Weird extrusion issue

-

I've been chasing a weird issue for awhile now... actually, probably since I built my Railcore 2 right after the Duet 3 was released.

Setup:

- Railcore II ZLT

- Duet 3 w/SBC

- Revo Roto w/ toolboard and custom aluminum mount

Previously, I had a Hemera and then converted that to a Hemera Revo.

I've completely rebuilt the Z axis system with better Z rods, kinematic bed mount, and oldham couplers, and I'm 99.43% positive that the Z axis is not my issue.

My next stop is to reach out to E3D if nobody here knows what's going on!

The problem has existed across two different extruders (Hemera and Revo Roto) and both direct and CAN toolboard based extruder drivers! The actual steps/mm at 16x microstepping is 90% of factory for the Revo Roto (2414 actual vs 2682 factory). When I was running the Hemera, the published 381 vs 409 steps/mm was about 93% (though I could have been calibrated to PLA at 1.0 extrusion explaining the difference).

I know that various factors affect extrusion flow rate for different materials but that's usually small single digit percentages. For the most part, this is all fine, i just calibrated the extrusion to match what I'm seeing but there appears to be a very, very, very subtle extrusion change every few layers where it under extrudes an almost imperceptible bit and it is driving me mad. Nothing I do changes the result unless I dramatically underextrude. I've even tried changing the stepper mode based on the youtube video from Thomas Sanlanderer.

I suspect the difference between published and actual steps/mm is the key here but it doesn't make sense and I'm at a loss!

