Yet another cast aluminum plate topic...

-

@mrehorstdmd thanks! Did you tap where the bolts go into the side of the plate? Also, what size bolts did you use for the bed spring retention? If I missed it in the blog post I apologize. The plate I ordered is 3/8" thick.

-

@tletourneau If you're referring to the screws that hold the plate-end of the hold-down springs, yes, they are tapped. I used #6-32 screws. The bolts that hold the other end of the hold down springs go into the axial holes in the bed support. They are 5/16-18 tapped holes and screws.

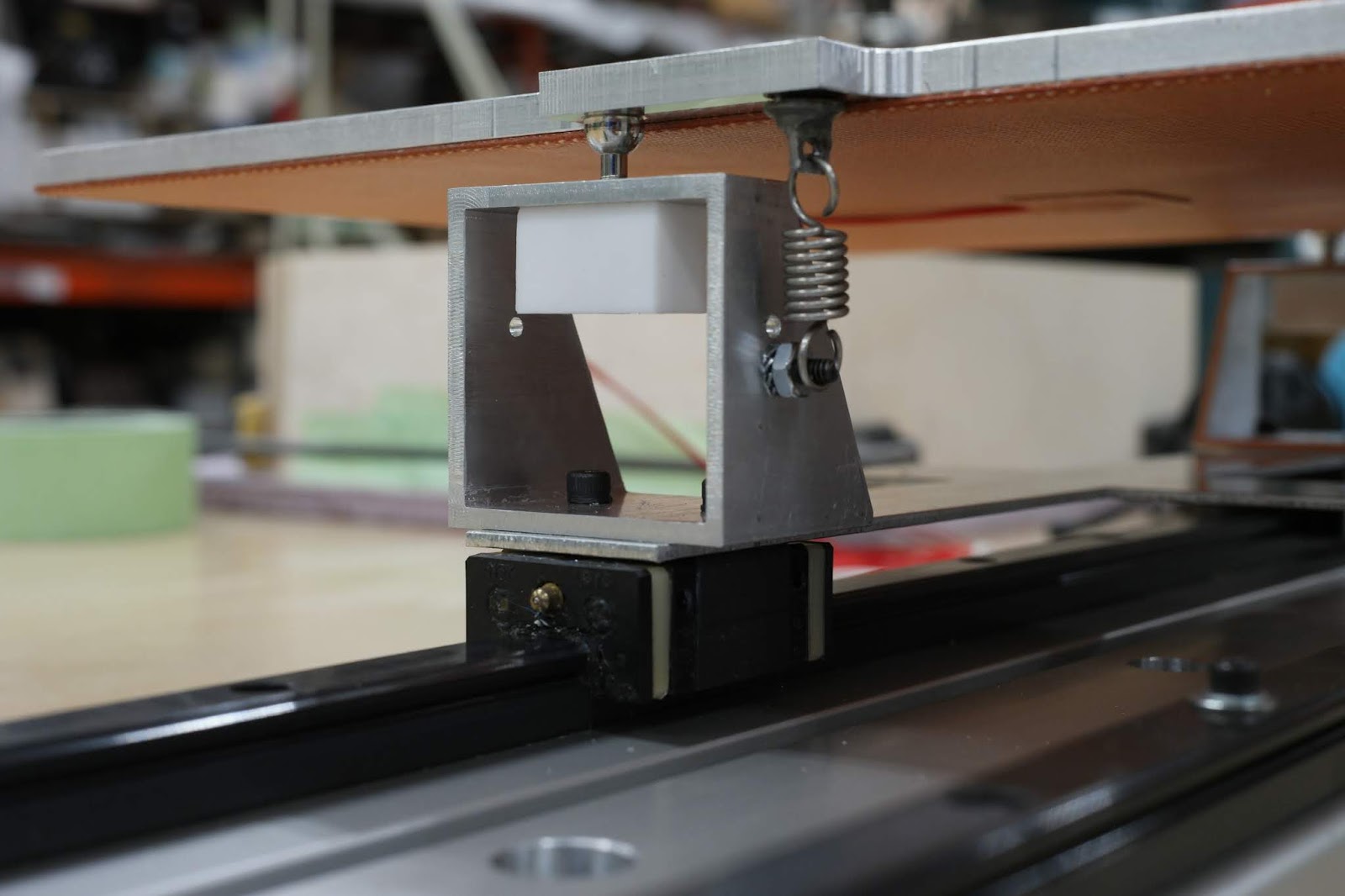

In SoM, which I recently upgraded to a line powered heater and kinematic mount, instead of drilling into the edge of the bed plate (only 1/4" thick), I made the ears wider and drilled through the plate and tapped the holes. Like this:

-

@mrehorstdmd thanks again! I'm going to try a slightly modified version of the kinematic mount. I'm going to have it mounted to 2020 with the ball screws and springs across the front and back of the plate. We'll see how it goes, the plate shipped out today so I should have it tomorrow or Monday. The heater shipped from China today as well so that should be here in a week or two (I hope).

