New hotend and delta effector

-

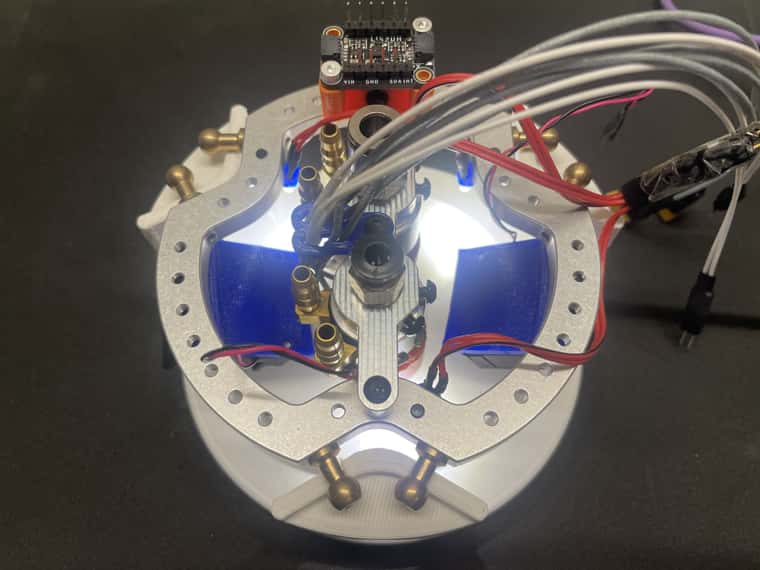

As a small "fun project" i have designed and produced a new hotend and effector for my Delta Tower V2.

My idea was to stay fully compatible with the original Delta Tower hardware but with a smaller and watercooled hotend.

Addititionally, the new hotend design is for 1.75mm filament, to cover both diameters in the future.

The effector is milled from "aircraft" aluminium. There is still some weight reduction possible because the effector is very stiff.But now some pictures of my design. Eventually, it gives some ideas to other forum users.

If someone has suggestions for improving the design... everything is welcome.

-

Some pictures of the "complete" effector.

At the moment, there is one hotend for 1.75mm and one for 2.85mm filament.

![IMG_1274[1].JPG](/assets/uploads/files/1723670462382-img_1274-1-resized.jpg)

![IMG_1276[1].JPG](/assets/uploads/files/1723670520229-img_1276-1-resized.jpg)

![IMG_1277[1].JPG](/assets/uploads/files/1723670578589-img_1277-1-resized.jpg)

![IMG_1280[1].JPG](/assets/uploads/files/1723670635753-img_1280-1-resized.jpg)

-

@cosmowave Looks nice!

Next step could be to integrate the two heatsinks into the mounting bar and also have waterflow in series.

Do you really need brass water connectors? Aren't the air tight Festo-pneumatic couplers also water tight? -

@o_lampe Thanks.

These aren't brass water connectors. That would be too heavy!

They are from coated titanium.EDIT: I tried to save weight where it is possible. I used aluminium bolts to mount the parts on the effector. Next time it would be suffizient to machine the effector in a "L-shape" instead of a "U-shape". Actually it is more than stiff enough and that would be safing much weight.