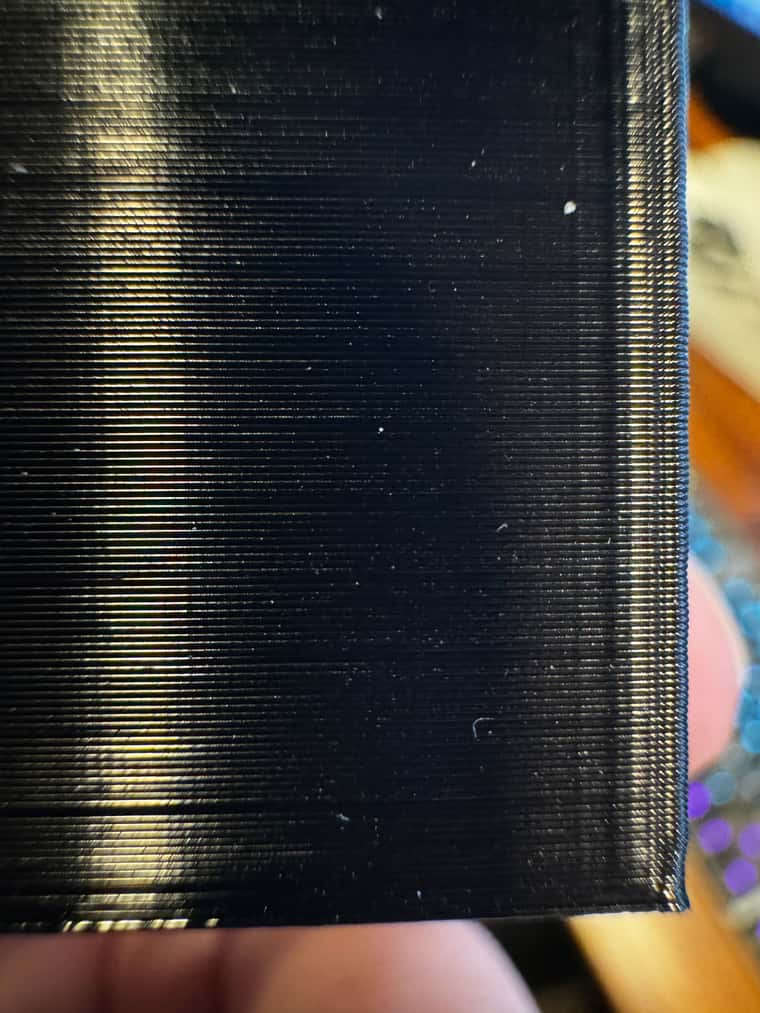

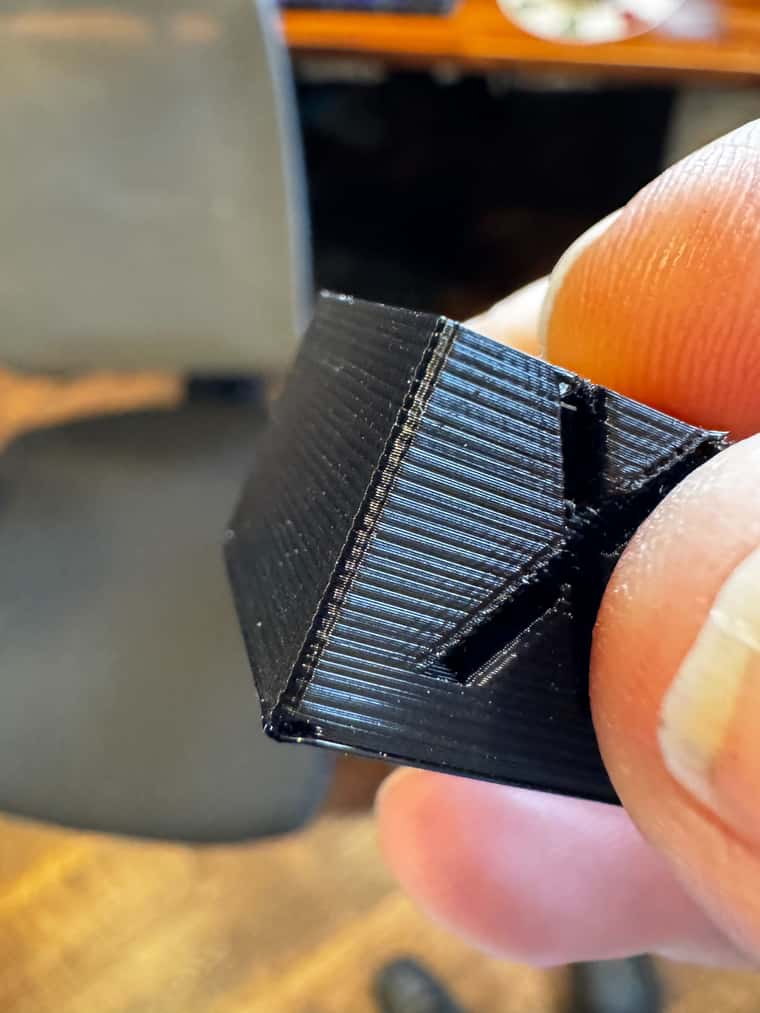

As you can see, part size/geometry does seem to have an impact. The second photo looks much, much worse than it actually is. I photographed it for maximum impact but you can barely see or feel the ridges in real life.

Any help, including being told to "go talk to E3D" is welcome! Thanks!

-

just to get the obvious out of the way: Did you PID tune your bed?

-

@LeonMF It looks like both the extruders you mentioned are dual drive type.

Have you seen this: https://youtu.be/32dTLRNIYmw?si=d5yZB3FCSG-k59EY ? -

@LeonMF In the first image, the wobble on the edge is very consistent, and has a period of 10 layers. What was the layer height, and what is the pitch of your leadscrews? I'd guess that one is a problem with the stepping distance of the Z motors, and you should try and use layer heights that are whole numbers of Z motor steps. Hopefully the Z leadscrews are metric, not inch!

The second one is also quite consistent (when you zoom in on the picture), and looks to have 7 or 8 layers in each period. What layer height was that done at?

Maybe post your config.g for good measure.

Ian

-

This post is deleted! -

@mrehorstdmd said in Weird extrusion issue:

@LeonMF It looks like both the extruders you mentioned are dual drive type.

Have you seen this: https://youtu.be/32dTLRNIYmw?si=d5yZB3FCSG-k59EY ?I'm at work so can't watch the video in detail but there's a good chance it's related to this. I'm not sure there's much I can do about it given the closed nature of the E3D components.

-

@oliof said in Weird extrusion issue:

just to get the obvious out of the way: Did you PID tune your bed?

I'm using Bang-bang because I've had problems with flickering lights in the past with PID. I'm open to trying it if there's a chance it could do something.

-

@droftarts said in Weird extrusion issue:

@LeonMF In the first image, the wobble on the edge is very consistent, and has a period of 10 layers. What was the layer height, and what is the pitch of your leadscrews? I'd guess that one is a problem with the stepping distance of the Z motors, and you should try and use layer heights that are whole numbers of Z motor steps. Hopefully the Z leadscrews are metric, not inch!

The second one is also quite consistent (when you zoom in on the picture), and looks to have 7 or 8 layers in each period. What layer height was that done at?

Maybe post your config.g for good measure.

Ian

The leadscrews are T8x2 leasdcrews with POM antibacklash nuts. I don't have the config.g here with me at work but I'm running 0.2 layer heights, which is an integer multiple of steps.

One thing I need to do is some testing with different sized models and see what the impact is. I've not been deliberate about that but it should highlight the extrusion considerations vs z-wobble.

-

@LeonMF These artefacts look like Bang-Bang induced bed displacement artefacts. I guess you are using an SSR with an AC bed. If its not a zero crossing SSR, get a better SSR, and try to reduce the SSR frequency (I had luck with 1Hz in the past, but it depends on your SSR).

-

@oliof said in Weird extrusion issue:

@LeonMF These artefacts look like Bang-Bang induced bed displacement artefacts. I guess you are using an SSR with an AC bed. If its not a zero crossing SSR, get a better SSR, and try to reduce the SSR frequency (I had luck with 1Hz in the past, but it depends on your SSR).

I'm embarrassed to admit that I defaulted to bang-bang after my last printer caused problems. I never considered it an issue as I wasn't aware that bed stability of a degree or two would be that much of a big deal. I PID tuned this printer and do not have flickering lights. It also seems to have solved my problems.

Ignore the first layer, I was a bit far away.

I have more testing to do but the preliminary results here look good.

Thank you!

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved