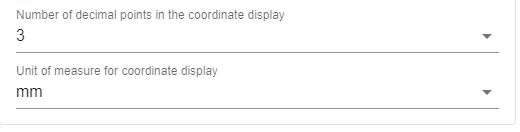

that only works for X and Y, how can i get 3 decimals for z ?

that only works for X and Y, how can i get 3 decimals for z ?

this is very odd

i flashed firmware 3.4.6 and dwc 3.4.6 and the www files that match

now it homes perfect

did not touch the config

@droftarts said in trouble with sensorless homing:

You’re using the web interface from RRF 1.x/2.x with RRF 3.4.6? I’m amazed that works at all!

will check that

i had trouble updating with the normal procedure, had to use fallback method number 1

but maybe its related

@droftarts ahh....

BIG box with this text:

This version of the Config Tool is still under development. If you encounter problems, please consider using the previous Config Tool instead.

so partly error 40

@droftarts it gets to the end but does not stop... hence a lot of "brrrrrr"

will try and experiment a bit

i started using it yesterday so it was not in the cache before that

EDIT: i did a ctrl+f to open a search window... no M906

but yeah i can copy it from config tool and insert as cutom command in the config tool and it gets written

odd i know

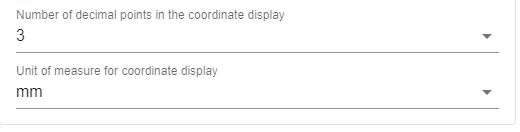

i tried this in homex.g and now the error is gone

; homex.g

; called to home the X axis

;

M400 ; Wait for motion to stop

G91 ; Use relative moves

G1 H2 X0.01 ; Move X a small amount to enable

M400 ; Wait for stop

G4 P200 ; Delay to allow TMC to detect stopped state

M915 P0 S1 H250 R0 ; Configure stall detect

M574 X2 S3 ; Configure X endstop

M913 X30 ; Lower X power

G4 P200 ; Delay to ensure settings are made

G1 H1 X-20 F2000 ; back away from endstop

M400

M915 P0 S5 H250 R0 ; Configure stall detect

G4 P200

G1 H1 X230 F2000 ; Move towards endstop until it stalls

M400 ; Wait until all stopped

M915 P0 S1 H250 R0 ; Configure stall detect

G4 P200 ; Delay to ensure settings are made

G1 H1 X-10 F2000 ; back away from endstop

M400

M915 P0 S5 H250 R0 ; Configure stall detect

G4 P200

G1 H1 X230 F2000 ; Move towards endstop until it stalls

M915 P0 S18 H250 R0 ; Configure stall detect to be less sensitive

G1 X1 F1000 ; Move away from stop and clear stall

M400 ; wait complete

G90 ; Absolute positioning

M913 X100 ; back to full power

;M915 P0 S20 H200 R1 ; Report any stalls

it sets X to being at ~491 dot something but it does not stop so a lot of "BRRRRRRRRRRR" at the endstop (or where it used to be)

I have now gotten so far that i can home the nozzle arround and control fans and heaters

thought the next would be sensorless homing

i have looked at my settings i had on a re-arm+sbc combo as a staring point but no dice

config.g and homex.g attached

it does move towards the end, and then back and then towards the end again, i have tried with as low as 20% motor current.... still no luck

Firmware Name: RepRapFirmware for Duet 2 WiFi/Ethernet

Firmware Electronics: Duet WiFi 1.02 or later

Firmware Version: 3.4.6 (2023-07-21)

WiFi Server Version: 1.27

Web Interface Version: 1.22.6

Board: Duet2 wifi

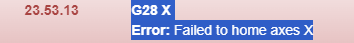

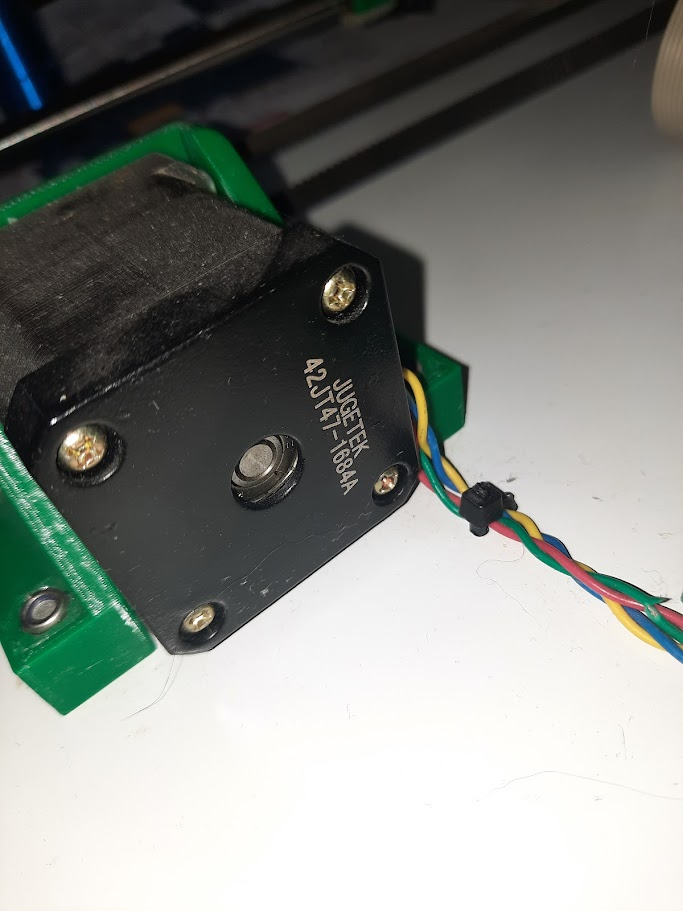

my steppers are all these

i run at 24V

https://docs.duet3d.com/User_manual/Connecting_hardware/Sensors_stall_detection#table-of-features

says it does not support stealthchop... hence i have set to spreadcycle

but i swear i read somewhere one was suggested to use stealthchop and it worked, but i trust the table until fold otherwise

i just found out that the config bundle is not correct

in the tool when i look at motor currents it says

; NOTE: This is later generated in the Axes and/or Extruders section

M906 X1400 Y1400 Z1400 E1200 ; set motor driver currents

but that is nowhere to be found in the generated config.g hence nothing will move

Fallback procedure #1 worked.... no idea why the normal procedure did not work

i just got a 2nd hand duet 2 wifi... created a new sd card from https://github.com/Duet3D/Duet-2-Hardware/tree/master/Duet2/SD Card Contents

then i got wifi connected and wanted to update firmware pr https://docs.duet3d.com/User_manual/RepRapFirmware/Updating_firmware#usual-procedure

it does upload the Duet2and3Firmware-3.4.6 zip file and ask if i want to update... i say yes but then in console i get Error: M997: File 0:/firmware/DuetWiFiServer.bin not found

do i have to rename something? the file is in the zip

nice link

i would glue the thermistor to the underside thou as it would be hotter than the top of the chip

has there ever been made FLIR pictures of the duet in action?

Hi

I tried to search a bit for my question but came up empty

Would it be possible to only run the fans when either heaters are active or when steppers are enabled plus 3 mins after they go off?

Or is that what popint 20 in the wishlist is about? https://www.duet3d.com/forum/thread.php?id=961&p=1

What happens with ideas that made it to the list but got no votes?

will they stay for a next round of voting?

you are right

the mk42's are matt black and the PEI is put on top

i too will end up with the mini ir, i assume that the duet will make use of the analog output

"no firmware other than RRF has supported any form of skew compensation"

Repetier does, but also has to be done manual

Q…. Would the mini IR board be a batter choice here? and how well would it work on that black matt surface with PEI sheet on?

"with specific hardware ( Prussia i3 mk2)."

what about others users with the same bed but not the same printer?

agree that it could be placed somewhat down the list and maybe be expanded to compensate for other than XY skew if possible

Consider: Use Stallguard to perform bed levelling/compensation.

that would only work where the Z steppers are able to push the nozzle down

if the X ends rest on Z isolators there will be no resistance when the nozzle touches the bed, but maybe the load will lighten enough that you can say that you are at the bed

"Prusa system does Need a specific Bed with the sensor points in it"

Yep or almost yes… it needs a bed with 9 points that triggers the probe, probe must not be triggered outside these points. other than that there is not so much special about it other than it has zoned heating so that the heat is more unitform

"I to prefer to make sure my Printer is as Accurate as possible" same here, but i might have bad tools or screwing up something so its less precise. having an option to be told you did a bad job on the frame and by this much would help. If i get it right hurra, but if i just cant get it spot on then i might have to bite the dust.

but as said above it could be a selling point, but as I said it should sit on the bottom of the list

And if at all possible it should of course be expanded so its dealing with more than just XY skew, and it should of course be possible to totally disable it for those that do not need or want it