6th-order jerk-controlled motion planning

-

@dc42 yes, symetric higher motion profiles like trigonometric functions or Bezier curves are advantageous. They simplify the implementation greatly and do not require to change the planner. I will elaborate.

Third order moves is quicker to calculate, but would require recalculating the planner variables like "accelDistance" and "accelDistance" and it would require many changes in DDA.

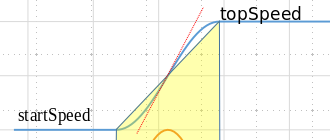

The beauty of Marlin/TinyG implementation or sinusoids (versus parabolic) is that the area under the S-curve is exacly the same as using the constant acceleration model. This is because the areas above and below the equivalent linear speed are equal and it allows to use the calculations and planning as if it was a constant acceleration move. To illustrate this check the next figure: the blue line is the speed versus time. The distance traveled from startSpeed to Top Speed is equal to the area of the yellow figure, which is the area used to plan movements using constant acceleration.

So basically Marlin does not change the planner "at all". Only when they calculate the step pulse frequency, they use a Bezier curve to evaluate the time to the next steps on the acceleration and deceleration phases versus using a constant acceleration.

Traditional 3rd order motion profile (like the parabolic profile on the paper) is not a mathematically complete solution. It will also produce zero acceleration at the start and end of a segment, but the difference with Bezier curves is that it does not assure zero jerk. On the paper the "Figure 5. Parabolic profile" shows the velocity and acceleration, but not the jerk. The jerk is the derivative of the acceleration which can be seen as the slope of the tangent at each point of the curve. For this figure 5 the jerk will be constant (no zero) in all joints.

From a mathematical point of view, and ease of implementation, Bezier curves are the perfect solution and at the end a simpler approach.

-

Like I said, the Marlin implementation only works because it assumes zero acceleration and jerk at the start end new of each move - and that assumption will have nasty consequences. Once you drop that constraint, Bezier curves lose their appeal.

-

@dc42 just playing with the implementation on Duet, this might give some ideas:

on Drivemovement.h I have declared new variables on the struct PrepParams as follows:

// Bezier coefficients for the acceleration phase float bezier_aA; float bezier_aB; float bezier_aC; float bezier_aF; bezier_aNormalizeTime; //required to normalize time between [0,1] // Bezier coefficients for the deceleration phase float bezier_dA; float bezier_dB; float bezier_dC; float bezier_dF; bezier_dNormalizeTime; //required to normalize time between [0,1]The reason to have duplicated coefficients is that Prepare is called once for the whole move.

These variables are evaluated on DDA::Prepareparams.bezier_aA = 6*(topSpeed - startSpeed); params.bezier_aB = 15*(startSpeed - topSpeed); params.bezier_aC = 10*(topSpeed - startSpeed); //bezier_D = 0 //bezier_E = 0 params.bezier_aF = startSpeed; params.bezier_aNormalizeTime =1/accelStopTime; //move starts at Time=0For the deceleration phase just replace startSpeed by topSpeed and topSpeed by endSpeed. params.bezier_dAV =1/(totalMoveTime - decelStartTime)

totalMoveTime does not exist in the current code and needs to be calculated (part of the work pending).On Drivemovement.cpp I have added a new function for the class DriveMovement that will calculate the instant velocity.

float instantVelocityBezierAccelerationPhase (const uint32_t currentTime) { // Instant velocity is defined by the formula // V(t) = At^5 + Bt^4 + Ct^3 + F // Implemented with Horner’s Method for Polynomial Evaluation // Polinomial coefficients are {bezier_aA,bezier_aB,bezier_aC,0,0,bezier_aF} // Current time shall be normalized between t=[0,1]. float t= currentTime*bezier_aNormalize; // this ensures time will be between 0 and 1 float result = bezier_aA; result = result*t + bezier_aB; result = result*t + bezier_aC; result = result*t*t*t + bezier_aF; return result;}

Finally, on CalcNextStepTime functions, for the Acceleration phase

nextCalcStepTime = 1/instantVelocityBezierAccelerationPhase(timeSinceMoveStart);I still have not figured out how to calculate "timeSinceMoveStart". I am reading the code many times and getting more and more familiar with it, but is hard for me as I am new to this firmware.

