 C"io3.in" H5 F250 T6000 ; set Z probe type to switch and the dive height + speeds

;G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M558 P5 C"^io4.in" H5 F250 T6000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X33.5 Y41.46 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:520 Y60:520 S100 ; define mesh grid

; Heaters

;Bed

M308 S0 P"temp0" Y"thermistor" T100000 B4138 C0 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out3" T0 ; create bed heater output on out0 and map it to sensor 0

;M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M307 H0 B0 R0.963 C150.8 D2.90 S1.00

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

;Tool0 Heater

M308 S1 P"20.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp0 on toolboard p20.0

M950 H1 C"20.out0" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;Tool1 Heater

M308 S2 P"21.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp0 on toolboard p21.0

M950 H2 C"21.out0" T2 ; create nozzle heater output on out1 and map it to sensor 1

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;Tool2 Heater

M308 S3 P"22.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp0 on toolboard p21.0

M950 H3 C"22.out0" T3 ; create nozzle heater output on out1 and map it to sensor 1

M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;Dock Indicator Switches

M950 J1 C"20.!^io0.in" ; GpIn0 = Tool 1 Dock Switch

M950 J2 C"21.!^io0.in" ; GpIn0 = Tool 2 Dock Switch

M950 J3 C"22.!^io0.in" ; GpIn0 = Tool 3 Dock Switch

; Fans

;Tool 1

M950 F0 C"20.out2" ; create fan 0 on pin out3 and set its frequency

M106 P0 S0 H1 T50 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"20.out1" ; create fan 1 on pin out4 and set its frequency

M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned off

;Tool 2

M950 F2 C"21.out2" ; create fan 0 on pin out3 and set its frequency

M106 P2 S0 H2 T50 ; set fan 0 value. Thermostatic control is turned on

M950 F3 C"21.out1" ; create fan 1 on pin out4 and set its frequency

M106 P3 S0 H-1 ; set fan 1 value. Thermostatic control is turned off

;Tool 3

M950 F4 C"22.out2" ; create fan 0 on pin out3 and set its frequency

M106 P4 S0 H3 T50 ; set fan 0 value. Thermostatic control is turned on

M950 F5 C"22.out1" ; create fan 1 on pin out4 and set its frequency

M106 P5 S0 H-1 ; set fan 1 value. Thermostatic control is turned off

; Tools

M563 P0 S"Tool 0" D0 H1 F1 ; define tool 0

G10 L2 P0 X23 Y45 Z14.465 ; set tool 0 axis offsets

G10 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Tool 1" D1 H2 F3 ; define tool 1

G10 L2 P1 X23 Y45 Z15.351 ; set tool 0 axis offsets

G10 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"Tool 2" D2 H3 F5 ; define tool 0

G10 L2 P2 X23 Y45 Z45.425 ; set tool 0 axis offsets

G10 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

Many thanks,

Tom

@fcwilt Hi Frederick,

You were spot on! Hadn't realised that RRF3 changed the way that H was utilised.

Works a treat now.

Many thanks,

Tom

Hi,

I've recently added two more Hermera tool changers with tool boards to my printer and I'm having trouble with the heatsink fans.

The original one (Tool 20) works fine and spins up at 50 degrees C.

The next two (Tool 21 and Tool 22) do not. I know the fans do work as they all spin for around about 3 seconds when I turn the machine on.

Here is the contents of my config.

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Mon Aug 03 2020 17:11:06 GMT+0100 (British Summer Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

G4 S1 ; Wait for expansion boards to start

; Drives

M569 P0.0 S0 ; X

M569 P0.1 S0 ; Y

M569 P0.2 S1 ; Z1

M569 P0.3 S1 ; Z2

M569 P0.4 S1 ; Z3

M569 P0.5 S1 ; Z4

M569 P1.0 S1 ; C

M569 P20.0 S1 ; E0

M569 P21.0 S1 ; E1

M569 P22.0 S1 ; E2

M584 X0.0 Y0.1 Z0.2:0.3:0.4:0.5 C1.0 ; set drive mapping for motion system

M584 E20.0:21.0:22.0 ; set drive mapping for tools

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M350 C8 I0 ; configure microstepping with no interpolation

M92 X80.00 Y80.00 Z817 C100 E350 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 C2 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X36000.00 Y36000.00 Z500 C5000 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z20.00 C400 E250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z2000 C400 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Leadscrew locations for bed tramming

M671 X590:-70:-70:590 Y-40:-40:670:670 S10

; Axis Limits

M208 X0 Y0 Z0 C0 S1 ; set axis minima

M208 X515 Y464 Z1000 C500 S0 ; set axis maxima

;Stall Detection

M915 C S3 F0 H200 R4700

; Endstops

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y2 S1 P"io2.in" ; configure active-high endstop for high end on Y via pin io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

;M558 P5 C"io3.in" H5 F250 T6000 ; set Z probe type to switch and the dive height + speeds

;G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M558 P5 C"^io4.in" H5 F250 T6000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X33.5 Y41.46 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:520 Y60:520 S100 ; define mesh grid

; Heaters

;Bed

M308 S0 P"temp0" Y"thermistor" T100000 B4138 C0 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out3" T0 ; create bed heater output on out0 and map it to sensor 0

;M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M307 H0 B0 R0.963 C150.8 D2.90 S1.00

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

;Tool0 Heater

M308 S1 P"20.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp0 on toolboard p20.0

M950 H1 C"20.out0" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;Tool1 Heater

M308 S2 P"21.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp0 on toolboard p21.0

M950 H2 C"21.out0" T2 ; create nozzle heater output on out1 and map it to sensor 1

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;Tool2 Heater

M308 S3 P"22.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp0 on toolboard p21.0

M950 H3 C"22.out0" T3 ; create nozzle heater output on out1 and map it to sensor 1

M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;Dock Indicator Switches

M950 J1 C"20.!^io0.in" ; GpIn0 = Tool 1 Dock Switch

M950 J2 C"21.!^io0.in" ; GpIn0 = Tool 2 Dock Switch

M950 J3 C"22.!^io0.in" ; GpIn0 = Tool 3 Dock Switch

; Fans

;Tool 1

M950 F0 C"20.out2" ; create fan 0 on pin out3 and set its frequency

M106 P0 S0 H1 T50 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"20.out1" ; create fan 1 on pin out4 and set its frequency

M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned off

;Tool 2

M950 F2 C"21.out2" ; create fan 0 on pin out3 and set its frequency

M106 P2 S0 H1 T50 ; set fan 0 value. Thermostatic control is turned on

M950 F3 C"21.out1" ; create fan 1 on pin out4 and set its frequency

M106 P3 S0 H-1 ; set fan 1 value. Thermostatic control is turned off

;Tool 3

M950 F4 C"22.out2" ; create fan 0 on pin out3 and set its frequency

M106 P4 S0 H1 T50 ; set fan 0 value. Thermostatic control is turned on

M950 F5 C"22.out1" ; create fan 1 on pin out4 and set its frequency

M106 P5 S0 H-1 ; set fan 1 value. Thermostatic control is turned off

; Tools

M563 P0 S"Tool 0" D0 H1 F1 ; define tool 0

G10 L2 P1 X23 Y45 Z15.5 ; set tool 0 axis offsets

G10 L2 P1 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Tool 1" D1 H2 F3 ; define tool 1

G10 L2 P1 X23 Y45 Z15.5 ; set tool 0 axis offsets

G10 L2 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"Tool 2" D2 H3 F5 ; define tool 0

G10 L2 P1 X23 Y45 Z15.5 ; set tool 0 axis offsets

G10 L2 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

I've read it through multiple times and I can't see where I've gone wrong! Each tool uses the V1 version of the board, updated to the newest stable firmware and are all wired the same.

Any ideas as to what to try would be greatly appreciated.

Many thanks,

Tom

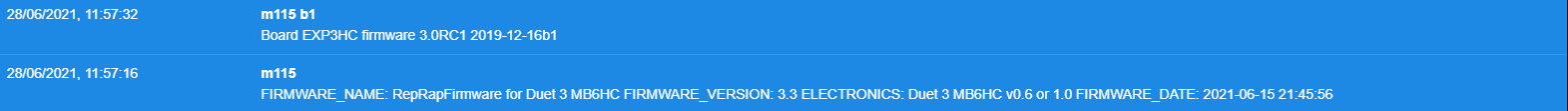

I sent M997 B1 and upgraded the board to 3.2. Couldn't find a bin file for 3.3 expansio board firmware.

The results of M122 are as below.

m122 b1

Diagnostics for board 1:

Duet EXP3HC firmware version 3.2 (2021-01-05)

Bootloader ID: not available

Never used RAM 154848, free system stack 200 words

HEAT 75 CanAsync 94 CanRecv 87 TMC 64 MAIN 309 AIN 257

Last reset 00:00:23 ago, cause: software

Last software reset data not available

Driver 0: position 0, 100.0 steps/mm, standstill, reads 45547, writes 18 timeouts 0, SG min/max 0/0

Driver 1: position 0, 80.0 steps/mm, standstill, reads 45558, writes 11 timeouts 0, SG min/max 0/0

Driver 2: position 0, 80.0 steps/mm, standstill, reads 45561, writes 11 timeouts 0, SG min/max 0/0

Moves scheduled 0, completed 0, in progress 0, hiccups 0

No step interrupt scheduled

VIN: 24.2V, V12: 12.2V

MCU temperature: min 50.2C, current 50.2C, max 50.2C

Ticks since heat task active 210, ADC conversions started 23702, completed 23700, timed out 0

Last sensors broadcast 0x00000000 found 0 213 ticks ago, loop time 0

CAN messages queued 72, send timeouts 0, received 133, lost 0, free buffers 36

Cheers!

Hi Jay,

Maybe that didn't quite work.

The only thing that the expansion is running is the tool pin for the tool changer mechanism.

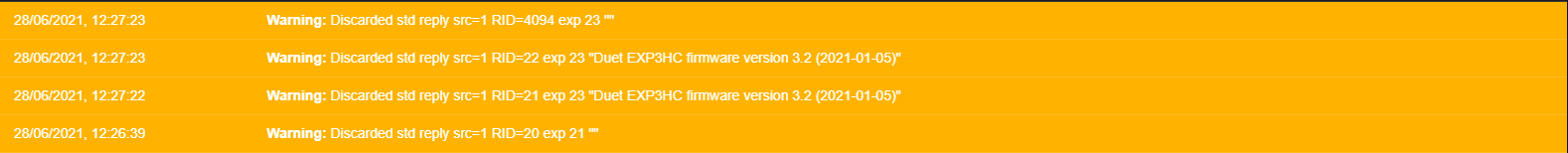

These are the errors I get, I'm still unable to home 'C' which is what that pin is called.

Cheers,

@jay_s_uk said in Duet 3 3HC Expansion board firmware update.:

M997

@jay_s_uk You've done it again! Cheers chap!

Hi,

I've managed to install the new V3.3 firmware on my Duet 3 however my expansion board is on V3.0.

I've tried moving the updated firmware for the expansion board onto the SD card however the option to install it doesn't come up like it did for the toolboards.

Any help appreciated.

Many thanks,

Tom

@jay_s_uk Ah I was unaware I had to update the toolboards too. Is there a guide on how to do this?

Thanks for your help