@NitroFreak said in Another Stratasys uPrint retrofit:

I can´t even begin to understand how you did the probing of the control board to figure out what signal goes where?

I assume you´re an electrical engineer of sorts?

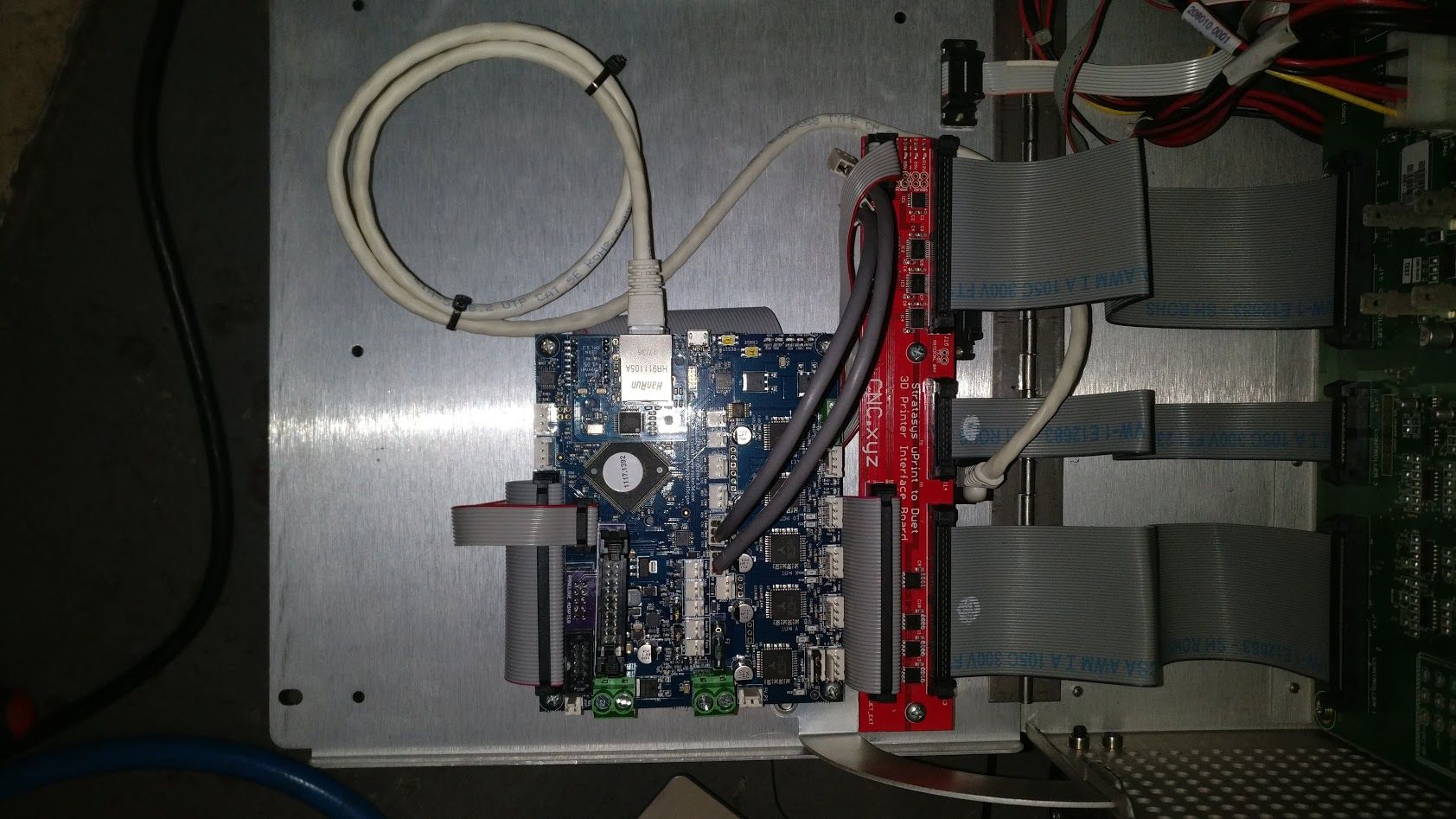

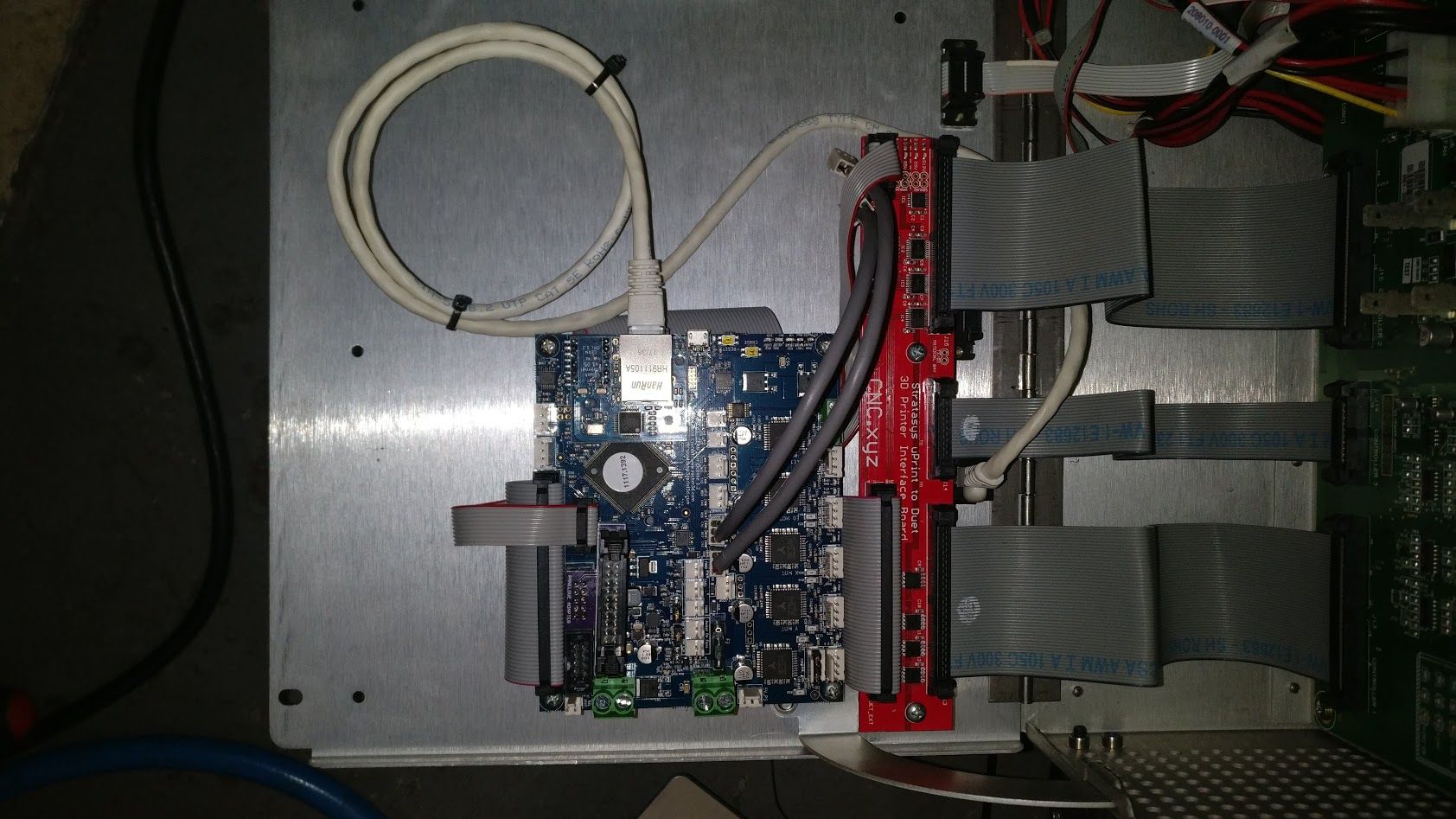

I'm a mechanical engineer, but do complete integrations of electronics and software as well. As far as the probing is concerned, it didn't actually take too long. My process was mostly this:

Find where a known connection enters the board such as a motor. Find the continuity between the motor pins and the motor driver chip. Look up the motor driver chip's datasheet to determine what pins do what. Follow the traces back from there to the next point of interconnection. Eventually you find that Pins 1, 3, 17 & 19 on connector J13 are what you need to interface with to control the X-axis stepper motor by sending Phase PWM and voltage reference signals for example.

If you send the right signals there (following the motor driver datasheet) you'll get controlled movement out of the stepper motor using all of the Stratasys' built in electronics.

@NitroFreak said in Another Stratasys uPrint retrofit:

I couldn´t help but overlook that you said DIY printers can easily achieve 50 micron while the Uprint is "stuck" at 254 micron.

This isn´t quite true.

I think you missed what the strength of the Stratasys machines is.

I actually greatly understand the rock solid nature of the hardware on the machine. That's why I want to push it to it's full potential by opening up the ability to print PLA, Nylon.. etc at whatever layer thickness I want. The idea that it is dimensionally flawless is a little misguided. I had TONS of failed prints on the uPrint. I had numerous times where the part failed spectacularly in a mess of spaghetti or when the filament spooled up in the head and fused the print head into a solid block of ABS. When you're spending $50 per print, you can't have that happening.