-

So I adhered the glass to my heated bed, got it level-ish, looked closely and the bed is warped pretty badly.

713 maker just ran out of stock on the milled bed, go figure.

So the question is, should I go SSR or with the Keenevo controller? I found a 300W silicone mat (I don't need crazy heat-up times)

-

@wyvern what is the keenovo controller?

-

@phaedrux Keenovo offers an external temperature controller.

-

It's a little self-contained heat controller and timer, no wiring to the Duet at all.

The problem I see with it is the inability to set the bed temp with G-code, the upside is the reduction in wiring and since it's remote, no chance of it damaging the due... unless it decides to start on fire.

-

@wyvern I went with a SSR, I prefer to let the Duet control the temperature. It is really useful for prints like some of the ABS where I drop the bed temp after a few layers.

-

I've heard of the SSR throwing high peak voltages during SSR deactivation/off cycling.

But usually that is with shutting down actual coils- so maybe that is bad information.

-

@wyvern I'd go with a Duet controlled SSR. Something like:

https://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=288I'd worry about forgetting to turn on or off a seperate controller. Might as well let the Duet automate it with Gcode.

-

Any success with PID tuning?

-

@wyvern said in Yet another cast aluminum plate topic...:

Any success with PID tuning?

Me? Yes, I have a 310mm ish square 6mm MIC6 plate with 600w 290mm ish silicone heater RTV siliconed to the plate and SSR. PID tuning it had no issues.

-

I'll be interested in how my PID turns out. Mine will be a 500x500mm and 3/8" (9.525mm) thick ATP 5 cast plate with a 450x450mm 1000 watt 120v SSR controlled heater with a 1/4" (6.35mm) glass plate on it.

-

Keenovo sells versions of their heaters with a controller ...

https://www.keenovo.com/Keenovo-Digital-Controller-Manual.pdfI don't know what the temperature tolerance is on them but it'd seem like extra expense and just one more point of failure. I'd stick with an SSR and let the Duet control the temperature.

oops, this was a late response

-

So I got's the stuff, I ordered a 13X13 ATP-5 1/4 cast plate from Midwest metals for $45 shipped. The MIC6 was more expensive $35 BUT another $35 to cut + $10 shipping, one other place wanted $93 just for a slice!

I ordered the 300W mat and a SSR. So it's like $115 for the setup, but there is no way I'm spending another $40 on a replacement heated bed that will warp in a month.

My question now is do I use the 8 mounting holes that was stock, or just 4? I feel the use of extra thumb screws was due to the warp of the cheaper heated bed.

I will not be probing this bed, and I don't trust myself to accurately drill a 3 hole setup, so the most accurate manual leveling is a must.

I just hope all my hardware for the 12mm Z rods come at the same time (ditching the wimpy 8mm crap)

-

@wyvern said in Yet another cast aluminum plate topic...:

My question now is do I use the 8 mounting holes that was stock, or just 4?

The FT5 mounting holes are trying to make up for a flimsy bed. With a stiff bed a 3 point system is ideal. Don't worry about drilling accuracy, it really won't matter as long as you're in the ballpark. It's far easier to get 3 points level than 4 points.

-

I'm thinking of forgoing the counter sunk holes, I think using them may cause things to be over restrained when it heats up.

Instead I'm thinking of using slightly oversize holes and aluminum washers (the washers are countersunk and the bottoms are flat) so long as tension and weight are enough to keep it from wriggling around.

-

@wyvern I've done a 3 point countersunk mount on mine. It's not up to the level of a kinematic mount, but it hasn't seemed to have a noticeable impact on first layer printing.

Originally I had intended to have two of the holes along the side to keep the pivot point along the center of the bed, but then there was a bit of instability, so I went with two corners and the opposite center. I was also going to use bolts with round heads to allow for some adjustment, but the screws were expensive and when the M4 bolts worked fine I didn't bother.

One corner is set static as reference, and the other two are pitch and roll.

Drilling wasn't too bad. It just took some patience. I used progressively larger bits and slowly reamed out the holes. I used a drop of oil each time which helped keep the chips from getting everywhere if nothing else.

-

I see. The stock setup on mine is a tapered screw and countersunk hole, so they fit flush- but it's unnecessary when the nozzle doesn't come anywhere near them.

I haven't worked with this type of Aluminum, it's supposed to be easier to work with than Mic6, I have a really nice IR hand drill, or, access to a really tired POS drill press, I just hate drilling crooked holes.

Is it really that hard of an alloy?

-

@wyvern I just used a hand drill. I oversized the holes slightly to give the bolt heads some space to self adjust. I used a piece of tape to judge the depth of the hole to leave 1mm at the bottom. I didn't find the MIC6 hard to drill.