Using a door switch is a clever idea, I may look into that.

M570 looks like it will work for what I need. Thanks for pointing that out.

Using a door switch is a clever idea, I may look into that.

M570 looks like it will work for what I need. Thanks for pointing that out.

I've recently upgraded to 3.4.0 and am having trouble with my heated chamber config. At first my M307 parameters didn't work at all, I would get a "heating to slowly" fault after a few seconds. I ran auto tune (which took 5+ hours to complete for my heavily insulated chamber...) and changed to the new M307 parameters. Those seem to work great, but have one major problem. If I open the door to get a better look at the print (or whatever) the heater faults in a few seconds. It's impressive that it can be modeled so accurately, but I need a way to loosen the restrictions for the chamber heater.

How can I adjust the settings so that it wont be so particular about the temp control? The chamber heater really doesn't need to be so accurate or fault for relatively small inconsistencies.

Thanks!

Hmm, well after some more prints still on 3.1.1 I got the layer shifting again. So I guess the problem is something else...

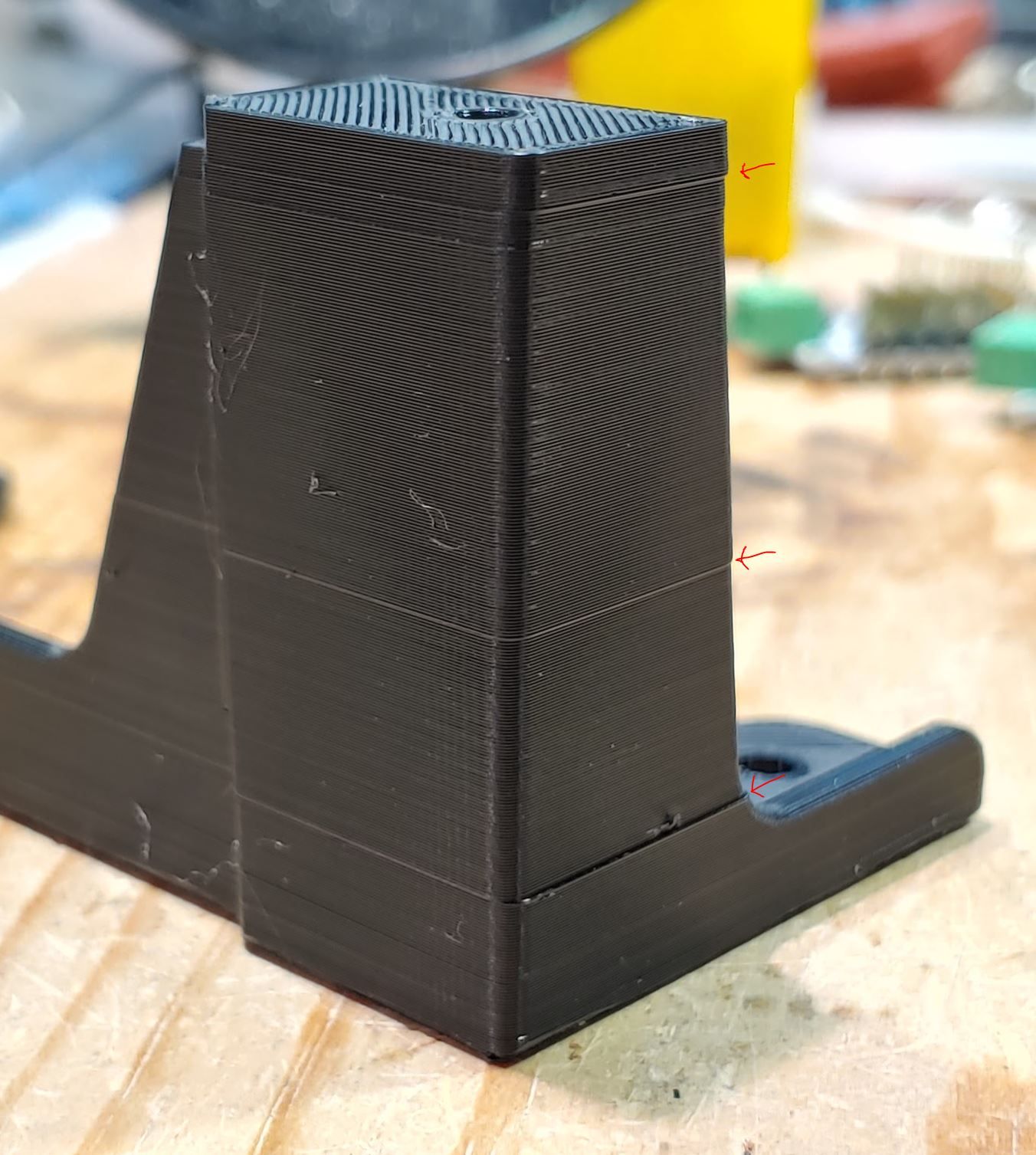

I seem to be having this same issue. After upgrading to 3.2.2 I started seeing layer shifts in prints. They seem to be only in the x axis, possibly a very tiny y shift at the same time. After printing this long print with 3 layer shifts, I downgraded to 3.1.1 and printed the same gcode again without changing anything else. The second print had no issues. Not totally conclusive I know, but suggestive.

I run a modified ATOM delta printer.

Each shift feels like the same distance, measures about 0.25mm. In this part it shifted negative, then positive, then positive.

M122 after downgrading, forgot to capture it while on 3.2.2.

M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.1.1 running on Duet WiFi 1.02 or later

Board ID: 08DDM-9FAM2-LW4S4-6JTDA-3SN6L-K3V7Y

