Home Z incorrect position

-

@SonnyD1 the scanning nozzle height should be the Z parameter in your G31 K1 command. You appear to have set this as 3mm in your G31 K1 command. You can send G31 K1 to check that it hasn't changed. It's reported as the trigger height.

You could also try setting the dive height (H parameter) in your M558 K1 command, although I don't think that should matter.

-

@dc42 The G31 K1 response:

G31 K1

Z probe 1: current reading 2467, threshold 500, trigger height 3.000, offsets X0.0 Y-38.0 U0.0Do I need to change it?

-

@SonnyD1 Follow the setup and calibration documentation: https://docs.duet3d.com/en/User_manual/Tuning/scanning_z_probe_calibration

- Your SZP is 2.7mm above the nozzle. Currently G31 Z3 is set. This means the probe should be triggering at 5.7mm. This is a bit high (we recommend in the range 4 to 5mm). I think reduce G31 to Z2, unless your bed is very warped (over +1mm).

- Your M558.2 S parameter is high, at S17. Which coil are you using (12mm or 15mm)? Being a bit lower to the bed (with G31 Z2) will most likely change this.

After that, follow the 'initial calibration' steps. I have updated the instructions to make them clearer.

Ian

-

@droftarts I am using the 12mm coil. The Calibration gave me a S parameter of 15. After I followed your instructions, I was able to complete the scan for the first time. However, I looks as though it should have done one more row. There's about 80mm of bed left unscanned. Also, I got a reply of:

Warning: the height map has a substantial Z offset. Suggest use Z-probe to establish Z=0 datum, then re-probe the mesh.

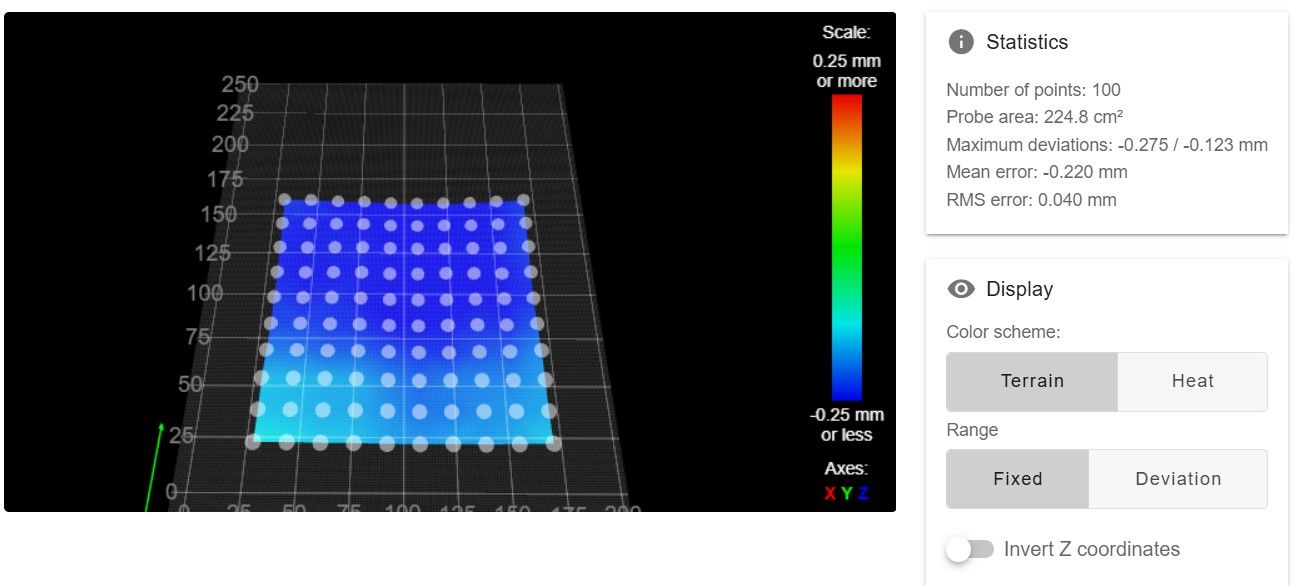

100 points probed, min error -0.275, max error -0.123, mean -0.220, deviation 0.041

Height map saved to file 0:/sys/heightmap.csvHow do I improve on that? Is it talking about Tram or a wavy bed? If its Tram the I can put I dial indicator on it to fix that. I'm going to continue to test at different heights pending your advice.