It has errors. For example instant velocity is float and nextCalcStepTime is defined as uint32_t, and is not complete.

it is necessary to define an M code to be able to select between actual linear velocity profile and S-Curve and add the corresponding "if" on the relevant sections.

Finally I have not evaluated performance and it is more than probable that we need modify the math to use fixed point values the same way marlin has done (https://github.com/MarlinFirmware/Marlin/pull/10337/files).

Let me know if I can help you.

-

@dc42 I do not see the nasty consequences.. Can you elaborate?.

I imagine this as a driving a car. I start the engine and start accelerating until I reach the maximum speed on the road (80Mps for the shake of the story). Then I maintain the velocity and to do that I do not apply any more acceleration to the car (acceleration =0). If I see a curve, I push the brake and reduce velocity a bit to 60Mps (decceleration) and at the exit of the curve I push the accelerator to increase speed again to 80Mps for the next road segment.

In this drive, there is an inflexion point when the car reaches the minimum speed and before it starts accelerating again (gains more velocity). If the movement is smooth the speed profile would be like a "U" with the minimum speed reached at 60Mps. On the bottom of the U, the tangent (acceleration) is horizontal and therefore the acceleration is 0, and this does not produce discontinuities or nasty consequences.Also a third order motion profile will have 0 acceleration at the start end new of each move and will have the same consequences so I see no differences (except for the fact that it will have jerk).

-

@dc42 said in 6th-order jerk-controlled motion planning:

...So at present I favour traditional S-curve motion (3rd order motion profile). See https://pdfs.semanticscholar.org/a229/fdba63d8d68abd09f70604d56cc07ee50f7d.pdf. But before I make a decision, is anyone reading this thread aware of any evidence that higher order motion profiles are advantageous?

@dc42 I'm gonna throw in this quote from the paper I linked to:

...the trigonometric S-curve trajectory is:

• simple as 3rd order polynomial model and

• capable of producing smooth trajectory as good as 5th order polynomial S-curves and quintic splinesThat's what drew me to this solution in my testing -- a close approximation of 5th order with only 3rd order effort, by replacing this angular jerk curve:

with a sinusoidal jerk curve -- I mean look at it, it's beggin' for it!

If you're considering limiting the implementation to 3rd order to keep it simple / maintain performance, this may be something easy and worth adding?

If you're considering limiting the implementation to 3rd order to keep it simple / maintain performance, this may be something easy and worth adding?Honestly, anything that get us away from instantaneous jerk is going to be the largest single improvement (even the simplest 3rd order will help).

Beyond that, the debate over what's the best way to shape higher orders (splines, trig, polynomials, etc) can go on forever, and no answer will please everyone. I don't know how reasonable it is, as this is deeply tied into everything motion planning, but maybe consider if it's possible to encapsulate that shaping math enough that others can plug in their favorite method? You know, to get people off your back.

-

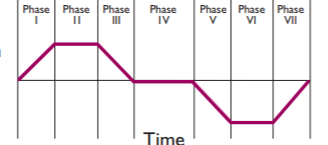

@larzarus, in the particular example you give, sinusoidal acceleration would indeed be a close approximation, although it would be computationally much more expensive unless the sine curve can always be generated by a lookup table. However, if you imagine the same profile but with phase II and phase VI much longer than phases I, III, V and VII then it will look nothing like a sine curve.

I think all the papers about movement profiles that have been quoted in this thread assume point-to-point movement, i.e. whatever we are trying to move starts at rest at one point, and we want to move it to be at rest at another point as fast as possible without exceeding acceleration and velocity limits, and with jerk controlled to reduce the tendency to excite vibrations. So the velocity and acceleration start and end at zero. Although most travel moves in 3D printing fit this profile, many printing moves do not.

-

@dc42 Zero acceleration at the end points is shown in many examples, but it is not a requirement of this approach. Jerk is zero at the end points (a good thing) but acceleration at the start and end of the segment can be any value.