Used output buffers: 3 of 24 (22 max)

=== RTOS ===

Static ram: 27980

Dynamic ram: 94164 of which 60 recycled

Exception stack ram used: 264

Never used ram: 8604

Tasks: NETWORK(ready,384) HEAT(blocked,1224) MAIN(running,1824) IDLE(ready,80)

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 00:00:44 ago, cause: power up

Last software reset details not available

Error status: 0

MCU temperature: min 11.0, current 16.4, max 16.5

Supply voltage: min 23.8, current 24.0, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

Driver 0: standstill, SG min/max not available

Driver 1: standstill, SG min/max not available

Driver 2: standstill, SG min/max not available

Driver 3: standstill, SG min/max not available

Driver 4: standstill, SG min/max not available

Date/time: 2021-02-20 11:15:45

Cache data hit count 69622987

Slowest loop: 6.92ms; fastest: 0.15ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 2.7ms, write time 0.0ms, max retries 0

=== Move ===

Hiccups: 0(0), FreeDm: 169, MinFreeDm: 169, MaxWait: 0ms

Bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== AuxDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = 2 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 30.56ms; fastest: 0.00ms

Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8

- WiFi -

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.23

WiFi MAC address 60:01:94:34:3e:3d

WiFi Vcc 3.36, reset reason Hardware watchdog

WiFi flash size 4194304, free heap 25480

WiFi IP address 192.168.12.123

WiFi signal strength -64dBm, reconnections 0, sleep mode modem

Socket states: 4 0 0 0 0 0 0 0

=== Filament sensors ===

Extruder 0 sensor: ok

; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare

;M555 P2 ; Set firmware compatibility to look like Marlin

G29 S1 ; Load Mesh Bed Compensation Map from SD Card

M911 S19.5 R22 P"G91 M83 G1 Z3 E-5 F1000" ; Setup auto pause on power fail

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration.

