Input shaper causing stutters and blobs on curves RRF3.5.0-rc.1

-

@Threepwood So the solution is to use a high quality stl's?

-

@Arminas If the solution is high quality STLs then you also have to try out different slicer resolutions.

In PrusaSlicer it is called G-code resolution (in Print Settings>Slicing). I experimented with this and found 0.5mm was terrible, 0.1mm was ok and 0.0125mm was great. The smaller the value the bigger the g-code file but the better the resolution.

I think the idea of this feature is to reduce g-code file size to not overload the printer's brain but still provide good results. It might be worth a look. The default is 0.0125mm.

Too many variables in too many places if you ask me.

-

@Arminas It does fix the problem and I usually print STLs I have exported from CAD myself, but I'm not happy to leave it as it is. For one, there are some occasions that I want to print STLs from elsewhere, but also there may be times where features also trigger this vibration.

I've tried messing with input shaper, acceleration, jerk, speed and even pressure advance. Unfortunately, nothing really eliminates it at or above 100mm/s speed. I did find it became less obvious when I increased to 1200mm/min (20mm/s) jerk. I think this is because the printhead isn't slowing down as much for each section of the curve. Reducing acceleration to 4000 or lower also improved things. So I've set my slicer to print outer walls at 3000 acceleration and 100mm/s speed. I need to run more tests to check how slow I need to print inner perimeters.

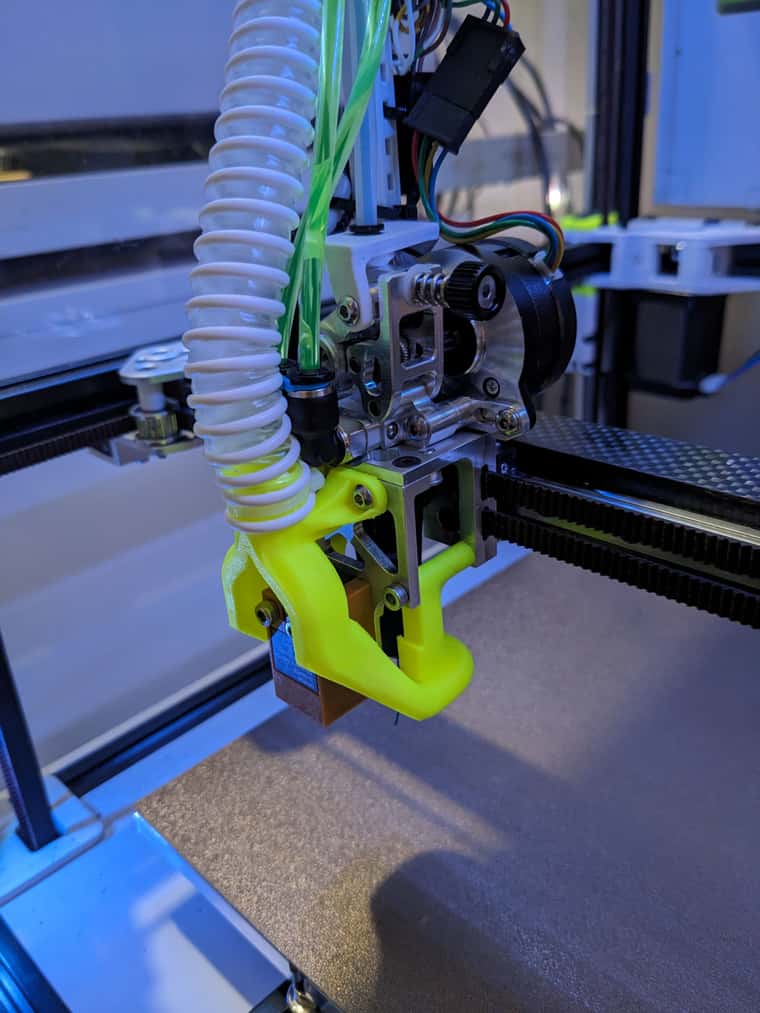

I've reduced the weight of my print head and x carriage to half, and increased my max flow rate from 13mm³/s to 50mm³/s, but can't really utilise increased speeds due to unexpected artifacts.

-

@Threepwood interesting to read about your issues, I have the exact same problem and I'm also running a light weight gantry VzBot extruder/hotend with a 1LC toolboard and CPAP.

I needed a funnel today, it printed but looked awful from all "shaking".

-

@Reine I'm using a carbon X gantry and I've just changed over to lightweight aluminium XY joints and mounted the hotend and extruder with a custom CNC aluminium bracket.

Since I've now replaced all the ABS printed parts with aluminium, the printhead is now much more rigidly held. I think it has taken away some of the dampening that the ABS parts gave and causes it to be more susceptible to higher frequency vibration. Sharp corners are no problem once input shaping is utilised, but this vibration in curves is something I have no idea how to approach without industrial equipment to detect where the vibration is eminating from.

The Goliath/LSD hotend is quite long and only held at the top. I wonder if that would be the problem?

I've watched almost all of Vez3D's videos, and he doesn't seem to have any problems like this at all.

-

I've had another thought. I'm now using 3.4.6. One of the updates for 3.5.0 is "Input shaping is now applied to a wider range of move types, in particular to short accelerate/decelerate moves".

Could it be that the 2-3mm distance between the points on a curve made of straight lines are too small to enable input shaping?

How short is a "short move"?

-

Here is another thought. I've always been used to having heavy multiple input , and or multiple heat zone hot ends. By their nature, they are big and heavy. Although primarily these type of hot ends are for multi colour or multi material parts, they are also capable of extremely high melt rates because of their having multiple parallel melt chambers, each one fed by its own extruder. This in turn has allowed me to print at up to 300 mm/sec using an 0.5mm nozzle and 0.3mm layer height (I've posted videos on my YT channel about this). This is despite the hot end gantry having a moving mass in excess of 2 Kgs..