The sinusoid function is applied to jerk, which will result in a graceful s-curve acc instead of an angular one. You can still calculate all seven phases separately, with the sine function only being applied to jerk when jerk !=0. The only difference to the normal 3rd order calculation is instead of calculating linear jerk (a = a + j *t) for phases I, III, V, and VII, you apply the sine scalar multiplier (half sine wave on each phase) to the j term. Phases II, IV, and VI stay linear (jerk = 0) and be as long or short as necessary.

Yes, sine is a lookup table (one quarter cycle is enough, as you can flip it and/or invert to get the entire curve as needed)

-

I really do like the approach of the sinusoidal functions. Is a good trade-off between desired effect and computational cost.

Just one thought: Is it worth dividing the movement on 7 phases or just 3 would be sufficient?. The reasons are the following:

-

As Lazarus correctly mentioned on a previous post, applying a sine scalar multiplier would have an almost-linear section in the middle, effectively making for three nicely blended sub-phases (net 7 motion planner phases, as dc42 is refers to) with less planning effort.

-

The sinusoidal approach is based on constraining the Acceleration time according to the equation [1] on the paper provided by Lazarus to T=(max Acceleration)*pi()/(max Jerk) so that jerk is zero on the joints. Maximum acceleration and maximum jerk are configurations parameters for the printer. Adding more phases/joints where this constraint needs to be met would probably limit/constraint the movement time to reach top speed, while the existing 3 phases movement would do the same with only one joint constraint.

At the end, maximum acceleration and maximum jerk are configuration parameters that can be tuned to obtain maximum performance, so that this is probably not a problem, but definitely facilitates the implementation.

Note that if acceleration is defined in mm/s2, jerk here is defined in mm/s3.

-

-

I have been exploring the idea of a sinusoidal s-curve that can be generated easily lately, you can check a crude implementation of a three-phase sinusoidal speed profile: http://fightpc.blogspot.com/2018/05/one-table-to-run-them-all.html

I am not yet there, but I reckon with some work the idea of a look-up table (as Lazarus did) can provide accurate results with quick computation.

However, only long moves can show a significant benefit as for short ones the number of accelerating steps will make the s-curve approximation a crude one.

-

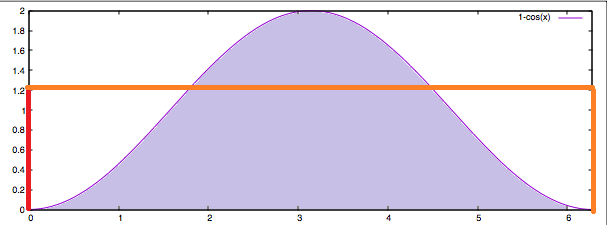

@carlosspr If you consider t-sin(t) expression for the speed increase you have a 1-cos(t) acceleration that will give you a smooth jerk at the speed corners.

A longer version with graphs that hopefully will show my point better:

http://fightpc.blogspot.com.es/2018/04/how-to-get-sinusoidal-s-curve-for.html -

@misan The basic principle in your blog is correct, but there are some constraints that need to be applied and they bring some complications to take into account.

You are modeling the acceleration as (1-cos(t)). The fists constraints to apply are:- Your motor is physically limited by a maximum acceleration (let’s call it Amax) and we would like to reach the maximum acceleration (if possible) to reach the travel constant speed in the shortest time.

- You might want to enter the segment with some initial acceleration (let’s call it a0)

Then you mathematical model for the acceleration becomes a(t) = a0 + (Amax-a0)(1-cos(t)).

