I've submitted a small fix to the Cura devs that stops the small line segments being created when you have curved walls lying immediately adjacent to each other and the overlap compensation is enabled. It should fix the project discussed above but doesn't really tackle the underlying problems that the overlap compensation has. Fixes are currently taking many months to get merged into Cura (assuming it is accepted) so don't expect the official releases to have this anytime soon. The next development version that I release will have this fix in it. See https://www.dropbox.com/sh/s43vqzmi4d2bqe2/AAADdYdSu9iwcKa0Knqgurm4a?dl=0

Best posts made by burtoogle

-

RE: Movement is stuttering. Appears to slow printing downposted in Tuning and tweaking

-

RE: My Experience with Relative extrusion (Problem and Solution)posted in General Discussion

This is a very common problem. Even when using absolute extrusion, low extruder resolution (steps/mm) causes serious quality issues. Using 2.85mm filament makes it even worse. People expect to be able to print tiny thin lines using weeny layer heights and wonder why the result is all lumpy or even missing completely.

Actually, RRF/DWC could report when G1 lines are asking for such small extrusions that the quality will be affected. It would be quite nice if the GUI displayed a red symbol when that situation is detected.

-

RE: [feature request] Air pressure advanceposted in Firmware wishlist

Perhaps it is better to implement fan look ahead in the firmware, I don't know. In the meantime, if you use Cura, install one of my builds and there is a setting (Cooling Fan Lag) that controls fan look ahead for feature specific fan speed changes (bridging, skin over support, etc.). You can find my builds at https://www.dropbox.com/sh/s43vqzmi4d2bqe2/AAADdYdSu9iwcKa0Knqgurm4a?dl=0 and they can be installed alongside the UM releases. Please read the README.md at the above location if you wish to give it a go.

-

RE: Trouble with poor extrusion on cylindersposted in Tuning and tweaking

Thanks for the gcode, in Cura, set Minimum Wall Flow to something like 20 or 30. That should help.

-

RE: Duet Slicer Integration?posted in Duet Web Control

In case you are interested, you can find armhf builds of my Cura development releases that will run on Buster at https://www.dropbox.com/sh/s43vqzmi4d2bqe2/AAADdYdSu9iwcKa0Knqgurm4a?dl=0

As you would expect, performance isn't stellar but it is actually usable. All the normal functionality is there apart from the fact that the layer display is using compatibility mode due to the legacy OpenGL support available on the Pi 4.

-

RE: Which Slicer?posted in General Discussion

Hi, here's my 2p worth… I have used slic3r, S3D and Cura.

I am currently using Cura more than anything else. I like the fact that it has zillions of settings and even more, as a programmer, I like the fact that it is possible to wade into the source and fix bugs, add features, etc. With my single extruder Kossel XL, I am getting some really nice prints using Cura. Although the Cura devs are focused on the Ultimaker machines, they do encourage contributions from the community that enhance the software for other printers. I think for the price (free), it's really very good.

Before I moved to Cura, I used S3D and it does produce some really nice looking prints but I find the way it is configured just doesn't suite me. It also has some annoying problems which the S3D devs seem unwilling to fix.

I haven't used slic3r for a while but I started with that and it worked well at the time. I do remember it being rather slow to process complex models.

-

RE: Retraction Tuning Guideposted in Tuning and tweaking

@ricky_grade10 said in Retraction Tuning Guide:

@phaedrux said in Retraction Tuning Guide:

printer settings plugin

I Installed the plugin but Im not sure what to do beyond that with cura. Whats next with the plugin?

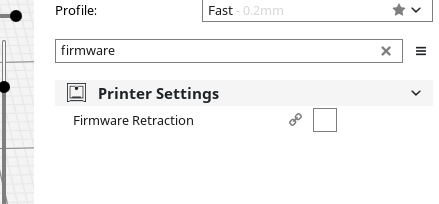

Type "firmware" into the setting search box and it should show you the setting which you can then set to true.

