New Product Release - Precision Piezo Orion

-

Thanks,

with ID 10mm I should get 1 x bowden and 1 x water tube in 1 whole, not? Should be 2 mm air theoretic

What printed parts are needed (in general)

Can you give me an example how to mount the Chimera air cooled? (With thingiverse links which parts I need)

I'm asking, because I want to think about a Chimera Aqua mount solution -

In theory yes but in practice the bowden tube has to go through the centre of the hole which I don't think will leave enough room for the cooling tubes.

With respect to the mounting, I don't think that the aqua variant has mounting holes on the top which will make mounting it to an Orion more difficult. I don't have an example of how to mount the Chimera Orion to a printer except that it mounts the same way as the screwmount standard Orion. The top part has four 3mm holes in an 18mm square that you would mount to your printer with some form of bracket. The rest of the Orion assembles in the normal way.

The chimera mount was intended as an example of how it could be done, for other people to take and adapt to their printers which is why it's marked as beta.

Idris

-

Why does the bowden tube has to go through the centre?

If I still got the bowden couplers on the heatsink, the bowden tube doesn't need to go in the centre, right?

Can you give a simple drawing of the orion pcb? I just want to try a design and have no orion

-

The bowden tube doesn't have to go through the centre. With the chimera you'll have two bowden tubes and one will have to go through each of the two diagonal holes. I don't have a drawing of the Orion to hand, the assembly holes are 26mm apart, the 10mm holes are on the diagonal and 19.8mm apart, the centre hole is 6mm and the overall PCB is 32x43mm

Idris

-

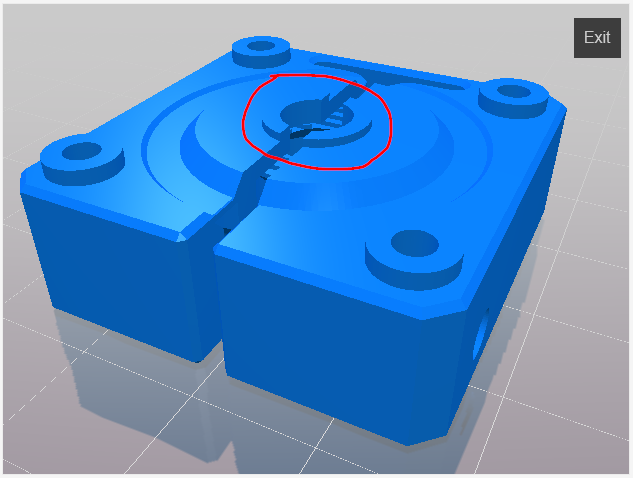

Is the part circled in red the part that deforms the piezo board during contact? I am going to attempt to make more room under it as it currently doesn't fit an E3D without depressing the PTC collet which allows the PTFE tubing to float causing problems on a Lite6 which has it all the way down to the nozzle. I was also not able to get it to clamp on either of the J-Heads I have, it appears to be hitting the chamfers. I think the groove height could be reduced so the width includes the ends of the chamfers.

I did find a way to constrain the PTFE liner on the E3D using the extruder and its working great.

-

Hi, how does the Chimera+ mount will mounted on a carriage? How was the idea to mount with parts given in the link?

-

Hi there,

Can I use this with an E3D titan Aero? if so do you have a link to details of how to?

Haha, teach me to look properly. Spotted it on the main website. amyone got alternative mounts? im printing on a BLV mod with mgn 12 rail on top of an alu 2020 extrusion so getting a decent hotend mount for the aero is proving challenging....

Cheers

James

-

@tjb1 That's correct. The PTC? collet on the e3d v6 can be removed, just pull it out when there's no PTFE tube in.

@hevilp I don't have details of how you would mount that to your printer, you would need to design some form of bracket that would have the top part of the chimera mount screwed to it.

@Dashik Currently the Orion is not compatible with the Titan aero, however, I have been testing a new board on my printer (a core XY) with a Titan aero and it's been working very well. I hope to release it when I get home from holiday on the 19th.

Idris

-

@moriquendi said in New Product Release - Precision Piezo Orion:

@tjb1 That's correct. The PTC? collet on the e3d v6 can be removed, just pull it out when there's no PTFE tube in.

