Hello everyone,

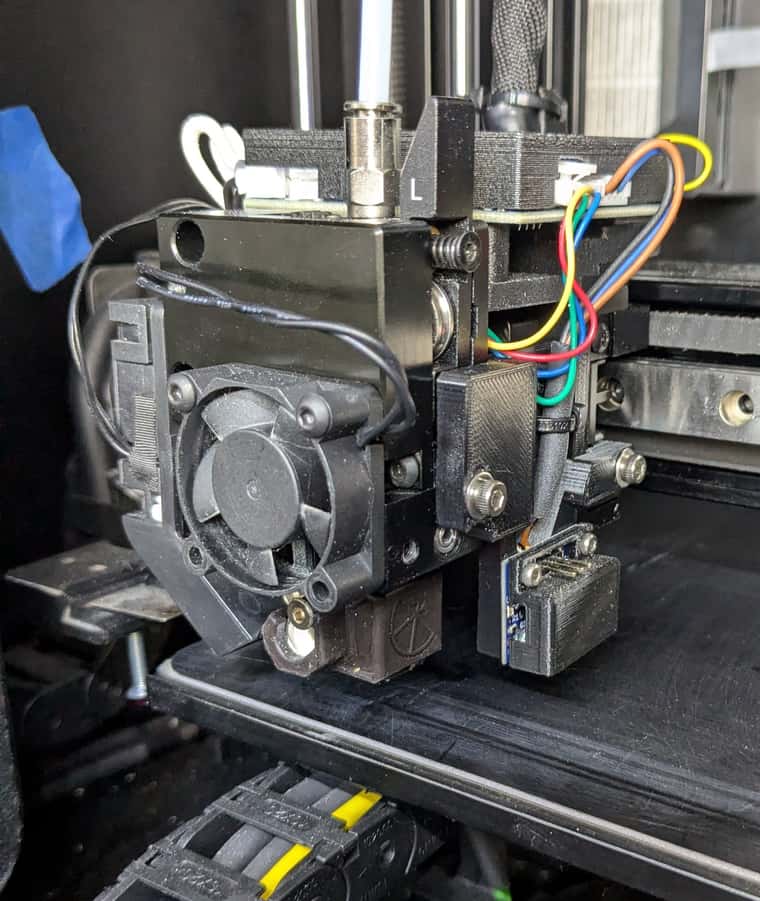

I have converted my Raise3d E2 to a Duet mini5 and 2 LC1 Toolboards and IR Z-Probe and have 2 problems that I cannot solve.

I would like to describe problem 1 here and I will open a new entry for the second. Link to problem 2