-

DWC 2.0.0 no longer shows "print another" buttonposted in Duet Web Control

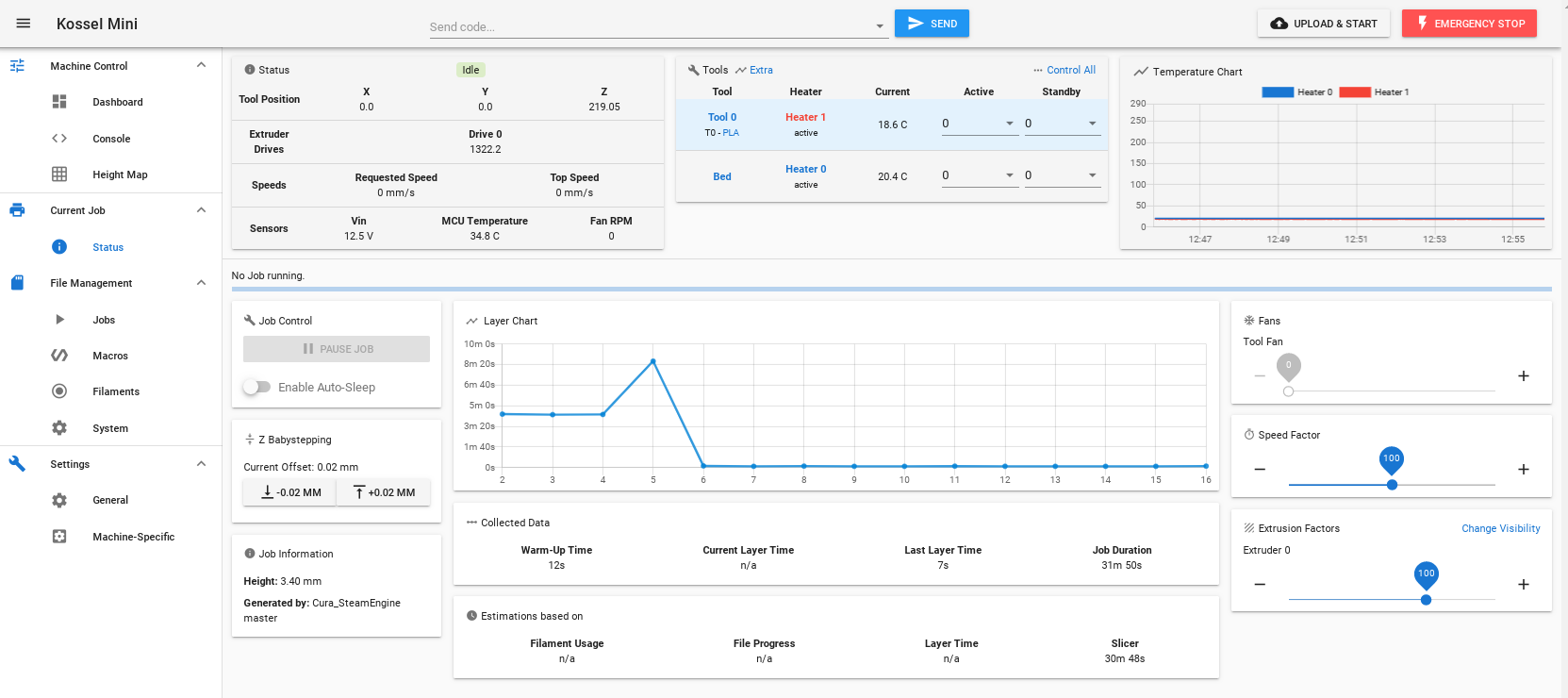

I mentioned this in another thread but that didn't elicit any response so here we go again. I recently upgraded from 2.0.0-RC7 to 2.0.0 and notice that the button to print another is no longer shown when the job completes. I am using a recent Chrome release. Here's a typical screen shot after a job has completed.

-

RE: Which Slicer?posted in General Discussion

BTW, I recently discovered that although the Duet is happy with just having the M82 in the start code to select absolute extrusion mode, it's also a good idea to also have G92 E0 to reset the length extruded so far to zero. This is because some non-Duet printers (e.g. Marlin based machines) seem to fail to zero that when a print is started and so the extruder gets very confused on the second print of the day!