M665 R105.11 L225.51 B110 H365 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them

M208 Z0 S1 ; Set minimum Z

; Endstops

M574 X2 S1 P"xstop"

M574 Y2 S1 P"ystop"

M574 Z2 S1 P"zstop"

; Z-Probe

M558 P5 C"^!e0stop" F60 T2000 A3 S0.01 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds, active high

G31 P600 X0 Y0 Z4.805 ; Set Z probe trigger value, offset and trigger height (Position for Inductive Iouch center mount)

;G31 P600 X0 Y0 Z14.805 ; Set Z probe trigger value, offset and trigger height (Position for IR Touch center mount)

;G31 P600 X0 Y0 Z-12.03 ; Set Z probe trigger value, offset and trigger height (Position for micro switch center mount)

;G31 P600 X0 Y0 Z15.765 ; Set Z probe trigger value, offset and trigger height (Position for induction center mount)

;G31 P600 X-24 Y-1 Z4.4 ; Set Z probe trigger value, offset and trigger height (Position for my Chimera print head)

; Calibration

M557 R105 S20 ; Define mesh grid. Radius and Spacing

; Filament Sensor (Using Endstop Input)

M591 P2 C"exp.e2stop" S1 D0

; External Triggers

M950 P1 C"e1stop"

M581 P1 T1 S0 ; Use a falling edge on E0 endstop to trigger a print Pause command

; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M92 X160 Y160 Z160 E412 ; Set steps per mm at default 16x microstepping

M350 X16 Y16 Z16 E128 I1 ; Configure microstepping with interpolation

M566 X1200 Y1200 Z1200 E600 ; Set maximum instantaneous speed changes (mm/min)

M203 X30000 Y30000 Z30000 E30000 ; Set maximum speeds (mm/min)

M201 X2000 Y2000 Z2000 E2000 ; Set accelerations (mm/s^2)

M906 X1500 Y1500 Z1500 E800 I35 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Stall Detection

M915 P0 S15 F0 H400 R3 ;On stall detection rehome and restart

M915 P1 S15 F0 H400 R3 ;On stall detection rehome and restart

M915 P2 S15 F0 H400 R3 ;On stall detection rehome and restart

; Temperature Sensors

M308 S0 P"bed_temp" Y"thermistor" T100000 B4725 C7.060000e-8 A"Bed"

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 A"Hot End"

M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.060000e-8 A"Air"

; Heater to Temperature Sensor Connection

; Set Bed Heater

M950 H0 c"bed_heat" T0

M140 H0

; Set Hot End Heater

M950 H1 c"e0heat" T1

; Set Chamber Heater

M950 H2 c"exp.heater4" Q0 T2

M141 H2

; Heater Config

M301 H0 S1.00 P10 I0.1 D200 T0.4 W180 B30 ; Use PID on bed heater (may require further tuning)

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M143 H1 S310 ; Set temperature limit for heater 1 to 310C

;M143 H2 S120 ; Set temperature limit for heater 2 to 120C

M570 S120 ; Configure heater fault detection. Cancel if heating takes longer than time (seconds)

; Tools Z Offset

; More negative z value is farther from the build plate

; Tools

M563 P0 D0 H1 S"Chimera CORE 0.4mm KKIINNGG" ; Define tool 0

G10 P0 X0 Y0 Z-10.8 ; Set tool 0 axis offsets (FlexPlate Magnet with PEI Powder Coated Spring Steel)

;G10 P0 X0 Y0 Z-9.8 ; Set tool 0 axis offsets (Old PEI Bed)

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M563 P1 D0 H1 S"Volcano 1mm" ; Define tool 1

G10 P1 X0 Y0 Z-18.6 ; Set tool 1 axis offsets (FlexPlate Magnet with PEI Powder Coated Steel)

;G10 P1 X0 Y0 Z-16.8 ; Set tool 1 axis offsets (Old PEI Bed)

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C

; Network

M550 PATOM2 ; Set machine name

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; Fans

M950 F0 C"fan0"

M950 F1 C"fan1"

M950 F2 C"!fan2" Q500

M950 F3 C"e1heat"

M106 P0 S0 H-1 C"Part Cooling"

M106 P1 S1 H1 T50 C"Hotend Fan"

M106 P2 C"Enclosure Fan"

M106 P3 S0 L1 H-1 C"Circulation Fan"

; Water Cooling (hot end and motors) Power Enable

M950 F4 C"exp.heater3"

M106 P4 S1 H1 T50 C"WaterCooling"

; Enclosure Filter Fan Power Enable

M950 F5 C"exp.heater5"

M106 P5 S1 H1 T35 C"EnclosureFan"

; Default tool selection

;T0

M912 P0 S-18 ; CPU Temp Calibration

M501 ; Load overrides

I'm having trouble with this as well for an openpnp machine. Trying to move from using an "extruder" to a rotary axis for part rotation. But whether I define:

M584 X0 Y2 Z1 A3

or

M584 X0 Y2 Z1

M584 U3 R1

or

M584 X0 Y2 Z1

M584 A3

My rotary axis, either A or U, still only lets me move from 0 - 200 position. There is no infinite rotation.

