@agz90 install firmware 3.6.0 Release Candidate 1

Posts made by agz90

-

RE: RRF to Duet3 6HCposted in General Discussion

@Phaedrux said in RRF to Duet3 6HC:

How are you checking it?

What error does it report?

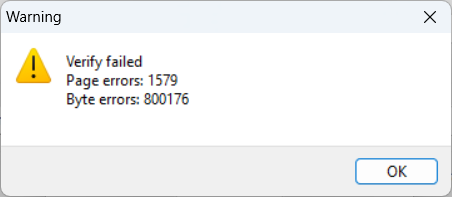

Are you following these steps to flash the firmware?Yes, I followed all the steps exactly as described. Checked with Bossa verify. My problem is that I thought I could install Clipper on the board, apparently I deleted the boot file and now it doesn't work. I don't know how to restore the rep rap on the board.

-

RE: RRF to Duet3 6HCposted in General Discussion

@agz90 said in RRF to Duet3 6HC:

Hello, I have a problem installing the rap rap on the board. I load the latest rap rap with Bossa, it saves it, but when I check it, it gives me an error and the board doesn't start.

-

Duet3 6HC with RRF36posted in Duet Hardware and wiring

Hi. My Duet3 6HC rev.1.02 after start print after a few printed layers it stops communicating with RRF36, more precisely it stops extruding thread and moving Z up, with baby steps I try to move but the motors just buzz and don't move. Could there be a problem with the board? I have a spare one but it's a clone version 1.01, I'll try it.

-

RE: Fly-RRF-36 fan2 not workposted in Tuning and tweaking

@edsped

Hello, I found the problem, not every fan is suitable for Can.

I tried several models and found the right one, now I'm satisfied.

Thanks for the help though. -

RE: Fly-RRF-36 RP2040 not work second fanposted in Other control boards

@agz90 said in Fly-RRF-36 RP2040 not work second fan:

@agz90

I tried swapping them but then none of the fans start. On the board, the diode lights up, but no fan moves.and where to set the fans with M563

-

RE: Fly-RRF-36 RP2040 not work second fanposted in Other control boards

@agz90

I tried swapping them but then none of the fans start. On the board, the diode lights up, but no fan moves. -

RE: Fly-RRF-36 RP2040 not work second fanposted in Other control boards

@jay_s_uk

I currently have a Fly-Super8Pro H723 board I'm experimenting with and my BTT Octopus Pro v1.0 F429 running on Voron 2.4. -

RE: Fly-RRF-36 RP2040 not work second fanposted in Other control boards

@jay_s_uk said in Fly-RRF-36 RP2040 not work second fan:

post your whole config so we can see your tool assignments

; Configuration file for BTT OctoPus V1 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.10+4-LPC on Tue Jan 19 2021 17:25:01 GMT+0800 (中国标准时间); General preferences

M111 S0 ; Debug off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"BTT-AGZ_VORON" ; set printer name

M669 K1 ; select CoreXY mode

G4 S20 ; wait for expansion boards to start

M575 P1 B57600 S1 ; Comms parameters for PanelDue

M564 S1 H1 ; Forbid axis movements when not homed; Network

;M552 S0

M552 S1 ; start network module (must have been configured first with M587)

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; --- Z Driver map ---

;

; ----+---- Z-Drives

; | 4 | 5 |

; ----+----

; | 3 | 6 |

; ----+----

; Front

;

; (lookking at the printer from the top); Drives

M569 P0 S1 ; A

M569 P1 S1 ; B

M569 P2 S0 ; physical drive 3 goes forwards using default driver timings

M569 P3 S0 ; Z1

M569 P4 S0 ; Z2

M569 P5 S1 ; Z3

M569 P6 S0 ; Z4

M569 P124.0 S1 ; physical drive 124.0 goes forwards; Motor mapping and steps per mm

M584 X0 Y1 Z3:4:5:6 E124.0 ; set drive mapping

;M669 K5 X1:1:0:0 Y1:1:0:-1 Z0:0:1:0;

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

;M92 X80 Y80 Z400 ; Set XYZ steps per mm (1.8deg motors)

M92 X126.00 Y126.00 Z400.00 ; Set XYZ steps per mm (0.9deg motors)

M92 E665.00 ; set E steps per mm

M350 Z16 I0 ; disable Z interpolation; Drive currents

M906 X1300 Y1300 Z1300 E500 ; XYZ and E current

M906 I30 ; Idle current percentage

M84 S120 ; Idle timeout

M566 X900 Y900 Z60 E8000 ; Set maximum instantaneous speed changes (mm/min)

M203 X18000 Y18000 Z3000 E15000 ; Set maximum speeds (mm/min)

M201 X2000 Y2000 Z250 E1800 ; Set maximum accelerations (mm/s^2)

