home z bug fix

-

Hello everyone,

I'm a complete beginner with Duet 3D, and I'm using the Duet2 WiFi version. After assembling everything, it all seemed to work well. However, I'm encountering an issue when homing the Z-axis. The print bed of the 3D printer moves down three times and then stops at a new position. If I run the home Z command multiple times, the print bed continues to lower until it starts making a noise, yet there are no error messages throughout this process.

I really need help with this issue, so any advice or guidance would be greatly appreciated. If more information is needed to help diagnose the problem, please let me know and I'll provide it as soon as possible. Thank you all in advance!

The home Z code:

; homez.g

; called to home the Z axisT-1 ;just in case there is a tool coupled, go try to drop it at the dock

M98 P/macros/Coupler - Unlock ;Open Coupler

G91 ; Relative mode

G1 H2 Z5 F5000 ; Lower the bed

G90 ; back to absolute positioningG1 X150 Y100 F50000 ; Position the endstop above the bed centre

G4 P500

G91 ; Relative modeG4 P500 ; wait 500msec

G1 Z-300 H1 F1000 ; Move Z down until the switch triggers (first pass)G4 P500 ; wait 500msec

G1 Z5 F5000 ; Lift ZG4 P500 ; wait 500msec

G1 Z-300 H1 F300 ; Move Z down until the switch triggers (second pass)G4 P500 ; wait 500msec

G1 Z5 F5000 ; Drop the BedG90 ; Back to absolute positioning

-

@Adamrobot have you tested whether the endstop is actually working using M119?

what type of printer is it? if its a toolchanger like the E3D one, the switch on the print head is usually treated as a probe and you should be using G30 rather than G1 H1 -

@jay_s_uk

hi jay its the output after using M119M119

Endstops - X: not stopped, Y: not stopped, Z: at min stop, no endstop, Z probe: at min stop

no endstop, Z probe: at min stopand yes its toolchanger, there is a sensor at the bottom of printhead

-

@Adamrobot so from the looks of it you should probably be using G30.

Can you post your config? -

@jay_s_uk hi jay here's the config

; Configurat; Configuration file for Duet WiFi / Ethernet

; executed by the firmware on start-up; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin; Network

; Read https://duet3d.dozuki.com/Wiki/Gcode#Section_M587_Add_WiFi_host_network_to_remembered_list_or_list_remembered_networks

M550 P"ToolChanger" ; Set machine name

M552 S1 ; Enable Networking

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable TelnetM667 S1 ; Select CoreXY mode

; Endstops

M574 X1 Y1 S3 ; Set X / Y endstop stall detection

M574 Z1 S2 ; Set Z endstop probe

M558 P7 X0 Y0 Z2 H3 F360 I0 T20000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds

G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height

M557 X10:290 Y20:180 S40 ; Define mesh grid; Drive direction

M569 P0 S0 ; Drive 0 X

M569 P1 S0 ; Drive 1 Y

M569 P2 S1 ; Drive 2 Z

M569 P3 S0 ; Drive 3 E0

M569 P4 S0 ; Drive 4 E1

M569 P5 S1 ; Drive 5 E2

M569 P6 S1 ; Drive 6 E3

M569 P7 S0 ; Drive 7 COUPLER

M569 P8 S0 ; Drive 8 UNUSED

M569 P9 S0 ; Drive 9 UNUSEDM584 X0 Y1 Z2 C7 E3:4:5:6 ; Apply custom drive mapping

M208 X-35:328.5 Y-49:243 Z0:300 C0:260 S0 ; Set axis maxima & minima

M350 C8 I0 ; Configure microstepping without interpolation

M350 X16 Y16 Z16 E16:16:16:16 I1 ; Configure microstepping with interpolation

M92 X100 Y100 Z1600 C100 E834:834:834:834 ; Set steps per mm

M566 X400 Y400 Z8 C2 E2:2:2:2 ; Set maximum instantaneous speed changes (mm/min)

M203 X35000 Y35000 Z1200 C5000 E5000:5000:5000:5000 ; Set maximum speeds (mm/min)