Is there something beyond configuring the axis as a rotation axis to remove the limits?

Thanks

Yep, that fixed it. Thank you!

I must have copied the new format from the example in the config upgrade guide and forgot to change the 1 -> 2's.

I've recently upgraded from RRF 2 to 3. I updated my config and it mostly is working, but I'm having problems with the home position. I have a delta printer.

At first I couldn't tell why it wasn't right, it seemed to just change sometimes. Then I realized that the position it thinks is home is changing depending on the position of the print head when it starts the homing process.

For example:

If the print head is all the way at the close to the top when the machine turns on, and I home, I get Z: 365mm (close to the correct value)

But If I turn the machine off, move the head down some distance, maybe 100mm, then turn it on again, then home, I get something like Z440mm

If I do the same and move it more or less, I get different values for z home every time

So there seams to be no way for me to get a consistent home position.

I have a delta printer with a Duet 2 wifi.

I have a z probe configured, but it is not normally attached. Not sure if that is relevant here, I see the same issue weather or not the z probe is attached. It doesn't fit on my print head really so I just use it for calibration then take it off. The top homing has been accurate enough for me to get a consistent z starting height. I have run delta calibration again since upgrading to RRF 3 and it seamed to run correctly.

I've tried v3.1.1 and v3.2 beta4.1, both have the same issue for me.

Thank you for your help!

M98 P"config.g"

Warning: the height map was loaded when the current Z=0 datum was not determined probing. This may result in a height offset.

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

Warning: Heater 1 appears to be over-powered. If left on at full power, its temperature is predicted to reach 809C

Error: Heater 3 not found

Error: Heater 4 not found

Error: Heater 5 not found

Error: Heater 6 not found

Error: Heater 7 not found

M115

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.1.1 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2020-05-19b2

conig.g

; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare

;M555 P2 ; Set firmware compatibility to look like Marlin

G29 S1 ; Load Mesh Bed Compensation Map from SD Card

M911 S19.5 R22 P"G91 M83 G1 Z3 E-5 F1000" ; Setup auto pause on power fail

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration.

M665 R105.11 L225.51 B110 H365 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them

M208 Z0 S1 ; Set minimum Z

; Endstops

M574 X1 S1 P"xstop"

M574 Y1 S1 P"ystop"

M574 Z1 S1 P"zstop"

; Z-Probe

M558 P5 C"e0stop" F60 T4000 A3 S0.01 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds, active high

G31 P600 X0 Y0 Z14.805 ; Set Z probe trigger value, offset and trigger height (Position for IR Touch center mount)

;G31 P600 X0 Y0 Z-12.03 ; Set Z probe trigger value, offset and trigger height (Position for micro switch center mount)

;G31 P600 X0 Y0 Z15.765 ; Set Z probe trigger value, offset and trigger height (Position for induction center mount)

;G31 P600 X-24 Y-1 Z4.4 ; Set Z probe trigger value, offset and trigger height (Position for my Chimera print head)

; Calibration

M557 R105 S20 ; Define mesh grid. Radius and Spacing

; Filament Sensor (Using Endstop Input)

M591 P2 C"exp.e2stop" S1 D0

; External Triggers

M950 P1 C"e1stop"

M581 P1 T1 S0 ; Use a falling edge on E0 endstop to trigger a print Pause command

; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M92 X160 Y160 Z160 E412 ; Set steps per mm at default 16x microstepping