Now we would lie a “jerk free” movement, therefore we need to apply another constraint and this is that the derivative of the acceleration shall be zero ant the beginning and the end of the acceleration phase. This gives you a limitation on the time for the acceleration phase

Tacc= Amaxpi/Jmax

This means that we cannot use the same trapezoid calculated for linear acceleration, where the acceleration goes from a0 to Amax instantly. For the trapezoids to be the same, the area under the graphs (this area equals the final velocity) shall be the same, this means that the sinusoidal model would “exceed” the maximum acceleration. I have used your graph to illustrate this:

Actually Marlin implementation using S-Curves has some benefits over the sinusoidal model:

- They use the same trapezoid logic used for instant acceleration model, thy know that they are exceeding the maximum acceleration configured on the firmware, and they are taking some risks here. The truth is that I have several Nema17 and I could not find manufacturer specs for maximum acceleration on any of the brands, and at the end of the day, the settings in my firmware are totally experimental,….

- Their model does not have the constraint of Acceleration time to obtain zero jerk that is required for sinusoidal models.

On my Ideal model I would also like to consider several use cases:

- Some movements are too short/fast and the Maximum desired kinematics (desired speed, maximum acceleration) can not be reached on the distance moved. This would impact/constraint the next segment with initial kinematics (final state of previous move), therefore the model shall consider to enter the segment with some initial acceleration and velocity.

- Some movements might ask for a travel velocity that can not be reached with a simple S-curve (we have a top on the maximum acceleration), and we the need to consider a "flat" acceleration phase until the travel speed is reached.

- Ideally physical constraints are specified by manufacturers and the firmware would respect them.

But it is also true that some approaches, even if the bend the rules (like Marlin and the Aceleration limit), might work easier and better on a real world. At the end of the day, if the model is so complex that it can not be implemented in realtime.... then is useless for now until future processors make them a reality.

-

@carlosspr I do agree motors have a limited torque, and therefore there is a limited acceleration they can produce. For stepper motors, the torque is maximum at low RPM and quickly goes down when motor speeds up (other motors do not have such a pronounced decay).

Static friction has to be overcome at the beginning of each motion with zero starting speed. Once motion is started, the dynamic friction is much smaller.

For a stepper motor, given the maximum speed we want to achieve, we go to the torque vs speed curve and choose, with a significant safety margin, the available torque at that speed. Please note that this is a very low value compared to what the motor is capable to deliver at slower speeds. But it is that low torque what we use to select our fixed acceleration for trapezoidal moves. If the value is too high, steps will be lost, so we chose it conservatively.

Conversely, if you can handle a variable acceleration, you do not need to keep that low value you calculated above for the worst case scenario, meaning motor can speed up faster and reliably.

My plan is to use the same trapezoid logic, with only 3 steps for the motion, with the difference that now acceleration and deceleration use variable acceleration instead of a fixed one (max accel is selected so accel time matches the same as a (smaller) fixed acceleration).

While I do agree the model has to consider non-zero initial or final speeds, I cannot say the same regarding acceleration, which I reckon should be zero at any joint between moves (but I am not sure about this entirely).

Trying to make it all possible in real-time with an 8-bit microcontroller is the reason I focused on working around a table-lookup, which is faster than an N-R solver.

I am still trying to understand Marlin's Bézier Jerk s-curve code.

The massive availability of torque of the steppers at low speeds is what made me think that an asymmetric acceleration s-curve could be a better fit (one with higher acceleration at the beginning instead of a pure symmetrical one like the sinusoidal curve). Of course, the logic would need to mirrored for deceleration.

-

I have finally managed to compile Reprapfirmware (had lots of problem with the ARM toolchain). I have tried to implement the S-Curve based in Bezier algorithm, but I cannot make it work.

I am posting here findings and reasoning to see if someone in the forum can see the errors and where it fails and/or clarify possible wrong concepts. i have the feeling that it might be related to unit conversions.... but I can not find the error.

There is not much documentation on how Reprap implements the Movement, so I have tried to understand it by reading the code. However, due to real-time optimizations the implementations are hard to follow and my findings can be wrong.

As far as I understood, the class Move controls all movement of the RepRap machine, both along its axes, and in its extruder drives.