M201 X6000 Y6000 Z400 C400 E2500:2500:2500:2500 ; Set accelerations (mm/s^2)

M906 X1800 Y1800 Z1330 C400 I30 ; Idle motion motors to 30%

M906 E1000:1000:1000:1000 I10 ; Idle extruder motors to 10%;Stall Detection

M915 C S5 F0 H200 ; Coupler;Stall Detection

M915 X Y S5 F0 H400 ; X / Y Axes; Heaters

M305 P0 T100000 B4725 C7.06e-8 ; Set thermistor

M143 H0 S225 ; Set temperature limit for heater 0 to 225CM305 S"T0" P1 T100000 B4725 C7.06e-8 ; Set thermistor

M143 H1 S300 ; Set temperature limit for heater 1 to 300CM305 S"T1" P2 T100000 B4725 C7.06e-8 ; Set thermistor

M143 H2 S300 ; Set temperature limit for heater 2 to 300CM305 S"T2" P3 T100000 B4725 C7.06e-8 ;Set thermistor

M143 H3 S300 ; Set temperature limit for heater 3 to 300CM305 S"T3" P4 T100000 B4725 C7.06e-8 ; Set thermistor

M143 H4 S300 ; Set temperature limit for heater 4 to 300C; Tools

M563 P0 S"T0" D0 H1 F2 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Reset tool 0 axis offsets

G10 P0 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0CM563 P1 S"T1" D1 H2 F4 ; Define tool 1

G10 P1 X0 Y0 Z0 ; Reset tool 1 axis offsets

G10 P1 R0 S0 ; Reset initial tool 1 active and standby temperatures to 0CM563 P2 S"T2" D2 H3 F6 ; Define tool 2

G10 P2 X0 Y0 Z0 ; Reset tool 2 axis offsets

G10 P2 R0 S0 ; Reset initial tool 2 active and standby temperatures to 0CM563 P3 S"T3" D3 H4 F8 ; Define tool 3

G10 P3 X0 Y0 Z0 ; Reset tool 3 axis offsets

G10 P3 R0 S0 ; Reset initial tool 3 active and standby temperatures to 0C; Fans

M106 P0 S0 ; UNUSED

M106 P1 S255 H1 T70 ; T0 HE

M106 P2 S0 ; T0 PCF

M106 P3 S255 H2 T70 ; T1 HE

M106 P4 S0 ; T1 PCF

M106 P5 S255 H3 T70 ; T2 HE

M106 P6 S0 ; T2 PCF

M106 P7 S255 H4 T70 ; T3 HE

M106 P8 S0 ; T3 PCFM593 F50 ; cancel ringing at 50Hz (https://forum.e3d-online.com/threads/accelerometer-and-resonance-measurements-of-the-motion-system.3445/)

;M376 H15 ; bed compensation taper;tool offsets

; !ESTIMATED! offsets for:

; V6-tool: X-9 Y39 Z-5

; Volcano-tool: X-9 Y39 Z-13.5

; Hemera-tool: X20 Y43.5 Z-6G10 P0 X-9 Y39 Z-5 ; T0

G10 P1 X-9 Y39 Z-5 ; T1

G10 P2 X-9 Y39 Z-5 ; T2

G10 P3 X-9 Y39 Z-5 ; T3;deselect tools

T-1;M572 D0 S0.2 ; pressure advance T0

;M572 D1 S0.2 ; pressure advance T1

;M572 D2 S0.2 ; pressure advance T2

;M572 D3 S0.2 ; pressure advance T3M501; load config-override.g

-

@Adamrobot so yes, your switch on your printhead it setup as a probe so you should be using G30.

I would also suggest you look into upgrading from RRF2 to RRF3 -

@Adamrobot said in home z bug fix:

When you did the M119 and got this back:

Z: at min stop, C: no endstop, Z probe: at min stopWas the endstop/probe touching the bed, or were you triggering it? If not, then you need to invert this in M558 in config.g, ie change

I0toI1:M558 P7 X0 Y0 Z2 H3 F360 I1 T20000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speedsIan

-

@droftarts @jay_s_uk

Hello jay and mr administrator,After implementing your suggestions, part of the home Z function succeeded. However, I need to manually move the printhead above the Print bed position before I run home Z. When I use the home Z command directly after homeX and Y, although the dashboard shows the Printhead's position as 150 and 100, it is actually still in the bottom left corner. In this position, the print bed cannot reach the probe Z sensor.

now im using RRF3

the home Z code:

; homez.g ; called to home the Z axis M98 P"/macros/Coupler - Unlock" ; Open Coupler G91 ; Relative mode G1 H2 Z5 F5000 ; Lower the bed G90 ; back to absolute positioning G1 X150 Y100 F50000 ; Position the endstop above the bed centre M558 F1000 G30 M558 F300 G30 -

@Adamrobot maybe F50000 is just too fast. Try something slower. Maybe take a 0 off

-

@jay_s_uk @droftarts

Great it works!and a followed question: When I attempt to heat the nozzle, it shows that the M568 command is no longer needed. I referred to other posts on forums, and they suggest the issue might be a mismatch but I believe I have installed the latest firmware version for the Duet 2 WiFi/Ethernet. Could there be another reason for this issue? or anywhere wrong?

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.2.2 running on Duet WiFi 1.02 or later + DueX5 Board ID: 0JD0M-9X6JA-JUNSN-6JTD2-3SD6T-KBRRV Used output buffers: 3 of 24 (24 max) === RTOS === Static ram: 23460 Dynamic ram: 76280 of which 60 recycled Never used RAM 12280, free system stack 115 words Tasks: NETWORK(ready,169) HEAT(blocked,308) DUEX(blocked,31) MAIN(running,449) IDLE(ready,20) Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:07:44 ago, cause: power up Last software reset at 2024-01-16 13:48, reason: User, GCodes spinning, available RAM 12280, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU temperature: min 29.7, current 37.5, max 37.5 Supply voltage: min 11.9, current 12.0, max 12.3, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: position 13750, standstill, SG min/max 0/1023 Driver 1: position -16250, standstill, SG min/max 0/1023 Driver 2: position 12800, standstill, SG min/max 0/1023 Driver 3: position 3641, standstill, SG min/max not available Driver 4: position 0, standstill, SG min/max not available Driver 5: position 0, standstill, SG min/max not available Driver 6: position 0, standstill, SG min/max not available Driver 7: position 0, standstill, SG min/max 0/79 Driver 8: position 0, standstill, SG min/max not available Driver 9: position 0, standstill, SG min/max not available Driver 10: position 0 Driver 11: position 0 Date/time: 2024-01-16 14:37:37 Cache data hit count 566541634 Slowest loop: 9.99ms; fastest: 0.18ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 4.0ms, write time 0.0ms, max retries 0 === Move === DMs created 83, maxWait 179513ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 26, completed moves 26, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 24.56ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.26 WiFi MAC address 48:3f:da:a6:84:05 WiFi Vcc 3.40, reset reason Power up WiFi flash size 2097152, free heap 24400 WiFi IP address 10.10.0.163 WiFi signal strength -71dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 2 0 0 0 0 0 0 === DueX === Read count 1, 0.13 reads/min -

@Adamrobot said in home z bug fix:

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.2.2

M568 is supported from RRF 3.3. An older version of the command was supported up to RRF 1.18.