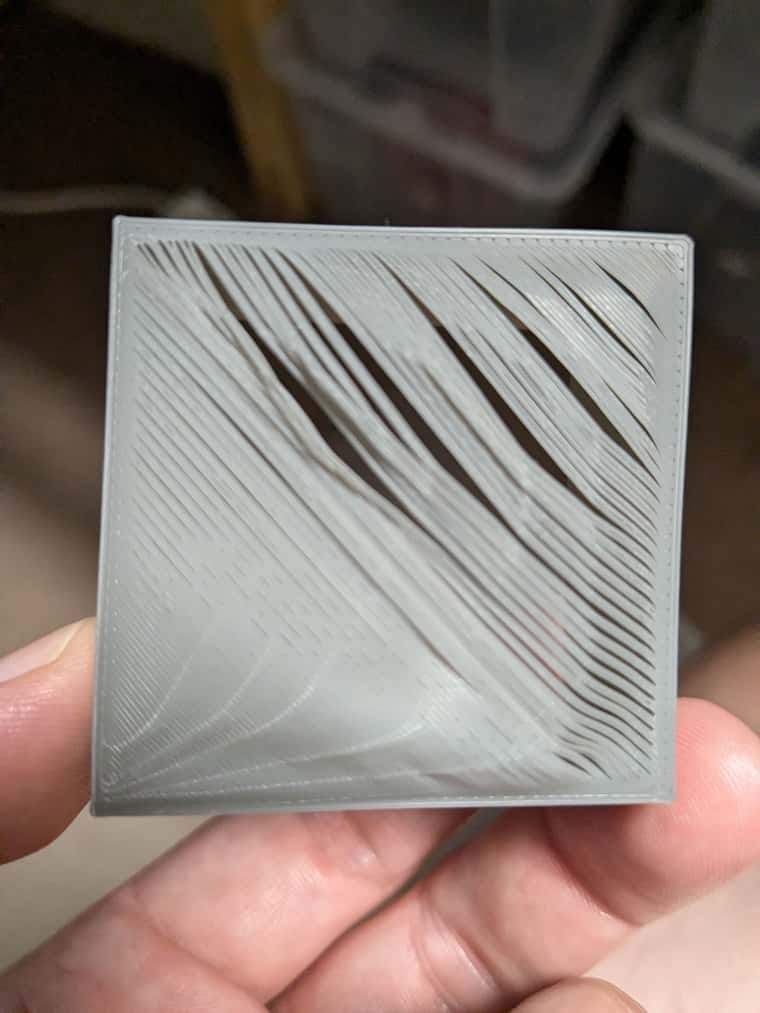

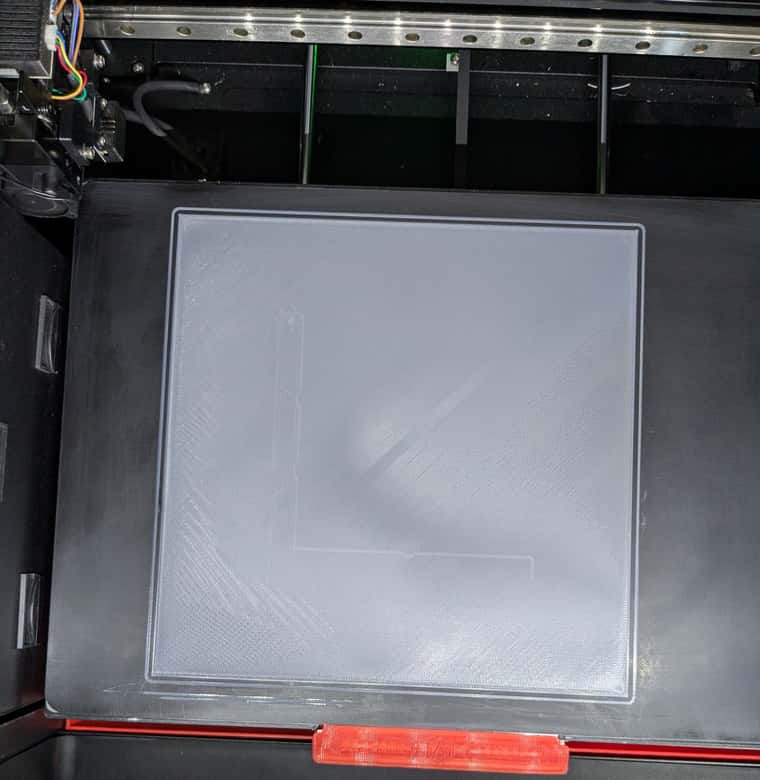

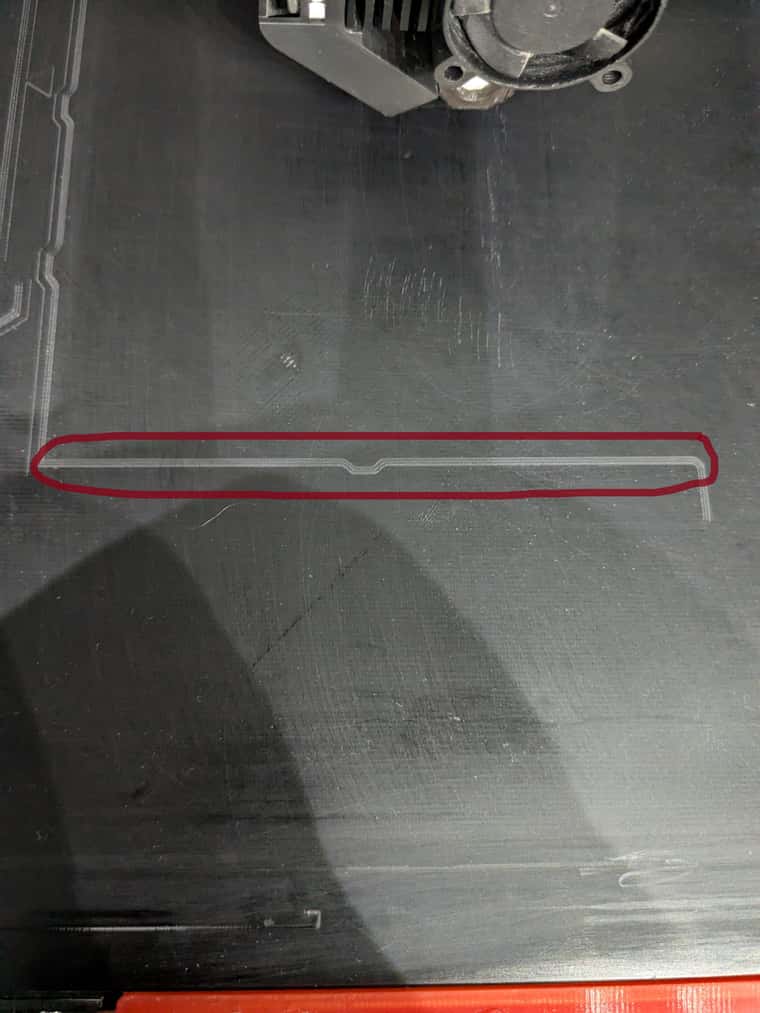

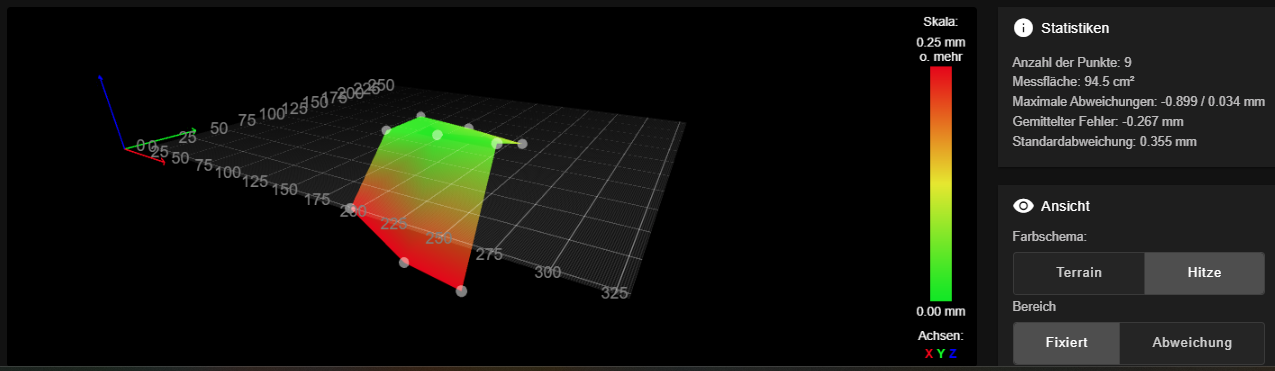

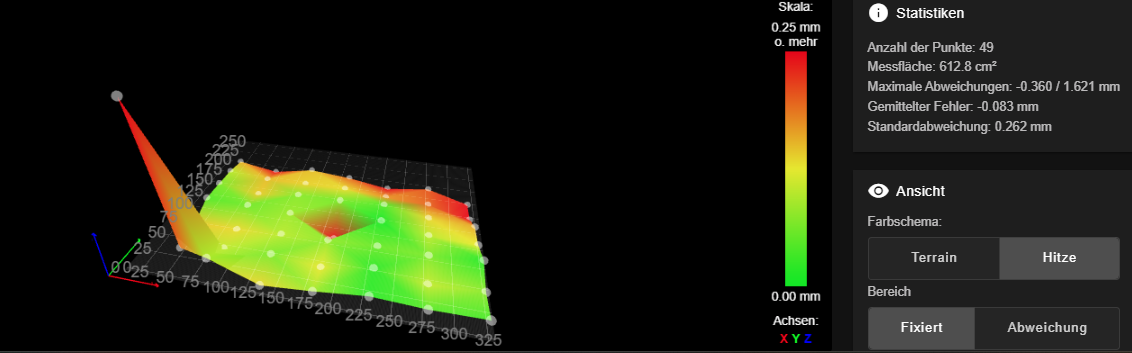

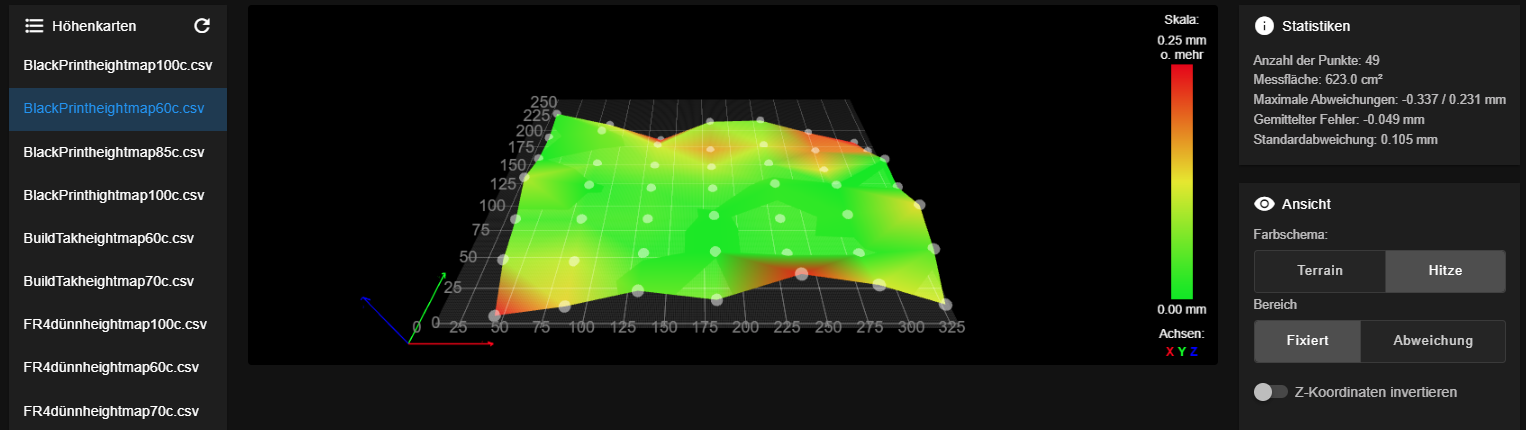

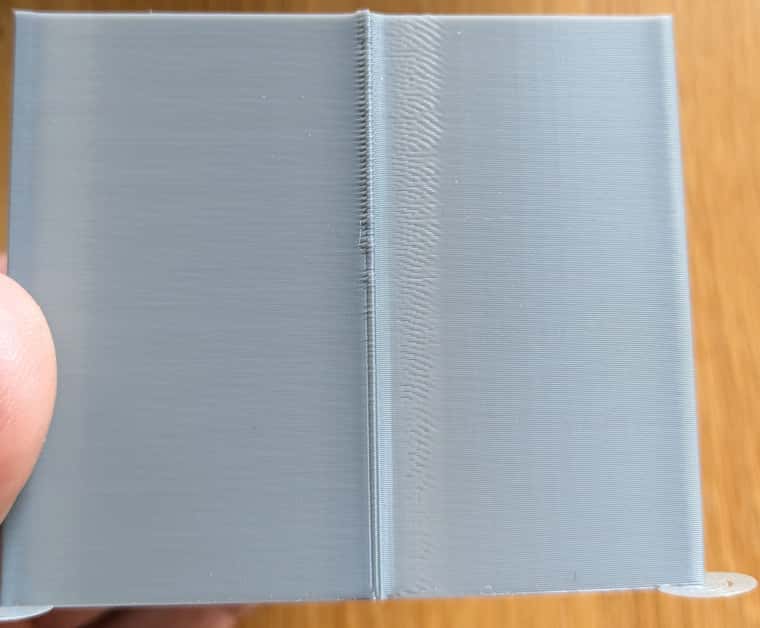

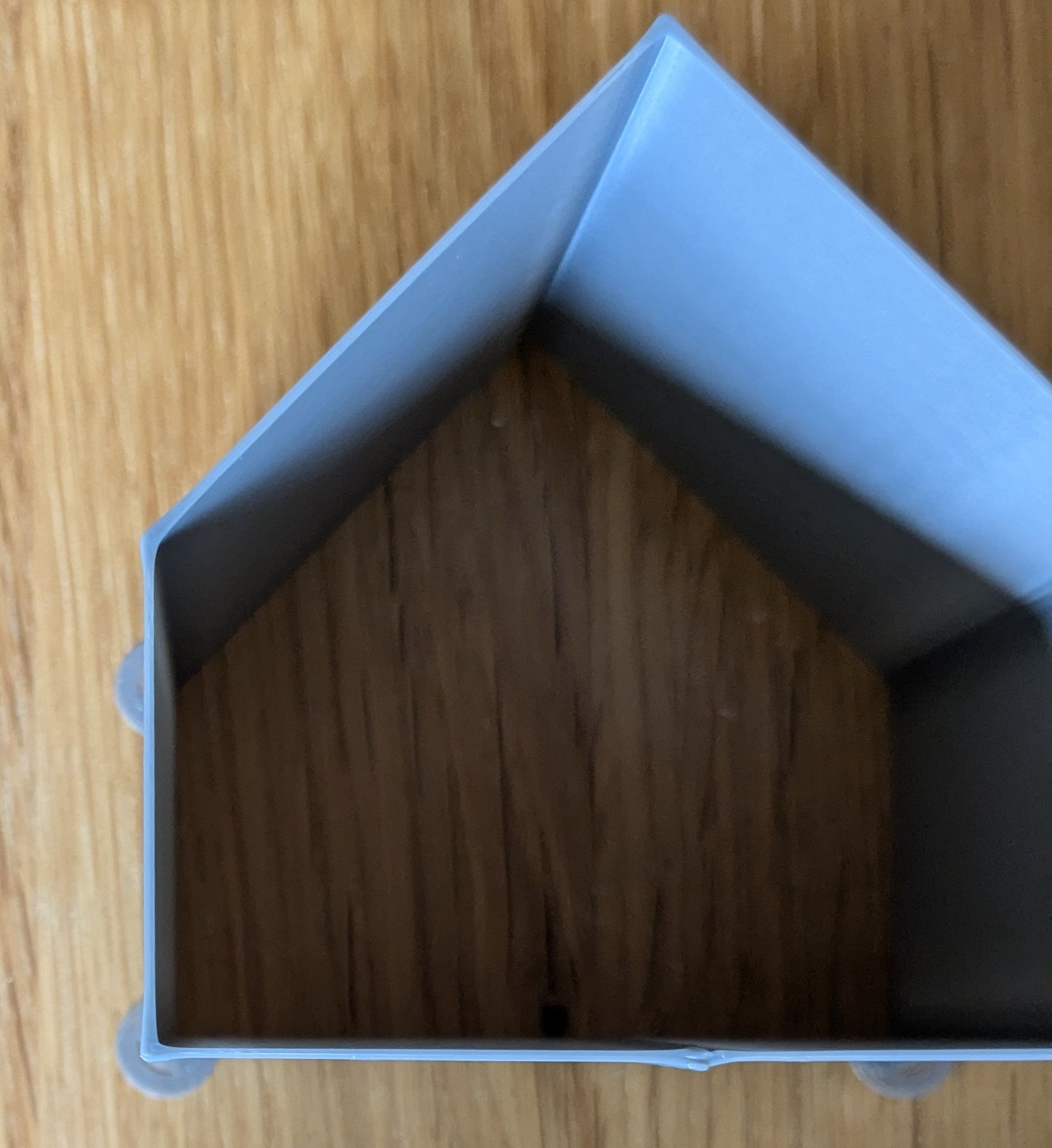

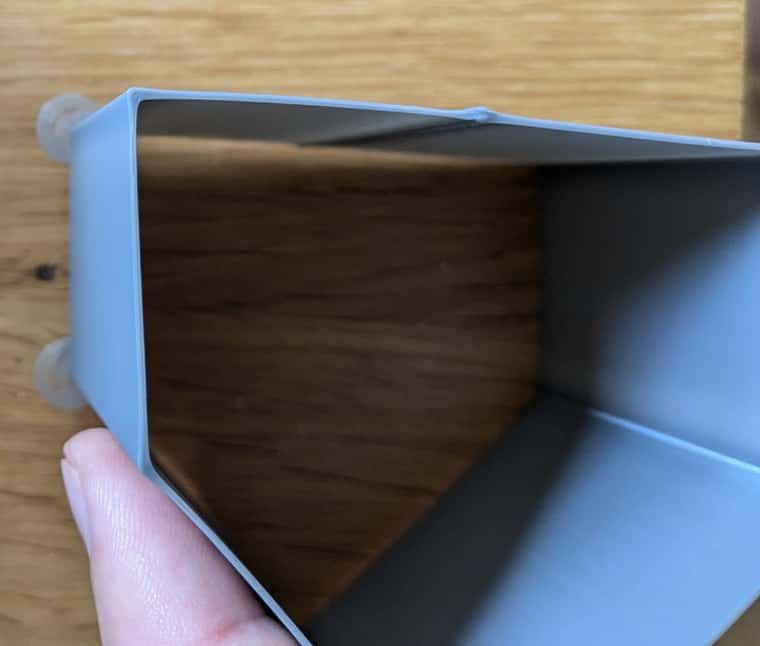

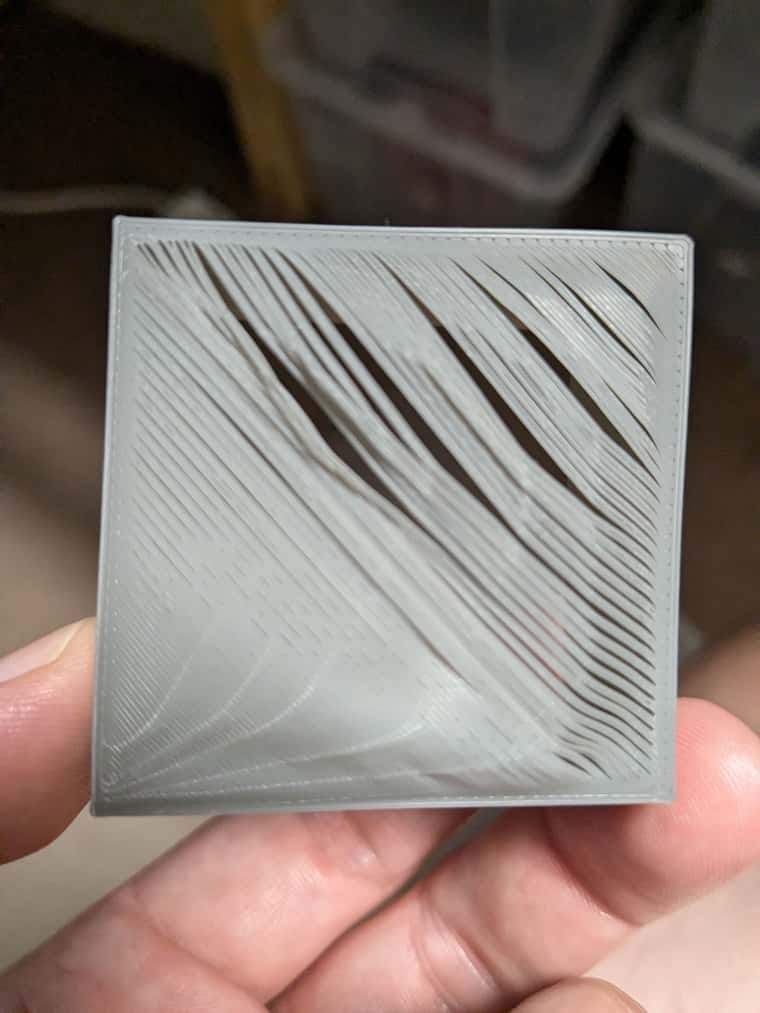

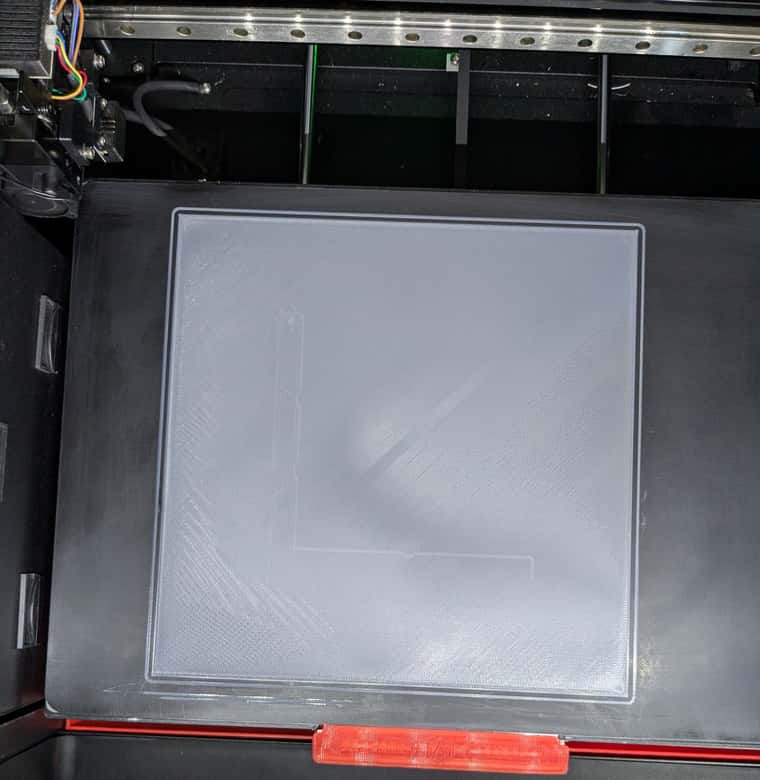

The first problem is that my first layer is not evenly closed. When I print one layer (180x180 mm) the first layer has a thickness of between 0.18mm and 0.26mm. The hardware on the printer is very solid and has no problems. I did not have these problems before the conversion either. Perhaps someone can give me tips on where I could look for the error.

My bed leveling is controlled by a macro that creates a Heightmap.csv depending on the print plate and filament used and then saves this in a BlackPrint 60°C file, which is called up in Start.g when printing.

RepRapFirmware 3.6.0-alpha.4+3

config.g:

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.15 on Sat Nov 26 2022 13:27:47 GMT+0100 (Mitteleuropäische Normalzeit)