-

@SonnyD1 Can you post your current mesh.g file? I don't think the error is from scanning, more likely a mesh is being loaded before Z is homed, so the offset from the nozzle is incorrect.

The scan is reporting a pretty flat bed, congratulations! The shape of the scan will show if you need to tram the rails linear rails, maybe take a screen shot of the mesh and post it.

Ian

-

@droftarts I think I found why it left out so much. Bed size is not correct. Fixing it now in the mesh.g. The M557 line should read M557 X19:188 Y15:210 P10 . The info you asked for is below. Is this how we fix the height map warning?

M557 X25:175 Y25:175 P10 ; Define grid for mesh bed compensation, origin in bed centre G29 S2 ; Disable mesh bed compensation G28 Z ; Home Z G1 Z6 ; To avoid backlash move to point higher than start of calibration M558.1 K1 S2 ; Calibrate probe G1 Z6 G29 S0 K1

-

@droftarts Have you given up on me? We're almost done! I'd like to eliminate the error if it's a problem. Let me know what I need to do.

-

@SonnyD1 Not given up, just busy! If you get the message after the SZP scan, I think most likely is that there is a difference between what the BLTouch thinks is Z0 and what the SZP thinks is Z0, with the difference being around 0.2mm. Or when you did the M558.2 calibration, the SZP was higher than Z2. Try doing this again.

Also, if you have G31 Z2 set for the SZP, this is the height around which the M558.1 calibration is done. If you have the M558.1 S parameter set to 2mm, it calibrates +/-2mm around the trigger height (G31 Z2 ie 2mm) so from Z4 to Z0. This means the nozzle will touch the bed. Best to change M558.1 S parameter to something a little smaller, eg 1.7.

Ian

-

@droftarts I did everything exactly as you suggested. I changed the M558 in both the config as well as the mesh.g to S1.7. Then, I meticulously went through the calibration steps. The G29 replied with in the console:

G29

Scanning probe coefficients [1.381e-1, -7.148e-4, -2.015e-8, 2.106e-14], reading at trigger height 8936, rms error 0.137mmAfter completion I got the following error in the console:

Warning: the height map has a substantial Z offset. Suggest use Z-probe to establish Z=0 datum, then re-probe the mesh.

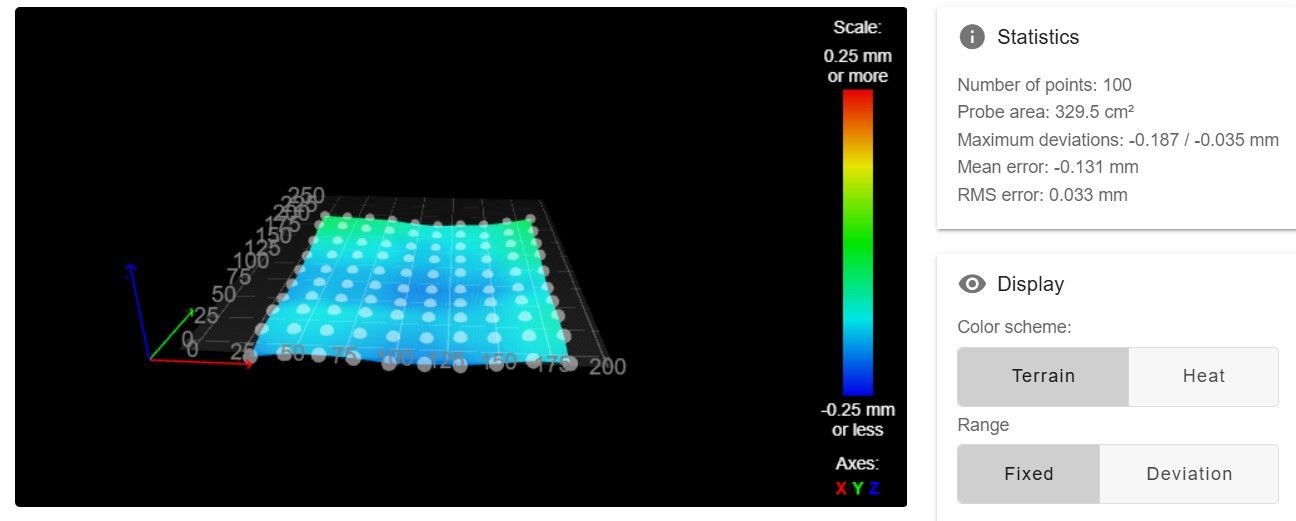

100 points probed, min error -0.187, max error -0.035, mean -0.131, deviation 0.033

Height map saved to file 0:/sys/heightmap.csvHere is the most recent config.g and mesh.g as well as a screenshot of the heightmap:

; Configuration file for RepRapFirmware on Duet 3 Mini 5+ WiFi ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.4 on Sat Aug 10 2024 17:00:36 GMT-0400 (Eastern Daylight Time) ; General G90 ; absolute coordinates M83 ; relative extruder moves M550 P"M3ID V2" ; set hostname ; Accessories M575 P1 S0 B57600 ; configure PanelDue support ; Network M552 S1 ; configure WiFi adapter M586 P0 S1 ; configure HTTP ; Wait a moment for the CAN expansion boards to become available G4 S2 ; Accelerometers M955 P121.0 I20 ; configure accelerometer on board #121 M955 P122.0 I20 ; configure accelerometer on board #122 ; Smart Drivers M569 P0.1 S0 D2 ; driver 0.1 goes backwards (X axis) M569 P0.2 S1 D2 ; driver 0.2 goes forwards (Y axis) M569 P0.3 S0 D2 ; driver 0.3 goes backwards (Z axis) M569 P0.4 S0 D2 ; driver 0.4 goes forwards (U axis) M569 P121.0 S1 D2 ; driver 121.0 goes forwards (extruder 0) M569 P122.0 S1 D2 ; driver 122.0 goes forwards (extruder 1) ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X0.1 Y0.2 Z0.3 U0.4 ; set axis mapping M350 X16 Y16 Z16 U16 I1 ; configure 16X microstepping with interpolation M906 X1750 Y1750 Z800 U1750 ; set axis driver currents M92 X80 Y88 Z1010 U80 ; configure steps per mm M208 X-7:203 Y-9:250 Z0:200 U28:258 ; set minimum and maximum axis limits M566 X900 Y900 Z12 U900 ; set maximum instantaneous speed changes (mm/min) M203 X6000 Y6000 Z180 U6000 ; set maximum speeds (mm/min) M201 X500 Y500 Z20 U500 ; set accelerations (mm/s^2) ; Extruders M584 E121.0:122.0 ; set extruder mapping M350 E16:16 I1 ; configure microstepping with interpolation M906 E424:424 ; set extruder driver currents M92 E2682:2682 ; configure steps per mm M566 E150:150 ; set maximum instantaneous speed changes (mm/min) M203 E3600:3600 ; set maximum speeds (mm/min) M201 E3000:3000 ; set accelerations (mm/s^2) ; Kinematics M669 K0 ; configure Cartesian kinematics ; BLtouch M558 K0 P9 C"121.io0.in" H5 F8000:120 T6000 ; configure BLTouch probe via slot #0 G31 P500 X0 Y24 Z4.249 ; set Z probe trigger value, offset and trigger height M950 S0 C"121.io0.out" ; create servo #0 for BLtouch ; Scanning Z probe M558 K1 P11 C"121.i2c.ldc1612" F36000 T36000 M308 A"SZP coil" S10 Y"thermistor" P"121.temp2" ; thermistor on coil G31 K1 Z1.7 Y-38 ; define probe 1 offsets and trigger height M558.2 K1 S16 R134312 ; set drive current and reading offset ; Endstops M574 X1 P"io1.in" S1 ; configure X axis low end endstop M574 Y1 P"io2.in" S1 ; configure Y axis low end endstop M574 Z2 S1 P"io3.in" ; configure Z axis high end endstop M574 U2 P"io4.in" S1 ; configure U axis high end endstop ; Mesh Bed Compensation M557 X19:188 Y15:210 S40:40 ; define grid for mesh bed compensation ; Sensors M308 S0 P"temp0" Y"thermistor" A"Heated Bed" T100000 B4725 C7.06e-8 ; configure sensor #0 M308 S1 P"121.temp1" Y"thermistor" A"Nozzle" T100000 B4725 C7.06e-8 ; configure sensor #1 M308 S2 P"122.temp0" Y"thermistor" A"Nozzle" T100000 B4725 C7.06e-8 ; configure sensor #2 ; Heaters M950 H0 C"out2" T0 ; create heater #0 (Bed) M143 H0 P0 T0 C0 S120 A0 ; configure heater monitor #0 for heater #0 (Bed) M307 H0 R0.167 K0.222:0.000 D26.05 E1.35 S1.00 B0 ; configure model of heater #0 (Bed) M950 H1 C"121.out0" T1 ; create heater #1 (T0) M143 H1 P0 T1 C0 S300 A0 ; configure heater monitor #0 for heater #1 (T0) M307 H1 R4.287 K0.528:0.232 D2.33 E1.35 S1.00 B0 V24.1 ; configure model of heater #1 (T0) M950 H2 C"122.out0" T2 ; create heater #2 (T1) M143 H2 P0 T1 C0 S300 A0 ; configure heater monitor #0 for heater #2 (T1) M307 H2 R4.334 K0.514:0.239 D2.21 E1.35 S1.00 B0 V24.0 ; configure model of heater #2 (T1) ; Heated beds M140 P0 H0 ; configure heated bed #0 ; Fans M950 F0 C"121.out2" ; create fan #0 T0 Heat Sink Fan M106 P0 C"T0 Heatsink Fan" S0 B0.1 H1 T45 ; configure fan #0 T0 Heat Sink Fan M950 F1 C"121.out1" ; create fan #1 T0 Part Cooling fan M106 P1 C"T0 Part Cooling Fan" S0 L25 X255 B0.1 ; configure fan #1 T0 Part Cooling Fan M950 F2 C"122.out2" ; create fan #2 T1 Heat Sink Fan M106 P2 C"T1 Heatsink Fan" S0 B0.1 H2 T45 ; configure fan #2 T1 Heat Sink Fan M950 F3 C"122.out1" ; create fan #3 T1 Part Cooling Fan M106 P3 C"T1 Part Cooling Fan" S0 L25 X255 B0.1 ; configure fan #3 T1 Part Cooling Fan ; Tools M563 P0 D0 H1 F1 ; create tool #0 T0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C M563 P1 D1 H2 F3 ; create tool #1 T1 M568 P1 R0 S0 ; set initial tool #1 active and standby temperatures to 0C ; Miscellaneous T0 ; select first toolM557 X19:188 Y15:210 P10 ; Define grid for mesh bed compensation, origin in bed centre G29 S2 ; Disable mesh bed compensation G28 Z ; Home Z G1 Z6 ; To avoid backlash move to point higher than start of calibration M558.1 K1 S1.7 ; Calibrate probe G1 Z6 G29 S0 K1 .

.I can say for certain that the BLTouch offset is accurate. It may be worth noting that the M558.2 S parameter changed to 16 with the new trigger height. I know I'm close but I can't seem to figure out what I'm missing. Maybe I could just try different trigger heights ranging from 1.6 to 2.0 and see what that does? I am at your disposal. Thank you for the help!

-

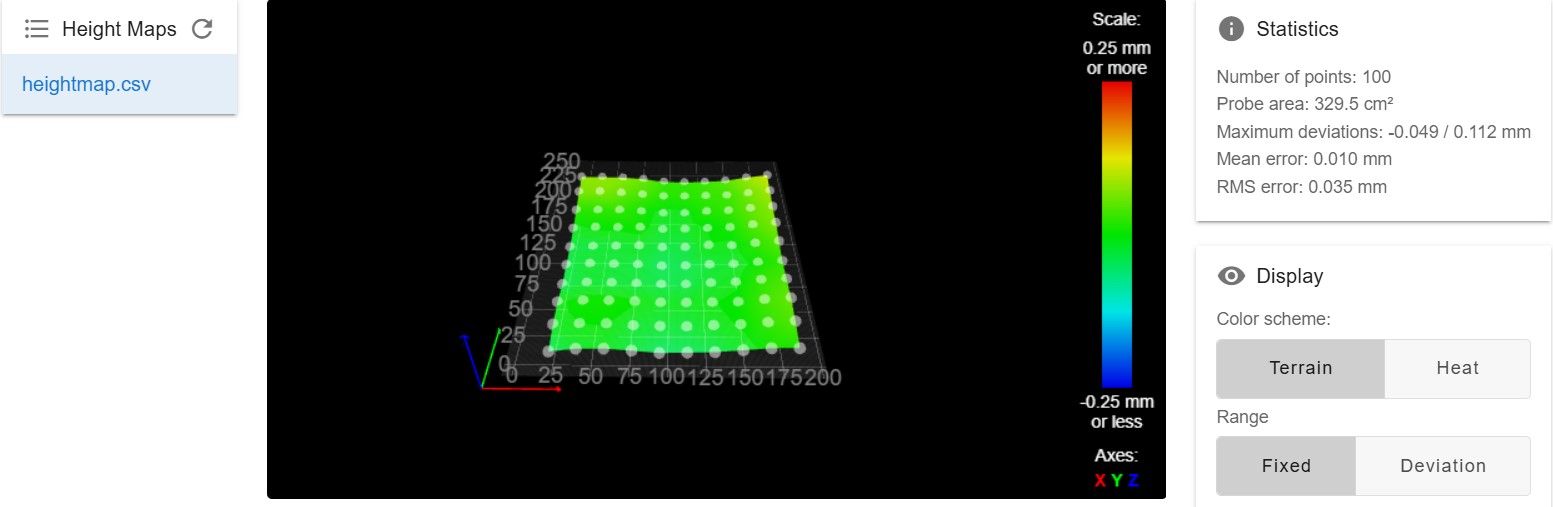

@droftarts After hours of trial and error and reading and trial and error and a bit more reading, I got it to work without the error. I feel like you abandoned me, but I understand that I and the machine were being difficult. In any case, I am attaching my new config.g, mesh.g and a screenshot of the heightmap. Thank you for getting me to the point that I could work through and solve it. Hopefully this will help somebody else.

; Configuration file for RepRapFirmware on Duet 3 Mini 5+ WiFi ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.4 on Sat Aug 10 2024 17:00:36 GMT-0400 (Eastern Daylight Time) ; General G90 ; absolute coordinates M83 ; relative extruder moves M550 P"M3ID V2" ; set hostname ; Accessories M575 P1 S0 B57600 ; configure PanelDue support ; Network M552 S1 ; configure WiFi adapter M586 P0 S1 ; configure HTTP ; Wait a moment for the CAN expansion boards to become available G4 S2 ; Accelerometers M955 P121.0 I20 ; configure accelerometer on board #121 M955 P122.0 I20 ; configure accelerometer on board #122 ; Smart Drivers M569 P0.1 S0 D2 ; driver 0.1 goes backwards (X axis) M569 P0.2 S1 D2 ; driver 0.2 goes forwards (Y axis) M569 P0.3 S0 D2 ; driver 0.3 goes backwards (Z axis) M569 P0.4 S0 D2 ; driver 0.4 goes forwards (U axis) M569 P121.0 S1 D2 ; driver 121.0 goes forwards (extruder 0) M569 P122.0 S1 D2 ; driver 122.0 goes forwards (extruder 1) ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X0.1 Y0.2 Z0.3 U0.4 ; set axis mapping M350 X16 Y16 Z16 U16 I1 ; configure 16X microstepping with interpolation M906 X1750 Y1750 Z800 U1750 ; set axis driver currents M92 X80 Y88 Z1010 U80 ; configure steps per mm M208 X-7:203 Y-9:250 Z0:200 U28:258 ; set minimum and maximum axis limits M566 X900 Y900 Z12 U900 ; set maximum instantaneous speed changes (mm/min) M203 X6000 Y6000 Z180 U6000 ; set maximum speeds (mm/min) M201 X500 Y500 Z20 U500 ; set accelerations (mm/s^2) ; Extruders M584 E121.0:122.0 ; set extruder mapping M350 E16:16 I1 ; configure microstepping with interpolation M906 E424:424 ; set extruder driver currents M92 E2682:2682 ; configure steps per mm M566 E150:150 ; set maximum instantaneous speed changes (mm/min) M203 E3600:3600 ; set maximum speeds (mm/min) M201 E3000:3000 ; set accelerations (mm/s^2) ; Kinematics M669 K0 ; configure Cartesian kinematics ; BLtouch M558 K0 P9 C"121.io0.in" H5 F8000:120 T6000 ; configure BLTouch probe via slot #0 G31 P500 X0 Y24 Z4.3 ; set Z probe trigger value, offset and trigger height M950 S0 C"121.io0.out" ; create servo #0 for BLtouch ; Scanning Z probe M558 K1 P11 C"121.i2c.ldc1612" F36000 T36000 M308 A"SZP coil" S10 Y"thermistor" P"121.temp2" ; thermistor on coil G31 K1 Z1.8 Y-38 ; define probe 1 offsets and trigger height M558.2 K1 S16 R134218 ; set drive current and reading offset ; Endstops M574 X1 P"io1.in" S1 ; configure X axis low end endstop M574 Y1 P"io2.in" S1 ; configure Y axis low end endstop M574 Z2 S1 P"io3.in" ; configure Z axis high end endstop M574 U2 P"io4.in" S1 ; configure U axis high end endstop ; Mesh Bed Compensation M557 X19:188 Y15:210 S40:40 ; define grid for mesh bed compensation ; Sensors M308 S0 P"temp0" Y"thermistor" A"Heated Bed" T100000 B4725 C7.06e-8 ; configure sensor #0 M308 S1 P"121.temp1" Y"thermistor" A"Nozzle" T100000 B4725 C7.06e-8 ; configure sensor #1 M308 S2 P"122.temp0" Y"thermistor" A"Nozzle" T100000 B4725 C7.06e-8 ; configure sensor #2 ; Heaters M950 H0 C"out2" T0 ; create heater #0 (Bed) M143 H0 P0 T0 C0 S120 A0 ; configure heater monitor #0 for heater #0 (Bed) M307 H0 R0.167 K0.222:0.000 D26.05 E1.35 S1.00 B0 ; configure model of heater #0 (Bed) M950 H1 C"121.out0" T1 ; create heater #1 (T0) M143 H1 P0 T1 C0 S300 A0 ; configure heater monitor #0 for heater #1 (T0) M307 H1 R4.287 K0.528:0.232 D2.33 E1.35 S1.00 B0 V24.1 ; configure model of heater #1 (T0) M950 H2 C"122.out0" T2 ; create heater #2 (T1) M143 H2 P0 T1 C0 S300 A0 ; configure heater monitor #0 for heater #2 (T1) M307 H2 R4.334 K0.514:0.239 D2.21 E1.35 S1.00 B0 V24.0 ; configure model of heater #2 (T1) ; Heated beds M140 P0 H0 ; configure heated bed #0 ; Fans M950 F0 C"121.out2" ; create fan #0 T0 Heat Sink Fan M106 P0 C"T0 Heatsink Fan" S0 B0.1 H1 T45 ; configure fan #0 T0 Heat Sink Fan M950 F1 C"121.out1" ; create fan #1 T0 Part Cooling fan M106 P1 C"T0 Part Cooling Fan" S0 L25 X255 B0.1 ; configure fan #1 T0 Part Cooling Fan M950 F2 C"122.out2" ; create fan #2 T1 Heat Sink Fan M106 P2 C"T1 Heatsink Fan" S0 B0.1 H2 T45 ; configure fan #2 T1 Heat Sink Fan M950 F3 C"122.out1" ; create fan #3 T1 Part Cooling Fan M106 P3 C"T1 Part Cooling Fan" S0 L25 X255 B0.1 ; configure fan #3 T1 Part Cooling Fan ; Tools M563 P0 D0 H1 F1 ; create tool #0 T0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C M563 P1 D1 H2 F3 ; create tool #1 T1 M568 P1 R0 S0 ; set initial tool #1 active and standby temperatures to 0C ; Miscellaneous T0 ; select first toolM557 X19:188 Y15:210 P10 ; Define grid for mesh bed compensation, origin in bed centre G29 S2 ; Disable mesh bed compensation G28 Z ; Home Z G1 Z6 ; To avoid backlash move to point higher than start of calibration M558.1 K1 S1.4 ; Calibrate probe G1 Z6 G29 S0 K1

-

@SonnyD1 I said in my last message that I felt there was a difference between where the SZP and BLTouch think Z0 is (and it was only a little difference, like 0.1 to 0.2mm), and suggested what to do. The only difference in your latest config.g compared to the earlier one is you made a small change to the Z offset of the BLTouch, and you recalibrated the SZP and changed it's offset too. That appears to have corrected the difference between them, as I suggested. So no, I didn't abandon you, just waiting for any further information if that wasn't the issue. I'm glad you got there in the end.

Ian