RRF 3.2.2 is not the latest version. RRF 3.4.6 is the current release; download the large zip file "Duet2and3Firmware-3.4.6.zip", without unzipping it, from https://github.com/Duet3D/RepRapFirmware/releases/tag/3.4.6

In DWC, click System > Upload System Files and upload the ZIP file to the Duet. This should update the firmware, DWC and probably the WiFi firmware.Ian

-

Hello Mr Administrator,

I upload the newest RRF version, but I still can't head the printhead:(

temperature rising too slowly: expected 2.32°C/sec measured 0.63°C/sec

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.6 (2023-07-21 14:08:28) running on Duet WiFi 1.02 or later + DueX5v0.11 Board ID: 0JD0M-9X6JA-JUNSN-6JTD2-3SD6T-KBRRV Used output buffers: 1 of 26 (19 max) === RTOS === Static ram: 23896 Dynamic ram: 78284 of which 0 recycled Never used RAM 9564, free system stack 118 words Tasks: NETWORK(notifyWait,15.5%,242) HEAT(notifyWait,0.0%,295) Move(notifyWait,0.0%,282) DUEX(notifyWait,0.0%,24) MAIN(running,84.3%,436) IDLE(ready,0.2%,30), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:10:47 ago, cause: power up Last software reset at 2024-01-16 15:56, reason: User, GCodes spinning, available RAM 9264, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 0 MCU temperature: min 33.8, current 38.5, max 39.7 Supply voltage: min 11.8, current 12.0, max 12.3, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 1 queued, 1 completed Driver 0: standstill, SG min 0 Driver 1: standstill, SG min 0 Driver 2: standstill, SG min 0 Driver 3: standstill, SG min n/a Driver 4: standstill, SG min n/a Driver 5: standstill, SG min n/a Driver 6: standstill, SG min n/a Driver 7: standstill, SG min 0 Driver 8: standstill, SG min n/a Driver 9: standstill, SG min n/a Driver 10: Driver 11: Date/time: 2024-01-16 16:11:41 Cache data hit count 4294967295 Slowest loop: 19.66ms; fastest: 0.19ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 8.9ms, write time 2.1ms, max retries 0 === Move === DMs created 83, segments created 14, maxWait 56617ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 145, completed 145, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 93], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === DueX === Read count 1, 0.09 reads/min === Network === Slowest loop: 22.38ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 = WiFi = Interface state: active Module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.27 WiFi MAC address 48:3f:da:a6:84:05 WiFi Vcc 3.40, reset reason Power up WiFi flash size 2097152, free heap 25136 WiFi IP address 10.10.0.163 WiFi signal strength -49dBm, mode 802.11n, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0 -

@Adamrobot Please post your config.g. Have you tuned your heaters? See https://docs.duet3d.com/en/How_to_guides/Commissioning#h-6-check-heater-functionality and the section after.

Ian

-

@droftarts Hello Mr administrator,

I tried to tune my heater, but it was always unsuccessful. The error displayed is: Auto tune cancelled because target temperature was not reached.

My config:

; Configuration file for Duet WiFi / Ethernet running RRF3 on E3D Tool Changer ; executed by the firmware on start-up ; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P2 ; Set firmware compatibility to look like Marlin M667 S1 ; Select CoreXY mode ; Network M550 P"ToolChanger" ; Set machine name ;M587 S"ssid" P"password" ; WiFi Settings ;M552 S1 P"ssid" ; Enable WiFi Networking M552 S1 ; Enable Networking M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drive direction M569 P0 S0 ; Drive 0 X M569 P1 S0 ; Drive 1 Y M569 P2 S1 ; Drive 2 Z M569 P3 S0 ; Drive 3 E0 M569 P4 S0 ; Drive 4 E1 M569 P5 S1 ; Drive 5 E2 M569 P6 S1 ; Drive 6 E3 M569 P7 S0 ; Drive 7 COUPLER M569 P8 S0 ; Drive 8 UNUSED M569 P9 S0 ; Drive 9 UNUSED M584 X0 Y1 Z2 C7 E3:4:5:6 ; Apply custom drive mapping M208 X-35:328.5 Y-49:243 Z0:300 C-45:360 ; Set axis maxima & minima M92 X100 Y100 Z1600 C91.022 E834:834:834:834 ; Set steps per mm assuming x16 microstepping M350 E16:16:16:16 I1 ; Configure microstepping with interpolation M350 C16 I10 ; Configure microstepping without interpolation M350 X16 Y16 Z16 I1 ; Configure microstepping with interpolation M566 X400 Y400 Z8 C2 E2:2:2:2 ; Set maximum instantaneous speed changes (mm/min) M203 X35000 Y35000 Z1200 C5000 E5000:5000:5000:5000 ; Set maximum speeds (mm/min) M201 X6000 Y6000 Z400 C500 E2500:2500:2500:2500 ; Set accelerations (mm/s^2) M906 X1800 Y1800 Z1330 I30 ; Idle motion motors to 30% M906 E1000:1000:1000:1000 C500 I10 ; Idle extruder motors to 10% ; Endstops M574 X1 Y1 S3 ; Set X / Y endstop stall detection M574 C0 Z0 ; No C Z endstop ; Z probe M558 P8 C"zstop" H3 F360 I0 T20000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height M557 X10:290 Y20:180 S40 ; Define mesh grid ;Stall Detection M915 X Y S3 F0 H400 R4700 ; X / Y Axes ; Heaters M308 S0 P"bedtemp" Y"thermistor" A"Bed" T100000 B4138 C0 ; Set thermistor M950 H0 C"bedheat" T0 ; Bed heater M143 H0 S225 ; Set temperature limit for heater 0 to 225C M140 H0 ; Bed heater is heater 0 M308 S1 P"e0temp" Y"thermistor" A"T0" T100000 B4725 C7.06e-8 ; Set thermistor M950 H1 C"e0heat" T1 ; Extruder 0 heater M143 H1 S305 ; Set temperature limit for heater 1 to 300C M308 S2 P"e1temp" Y"thermistor" A"T1" T100000 B4725 C7.06e-8 ; Set thermistor M950 H2 C"e1heat" T2 ; Extruder 0 heater M143 H2 S305 ; Set temperature limit for heater 2 to 300C M308 S3 P"e2temp" Y"thermistor" A"T2" T100000 B4725 C7.06e-8 ; Set thermistor M950 H3 C"duex.e2heat" T3 ; Extruder 0 heater M143 H3 S305 ; Set temperature limit for heater 3 to 300C M308 S4 P"e3temp" Y"thermistor" A"T3" T100000 B4725 C7.06e-8 ; Set thermistor M950 H4 C"duex.e3heat" T4 ; Extruder 0 heater M143 H4 S305 ; Set temperature limit for heater 4 to 300C ; Tools M563 P0 S"T0" D0 H1 F2 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Reset tool 0 axis offsets G10 P0 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0C M563 P1 S"T1" D1 H2 F4 ; Define tool 1 G10 P1 X0 Y0 Z0 ; Reset tool 1 axis offsets G10 P1 R0 S0 ; Reset initial tool 1 active and standby temperatures to 0C M563 P2 S"T2" D2 H3 F6 ; Define tool 2 G10 P2 X0 Y0 Z0 ; Reset tool 2 axis offsets G10 P2 R0 S0 ; Reset initial tool 2 active and standby temperatures to 0C M563 P3 S"T3" D3 H4 F8 ; Define tool 3 G10 P3 X0 Y0 Z0 ; Reset tool 3 axis offsets G10 P3 R0 S0 ; Reset initial tool 3 active and standby temperatures to 0C ; Fans M950 F1 C"fan1" M950 F2 C"fan2" M950 F3 C"duex.fan3" M950 F4 C"duex.fan4" M950 F5 C"duex.fan5" M950 F6 C"duex.fan6" M950 F7 C"duex.fan7" M950 F8 C"duex.fan8" M106 P1 S255 H1 T70 ; T0 HE M106 P2 S0 ; T0 PCF M106 P3 S255 H2 T70 ; T1 HE M106 P4 S0 ; T1 PCF M106 P5 S255 H3 T70 ; T2 HE M106 P6 S0 ; T2 PCF M106 P7 S255 H4 T70 ; T3 HE M106 P8 S0 ; T3 PCF M593 F42.2 ; cancel ringing at 42.2Hz (https://forum.e3d-online.com/threads/accelerometer-and-resonance-measurements-of-the-motion-system.3445/) ;M376 H15 ; bed compensation taper ;tool offsets ; !ESTIMATED! offsets for: ; V6-tool: X-9 Y39 Z-5 ; Volcano-tool: X-9 Y39 Z-13.5 ; Hemera-tool: X20 Y43.5 Z-6 G10 P0 X-9 Y39 Z-5 ; T0 G10 P1 X-9 Y39 Z-5 ; T1 G10 P2 X-9 Y39 Z-5 ; T2 G10 P3 X-9 Y39 Z-5 ; T3 ;M572 D0 S0.2 ; pressure advance T0 ;M572 D1 S0.2 ; pressure advance T1 ;M572 D2 S0.2 ; pressure advance T2 ;M572 D3 S0.2 ; pressure advance T3 M575 P1 S1 B57600 ; Enable LCD G29 S2 ; disable mesh T-1 ; deselect tools M501 ; load config-override.gand the PID parameter:

