toolboard endstop problem

-

@nick9one1 I'd be checking the board and the connector in that area very closely to see if there is any sort of solder bridge or stray wire etc. bridging io1.in to gnd.

Other then that I'm out of ideas, maybe one of the duet folks has some suggestions?

-

thanks for you r help with this. I removed the 1LC, reflowed the connectors with plenty of flux and cleaned with IPA - now working.

-

@nick9one1 That's great news! Probably worth pinging @droftarts on this as I know the Duet folks like to keep track of hardware problems!

-

Well I thought it was working, but I think there is still a slight issue with the duet config or slicer.

The hotend fan turns on correctly at 45C

But the part cooling fan doesn't start automatically. If I use the fan slider once the print has started it does work.

The slicer is set to enable it at layer two. -

@nick9one1 change

; Fans M950 F0 C"121.out2" Q80 ; create hotend fan 0 on pin toolboard out1 and set its frequency M106 P0 S0 H1 T45 C"Hotend Fan" ; set fan 0 value. Thermostatic control is turned on M950 F1 C"121.out1" Q250 ; create cooling fan 1 on pin toolboard out1 and set its frequency M106 P1 S0 H-1 B1 C"Part Cooling Fan" ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F1 ; define tool 0to

; Fans M950 F1 C"121.out2" Q80 ; create hotend fan 0 on pin toolboard out1 and set its frequency M106 P1 S0 H1 T45 C"Hotend Fan" ; set fan 0 value. Thermostatic control is turned on M950 F0 C"121.out1" Q250 ; create cooling fan 1 on pin toolboard out1 and set its frequency M106 P0 S0 H-1 B1 C"Part Cooling Fan" ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0Slicers expect the part cooling fan as fan 0

-

deleted.

Thought it wasn't working but it is -

@nick9one1 sounds like something going on in your gcode. could you upload an example file?

-

you were too fast and replied before I removed my post!

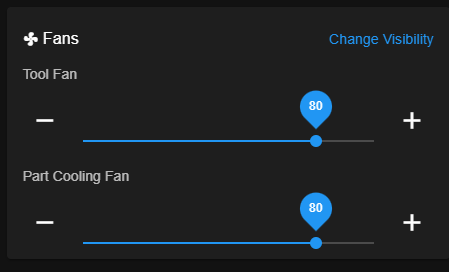

I assumed the 'tool fan' was the hotend fan, but it isn't. If I take both of these down to 0, only the part cooling fan stops.

Although I'm not sure why there are two fans showing in the UI

-

@nick9one1 the tool fan is the part cooling fan of a currently active tool. good for multi tool setups, redundant for single hotend systems (you can hide it)

-

@nick9one1 said in toolboard endstop problem:

I removed the 1LC, reflowed the connectors with plenty of flux and cleaned with IPA - now working.

Sorry you received a poorly soldered 1LC. Do you have a picture of it before you resolder it?

But the part cooling fan doesn't start automatically. If I use the fan slider once the print has started it does work.

The slicer is set to enable it at layer two.Your config:

M950 F1 C"121.out1" Q250 ; create cooling fan 1 on pin toolboard out1 and set its frequency M106 P1 S0 H-1 B1 C"Part Cooling Fan" ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F1 ; define tool 0The part cooling fan F1 is defined as being part of tool 0, so any M106 S# command should turn it on or off. Either your slicer is outputting a P parameter (so trying to turn on a specific fan and not the part cooling fan), or it's setting S below the speed that the fan turns on at. So check the Gcode for M106 commands, and see what it is sending, then check by sending the same command. M106 S255 (or M106 S1) should set it full on.

Your config has the fan frequency as Q250, ie 250Hz. Check that the fan spins up when setting low PWM values - some fans don't like running on PWM, but changing the frequency can help.

Ian