;###########################################################################################################################

; General preferences

;###########################################################################################################################

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Raise 3D E2" ; set printer name

;##########################################################################################################################

; Network

;##########################################################################################################################

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; disable FTP

M586 P2 S0 ; disable Telnet

;##########################################################################################################################

; Drives

;##########################################################################################################################

M569 P0.0 S0 D3 H50 V30 ; physical drive 0.0 goes forwards

M915 P0.0 T50

M569 P0.1 S0 D3 H50 V30 ; physical drive 0.1 goes forwards

M915 P0.1 T30

M569 P0.2 S0 D3 H50 V30 ; physical drive 0.2 goes forwards

M915 P0.2 T50

M569 P20.0 S0 ; physical drive 0.3 goes forwards Extruder links

M569 P0.4 S0 D3 H50 V30 ; physical drive 0.4 goes forwards

M915 P0.4 T50

M569 P21.0 S1 ; physical drive 0.5 goes forwards

M584 X0.0 Y0.1 Z0.2 E20.0:21.0 U4 ; set drive mapping

M350 X16 Y16 U16 Z16 E16:16 I1 ; configure microstepping without interpolation

M92 X80 Y80 U80 Z800 E286.216 :286.216 ; set steps per mm linker Extruder : rechter Extroder

M566 X600 Y600 U600 Z30 E300:300 ; set maximum instantaneous speed changes (mm/min)

M203 X10000 U10000 Y9000 Z600 E3000:3000 ; set maximum speeds (mm/min)

M201 X1500 U1500 Y1500 Z120 E3000:3000 ; set accelerations (mm/s^2)

;M906 X850 U850 Y850 Z800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent

M906 X1200 U1200 Y1200 Z900 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

;##########################################################################################################################

; Axis Limits

;##########################################################################################################################

M208 X10 Y-3 Z0 U35 S1 ; set axis minima

