Equipment for measuring hot end temperature?

-

@zapta A little while back I did a comparison between a PT1000 and an ntc thermistor. The method I used was to make a heater block, more or less a 20mm cube, with a 6mm hole in the centre for the heater, and two 3mm holes for the sensors spaced equidistant from the heater. The heater and sensors were installed using Boron Nitride paste to ensure good contact. I made sure that both sensors used the same ADC channel to eliminate errors in the conversion process. I made a video about it on my YT channel.

But however you do it, you are still only comparing one sensor with another. The only way to be sure of accurate measurements and readings, is to use an expensive temperature bath, calbrated to a traceable standard. Or you could possibly use iced water and boiling water but that would only give you two points (0 and 99.999 Deg C).

Edit. Oh and then you still have the problem that the temperature inside the nozzle will be different from the temperature you read in the heater block. I did a video about that too.....

-

@deckingman @zapta The difference between using an NTC and either a Pt RTD or thermocouple is that tiny variations in beta on an NTC correspond to large variations when applied over a wide temperature range. RTDs and thermocouples have low sensitivity (resolution), but tend to be more accurate without secondary calibration over a very wide range. The problem with NTCs is that commercial uncalibrated ones are trimmed to give the right answer at 25C, typically, and without secondary calibration to determine specific values of beta and c (etc.), one is using faith-based thermometry.

Note: I make my living on experiments that require precision (<0.01C) thermometry. For narrow range work, calibrated NTCs are unbeatable. I have one calibrated to 0.01C accuracy from -30C to 70C. The cost of the unit and calibration by Fluke was $1800. To go outside that range, though, really is hard with that type of sensor.

-

Thanks everybody for the informative response. I guess what I am trying to do at this point is to find a way to independently validate the thermistor reading at the 200 - 240C range without investing tons of money in equipment. Dealing with the temperature differences in the hottend (e.g. chamber vs nozzle) will come latter.

The temperature channel works in two stages, first measure the resistance and then converts to temperature. Calibrating the resistance measurement is easy with a precision resistor is not too expansive but calibrating the temperature seems more challenging.

For for variance in thermistors beta, I believe that with a good calibration in the workin area, the nominal beta should provide good accuracy in the range 200-240C.

I also have access to a FLIR camera that is specified at +/-2C accuracy in a very wide range of temperatures but am not sure how to calibrate the emissivity to have accurate temperature reading.

-

@zapta I still don't understand what it is that you are trying to achieve. If you that worried about the accuracy of the sensor itself, just use a PT 100/1000. It'll be cheaper than buying the test equipment needed. But take a look at the video I made comparing at NTC with a PT1000 before you waste your money.

Most filaments will print equally well with a tollerance of +-5 Deg from their optimum but if you change from a brass nozzle to a hardened steel one, you'll likely have to increase the temperature by 10 degC or so, no matter how accurate the sensor is.

So I don't see what it is that you are trying to achieve.

-

@deckingman, what I am trying to do is to measure independently the temperature of the thermistor at the working range of a hot end, to verify it's reading.

I watched your video but as you said, you don't measure absolute temperatures but just compare reading between two sensors.

Two notes regarding your video:

-

The percentage column is kind of arbitrary since 0C is arbitrary.

-

Even though there two channels use the same ADC, they still have separate input networks that may affect the reading. You can confirm the similarity by setting both to be the same sensor type (e.g. thermistor) and switch the thermistor between the two channels.

-

-

@zapta said in Equipment for measuring hot end temperature?:

@deckingman, what I am trying to do is to measure independently the temperature of the thermistor at the working range of a hot end, to verify it's reading.....

I get that. What I don't understand is why the infatuation with the sensor when there are so many other variables.

-

@deckingman said in Equipment for measuring hot end temperature?:

I get that. What I don't understand is why the infatuation with the sensor when there are so many other variables.

One variable at a time, but calibrating the temperature anchors everything to absolute values.

What I leaned is that accurate measurement of voltage, current, resistance, time, and frequency, is easy and inexpensive but temperature is not, for some reason.

-

@zapta What I meant was that there are so many other variables which affect the temperature of the filament as it exits the nozzle. Which is why I don't understand the infatuation with the accuracy of a sensor buried some distance away from the nozzle, inside a block which is made from a different material, and somewhat isolated from deflected part cooling air. I just don't get it....

-

@zapta if you are manufacturing printers and supplying filament to go with them, then you may require consistency between all the machines so that you can recommend what temperatures to use. In that case, it may be worth using a PT100 or PT1000 sensor instead of a thermistor, to get better consistency.

