@jay_s_uk oh fair enough, thank you for pointing that out, I will check the output before fully conecting them up.

I'll post back with the outcome when the convertor arrives

thank you again

@jay_s_uk oh fair enough, thank you for pointing that out, I will check the output before fully conecting them up.

I'll post back with the outcome when the convertor arrives

thank you again

@droftarts I did print the tower but it was with setting that I have been running 0.25mm nozzle and 0.125 layer height and there was hardly any blemishs, so I didn't mention it  Also since my last post about refitting the heater I have rechecked my wiring connections and run another PID tune.

Also since my last post about refitting the heater I have rechecked my wiring connections and run another PID tune.

I will change to a 0.4mm nozzle and rerun the test with the recomended setting of 0.65mm walls and 0.3 layer height in vase mode. then I will post a pic to show my findings.

@droftarts HI Ian, thank you for giving me a nodge to do the woodgrain test properly.

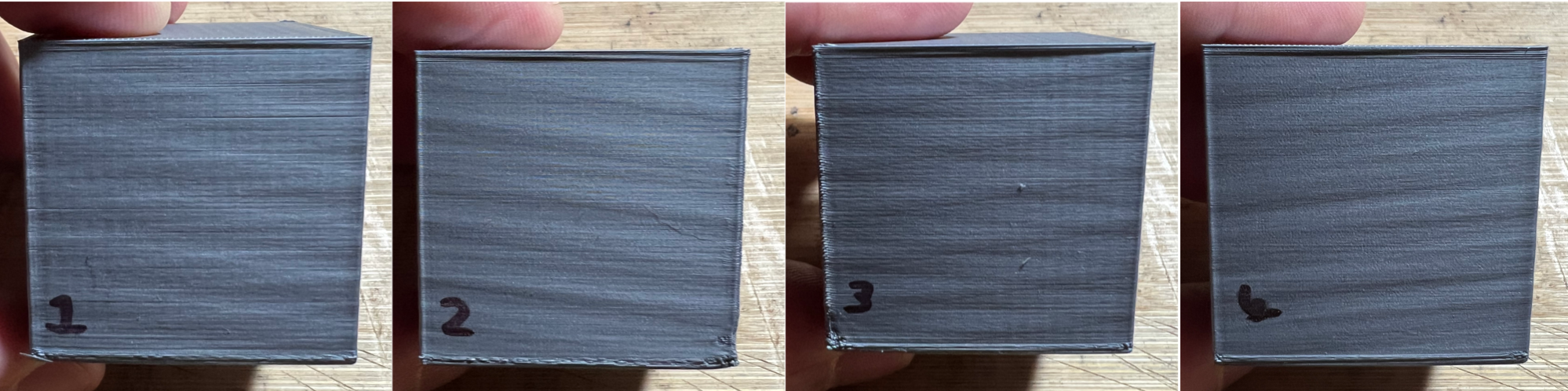

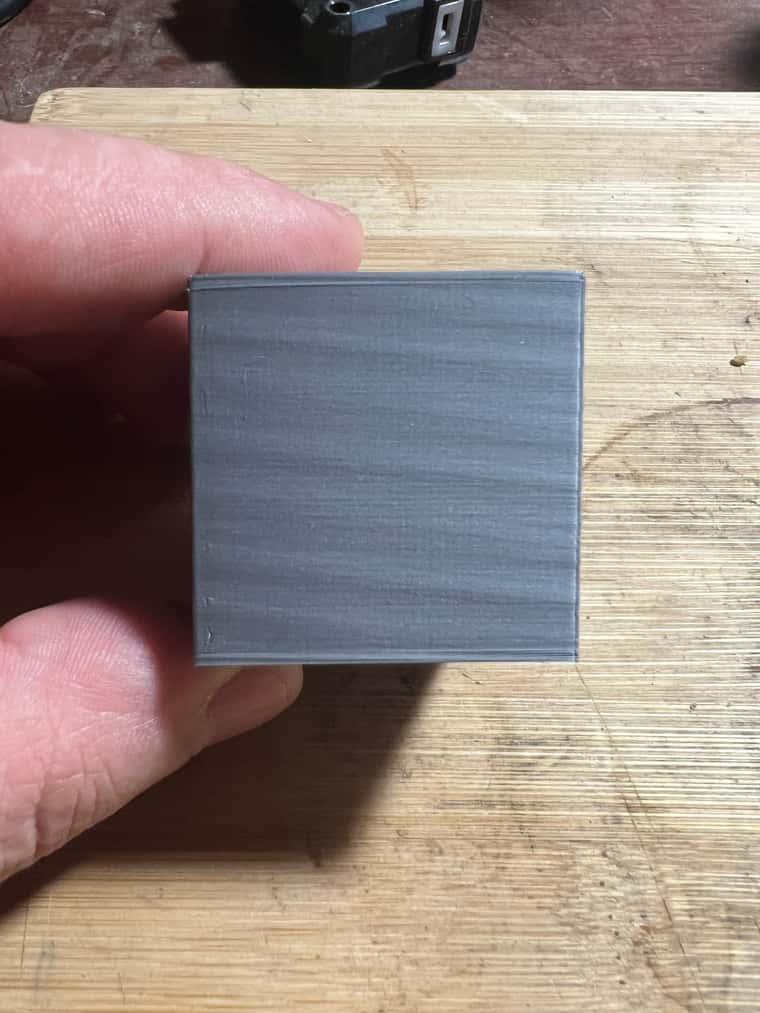

I changed to the 0.4mm nozzle and setup the test for 0.65mm outer wall thickness, 0.3mm layer height at 20mms in vase mode. And this is what happened:

Apart from the slight VFA’s from the slow feed, it is pretty much spot on.

I’m starting to wonder if this is more of a slicer issue as I seem to have the problems when printing models not in vase mode, All along I have been using the same Gcode program for the cube to use as a baseline, which may have been misleading me.

I’ll try using 2 different slicers on the same model to compare the results. I have been using Orca for a while, but I still have a working profile in S3D. I will post up my results

@Ce72 Hi, thank you for your input and any suggested test are much appreciated. I have tried changing the extruder gears and that unfortunatly had no effect, as for z wobble I would have thought the pattern would be the same on all faces, but what I have noticed is that the pattern changes direction and not on opposite face so it just adds to my confusion