M350 X16 Y16 Z16 E128 I1 ; Configure microstepping with interpolation

M566 X1200 Y1200 Z1200 E600 ; Set maximum instantaneous speed changes (mm/min)

M203 X30000 Y30000 Z30000 E30000 ; Set maximum speeds (mm/min)

M201 X2000 Y2000 Z2000 E2000 ; Set accelerations (mm/s^2)

M906 X1500 Y1500 Z1500 E800 I45 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Stall Detection

M915 P0 S15 F0 H400 R3 ;On stall detection rehome and restart

M915 P1 S15 F0 H400 R3 ;On stall detection rehome and restart

M915 P2 S15 F0 H400 R3 ;On stall detection rehome and restart

; Temperature Sensors

M308 S0 P"bed_temp" Y"thermistor" T100000 B4725 C7.060000e-8 A"Bed"

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 A"Hot End"

M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.060000e-8 A"Air"

; Heater to Temperature Sensor Connection

M950 H0 c"bed_heat" T0

M140 H0

M950 H1 c"e0heat" T1

M950 H2 c"e1heat" T2

; Heater Config

M301 H0 S1.00 P10 I0.1 D200 T0.4 W180 B30 ; Use PID on bed heater (may require further tuning)

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M143 H1 S310 ; Set temperature limit for heater 1 to 310C

;M143 H2 S120 ; Set temperature limit for heater 2 to 120C

M570 S120 ; Configure heater fault detection. Cancel if heating takes longer than time (seconds)

; Tools Z Offset

; More negative z value is farther from the build plate

; Tools

M563 P0 D0 H1 S"Chimera CORE 0.4mm KKIINNGG" ; Define tool 0

G10 P0 X0 Y0 Z-17.6 ; Set tool 0 axis offsets (FlexPlate Magnet with PEI Powder Coated Spring Steel)

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M563 P1 D0 H1 S"Volcano 1mm" ; Define tool 1

G10 P1 X0 Y0 Z-18.6 ; Set tool 1 axis offsets (FlexPlate Magnet with PEI Powder Coated Steel)

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C

; Network

M550 PATOM2 ; Set machine name

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; Fans

M950 F0 C"fan0"

M950 F1 C"fan1"

M950 F2 C"!fan2" Q500

M106 P0 S0 H-1 c"Part Cooling"

M106 P1 S1 H1 T60 c"Hotend Fan"

M106 P2 C"Enclosure Fan"

; Default tool selection

;T0

M912 P0 S-18 ; CPU Temp Calibration

M501 ; Load overrides

config-override.g

; config-override.g file generated in response to M500 at 2020-08-30 08:17

; This is a system-generated file - do not edit

; Delta parameters

M665 L231.666:231.666:231.666 R106.843 H364.543 B110.0 X-0.116 Y0.475 Z0.000

M666 X0.098 Y0.387 Z-0.485 A0.00 B0.00

; Heater model parameters

M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B0

M307 H1 A784.7 C147.2 D1.6 S1.00 V24.0 B0

M307 H2 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H3 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H4 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H5 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H6 A340.0 C140.0 D5.5 S1.00 V0.0 B0

M307 H7 A340.0 C140.0 D5.5 S1.00 V0.0 B0

G10 L2 P1 X0.00 Y0.00 Z0.00

G10 L2 P2 X0.00 Y0.00 Z0.00

G10 L2 P3 X0.00 Y0.00 Z0.00

G10 L2 P4 X0.00 Y0.00 Z0.00

G10 L2 P5 X0.00 Y0.00 Z0.00

G10 L2 P6 X0.00 Y0.00 Z0.00

G10 L2 P7 X0.00 Y0.00 Z0.00

G10 L2 P8 X0.00 Y0.00 Z0.00

G10 L2 P9 X0.00 Y0.00 Z0.00

I don't see any error message listed. I changed it back and tested the Home All button as well as sending G28 manually from the G-Code Console page. It only logs the G28 call. Also, the notification message about the axis's not being homed disappears despite the homing having failed.

Fantastic, that did it  Thank you

Thank you

I guess it hit the end stops on the "bottom" when it was going up, sensed the error and aborted setting the home position? Something like that. Makes sense now.