Idris

The PTFE is required on a Lite6 as it's going all the way to the nozzle and most printers don't have another way of holding the tube in or tight against the nozzle. The PTFE isn't as important on a normal V6 as it stops midway in the heat sink.

-

@tjb1 I think I may have misunderstood. If you're using a Bowden Orion from me then you have a bowden collet on the top of the Orion module, in which case you'll probably want to remove the bowden collet from the top of the V6 otherwise your bowden tube will be very difficult to remove.

If you're using a direct extruder you should be able to cut a piece of PTFE tube that's exactly the right length to go between your extruder and the v6 without any movement. In which case the bowden collet on the v6 simply gets in the way if you need to remove the PTFE tube for any reason.

Or maybe I'm missing something ??

Idris

-

@moriquendi Thanks, I look forward to reading about it.

-

I find that https://www.thingiverse.com/thing:3046312 , should fit my needs..

In your thing you say you need 8 x M3 x 3 brass inserts. Where do they go? In the outer screw wholes?

-

@hevilp Four go into the assembly holes in the corners of the bottom part, four go into the diamond arrangement of holes nearer the centre of the top part.

Idris

-

Okay thanks,

the orion is titan extruder compatible or?

-

Yes, it is compatible with the titan extruder.

Idris

-

Any chance that a version might be usable somehow with the diamond nozzle? Really like the idea of multimaterial and multicolour options.

-

I have a product in development that should be much easier to integrate with more exotic hotends like the diamond.

Idris

-

New Orion user - first impressions and feedback...

(This is fairly long, so if you're only interested in the Orion itself, please skip 3 paragraphs.)I had been using a Titan Aero direct drive extruder on my delta printer, with FSRs for bed leveling. While others have had great success with FSRs, I haven't been so lucky. With the FSRs on my printer, things were inconsistent enough that even 2 days after manually setting the trigger heights on every location in bed.g, I'd end up with a not quite "flat" Z plane (which, as far as I can tell, is a result of duet auto-calibration and inconsistent Z probe triggering.) I actually had better luck using probe type "0" and manually finding Z0 on auto-calibrations (and then NOT doing an auto-calibration each build.)

My first idea for "fixing" this was to somehow get a precision piezo system working with the titan aero. However, that's really not easy when the titan aero (and stepper) is hanging from a delta effector. I'm sure someone with better mechanical engineering skills than I possess would be able to figure it out, but I took an easier way out:

I purchased the precision piezo orion, and "downgraded" my titan aero to a simple titan extruder with a genuine E3D V6 heatsink/hot end. I lost about 44mm of build height in doing this (which leaves me with a mere 411mm in the center of the delta and about 50mm less at the edges.) I see/hear no performance or noise difference whatsoever in regards to the extruder/heatsink setup. I will mention that I've seen two benefits of the "downgrade": First, I prefer the more controlled airflow of the heatsink fan and second, I like that I can actually see the tension adjustment in the little titan extruder window.

As for the Orion itself, my very first impression was NOT positive. In order to properly attach the base part of the orion to the genuine E3D heat sink, I actually had to clamp it closed with a pair of vice-grips. Without doing that, the orion "sandwich" wouldn't go together as the 4 holes wouldn't line up. This was much more force than I expected to have to use and I'm relieved that the plastic didn't break as a result. (The inside of the base piece didn't seem to have any stray plastic in the channel for the heatsink. It just looks like the gap/channel might be very slightly too small.)

However, once I got things physically assembled, I have to admit that this thing is absolutely incredible (at least compared to my experience with FSRs.) My first attempt had the sensitivity a bit too high, and the V6 heatsink fan vibration would trigger the piezo. After turning that down a bit, I have an extremely consistent trigger height of 0.065 +/- 0.002mm with a 195C nozzle pressing on a 65C PEI/glass/aluminum heated bed. (I've actually adjusted the trigger height to 0.068 in my G31 in order to produce a very near perfect first layer height.)

Not only is the trigger height consistent, it's consistent all over my heated bed. The entire 300mm diameter plate has the same trigger height. I no longer need any "H" parameters in my bed.g file, and I can actually use mesh compensation if I want to. My method of checking consistency was to check the trigger height at each of the locations used in bed.g, and the ultimate test of printing several single layer, single line/wall "rings" around the build the plate, letting it cool, pulling it off, and spot checking with calipers.

I have to admit - I'm impressed. Thank you, Idris.