@mikeabuilder Hi, Thank you for your thoughts, but after going down the rabbit hole replacing the SSR and bed heater, I tried running a test print with the bed heater turned off to try and eliminate the bed heater and I still had the same results. but I'm not that clued up on electrics to know if that would negate any effects.

Hi Ian thank you for pointing me in the right direction to set the PID tune.

Then I run some tests to see If the banding had finally gone, unfortunately not so I decided to run some other tests to see if I could isolate the problem or ever just work out what effects the banding pattern.

This is the first test print after changing the heater and SSR as well as retuning the extruder PID. banding is the same as before.

The next test I turned off the bed heater after the first couple of layers. To see if the banding was being affected by the bang-bang theory being caused by the bed heater but the banding was still the same. This left me wondering if it was a back to a mechanical issue the good old Z wobble as nothing electrical or extruder seemed to be affecting the outcome.

The last test I did after reimaging the pi (hey try anything at this point ) This time I resized the test model from a 40mm cube the a 80mm square by 25mm high same slicing profile as before but this time the banding was a lot closer together than before, To me me this eliminates a mechanical problem as the pattern frequence is so far away from the ball screw pitch.

As mentioned earlier in this thread I have also tried a diffent slicer, so it’s also not that  I’m running out of things to try so any further suggestions from anyonre would be greatly appreciated

I’m running out of things to try so any further suggestions from anyonre would be greatly appreciated

And sorry for the long post.

So, this is now confusing, I have replaced the relay and fitted a new Silicon heater back to the original setup, which ran perfectly fine for 2 years. And when I run the PID tuning cycle I now constantly get:

Warning: heater behaviour was not consistent during tuning

M307 H0 R0.779 K0.208:0.000 D5.70 E1.35 S1.00 B0

M307 H0 R0.776 K0.270:0.000 D5.24 E1.35 S1.00 B0

M307 H0 R0.789 K0.265:0.000 D5.85 E1.35 S1.00 B0

M307 H0 R0.779 K0.247:0.000 D5.35 E1.35 S1.00 B0

M307 H0 R0.778 K0.257:0.000 D5.49 E1.35 S1.00 B0

Could it be the heater output on the mainboard? Is it possible to use a spare extruder output as I’m running through a relay? To test.