But the point of all this, is that I have never had ringing, ghosting, or other similar artefacts. This will I know be contentious but it seems to me that the ongoing trend to try and reduce moving mass far below the minimum required (because the melt rate is the limiting factor not mass), is the root cause of why so many people have problems and why things like input shaping are necessary.

Higher mass has lower resonant frequency. My latest printer design has a single light weight direct drive extruder (LGX Ace/Mosquito combo) but it's rigiditly mounted to heavier than they need be aluminium carriage plates. Still no sign of ringing, ghosting or other such artefacts so still no need for any sort of compensation.

-

@Threepwood Well, it that case, I will do some test print with the L parameter that we have been talking before, hope it will help...

-

@deckingman It's not maximum speed that we are trying to achieve with a lightweight gantry, but higher accelerations and jerk. I do like the printers you have built, but comparing them to something like the VZbot is like comparing a TGV train to an F1 car, at least in terms of linear acceleration.

@Arminas I don't think the M593 L parameter will change the minimum length move that input shaper will be applied to. It will only stop input shaping being applied if it slows down the overall acceleration of the move too much.

-

@Threepwood said in Input shaper causing stutters and blobs on curves RRF3.5.0-rc.1:

@deckingman It's not maximum speed that we are trying to achieve with a lightweight gantry, but higher accelerations and jerk. I do like the printers you have built, but comparing them to something like the VZbot is like comparing a TGV train to an F1 car, at least in terms of linear acceleration.

You miss the point. In order to achieve high print speeds, one must by necessity use high(ish) accelerations. But that's not the point. Any print move must must keep the axes movement synchronised with the extruded filament flow. If the rate of change of extrusion flow cannot keep up with the rate of change of the print head position, you'll get under extrusion. But the laws of physics dictate that there is a (low) limit to how fast you can alter the rate of flow of a viscous fluid through a small orifice. Essentially, you cannot accelerate that flow rate at anything like the rate that you can accelerate the position of the print head. So using your analogy of an F1 car, it's like using one to do the school run in heavy traffic and without breaking the speed limit for a built up area. No matter how capable it is, you can't use that acceleration for anything other than non-print moves.

-

@Threepwood said in Input shaper causing stutters and blobs on curves RRF3.5.0-rc.1:

@Arminas It does fix the problem and I usually print STLs I have exported from CAD myself, but I'm not happy to leave it as it is. For one, there are some occasions that I want to print STLs from elsewhere, but also there may be times where features also trigger this vibration

you may want to look into arcwelder to post process low quality third party STLs. It might help with curves ...

-

@deckingman You are correct that flow cannot be increased as suddenly as an X/Y acceleration on a well tuned printer. But pressure advance will counter this. As long as the printer knows the hotend is about to slow down for a corner, then speed up again, it can reduce and then increase filament pressure ahead of the X/Y moves by a set time in M572. In my case this is around 0.025 of a second.

-

@Threepwood From my testing, there are limits to what PA can do. For sure accelerating the extruder faster than the axes at the start of a move (which is what PA does) should in theory help. But there is still a physical limit on how fast viscous filament can be made to pass throug a small orifice. So in practice, at high accelerations, all PA does is give a pressure pulse inside the hot end which does not translate to an increase in flow at the outlet of the nozzle. Even though my hot end gantry is heavy compared to the concensus, I can still accelerate it at upwards of 3000 - 4000mm/sec^2 without any issues, but to get decent prints for reasons already laid out, I have to run lower acceleration.

Which brings me back to my point. There is a limit in how fast the flow of a viscous filament can be made to accelerate through a small orifice. So reducing carriage mass beyond that limit is a pointless thing to do.

-

@deckingman Then how do you explain this? Printing at 600MM/s 35K

-

@Threepwood Perhaps Vez3D has already answered your question? From the comments "This part was perfect for high accel since it doesn't have corners or sharp angle...". He is also printing PLA pretty hot 250C and using a 0.5 nozzle with a small layer height (0.1mm) all of which I think may help with the flow (not sure how those figures compare with your own experiments).

I also get the impression from his comments that he thinks this is very much on the limit of things, so small changes may make a big difference in how well things work, he has spent a lot of time tuning his setup.

I've no direct experience of trying to print at these speeds but that was my takeaway from the video...

-

@gloomyandy I hadn't noticed he was printing at 0.1mm layer height. I suppose that will help a bit with getting consistent extrusion since he's only having to get to 30mm³/s rather than 60mm³/s (I'm asuming 0.5mm width). But still he seems able to print each of the holes very cleanly even though he's going from retration to 30mm³/s with an acceleration of 35,000mm/s² and a jerk of 30 (or 1800 in RRF language).

My point was just that it does seem he is able to get the extruder to keep up with incredible acceleration and that, in my opinion, it's not pointless to reduce X carriage and printhead weight.

I'm still on a 24v system and 2 motors, whereas Vez is using 4 motors and 48v, so I won't be hitting the speeds he's getting. I seem to be able to get decent results with 200mm/s outer walls, 250mm/s inner walls at 4000mm/s² acceleration and 300mm/s, 10,000mm/s² acceleration for infill. All at 1200 jerk and 0.2mm layer height. Weirdly 600 jerk was causing the ringing in low poly curves to be much worse.

I did try going back over to 3.5.0-rc.1 just to test if the input shaping changes would improve the low poly curve banding, but the result was identical.

-

undefined Threepwood referenced this topic

undefined Threepwood referenced this topic

-

undefined Threepwood referenced this topic

undefined Threepwood referenced this topic