-

RE: Retraction Tuning Guideposted in Tuning and tweaking

@phaedrux said in Retraction Tuning Guide:

@burtoogle seems so. I don't tend to use the betas. Experimental features is as far as I'm willing to go. But glad it will become widely available. Though I still think firmware retraction belongs in the main settings.

Thanks for the heads up.

FYI Cura 3.4 has been released today.

-

RE: New Product Release - Precision Piezo Orionposted in Third-party add-ons

Hello @pogo1213 . Is it the Orion groove mount STL you want? If so, I can provide that and also a modified version that I am currently using because the original did not fit well and was also too flexible.

-

RE: Determine real nozzle diameterposted in General Discussion

You should be aware that one of Cura's limitations is that it doesn't do thin walls at all well. This is because all walls are printed with two lines (the outside perimeter and the hole inside it. It does have what is known as "overlap compensation" which tries to reduce the flow for wall lines that don't actually fit in the space that is available. So, in theory, when you have a wall that is only as wide as the line width (note, not the same as the nozzle width), one of the lines will be printed using the normal line width and the second wall should be flow reduced down to nothing. Unfortunately, the overlap compensation part of Cura is very flawed and so the result is a bit hit and miss.

-

RE: New beta firmware 2.02beta1posted in Firmware installation

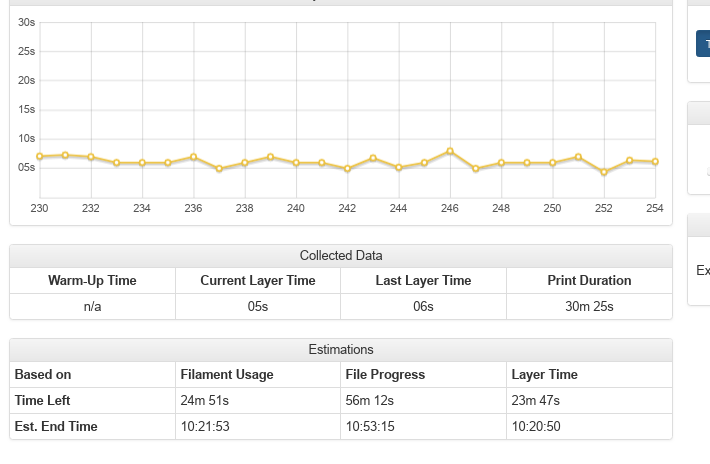

And now, a couple of minutes later...

I know! you're using the same algorithm as was used in the Windows copy file utility, the estimated completion time in that used to go up and down like a yoyo!

-

RE: Tuning for smooth extrusionposted in Tuning and tweaking

If the extruder isn't geared, the steps/mm value is going to be quite low and, therefore, the resolution of the extruder is going to be low. I think this can cause quality issues, especially when using relative extrusion and made even worse if using 2.85mm filament.

-

RE: Determine real nozzle diameterposted in General Discussion

Small holes are particularly problematic because the inside and outside radii of the wall differ so much. It effectively overextrudes inside of the wall's centre line and underextrudes outside of that centre line. I can't remember who did the work now but years ago someone came up with a scheme whereby the number of points used for the wall of a circular hole would reduce as the hole diameter got smaller. For really small holes, the wall ends up having just 3 points (i.e. it's a triangle). Holes a little larger have 4 points, and so on. It actually worked pretty well.

Here's the scad that does this:

module polyhole(h, d, taper = 1) { n = max(round(2 * d),3); r = (d / 2) / cos (180 / n); rotate([0,0,180]) cylinder(h = h, r1 = r, r2 = r * taper, $fn = n); } -

RE: Movement is stuttering. Appears to slow printing downposted in Tuning and tweaking

Thanks @asdasd1234 for the comprehensive report and photo. The results are pretty much what I was expecting.