Has anyone got any suggestions?

@o_lampe Thank you for pointing that out, I have ordered a new heater, and when it's been installed I will post back here the results hopefully it will cure the banding issue.

@Notepad Well, I have now changed the SSR, but I am still getting some fluctuation, but at least some are fault free. Here are the results:

M307 H0 R0.863 K0.260:0.000 D5.37 E1.35 S1.00 B0 XXXXXX

M307 H0 R0.875 K0.265:0.000 D5.36 E1.35 S1.00 B0 XXXXXX

M307 H0 R0.874 K0.346:0.000 D5.72 E1.35 S1.00 B0

M307 H0 R0.856 K0.307:0.000 D4.85 E1.35 S1.00 B0

M307 H0 R0.852 K0.301:0.000 D5.32 E1.35 S1.00 B0 XXXXXX

XXXXXX = Warning: heater behaviour was not consistent during tuning

My next step of thinking down this rabbit hole of fluctuation is, where I have used RTV to refix the silicon heater could the layer be too thick or uneven (It’s not easy stuff to work with) causing a slow transition of heat, resulting in a slow reaction that the PID loop is struggling with?

Does anyone know of anywhere in the UK, where I can get a good 330 x 330mm 240v high temp (I print a lot of ABS and the like) silicon heater. At a good price and quick delivery? As even Keenovo has started using a NTC 100K thermistor on there heaters which from what I understand can be a pain to setup and not that great for the higher temps.

@droftarts I know theres a better way of doing this but I'm not sure how

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; reconfigured HevORT V1 file for V2.8 on Sat Sep 14 2024

;

; Port Layout

; Mainboard Ext board

; 0.0 Extruder 1.0 Front Left

; 0.1 Y Back Left 1.1 Rear Middle

; 0.2 Y Front Right 1.2 Front Right

; 0.3 X Back Right

; 0.4 X Front Left

;

; General preferences

G4 S2 ; wait for expansion boards to start

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"HevORT" ; set printer name

M669 K1 ; select CoreXY mode

;

; Network

;M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

;M586 P0 S1 ; enable HTTP

;M586 P1 S0 ; disable FTP

;M586 P2 S0 ; disable Telnet

;

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards Extruder

M569 P0.1 S1 ; physical drive 0.1 goes forwards Y1 stepper

M569 P0.2 S1 ; physical drive 0.2 goes forwards Y2 stepper

M569 P0.3 S1 ; physical drive 0.3 goes forwards X1 stepper

M569 P0.4 S1 ; physical drive 0.4 goes forwards X2 stepper

M569 P1.0 S1 ; physical drive 1.0 goes forwards Z1 stepper on extension board

M569 P1.1 S1 ; physical drive 1.1 goes forwards Z2 stepper on extension board

M569 P1.2 S1 ; physical drive 1.2 goes forwards Z3 stepper on extension board

M584 E0.0 X0.3:0.4 Y0.1:0.2 Z1.0:1.1:1.2 ; set drive mapping

M906 X2096. Y2096. Z1179. E995.6 I30 ; set motor currents (mA) and motor idle factor in percent

M917 X70 Y70 Z80 E70 ; Set motor standstill current reduction

;M970 X0 Y0 Z0 E0 ; Enable/disable phase stepping

;M970.1 X1000.0 Y2000.0 Z1000.0 E1000.0 ; Configure phase stepping velocity constant

;M970.2 X50000.0 Y50000.0 Z50000.0 E50000.0 ; Configure phase stepping acceleration constant

M84 S30 ; set idle timeout

M671 X-28.0:168.35:364.7 Y40.0:348.8:20.0 S10. ; Z leadscrew positions

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.1 Y80.1 Z800.00 E394.00 ; set steps per mm

