Build Plate was completely rebuilt. Stock build plate was a piece of boron glass (I believe) with four studs glued on. It used a 24VDC heater pad that would barely get to 45˚C. Scraped that (well, just put it in a dark corner for now).

The new build plate is a 1000W 120V Keenovo sandwich topped with a layer of 1/4" tempered plate...

The 5mm silicon foam does wonders for the heating ability. It's hard to believe this is not standard on new printers.

The 1/4" glass is overkill and quite heavy. Upon the finish of my first print on it the build plate costed all the way to the bottom - very strange. I found that I had been using M84 in the post process script of the slicer. Changing it to "M84 X Y" should solve the Z motor idle hold from turning off.

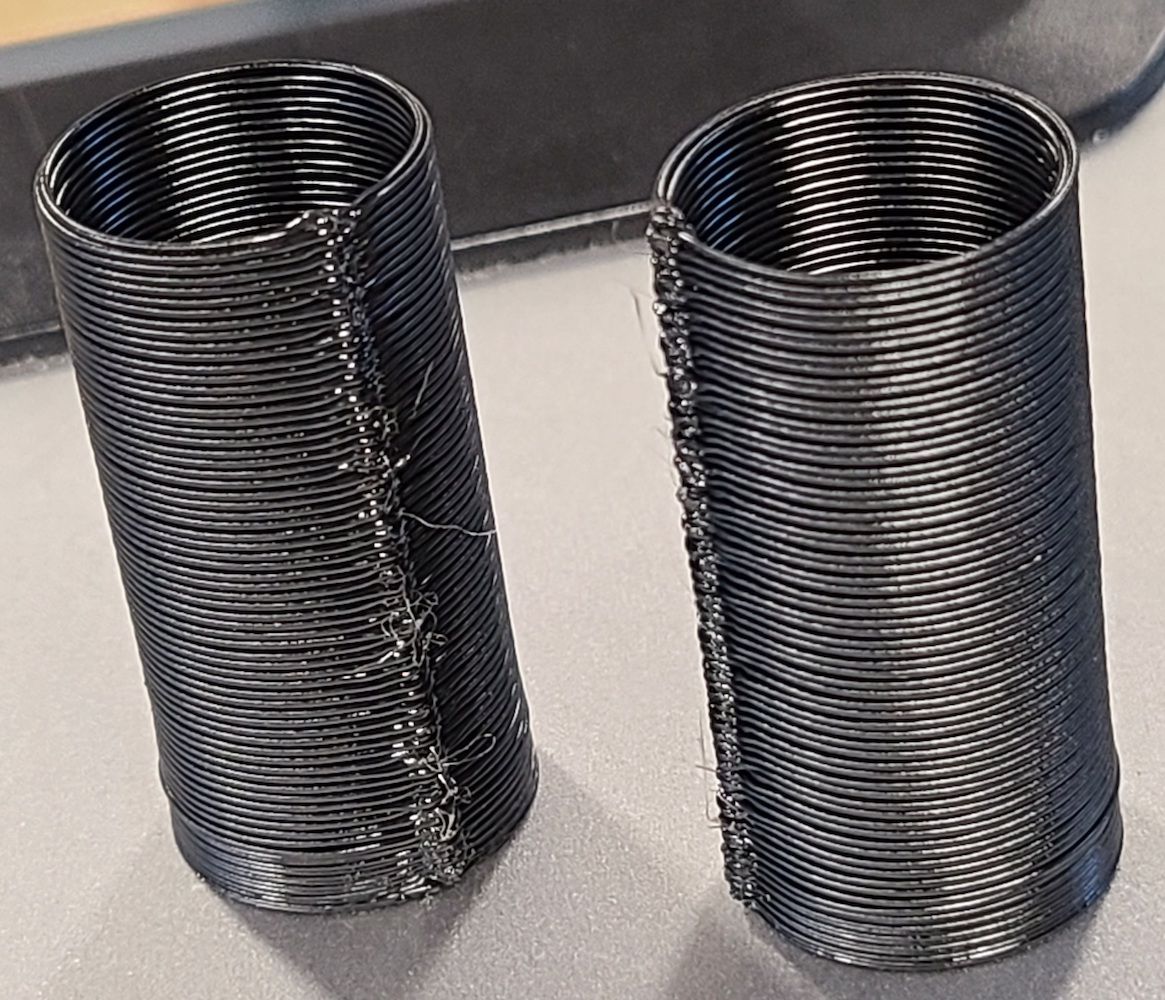

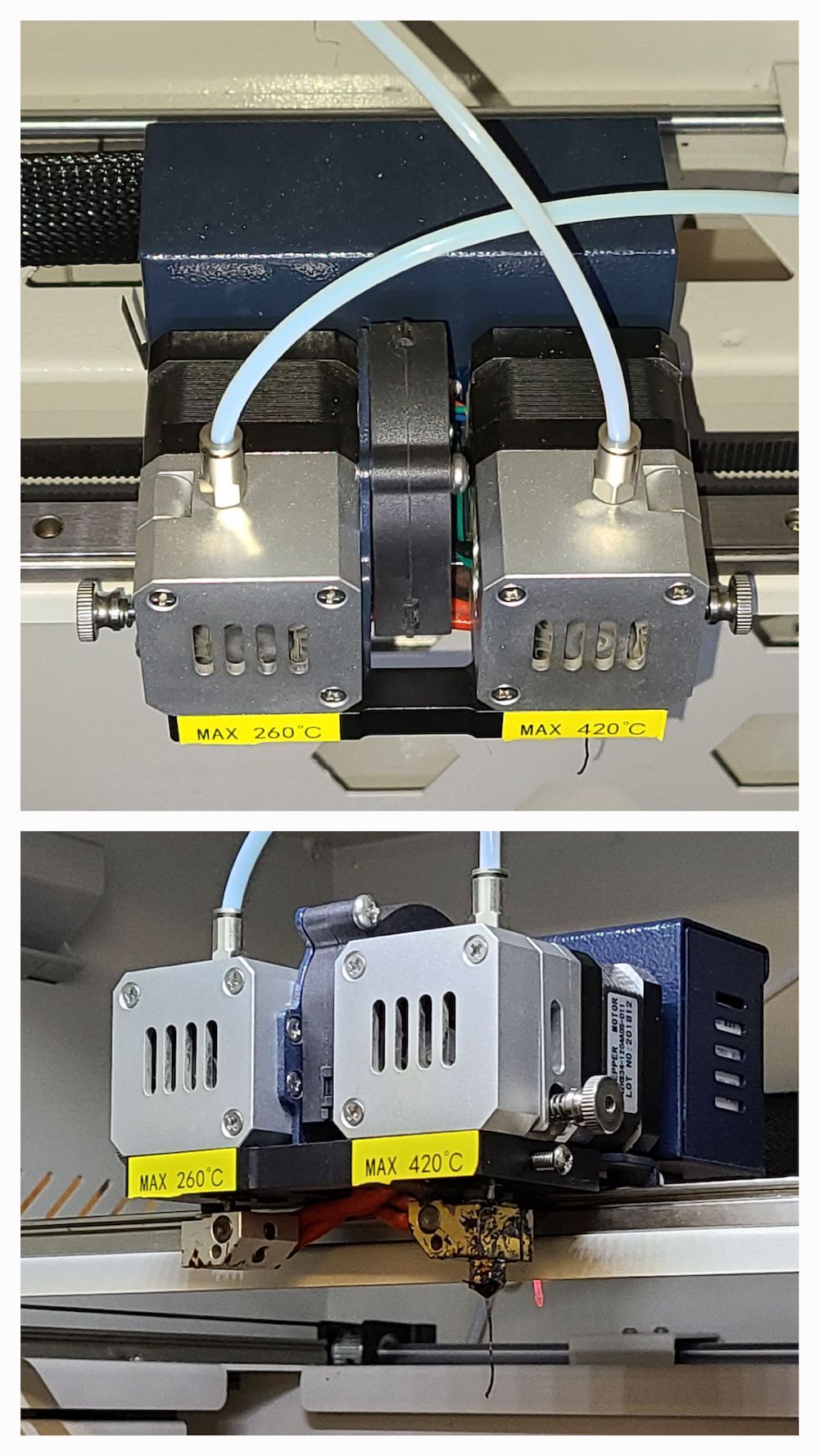