[c]; Configuration file for Duet WiFi (firmware version 1.17 to 1.19)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Tue Nov 21 2017 15:00:31 GMT-0800 (Pacific Standard Time)

; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates…

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare

;M555 P2 ; Set firmware compatibility to look like Marlin

M911 S19.5 R22 P"G91 M83 G1 Z3 E-5 F1000" ; Setup auto pause on power fail

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration.

M665 R105.11 L225.51 B100 H348.693 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X3.28 Y-2.85 Z-0.43 ; Put your endstop adjustments here, or let auto calibration find them

M208 Z0 S1 ; Set minimum Z

; Endstops

M574 X1 Y1 Z1 S1 ; Set active high endstops

M558 P4 X0 Y0 Z0 H5 F120 T6000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds

G31 P600 X0 Y0 Z2.5 ; Set Z probe trigger value, offset and trigger height

M557 R100 S20 ; Define mesh grid

; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z80 E408 ; Set steps per mm

M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X30000 Y30000 Z30000 E1200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I45 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Heaters

M301 H0 S1.00 P10 I0.1 D200 T0.4 W180 B30 ; Use PID on bed heater (may require further tuning)

M305 P0 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S310 ; Set temperature limit for heater 1 to 310C

; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X9 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

; Network

M550 PATOM2 ; Set machine name

M552 S1 ; Enable network

M587 S"xxx" P"xxx" ; Configure access point. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T60 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S0 I0 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off

; Custom settings are not configured

[/c]

I've just started setting up my new Duet WiFi in my delta printer and it is fantastic. Well above and beyond any control board I've used (I had a smoothieboard in it but just had way too many problems)

The one thing I'm confused about is the homing. When I Home All it moves up to the end stops as it should, double taps them correctly, but then it moves back to where ever it was before power on (or to where it was moved manually with the motors off) and set that position as X0 Y0 Z<homed height="" value="">. Even if that position is nowhere close to the center or the configured home height value. Even if the carriages are different distances from the endstop switches.

After this I can't move up from that position, as it thinks it's at the highest allowable point, even if it's near the bottom of the range close to the bed (if that's where it was when it powered on). And since it's always set to X0 Y0 Z <homed height="" value="">even if the print head is 10mm off the build plate, it will happily crash into the build plate when it moves down (like when trying to auto calibrate).

I started out with 1.19.2 stable release and have moved to Firmware Version: 1.20beta8+1 (2017-11-18) WiFi Server Version: 1.20b9 with the same results.

I generated my config files with the Configuration Tool and they are pretty standard. I did get the auto calibration to run by powering on the printer with the head all the way up, and added those values to my config

[c]M665 R105.11 L225.51 B100 H348.693 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X3.28 Y-2.85 Z-0.43 ; Put your endstop adjustments here, or let auto calibration find them

M208 Z0 S1 ; Set minimum Z[/c]

My homedelta.g file is just the default

[c]; homedelta.g

; called to home all towers on a delta printer

;

; generated by RepRapFirmware Configuration Tool on Tue Nov 21 2017 15:00:31 GMT-0800 (Pacific Standard Time)

; Use relative positioning

G91

; Move all towers to the high end stopping at the endstops (first pass)

G1 X400 Y400 Z400 F3500 S1

; Go down a few mm

G1 X-5 Y-5 Z-5 F1800 S2

; Move all towers up once more (second pass)

G1 X10 Y10 Z10 F360 S1

; Move down a few mm so that the nozzle can be centred

G1 Z-5 F6000

; Switch back to absolute positioning and go to the centre

G90

G1 X0 Y0 F6000

[/c]

If I run the homedelta.g commands manually everything works fine until the G1 Z-5 F6000 call, then instead of moving relative down 5mm it moves straight down to what looks like the power on position minus 5mm. Then the G1 X0 Y0 F6000 call moves it up 5mm and over to the exact position the head was in at power on.

What am I doing wrong?

Thanks for your help.</homed></homed>