M203 X30000.00 Y30000.00 Z250.00 E1200.00 ; set maximum speeds (mm/min)

M201 X20000.0 Y20000.0 Z50.00 E500.00 ; set accelerations (mm/s^2)

M204 P10000. T10000. ; Max Acceleration

M566 X900. Y900. Z60. E120. ; set maximum instantaneous speed changes (mm/min)

M205 X15. Y15. Z1. E2. ; set working instantaneous speed changes (mm/sec)

M572 D0 S0.080 ; Preasure advance

;

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minimium

M208 X285.0 Y295.0 Z340 S0 ; set axis maximium

;

; Endstops

M574 X1 S1 P"!io0.in" ; configure active-high endstop for low end on X via pin !io0.in

M574 Y1 S1 P"io1.in" ; configure active-high endstop for low end on Y via pin !io1.in

;

; Z-Probes

; Probe 1 BL Touch

M950 S0 C"io7.out" ; create servo pin 0 for BLTouch

M558 K0 P9 C"^io7.in" H10 F300:120 T6000 ; set Z probe type to bltouch and the dive height + speeds

;M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P500 X0. Y-35.09 Z1.65 ; set Z probe trigger value, offset and trigger height

; Probe 2 Scanning Z probe

M558 K1 P11 C"120.i2c.ldc1612" F36000 T36000 ; configure SZP as probe 1, type 11, on CAN address 120

G31 K1 Z2.15 Y27. ; define probe 1 offsets and trigger height

M558.2 K1 S16 R134773 ; set drive current and reading offset

M308 A"SZP coil" S10 Y"thermistor" P"120.temp0" ; thermistor on coil

M955 P120.0 I56 ; Add accelerometer on SZP with CAN address 120 and specify orientation

M557 X10.0:275.0 Y35.0:285.0 S10 ; define mesh grid

;

; Heaters & Sensors

M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0 BED TEMP

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 R0.859 K0.301:0.000 D4.90 E1.35 S1.00 B0 ; BED HEATER PID SETTINGS

M140 H0 ; map heated bed to heater 0

M143 H0 S135 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as Termistor on pin temp1 EXTRUDER TEMP

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 R5.007 K0.417:0.603 D2.71 E1.35 S1.00 B0 V23.6

;M307 H1 R5.395 K0.416:0.839 D2.53 E1.35 S1.00 B0 V23.7 ; PID Tune

M143 H1 S300 ; set temperature limit for heater 1 to 300C

M308 S2 A"Chamber" P"temp2" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp2 CHAMBER TEMP SENSOR

M308 S3 A"CPAP Pump" P"temp3" Y"pt1000" R2200 ; configure sensor 0 as thermistor on pin temp3 CPAP TEMP SENSOR

M308 S11 Y"mcu-temp" A"MCU" ; defines sensor 10 as MCU temperature sensor MCU TEMP SENSOR

;M308 S12 Y"drivers" A"Stepper Drivers" ; defines sensor 11 as stepper driver temperature STEPPER TEMP SENSOR

;

; Fans

M950 F0 C"1.out3" ; create fan 0 on pin out3 on Expansion board PART COOLING FAN

M106 P0 S0 X180 H-1 ; set fan 0 value. Thermostatic control is turned oFF

M950 F1 C"out7" Q250 ; create fan 1 on pin out7 and set its frequency EXTRUDER FAN

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"!out5+out5.tach" Q250 ; create fan 2 on pin out5 and set its frequency MCU COOLING FAN

M106 P2 H11 T45:60 ; set fan 2 value. Thermostatic control is turned on

M950 F3 C"!out6+out6.tach" Q250 ; create fan 3 on pin out6 and set its frequency CHAMBER FAN

M106 P3 H2 T30:35 ; set fan 3 value. Thermostatic control is turned on

;

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

;

; Axis Correction

M556 S80 X0. Y0. Z0. ; Axis Correction

;

; Input shaping

M593 P"mzv" F45.0 S0.1 ; use ZVD input shaping to cancel ringing at 67.0Hz

; Shaping Options "none" "zvd" "zvdd" "zvddd" "mzv" "ei2" "ei3"

;M593 P"none" ; disable input shaping

;

; Custom settings are not defined

; LED Settings

;

;M150 X1 ; Set LED Type ( PRE 3.5.0 FORMAT)

M950 E0 C"led" T1 U32 ; create a RGB Neopixel LED strip on the LED port (3.5.0 FORMAT)

M150 R255 U255 B255 P200 S10 F1 ; Left side White

M150 R31 U81 B255 P220 S11 F1 ; Blue back

M150 R255 U255 B255 P200 S10 F0 ; Right side white

;

M950 E1 C"io2.out" T1 U10 ; create a RGB Neopixel LED strip in Electric box on the io2 port

M150 R255 U255 B255 P200 S10 F0 ; Left side White

;

; Miscellaneous

T0 ; Call T0

M501 ; load saved parameters from non-volatile memory

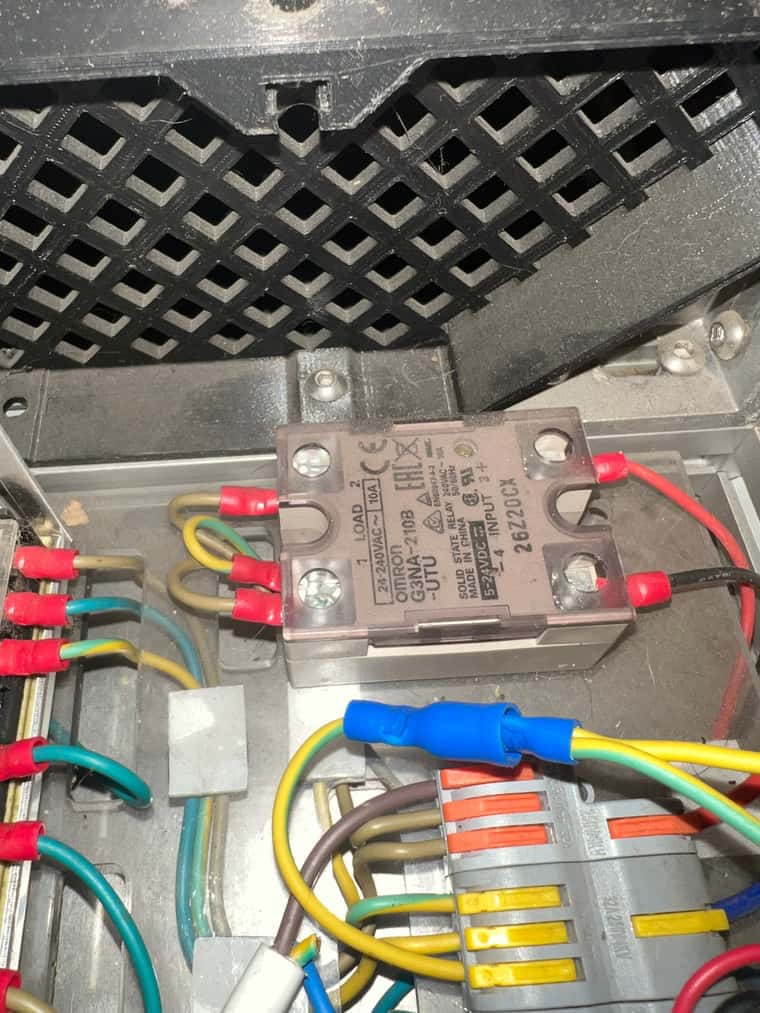

@Notepad Thank you for posting back to me, I am not fully clued up with electronics, but my understanding is from what your saying is that the heater seems ok, but it could be the relay starting to fail causing the control fluctuation.

I am not sure what you mean by fails deadly, I take it you mean open circuit? I am glad to say when I built the machine, I grounded both the metal bed plate and the relay down to the plug’s earth pin and not just the frame. I know not to take risks with the mains.

The pic shows the relay I am using to clarify, and if that is the case I will replace it before switching the printer on again.

@o_lampe I have tried a few different PA settings from 0.03 upto 0.08 and it had very little to no effect on the banding unfortunatly.