The quality of the proprietary ABS was poorer than the stuff you could buy for $15 per spool. I had Stratasys' technicians out to troubleshoot my brand new machine and we went through every single spool of filament I had and determined each one was filled with too much moisture and had to request Stratasys replace them all. Eventually it made more sense to buy a genuine $200 roll of filament to get a new eprom and a $15 roll of a no-name brand ABS, spool it onto an empty reel and use it instead of the expensive stuff.

You can have just as great dimensional accuracy on a cheap printer. It just may not print as fast and may require more adjustment. I think you may be disappointed in the amount of effort it takes to put the Stratasys extruder on your build when compared to what other options are out there.

You may not have an easy time finding replacement parts should something break either. You'll be stuck buying used parts.

@NitroFreak said in Another Stratasys uPrint retrofit:

Anyway, the upper three points are why i want to try the uPrint head in my own printer.

What i am still missing is how to drive the 120VDC servo.

How did you realize that ?

It's fairly straight forward. Look up the model number on the servo drive. You'll find it is a proprietary part number, but the company that makes them has other similar models to look up the datasheet. You should see that the IDC 10 pin connector from the servo is a common pinout. You've got motor power and the 2 or 3 encoder signals (2 differential signals, plus ground I think).

You can hook that up directly to a servo driver, such as the Geckodrive G320X. Note: The servo does not run on 120VDC, probably something like 12V or 24V, but I don't remember off the top of my head.

The heaters run on 120VDC. You'll need a very high quality DC:DC relay to turn those on and off. Don't skimp out on that, it's some serious voltage. If you can snag two 120VDC power supplies from a Stratasys machine that would help. Note that each printer has two power supplies at 120VDC, but one is a modular supply and one is built into the main Power Distribution Board, so you'd need parts from 2 different printers.

If you are interested I designed and made a prototype head thermocouple board that takes the temperature readings from the Stratasys thermocouples and converts the signal directly to SPI. It mounts directly to the Stratasys print head. (The standard board uses voltage reference to produce the signal that must be interpreted later.)