So, the problem is that Cura is generating a mishmash of line segment lengths for the inner walls. The Duet's pressure advance doesn't like that and the result is poor print quality and slowness.

Unfortunately, I do not have a fix for the non-uniform line segment lengths yet but will continue to work on it and will come back to this topic if I make any progress. Fingers crossed.

-

RE: Why don't you use Cura slicer?posted in General Discussion

@dalton said in Why don't you use Cura slicer?:

- No slowdown when printing bridges.

- Too much options.

1 - the options are there to slow down the walls and/or skin when printing bridges.

2 - there's lots of options right now because they are experimental! When we know what is useful and what isn't perhaps the number of options can be reduced or set to good default values. However, as what is a good value for speed/flow/fan, etc. differs from material to material so it's unlikely that all of these options can have defaults that work for all materials/printers/models.

-

RE: Help on setting firmware retract pleaseposted in Tuning and tweaking

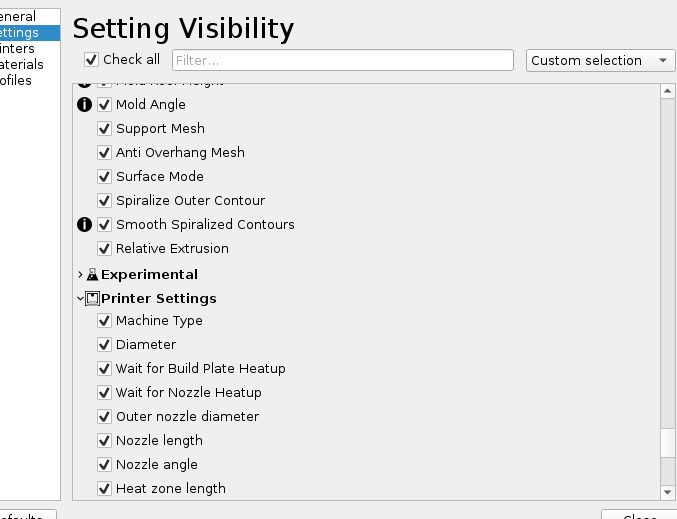

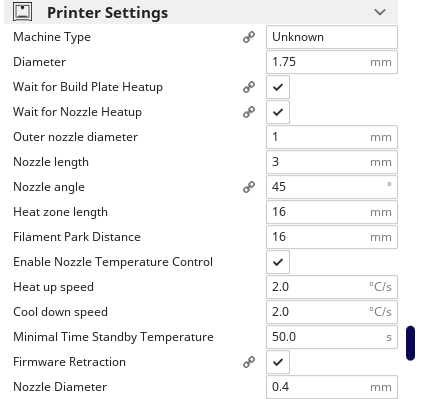

Hello @pro3d . You have to restart Cura after adding a plugin. You should then see Printer Settings in that dialog. Like this...

With the settings made visible you can then access the firmware retraction setting over in the profile...

Don't forget to configure the firmware retraction settings in your Duet's config.

I have only recently started using firmware retraction. One thing I realised is that Cura will still control extra prime and z-hop independently of the M207 setup. So you must set z-hop and/or extra prime to zero in either the Cura profile or the M207 otherwise you will get two lots of z-hop or extra prime. I have chosen to keep the z-hop and extra prime in the Cura profile and use M207 Z0 R0.

On the Duet I have configured a couple of macros to support different materials so I can select retraction distance for flexibles or other filament types.

-

RE: Why don't you use Cura slicer?posted in General Discussion

@wilriker said in Why don't you use Cura slicer?:

The only thing I am missing right now is a feature that I found in ideaMaker and liked a lot: change any setting at a given Z-height. Cura allows to change a few settings through built-in post-processing but I would like to have at least the option to change arbitrary settings. One use-case I had in the past was that I wanted to print a model with low infill at the bottom and 100% infill at a specific area that needed maximum rigidity - possibly but not necessarily going back to a lower infill further up.

This is possible via the use of infill meshes. You can change all infill parameters for an arbitrary region within a model, I use that for reinforcing areas around holes like this example: