@jay_s_uk yeah you are right this might be more of a firmware thing.

So there aren't any hardware limitations to this? I might try to tackle it myself then.

@jay_s_uk yeah you are right this might be more of a firmware thing.

So there aren't any hardware limitations to this? I might try to tackle it myself then.

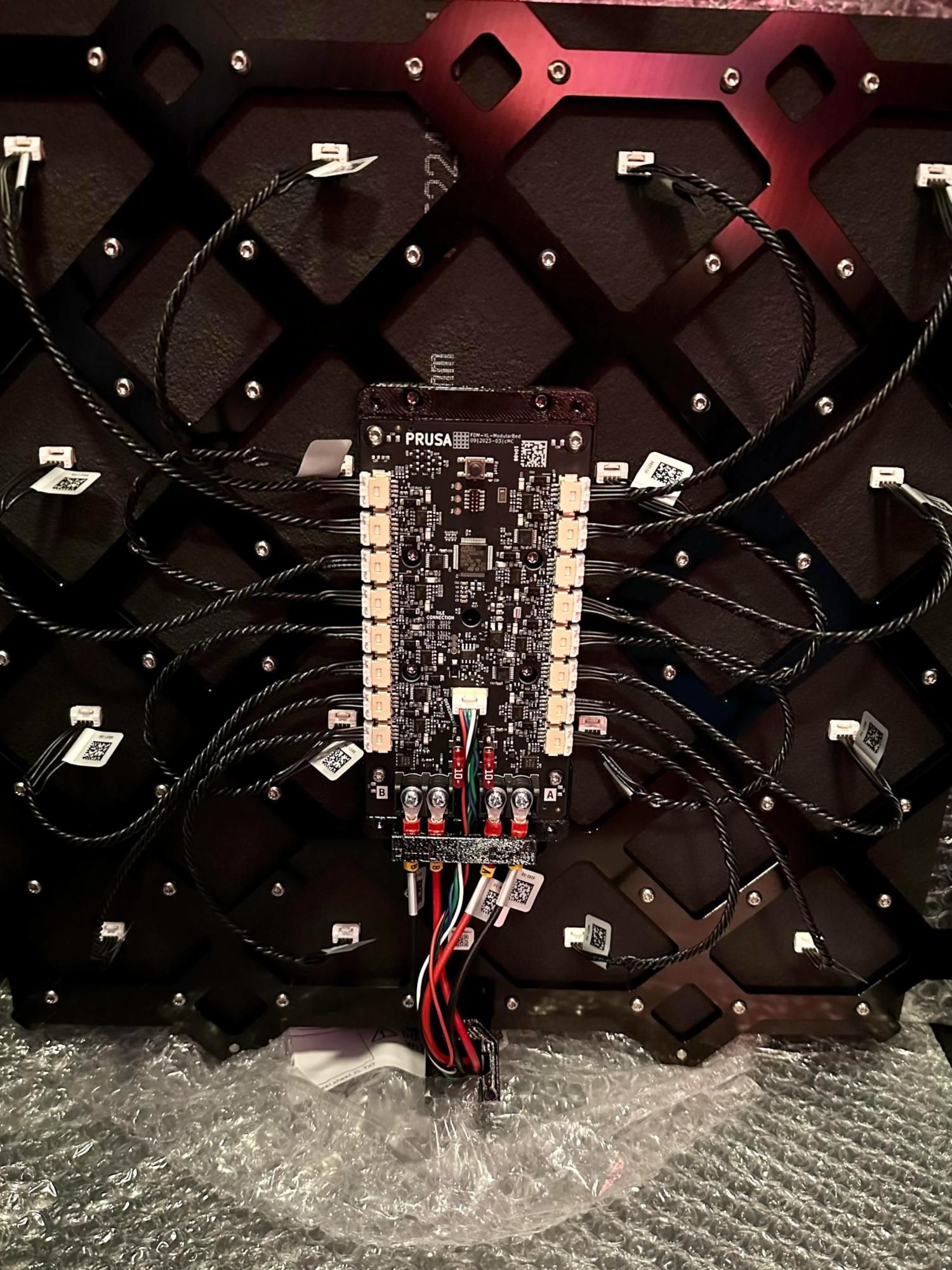

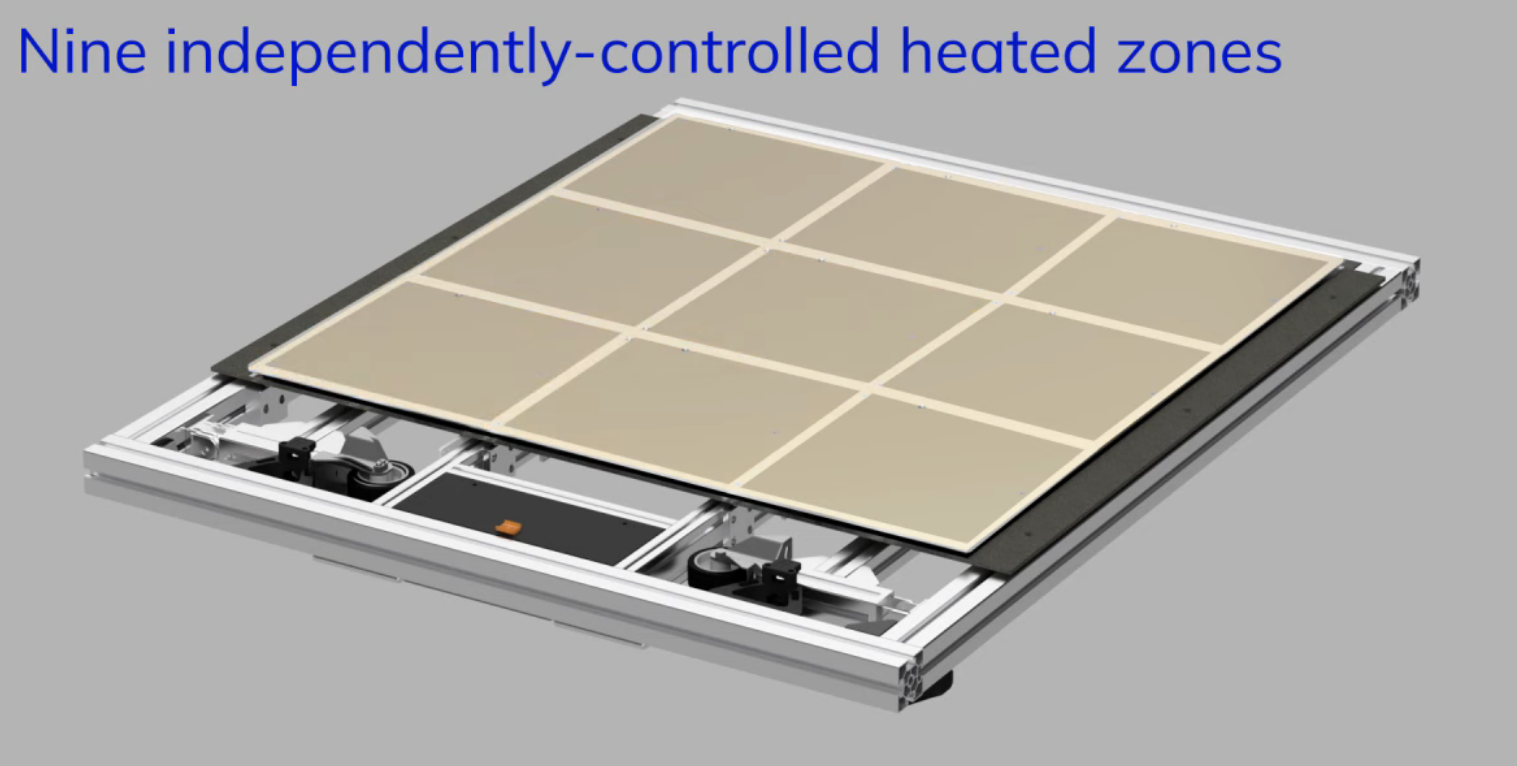

Is there an easy-ish way to run a heater bed with multiple heating elements and then just turn on whatever part of the bed is needed?

Like what the Prusa XL does?

Would be neat for big printers.

@fcwilt the motors run better at 60V when you push it

@T3P3Tony true, the board being 24V max is what keeps the size down (and the board is pretty big already)

one solution might be a double sided PCB and perhaps moving away from the "sticks to a stepper" design (which is weird anyway since most of the nice new extruders use pancake steppers anyways...)

@o_lampe Yeah that's a possibility too (maybe even a superior from engineering standpoint I know there were some hotends that used dual cartridges for more even heating of the nozzle).