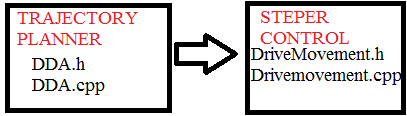

The planner is implementer in DDA.h/DDa.cpp and the Control of the steppers in DriveMovement.h/Drivemovement.cpp

TRAJECTORY PLANNER (DDA): Implements a line tracing using Bresenham algorithm. In other words, it buffers movement commands and manages the movement profile plan. This ensure that our printer moves as fast as is possible within the kinematic constant constraints at the configuration.

This are the variables used by the motion planner to manage acceleration (defined in DDA.h).

float accelDistance; float steadyDistance; float decelDistance; float requestedSpeed; float startSpeed; float topSpeed; float endSpeed; float targetNextSpeed;All speed units are in mm/s

STEP CONTROL: The step control is performed at Movement.h and Movement.cpp. The process determines for each drive instants of the time t (in processor [cycles]) when pulses (steps) are generated based on the calculated profile.

There are two methods – two group of algorithms - for calculating instants of time when pulses must be generated. They are named as: “time per step” and “steps per time”. Reprap uses "time per step" with the following operation mode (as I could understand from the code):

- 1./ calculate time period to next pulse (nextCalcStepTime),

- 2./ wait until that much time period elapses,

- 3./ generate next pulse and

- 4./ go back to step (1) and repeat until desired number of pulses is over .

It is not very clear to me the algorithm followed to calculate nextCalcStepTime and I could see some compensation clocks on the formula which also I do not quite understand well.

In order to add an S-Curve profile, I followed Marlin approach to use the same trapezoid generated by DDA and only implemented changes in DriveMovement.

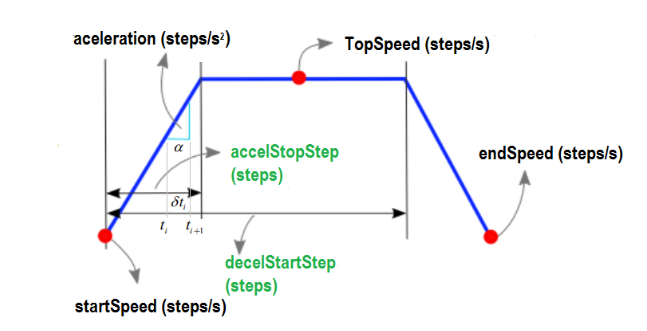

The first step I did was to draw the trapezoid using as speed units steps/s and the variables available in the code:

The trapezoid is the shape the speed curve over time in steps per second.

- It starts at step=0, accelerates until accelStopStep,

- then keeps going at topSpeed (constant speed) until it reaches decelStartStep

- after which it decelerates until the trapezoid generator is reset to next DDA at totalSteps.

The first pulse (step) controller generates at the start of motion, at the start of the phase of acceleration, i.e. at the step time t=0. After the first pulse is generated, the controller needs to calculate the time period until the next pulse (nextCalcStepTime) wait until this period has elapsed, and then generate the next pulse, at step time t=1. This will go on until the desired position is achieved, or in other words, the desired number of pulses (steps) has been generated.

Since after each pulse the motor makes one step of distance 1/stepsPerMm, the time delay between two successive steps is given by

*nextCalcStepTime* = 1 / ( stepsPerMm * V(t) )Instead of a linear speed in the acceleration and deceleration phases, V(t) is replaced by the quintic (fifth-degree) Bézier polynomial for the velocity curve:

V(t) = V_f(t) = A*t^5 + B*t^4 + C*t^3 + D*t^2 + E*t + FAnd this is calculated using the Bezier S-Curve with the same code developed by Eduardo José Tagle (Marlin).