M208 X335 Y255 Z240 U355 S0 ; set axis maxima

;##########################################################################################################################

; Endstops ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin null

;##########################################################################################################################

M574 Y1 S1 P"io1.in"

M574 X1 S1 P"io2.in"

M574 U2 S1 P"Io4.in"

;M915 X S-63 H10 R1 ; Set very sensitive stall detect

;M574 X1 S3 ; configure endstop for stall detection

;M915 X S20 H140 R0 ; Set very sensitive stall detect

;M915 X S-63 H10 R1 ; Set very sensitive stall detect

;##########################################################################################################################

; Switch

;##########################################################################################################################

M950 J1 C"SPI.CS2"

;M581 P1 S0 T5 R0 ;Alarm wenn tür beim drucken geöffnet wird

;M581 P1 S1 T6 R0 ;TEST war vorher nicht drin

;##########################################################################################################################

; Filament Sensoren

;##########################################################################################################################

M591 D1 P1 C"io6.in" S1

M591 D0 P1 C"io5.in" S1

;##########################################################################################################################

; Z-Probe

;##########################################################################################################################

M558 P8 C"20.io0.in" H5 A7 S0.008 F200 T10000 ; P=Sondentyp C=Eingangspin H=Anfahrhöhe A=Anzahl Tastvorgänge S=Tolleranz (Standard 0,03) F=Abtastgeschwindigkeit T=Verfahrgeschwindigkeit

G31 P500 X17 Y21 Z1.30 ; set Z probe trigger value, offset and trigger height + Tiefer - höher

M557 X31:335 Y20:225 P7 ; define mesh grid

;##########################################################################################################################

;Acclerometer

;##########################################################################################################################

M955 P20.0 I24 ; configure accelerometer on toolboard with CAN address 121 and specify orientation