If the machine is a one-off then you don't need to know the heater block temperature accurately, you just need to know what indicated temperature gives good prints, which you will need to determine anyway. The slight downside is that if you need to change the thermistor, you might possibly need to determine the best indicated temperature again.

-

Thanks @dc42. It seems that my best chance of having a reasonable absolute measurement at a reasonable price is to using a PT100x and just trust its datasheet, possibly calibrating it at 100C for extra accuracy.

They seem to come at different tolerances, but I couldn't find the specification of E3D PT1000. Anybody happens to have it?

-

I found this RTD which seems to be a good reference for absolute temperature. It's Class A (accurate), reasonably priced, and liquid proof.

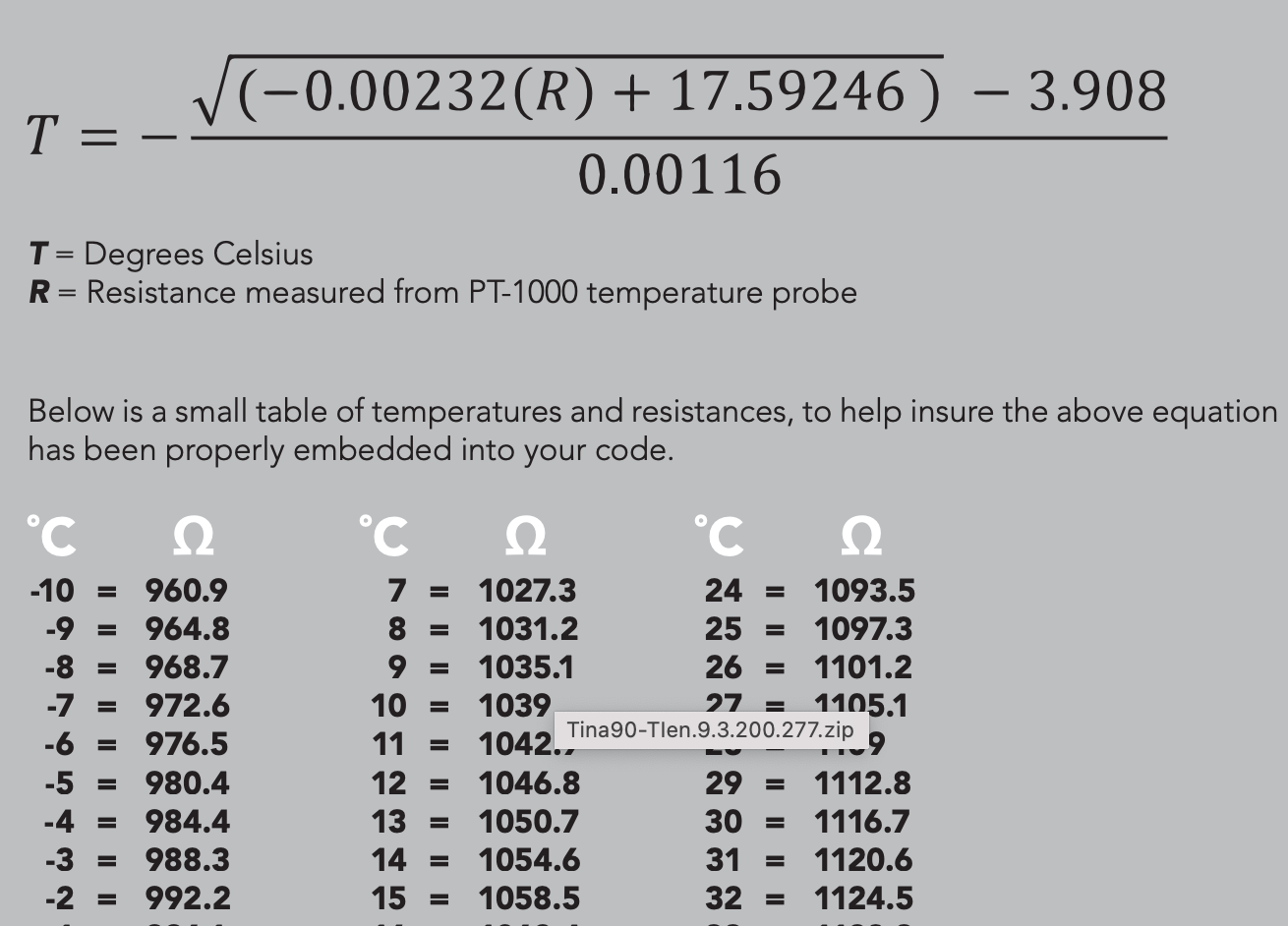

One thing I don't understand is the formula in its datasheet, I expected to have a linear relation between temperature and resistance but it has a SQRT. Am I missing something?

https://atlas-scientific.com/probes/pt-1000-temperature-probe/

-

This post is deleted! -

@zapta said in Equipment for measuring hot end temperature?:

One thing I don't understand is the formula in its datasheet, I expected to have a linear relation between temperature and resistance but it has a SQRT. Am I missing something?

The relationship is not completely linear over the full temperature range of the sensor (though it approximates it over small ranges). The above formula is a simplified version of the full conversion normally used. See https://techoverflow.net/2016/01/02/accurate-calculation-of-pt100pt1000-temperature-from-resistance/ for lots more details. RRF uses a lookup table to generate the temperate readings.

-

Thanks @gloomyandy, this is very useful. Until today I thought that the common model for PTx is linear, and you are right, Duet indeed uses a table with 10C intervals and linear interpolation in between (same table for pt100 and pt1000).

https://github.com/Duet3D/RepRapFirmware/blob/3.4-dev/src/Heating/Sensors/TemperatureSensor.cpp#L278

And that python package is exactly what I need. I will look at it.

-

If anybody is planning to measure their sensor with boiling water, apparently there is a category of products to do just that. They are called thermowell, and are metal tubes that are closed on one end, with optional means to attached it on the other hand.

I just ordered one from amazon. Ali express also has them.

https://www.amazon.com/gp/product/B0BRW5FSGJ?th=1

-

Apparently, calibrating a temperature sensor is easy, if you have the right equipment.

-

@zapta hah, let me know if that equipment works out if you choose to buy it.

I think alot of the discussion on this thread is because we (the FDM printing community) have (traditionally) not bothered too much about absolutes in temperature (as every batch of filament is different so a bit of recalibration is needed). Even when we do want to be more accurate, consistency between different readings (the same filament on multiple printers with the same hotend uses the same temperature) was more important than absolutes. Given filament manufacturers give wide ranges of correct printing temperatures and hotend geometries mean that nozzle temperature vs temperature measurement are widely variable between hotend designs, and all this changes based on flow rate and sometimes part cooling, the general consensus is "vaguely good enough is good enough".

I am curious why thats not the case for your application?

-

Hi @T3P3Tony, I don't have a specific application that require high accuracy but more a research/challenge project trying to get accurate temperature measurement. I am used to reasonably priced and accurate meters for voltage, current, frequency, weight, time, capacitance, distance, and more, and am surprised that it's not the same with temperature (not counting medical range thermometers which are inexpensive and sensitive).

I manage to get stable reading at milidegrees C, such that the reading changes when I enter the room, I presume due to air movement, but would like to be able to anchor it at absolute values, an my best bet at this point is to rely on the spec of a class A RTD.

My post is not specific to Duet, it's just the best place I know with people that may have useful information.

-

@zapta The problem with your analogy with other measuring devices is that they mostly have the sensor encapsulated within the device whereas for fdm printing, we use a remote sensor. Whatever is being measured has to be converted to an electrical signal of some sort. With electronic scales for example, the device which responds to changes in force or pressure is usually a load cell (or several connected using a Wheatstone bridge). So it's reasonably easy to calibrate the device as a whole by checking it against known standard weights. On our printers, the sensor is nothing more than a device which changes resistance with temperature. So we actually measure resistance then do a mathematical conversion to get temperature. We can calibrate the whole against a known standard but if we change the sensor then we have to recalibrate. The same would apply to our electronic scales if we changed the load cells. In fact, load cells are notoriously prone to drifting and scales are usually "tared" before use.

Ultimately most electronic measuring devices can drift over time. So the only way to be sure of accurate readings is to calibrate the device (including its sensor) against a known, traceable standard, then take a measurement, then re-check the calibration. This is in fact what we used to do when I was involved in measuring vehicle exhaust emissions.

-

@zapta A class A RTD is probably the most reliable, affordable temperature measurement device you can use to cover a moderately wide range with no special calibration. A thermocouple of appropriate type can be used without any calibration, and fairly good accuracy, over a very wide range, but the resolution isn't so good. If you want to go first-class, an SPRT (standard platinum resistance thermometer) is ideal, but costs. These are RTDs manufactured to extremely precise specification (loosely wound, special platinum wire, so thermal stresses don't change it, etc.).