M204 P1500 T2000 ; Set printing acceleration and travel accelerations

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; S1 = set axes minimum

M208 X320 Y340 Z300 S0 ; S0 = set axes maximum; Endstops

M574 X2 S1 P"124.io2.in" ; Map the X endstop to toolboard io2.in

;M574 X1 S1 P"124.io0.in"

;M574 X2 S1 P"xstop" ; X max active low endstop switch

M574 Y2 S1 P"ystop" ; Y max active low endstop switch

;M574 Z1 S1 P"zstop"

M574 Z0 P"nil" ; No Z endstop;Filament sensor

;M591 D0 P7 C"e0stop" S1 R50:130 L7.0 E10

;M591 D1 P7 C"e1stop" S1 R50:130 L7.0 E10; Accelerations and speed

M98 P"/macros/print_scripts/speed_printing.g";================================== ;

; Z-Probe (TAP) ;

;================================== ; Voron OptoTAP pcb 5V|sig|gnd on 124.io0

M558 P8 C"^124.io0.in" H5 F600:120 T18000 A5 S0.01 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z-0.875 ; set Z probe trigger value, offset and trigger height

M671 X-65:-65:365:365 Y0:395:395:0 S20 ; Difine Z belts locations (Front_Left, Back_Left, Back_Right, Front_Right)

M557 X20:290 Y20:290 S25 ; Difine bed mesh grid (inductive probe, positions include the Y offset!);Bed heater dual thermistor setup

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 A"Bed Pad" ; configure sensor 0 as thermistor on pin bedtemp (pad sensor)

M308 S2 P"e1temp" Y"thermistor" T100000 B3950 A"Bed Plate" ; configure sensor 2 as thermistor on pin e1temp (plate sensor)

M950 H0 C"bed" T2 Q10 ; create bed heater output on out0 and map it to sensor 2 (plate sensor). Set PWM frequency to 10Hz

M140 P0 H0 ; Mark heater H0 as bed heater (for DWC)

M143 H0 P1 T0 A2 S115 C0 ; Regulate (A2) bed heater (H0) to have pad sensor (T0) below 110°C. Use Heater monitor 1 for it

M143 H0 P2 T0 A1 S125 C0 ; Shut off (A1) bed heater (H0) if pad sensor (T0) exceeds 120°C. Use Heater monitor 2 for it

M143 H0 S120 ; Set bed heater max temperature to 120°C, use implict monitor 0 which is implicitly configured for heater fault

M307 H0 B1 S0.2 ; Enable Bang Bang mode and set PWM to 70% to avoid warping; T0 = HotEnd

M308 S1 P"124.temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 on pin 124.temp0

M950 H1 C"124.out0" T1 ; create nozzle heater output on 124.out0 and map it to sensor 1

;M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp

;M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F1 C"124.out2" Q500 ; create fan 0 on pin out5 and set its frequency

M106 P1 C"PartCool" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F0 C"124.out1" Q500 ; create fan 1 on pin out4 and set its frequency

M106 P0 C"HotEnd" S1 H1 T55 ; set fan 1 name and value. Thermostatic control is turned on

;M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

;M106 P0 S0 H-1 C"PartCooler" ; Name it "PartCooler"

; hotend_fan

;M950 F1 C"fan1" Q1000 ; create hotend_fan on pin fan1 and set its frequency

;M106 P1 S1.0 H1 T50 C"ToolFan" ; attach hotend fan to heater 1 and set

; controller_fanM308 S3 Y"drivers" A"DRIVERS" ; configure sensor 3 as temperature warning and overheat flags on the TMC2209 on BTT Octopus

M308 S4 Y"mcu-temp" A"MCU" ; configure sensor 4 as on-chip MCU temperature sensor

M950 F2 C"fan2" Q1000 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S255 H3:4 B0.1 T35 C"MCUCooler" ; set fan 2 value and Name it "MCUCooler"

M950 F4 C"fan4"

M106 P4 S0.7 H4 B0.8 T34:36M950 H3 C"nil" ; free up e3heat pin

M950 F9 C"e3heat" T4

M950 H9 C"e3heat" T4 Q100

M106 P9 S255 H4 T36 C"MCUCooler" ; set fan 4 value and Name it "MCUCooler"; exhaust_fan

M950 H2 C"nil"

M950 F10 C"e2heat" T10

M950 H10 C"e2heat" T10 Q1000 ; create exhaust_fan on pin fan3 and set its frequency

M106 P10 S255 H10 T39:55 C"ChamberFan"

M106 P10 S1 H0 T50 ; Chamber filter fan, turn on when bed is hotter than 50C;Extruder heat Fan

;M308 S5 P"e2temp" Y"thermistor" T100000 B3950 ; configure sensor 5 as thermistor on pin e5temp

M950 F5 C"fan5" Q1000

M106 P5 S1 H1 T150

M106 P5 S0 H1 T50 ; Extruder heat Fan, turn on when hotend is hotter than 50C; Tools