The trapezoid generator state in DriveMovement.cpp contains the following information, that we will use to create and evaluate the Bézier curve:

accelStopStep [TS] = The total count of steps for this movement. (=distance) dda.startSpeed * stepsPerMm [VI] = The initial steps per second (=velocity) dda.topSpeed * stepsPerMm [VF] = The ending steps per second (=velocity) nextStep [CS] = count of steps completed(=distance until now or current step)In DriveMovement:Prepare, at the start of each trapezoid, I calculated the coefficients A,B,C,F and Advance [AV], as follows:

* A = 6*128*(VF - VI) = 768*(VF - VI) * B = 15*128*(VI - VF) = 1920*(VI - VF) * C = 10*128*(VF - VI) = 1280*(VF - VI) * F = 128*VI = 128*VI * AV = (1<<32)/TS ~= 0xFFFFFFFF / TS (To use ARM UDIV, that is 32 bits) (this is computed at the planner, to offload expensive calculations from the ISR) **/For the deceleration part, we use the same approach, but adapted to the initial velocity and final velocity of the segment:

* totalSteps - decelStartStep [TS] = The total count of steps for this movement. (=distance) * dda.topSpeed * stepsPerMm [VI] = The initial steps per second (=velocity) * dda.endSpeed * stepsPerMm [VF] = The ending steps per second (=velocity) * nextStep [CS] = count of steps completed(=distance until now or current step)Finally, in DriveMovement::CalcNextStepTime we calculate nextCalcStepTime for the S-Curve profile

nextCalcStepTime = 1 / (eval_bezier_curve(nextStep) * stepsPerMm); nextCalcStepTime = nextCalcStepTime * StepClockRate;The time is multiplied by the StepClockRate to get the number of clock cycles.

Probably I would need to add compensation Clocks.... but I do not understand why this is in the formula on the current firmware and could not test because it does not work properly.I could provide the Source code from DriveMovement.cpp and DriveMovement.h which are the only parts changed in case that anyone wants to investigate further......

-

It sounds that you have done some good work. The compensationClocks parameter is only used when applying pressure advance. So it is zero for ordinary axis movements, and zero for extruder movements if the pressure advance for that extruder is set to zero.

-

Bit late to the party, but adding some points that I think are important...

Yes, corner velocity jumps are a bigger deal than the straight-line acceleration scheme. But those are separate issues. You can improve print quality by changing cornering behavior OR straight-line acceleration behavior.

There IS value in going up to 4th-order motion. Specifically, this is what is required to get those nice "glass of beer doesn't slosh" or "pendulum stops nicely" motion profiles. Anything over 4th order is pointless in this application (and frankly EVERY application except satellite moment control) but the G2/Marlin Bezier curve implementation has more processor-friendly math with 6th order motion than it would with a 4th order implementation. So there was no downside for Synthetos to go straight to 6th-order in G2. If it weren't for implementation math quirks, 4th order would be where you'd stop.

There are two very real factors for why 4th-order (or higher) motion control will give better print quality:

-

When you traverse a corner via the normal decel-jump-accel scheme in RRF, the motor torque demands and drivetrain loads from the corner and from the straight-line acceleration out of the corner are ADDITIVE. The printer is still violently executing the corner velocity jump when the next segment's straight-line acceleration kicks in, so you have larger peak forces/deflections. Any S-curve profile has a brief moment of negligible straight-line acceleration out of the corner, which reduces peak forces and allows the system to settle a bit. (Note that you could emulate this by simply waiting a millisecond or whatever before acceleration starts on the next segment.)

-

As we all know, real drivetrains (and the stepper torque response as well) are elastic and have a position error that depends on drivetrain force. And force is mass * acceleration. And RRF's second-order motion control has instantaneous changes in acceleration. For a rigid body, that's fine, acceleration/force can change "instantly" (ignoring stuff too fast to worry about like speed of sound in the material anyway) and there's no problem. But it's an issue for elastic systems. Instantaneous change in acceleration means an instantaneous change in force, which for an elastic system means instantaneous change in drivetrain deflection, which means instantaneous change in nozzle position error. And THAT is impossible. If you try to instantly change force on an elastic system, you get oscillation and you get peak deflections ~2x higher than the equivalent steady-state force. Thus, more ringing.

Now, what people tend to forget in these discussions is that the motion controller isn't moving the load, it's sending step pulses to a stepper driver, which generates a target position (coil energization phase angle), which generates a torque in proportion to the rotor angle error. So you've got two problems that people don't like to talk about:

- Position quantization and timing jitter -- there's no point in trying to control motion much more precisely than the fundamental precision of the step pulse train and resulting position stairstep profile.