M307 H4 Heater 4: heating rate 2.430, cooling rate 0.560, dead time 30.00, max PWM 1.00, mode PID, calibrated at 0.0V Predicted max temperature rise 296°C PID parameters: heating P2.4 I0.032 D51.4, steady P2.4 I0.045 D51.4 Heater 4: heating rate 2.430, cooling rate 0.560, dead time 30.00, max PWM 1.00, mode PID, calibrated at 0.0V Predicted max temperature rise 296°C PID parameters: heating P2.4 I0.032 D51.4, steady P2.4 I0.045 D51.4 -

@Adamrobot Is it just heater 4 that can't tune, or is it a problem for all heaters? What command are you sending to tune the heater? What does the graph look like when you tune that heater, and is it different from the other heaters if their tuning succeeds?

Ian

-

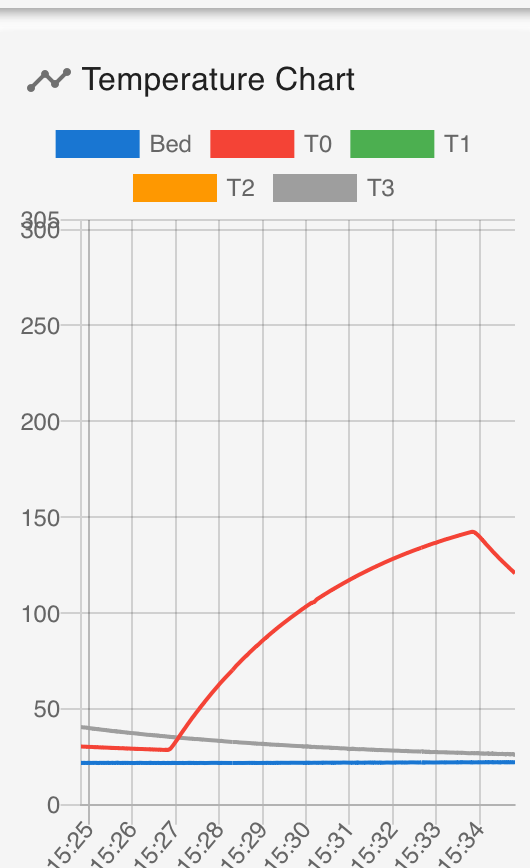

@droftarts I attempted to tune heater1 and heater4, the Command is M303 T0(T3) S200, and the result was the same, both heaters can only reach a maximum of around 150 degrees, and the heating will stop and in Console shows tune canceled.

the temperature is as follows

-

@Adamrobot From your M122 report, you are running this machine on 12V. Are your heaters 12V? I think they are 24V heaters, which will not get to temperature on 12V.

Ian

-

@droftarts

Hello mr administrator,If it's an issue of insufficient voltage, can I adjust the voltage of the heater on DWC? Or do I need to replace it with a higher power supply module?

-

@Adamrobot

This has nothing to do with a problem in the power supply unit.

You have to check whether the heating cartridge is made for 12V or 24V.

Either check the marking on the sleeve or measure the internal resistance.

In general 24v supply voltage would be an advantage. However, you then also have to replace the heating bed and maybe the fans.