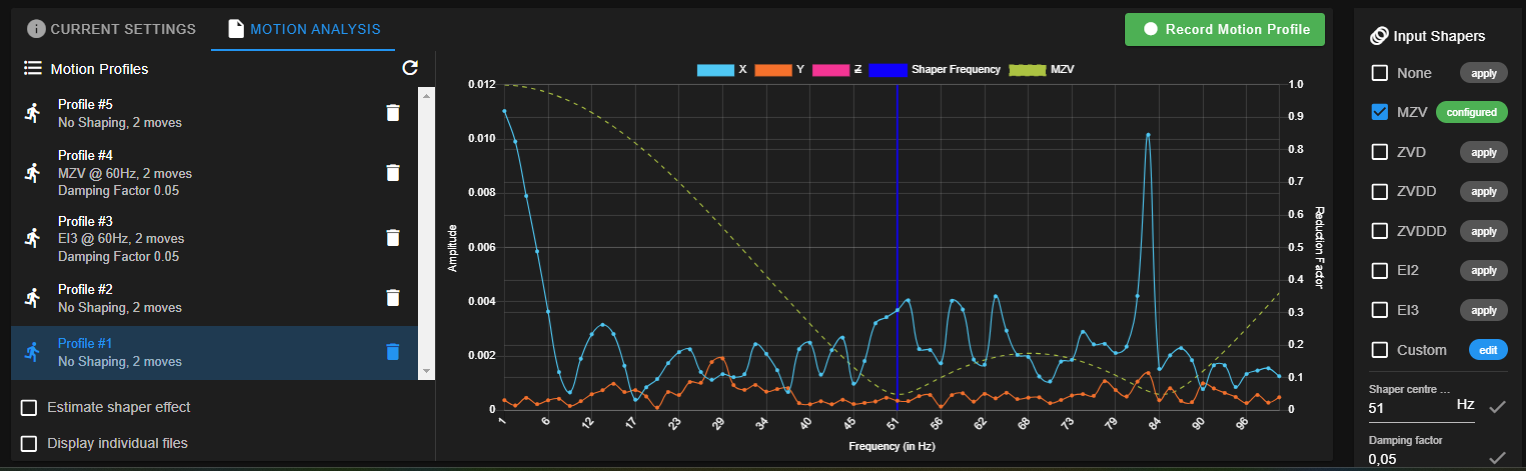

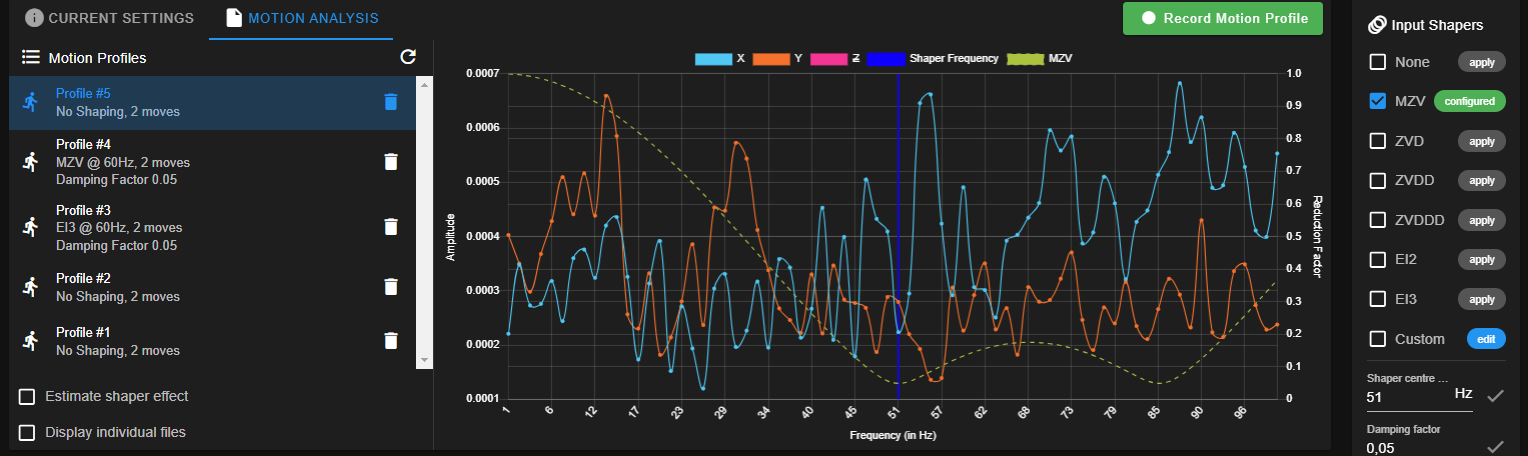

M593 F51 S0.2 P"zvddd"

M955 P21.0 I24 ; configure accelerometer on toolboard with CAN address 121 and specify orientation

;##########################################################################################################################

; Heaters

;##########################################################################################################################

M308 S0 P"Temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S2 P"21.Temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp2

M950 H2 C"21.out0" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S340 ; set temperature limit for heater 2 to 340C

M308 S1 P"20.Temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin temp2

M950 H1 C"20.out0" T1 ; create nozzle heater output on out2 and map it to sensor 2

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S340 ; set temperature limit for heater 2 to 340C

;##########################################################################################################################

; Temp Sensoren

;##########################################################################################################################

M308 S10 Y"mcu-temp" A"MCU" ; defines sensor 10 as MCU temperature sensor

M308 S11 Y"drivers" A"Duet stepper drivers" ; defines sensor 11 as stepper driver temperature sensor

