@agz90 install firmware 3.6.0 Release Candidate 1

Latest posts made by agz90

-

RE: RRF to Duet3 6HCposted in General Discussion

@Phaedrux said in RRF to Duet3 6HC:

How are you checking it?

What error does it report?

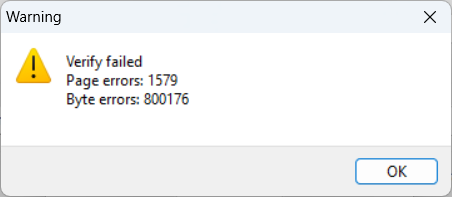

Are you following these steps to flash the firmware?Yes, I followed all the steps exactly as described. Checked with Bossa verify. My problem is that I thought I could install Clipper on the board, apparently I deleted the boot file and now it doesn't work. I don't know how to restore the rep rap on the board.

-

RE: RRF to Duet3 6HCposted in General Discussion

@agz90 said in RRF to Duet3 6HC:

Hello, I have a problem installing the rap rap on the board. I load the latest rap rap with Bossa, it saves it, but when I check it, it gives me an error and the board doesn't start.

-

Duet3 6HC with RRF36posted in Duet Hardware and wiring

Hi. My Duet3 6HC rev.1.02 after start print after a few printed layers it stops communicating with RRF36, more precisely it stops extruding thread and moving Z up, with baby steps I try to move but the motors just buzz and don't move. Could there be a problem with the board? I have a spare one but it's a clone version 1.01, I'll try it.

-

RE: Fly-RRF-36 fan2 not workposted in Tuning and tweaking

@edsped

Hello, I found the problem, not every fan is suitable for Can.

I tried several models and found the right one, now I'm satisfied.

Thanks for the help though. -

RE: Fly-RRF-36 RP2040 not work second fanposted in Other control boards

@agz90 said in Fly-RRF-36 RP2040 not work second fan:

@agz90

I tried swapping them but then none of the fans start. On the board, the diode lights up, but no fan moves.and where to set the fans with M563

-

RE: Fly-RRF-36 RP2040 not work second fanposted in Other control boards

@agz90

I tried swapping them but then none of the fans start. On the board, the diode lights up, but no fan moves.

image url)

image url)