- Motor following error -- steppers only generate torque in proportion to POSITION ERROR (strictly the sine of error) so all your fancy motion control step pulse train timing is getting low-pass filtered by the motor. This is the main reason velocity jumps at corners are possible. Your printer is probably about a 1/16th microstep behind where you think it is, any time it's accelerating. (You could feed-forward control this error out if you know the load inertia and motor torque, but it's probably not worth the trouble.)

So, yeah, S-curves are better than constant-accel, but you also want to understand how the firmware behavior gets turned into nozzle motion so you don't go overboard.

As for the G2/Marlin Bezier 6th-order code specifically... I don't like it. I think it does something dumb on arcs, which will be brutal on segmented delta firmwares like Marlin: it drops to 0 acceleration at every segment corner. When you have axis direction reversals, like a >90 degree corner on a Cartesian printer, that's good and normal behavior. But that's undesirable on arcs where you have multiple segments in the same axis direction but at different speeds/accels. For example, say you're starting from zero into a gentle, finely-faceted arc with a lot of short segments. The cornering speed algorithm will not register any need for corner slowdowns on this kind of geometry. (Which is itself an issue with the code, but that's a separate discussion.) So RRF will try to accelerate through the arc over multiple segments until it reaches command speed. We WANT acceleration to continue through these gentle corners so you don't cause unnecessary loss of speed or unnecessary changes in drivetrain force. But the Bezier code implementation can't handle non-zero entry/exit acceleration values... which I think is a big implementation failure.

-

-

@rcarlyle, I agree with all of that. The fact that the Marlin algorithm forces zero acceleration at the segment boundaries was bothering me too.

I expect to start work on this in July. Using a 6th order Bezier curve, I think there are enough parameters to match target accelerations at the segment start and and as well as target speeds, but the maths to work out the parameters may be difficult. If it turns out to be too hard then I can try implementing classic 7-phase motion instead of the current 3-phase.

Any solution also needs to eliminate commands to change velocity instantaneously ("jerk" in the 3D printer sense), by planning a deliberate deviation from the commanded path instead of commanding instantaneous speed changes and getting an unplanned deviation as a result.

-

Dear @carlosspr , thanks for explaining part of the firmware source files. If you want, I can help you checking your changes.

My proposal:

- isolate the formulas so they can be tested independently (unit testing)

- take real world examples of parameters

- calculate the values with your formulas

- test plausibility by differential time slices, e.g. V-t diagram. E.g. the S curve should show up

- if the formula are correct, at least some sums must be correct, like total distance in given time

It is possible to use mathematical simulation programs for the task, but to start easy you can use a spreadsheet program, each row a diff t. The lower diff t, the more exact the results.

-

@dc42 I think you need to decide whether to work on addressing corner jerks or work on nth-order straight-line motion, because the solutions strike me as more or less mutually exclusive. Deviating from corners means your paths are no longer exclusively a series of straight lines and corners, so from what I understand the entire motion planner and step interpolation scheme have to be reworked. For long segments you can just clip off the start and end, insert a new radius-arc motion to replace the corner, and keep the segment-middles as straight-line paths like normal. But with short segments, I think there's some complexity around deciding when/how to merge multiple gcode commands into a single radius'd arc or what have you. (Maybe you have something in mind.)

Personally, I'm fine with corner velocity jumps for this application, and am even fine with position jumps on extruder axis (eg pressure advance motions), because they work just fine with real steppers and servos when you stop ignoring driver+motor behavior. I would prefer to see a better cornering-speed-determination algorithm invented rather than eliminate them entirely. You probably know this, but here's what I've seen done:

- Limit speed change for each motor (Sailfish)

- Limit nozzle velocity vector delta magnitude (older Marlin, Repetier)

- Limit "junction deviation" which is some arbitrary hocus with no real physical significance, but gives pretty good results... the CONCEPT is combining a radial acceleration limit with an error tolerance to round off corners, but it doesn't actually follow the trajectory required to implement that; it just uses the derived speed you WOULD use if you did it