;M950 F5 C"out6" Q500 ; create fan 2 on pin fan2 and set its frequency

;M106 P5 H3 T40:70 ; set fan 2 value

;##########################################################################################################################

; Fans

;##########################################################################################################################

;M950 F0 C"vfd" Q500 ; create fan 0 on pin out4 and set its frequency

;M106 P0 C"Bauteil-Lüfter L" S0 H-1

M950 F0 C"20.out1" Q500

M106 P0 C"Bauteil-Lüfter L" S0 H-1

M950 F1 C"21.out1" Q500

M106 P1 C"Bauteil-Lüfter R" S0 H-1

M950 F3 C"out5" Q500 ; create fan 2 on pin vfd and set its frequency

M106 P3 C"LED" S150 H-1 ; set fan 2 value. Thermostatic control is turned off

M950 F4 C"out4+out4.tach" Q25000

M106 P4 C"Filter-Lüfter" S0 H-1

M950 F5 C"21.out2" Q500 ; create fan 0 on pin out3 and set its frequency

M106 P5 C"Hotend Fan rechts" S1 H2 T45 ; set fan 0 name and value. Thermostatic control turned on for Hotend

M950 F6 C"20.out2" Q500 ; create fan 0 on pin out3 and set its frequency

M106 P6 C"Hotend Fan links" S1 H1 T45

;##########################################################################################################################

; Create a tool that uses the low end (X) carriage

;##########################################################################################################################

M563 P0 D0 H1 F0 S"linker Extruder" ; tool 0 uses extruder 0, heater 1 and fan 0 (P=Werkzeug Nr., S=Name, D=Extruder Motor, H=Heizung, F=Bautellüfter)

G10 P0 X0 Y0 Z0 S0 R0 ; set tool 0 offsets and temperatures

;##########################################################################################################################

; Create a tool that uses the high end (U) carriage

;##########################################################################################################################

M563 P1 D1 H2 X3 F1 S"rechter Extruder" ; tool 1 uses extruder 1, heater 2, fan 2, and maps X to U

G10 P1 Y0.1 U26.6 Z0.02 R0 ; set tool 1 offsets and temperatures für Z: + Tiefer - höher U: - weiter nach rechts + weiter nach links (G10 P1 Y0 U27.0 Z0.02 R0)

;##########################################################################################################################

; Create a tool that prints 2 copies of the object using both carriages

;##########################################################################################################################

M563 P2 D0:1 H1:2 X0:3 F0:0 S"Duplikation" ; tool 2 uses both extruders, hot end heaters and fans, and maps X to both X and U

G10 P2 X-25 Y0 U-176.3 Z0 S0 R0 ; set tool offsets and temperatures

;G10 P2 X10 Y0 U-176.3 Z0 S0 R0 ; set tool offsets and temperatures

;G10 P2 X0 Y0 U-40 Z0 S0 R0 ; set tool offsets and temperatures

G10 P2 R0 S0

M567 P2 E1:1 ; set mix ratio 100% on both extruders

;##########################################################################################################################

;Create a tool that Prints in Mirrior Mode

;##########################################################################################################################

;M563 P3 H1:2 D0:1 X0:3 F0:0 S"Spiegeln"

;G10 P3 X-25 Y0 U-176.3 Z0 S0 R0

;G10 P3 R0 S-2

;##########################################################################################################################

; Custom settings are not defined

;##########################################################################################################################

;##########################################################################################################################

;Temperatur anpassung MCU

;##########################################################################################################################

M912 P0 S2

;##########################################################################################################################

; Miscellaneous

;##########################################################################################################################

M501 ; load saved parameters from config-override.g

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

M98 P"GlobaleBuildplate.g"

G4 S2 ; wait for expansion boards to start```

start.g:

M291 P"Start.g wird ausgeführt" S0

if !move.axes[0].homed || !move.axes[1].homed || !move.axes[2].homed

G28

M98 P"/Macros/SUB/CheckDoor"

M561 ; Disable Mesh Bed Kompensation

G4 S1

M106 P3 S25 ; LED schalten 25%

M98 P"/Macros/SUB/Preheat"

G28 Z0 ; Z Homen

M98 P"/Macros/Buildplate"

The mesh is then called up via M98 P"/Macros/Buildplate". For example, for the BlackPrint and PLA printing plate it is BlackPrint60°C.csv

this is my slicer start code:

T0

M291 P"Beginne slicer start gcode" S0

M703 ; load config file for [filament_type]

G90 ; set printer absolute mode

M82 ; set extruder to absolute mode

M106 S0 ; fan off

M106 P3 S180 ; LED an

T0 ; set first toolhead

M703 ; load config file for [filament_type]

G1 Z3 F2000 ; Move to Z3 for height clearance before Intro line

G92 E0 ; set position

M291 P"Intro Line" S0

M116 S5

M400

; intro line

G1 Z0.35 F5000

G1 X60 Y-2 F5000

G1 X150 Y-2 E16 F1000

G1 X170 y-2 F5000

G1 X170 Y0 F5000

G1 X150 Y0 F500

G1 X60 Y0 E30 F1000

G1 X40 Y0 F5000

G1 Z5 F2000 ; Move to Z5 to prevent dragging nozzle and scratching bed

G92 E0 ; set position

G1 F2000

M117 "Druck wird gestartet"