But people should know that before starting this thread I did message a few sellers on a famous Chinese B2B marketplace and some do sell 48V versions and the rest was like "we can customise whatever you like". So the whole "heating cartridges are only 24V" is a moot point.

these "nooo 24V is the standard no progress must be made!" and "there aren't any 48V heater cartridges anyways" arguments are pointless since

A) having one voltage for all boards and being able to use just one power supply for the DC side is without a doubt the best engineering solution

B) there are 48V heater cartridges just because printing shops don't sell them (chicken and egg problem) doesn't mean progress can't be made

So all in all anyone from Duet cares to chime in and point any real engineering reason why this board couldn't run at 48V?

I had a quick glance at the schematics and the 12V side (TS30041-M000QFNR) can run only at 40V (42V) max. So I guess that's the reason? I can't seem to find any 1:1 replacement chip that would support 48V so a complete redesign of the 12V side would be required?

(I've searched a bit more and the TS30041 is the same chip previously used on the Duet3D. So I would bet this was solved already.)

@T3P3Tony Ah, I'll be visiting Formnext this year so we can talk there and arrange shipping if needed.

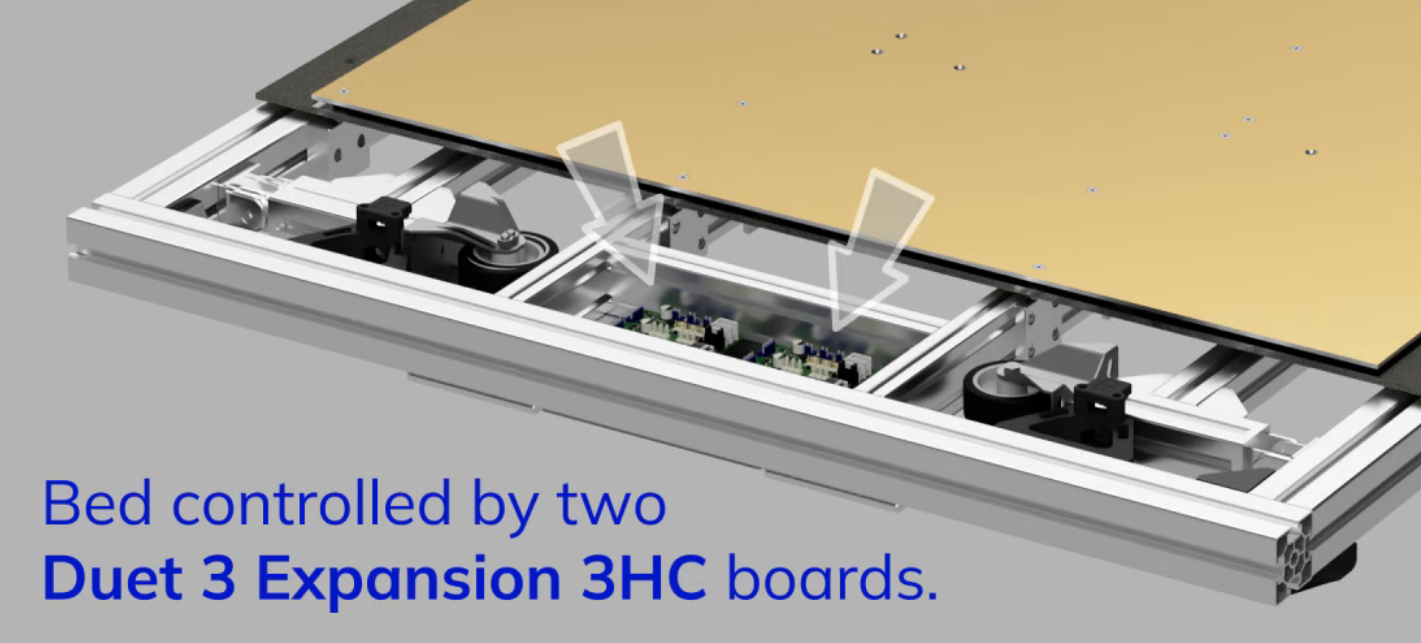

@dc42 So AC SSRs connected to the 3HC PWM outputs? How were the segments controlled? Was it automatic or do you have to manually choose what segments to heat?

I mean this was made by you (Duet3D).

Any documentation to go with it?

How were the 3HC board connected to the beds? I mean each 3HC only has 3 high amps outputs but that bad has 9 segments?