My opinion, what we really ought to do is take the motor's behavior into account. For example, 3d printers are typically built with utterly ridiculous torque safety factors (like 50:1 on nominal acceleration), and what really limits cornering speed is the force:error relationship for the printer versus acceptable print quality. (IE the sum of motor following error and drivetrain deflections.) So we should be using a calculation connected to how velocity jumps exert forces on the mechanism. If those forces are comparable to the desired acceleration forces, there's no issue whatsoever with the corner velocity jump. I think that can be reasonably approximated as an elastic impact model, ie the change in kinetic energy due to the velocity jump is converted into elastic energy stored in the drivetrain as a spring deflection. You can thus turn the velocity jump into a peak force and predicted error. The trick here -- what nobody has brought together yet to my knowledge -- is that a lot of the drivetrain inertia is in the rotor, and a lot is in the extruder/bed, so on printers like deltas where the drivetrain ratio is variable, you need to check BOTH the rotor delta-V and the nozzle delta-V and either limit both separately or limit some kind of summing function of the two.

Ideally you'd calculate the total system inertia (moving mass reflected through drivetrain ratio, plus rotor) and velocity changes at each corner to get an actual delta-Ke value, and also calculate the total drivetrain elasticity at each corner according to the machine position, and use those to model a corner error due to the jump, but I doubt that's worth all the trouble. There's probably a simplified approach that captures the various factors with an empirically-tuned limit parameter like we use today. For example, combine a junction-deviation type calculation with a Sailfish-style motor speed change limit. Or convert the cornering jump into an equivalent acceleration based on some heuristic. Etc.

Changing gears. Deviating from the path according to a defined tolerance is a viable and reasonable approach as long as the max error is user-configured. MachineKit has a 3-axis trajectory planner mode that does this. (People use velocity extrusion to slave extruder motion to the 3-axis planner for 3d printing, although I personally think this violates a Stratasys patent.) However, it's a huge change from the GRBL ancestry all the major 3d printer firmwares use. You also probably want to be able to switch the allowed error mid-print so you can run infill rougher and perimeters finer, for example. (There's no fundamental reason for infill to use higher nominal feedrates than perimeters -- we just don't have good motion planners for complex perimeter geometry yet, so we drop perimeter speed to compensate for GRBL sucking.)

What I would suggest with corner-rounding is apply either a RADIAL nozzle acceleration cap and an acceptable path deviation, or PER-AXIS acceleration caps (cartesian axis or motor) and position errors. The path and rounded-cornering speed is then whatever trajectory achieves those max accels and errors. You get different corner-rounding shapes with the different approaches -- circle arcs from a radial acceleration cap, elipses for cartesian axis acceleration caps, and who-the-hell-knows-what from delta motor acceleration caps.

This gets more complicated when the segment size is small enough (ie similar magnitude as allowable error) such that the rounded trajectory spans more than two segments. Machinekit starts by merging small segments wherever the merged path results in less path-following error than the defined limit. That helps a lot. But it's another source of lost path-following fidelity. Then you have to do some iterative work over a queue to generate the overall rounded path, but I'm fuzzy on the details of how that's done.

If you really want to get complicated, you corner more like a car does, and combine centripetal acceleration with radial acceleration along a conic profile or something to achieve a constant combined acceleration. But that seems like too much to try to tackle.

-

Oh, I also want to point out that GRBL's biggest speed control shortcoming is that it only looks at corners, and not radial acceleration across lots of segments. Finely-faceted smooth curves are basically ignored by all the mainstream 3d printer firmwares (except MachineKit). We really ought to be checking radial acceleration through arcs so the printer doesn't overspeed through them. The challenge there is how the firmware identifies an arc and determines what run of segments to check for radial acceleration...

-

Somebody wrote above that it's not possible to test different methods easily without a new firmware version and uploading.

But there is a possibility of scripting inside a program: you can script on the fly and test different possible functions, like the jerk functions above. A true evolutionary approach would be script variations - print and measure - take best of the variations. Print + measure could be a laser or led through the nozzle and photodiodes instead of real filament.