M563 P0 D0 H1 F0 S"Dragonfly" ; define tool 0

G10 P0 X0 Y0 Z0 S0 R0 ; set tool 0 axis offsets;Chamber sensor (DHT22)

M308 S10 P"B.5" Y"dht22" A"Chbr Temp[C]"

M308 S11 P"S10.1" Y"dhthumidity" A"Chbr Hum[%]"M308 S7 A"Fly-RRF-36" Y"mcu-temp" P"124.dummy" ; Sensor 7 Built in temp monitor in Fly-RRF-36

M950 F1 C"fan1"

M106 P1 H7 B0.8 T36; Accelerometer

M955 P124.0 I10;LED strip RGB

M950 C"124.rgbled" E0 T1 Q1000 ; create a RGB Neopixel LED strip on the Fly-RRF-36 LED port

M98 P"/macros/LED/white.g" S{true}

;M150 R255 B225 U255 F1 ; white

M98 P"/macros/LED/green.g" S{true}

;M150 U255 P220 S3 F1 ; green

M98 P"/macros/LED/blue.g" S{true}

;M150 B255 P220 S3 F1 ; blue

M98 P"/macros/LED/red.g" S{true}

;M150 R255 P220 S3 F1 ; red;M950 C"neopixel" E0 T1 ; create a RGB Neopixel LED strip on the LED port

M98 P"/macros/LED/red.g"

M98 P"/macros/LED/blue.g"

M98 P"/macros/LED/green.g"

M98 P"/macros/LED/white.g"; Misc

M912 P0 S-4 ; MCU temperature calibration (yours will be different)

;M572 D0 S0.075 ; Presure Advance

M572 D0 S0.01 ; Presure Advance

M592 D0 A0.015 B0.0012 L0.2 ; Non-linear extrusion

M376 H10 ; Fade mesh out compensation over 10mm Z; Custom settings are not defined

M552 S1

; paneldue --------------------------

M575 P1 S1 B57600 ; activate paneldue

;M575 P1 S2 B57600

M501 ; read config-override.g

T0 ; select tool 0M150 X2

T0 P0 -

RE: Fly-RRF-36 RP2040 not work second fanposted in Other control boards

@agz90 said in Fly-RRF-36 RP2040 not work second fan:

@gloomyandy

Hello. This is my config for the fans.

; Fans

M950 F1 C"124.out2" Q500 ; create fan 0 on pin out5 and set its frequency

M106 P1 C"PartCool" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F0 C"124.out1" Q500 ; create fan 1 on pin out4 and set its frequency

M106 P0 C"HotEnd" S1 H1 T55 ; set fan 1 name and value. Thermostatic control is turned onthe heater works, the extruder cooling fan works, but the parts cooling fan does not.

-

RE: Fly-RRF-36 RP2040 not work second fanposted in Other control boards

@gloomyandy

Hello. This is my config for the fans.

; Fans

M950 F1 C"124.out2" Q500 ; create fan 0 on pin out5 and set its frequency

M106 P1 C"PartCool" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F0 C"124.out1" Q500 ; create fan 1 on pin out4 and set its frequency

M106 P0 C"HotEnd" S1 H1 T55 ; set fan 1 name and value. Thermostatic control is turned on -

RE: Fly-RRF-36 fan2 not workposted in Tuning and tweaking

@KenW said in Fly-RRF-36 fan2 not work:

Like you I know little about the actual board so hopefully @jay_s_uk or @gloomyandy are not busy at the expo if it is still running. Wish I could have been able to afford going to one of those.

I tried your code and it seems to work.

I continue with the settings that something Y the brake does not work. -

RE: Fly-RRF-36 fan2 not workposted in Tuning and tweaking

@KenW said in Fly-RRF-36 fan2 not work:

I have been playing around with one of these too. Is the firmware on the toolboard the same version as the mainboard? If not that's probably the problem. I was able to heat the hotend and the hotend fan would come on but very little else worked correctly when I had 3.4.6 on the mainboard.

thats my RRF:

Board: fly_super8_pro_h723 (stm32h723-wifi)

Firmware: RepRapFirmware for STM32H7 based Boards 3.5.0-rc.1+102 (2023-09-05)

Duet WiFi Server Version: 1.27-01S32-D -

Fly-RRF-36 fan2 not workposted in Tuning and tweaking

I have Fly-RRF-36 RP2040 Based CAN-FD Toolboard in my Voron burner,fan2 Partcooler fan not work.

my G-code:

; Fans

M950 F0 C"124.out1" Q500 ; Hotend fan on "out5" connector

M106 P0 C"Hotend Fan" H1 T55 ; Enable thermostatic mode for hotend fan

M950 F1 C"124.out2" Q500 ; Layer fan on "out4" connector

M106 P1 C"Layer Fan" H-1 S0 ; Layer Fan -

RE: How to configure filament and everythig file you me neededposted in Duet Hardware and wiring

Thank you, thank you very much for telling me how to write it, in the above posts I wrote what my files contain.

image url)

image url)