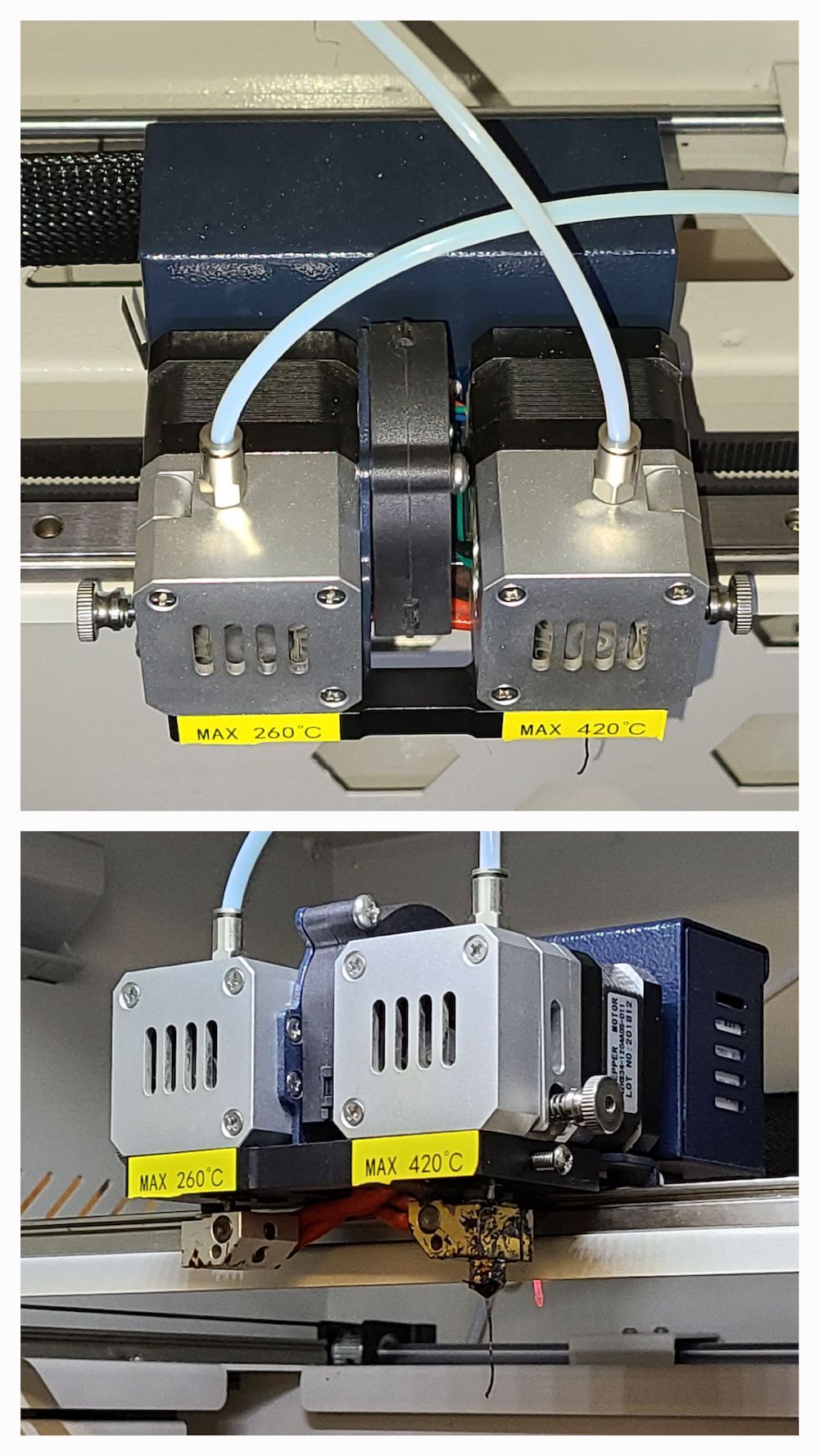

Stock print heads is what got me thinking that an update might be possible. Problem was that I was getting heat creep as the little fans were poorly implements and starved for air. I couldn't heat the chamber and keep the filament from jamming on certain filaments. Here is a picture of the stock heads.

Very nicely built but not as functional as I would have liked.

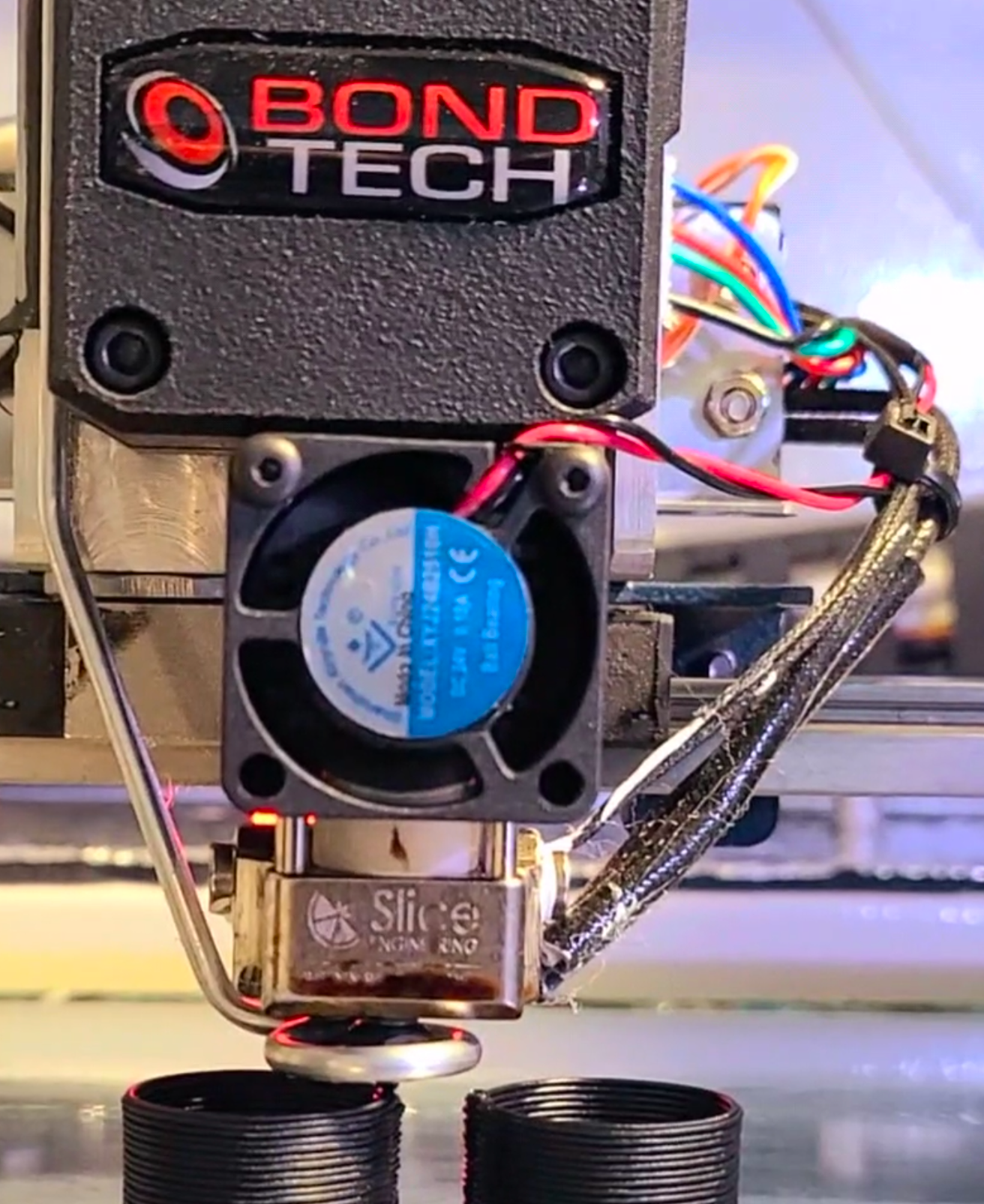

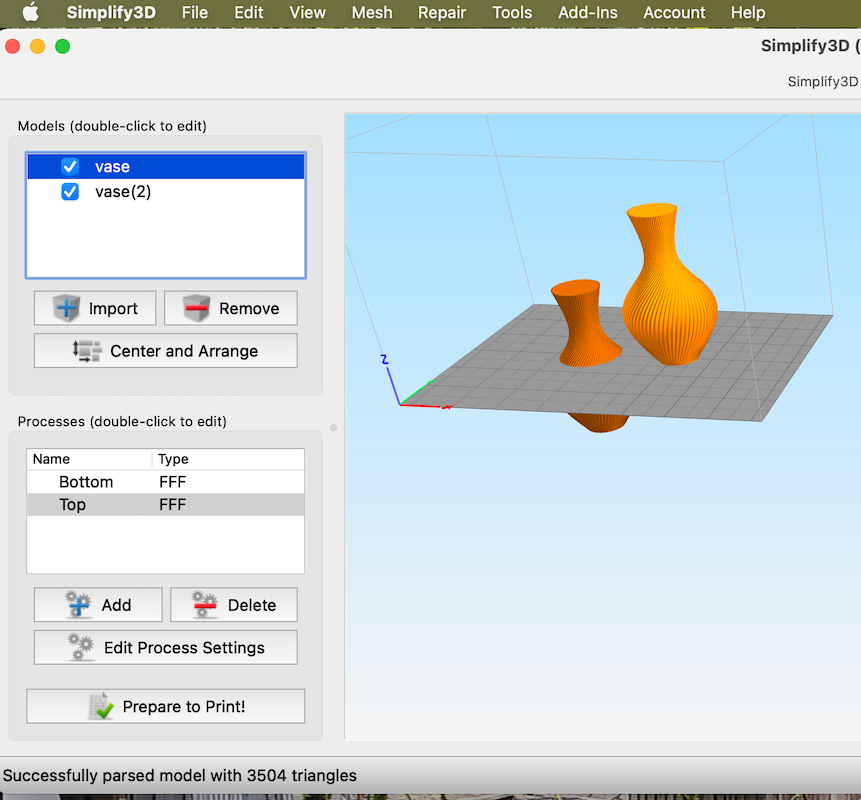

Since I ever only used one head, that is what I switched to...

So far I like the mosquito and BMG extruder. If I have trouble with heat-creep again the next step would be to convert to water cooled which should be fairly easy since mosquito make a water cooled version of what I have here. So it would just require one part plus the water.

Well that's about all I have to say about that subject.

Have a blessed Independence Day celebration

----(for my friends in the USA)