Why isn't this compensated by ABL?

-

Can someone explain this -- why isn't this compensated better?

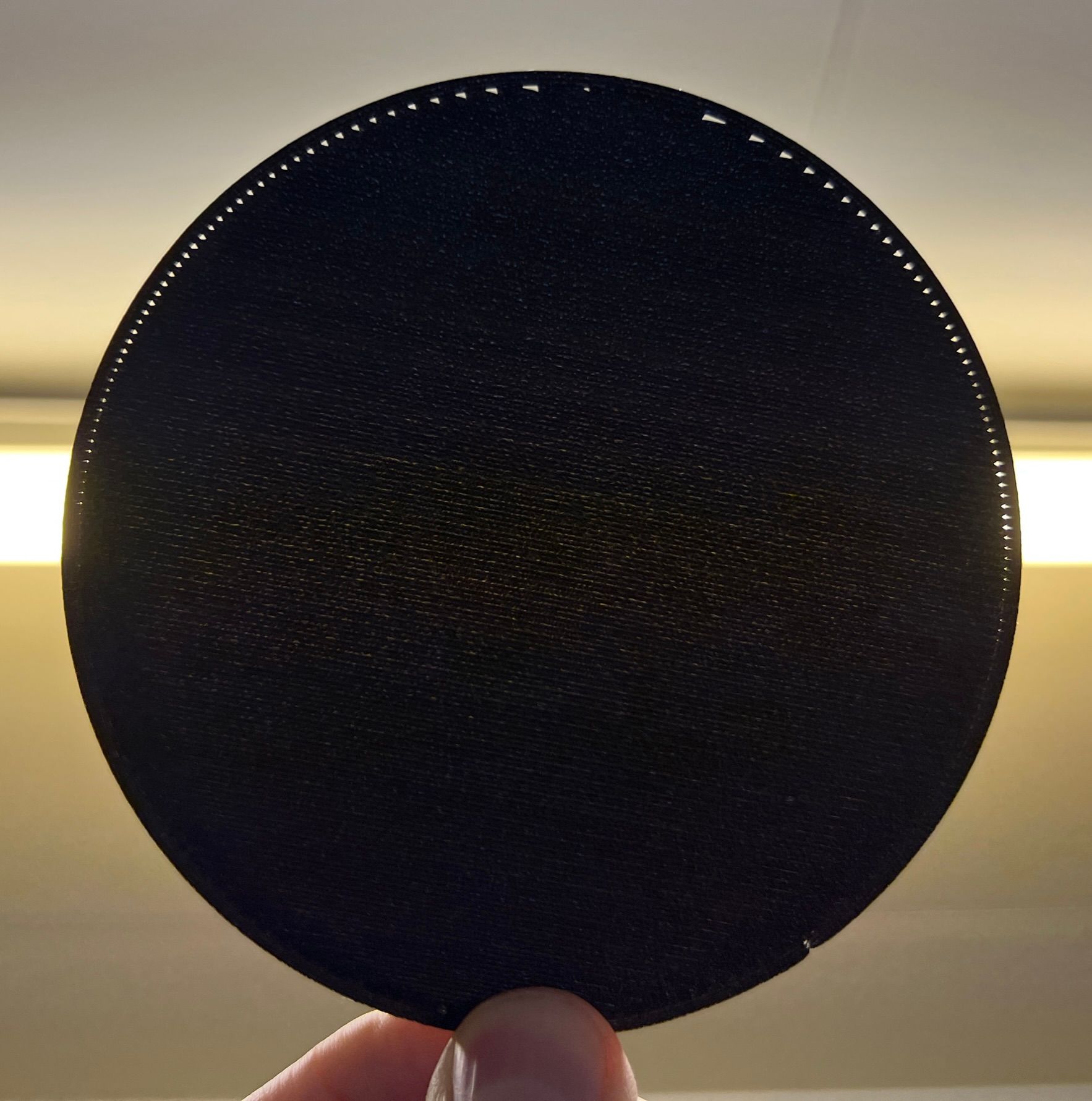

In general the (first and only) layer looks good, but on the ends there are some issues. On the right it's slightly under extruded which can be seen as smal gaps where the infill connects with the perimeter, on the left side it's the opposite, there it's slightly over extruded with small bulges.

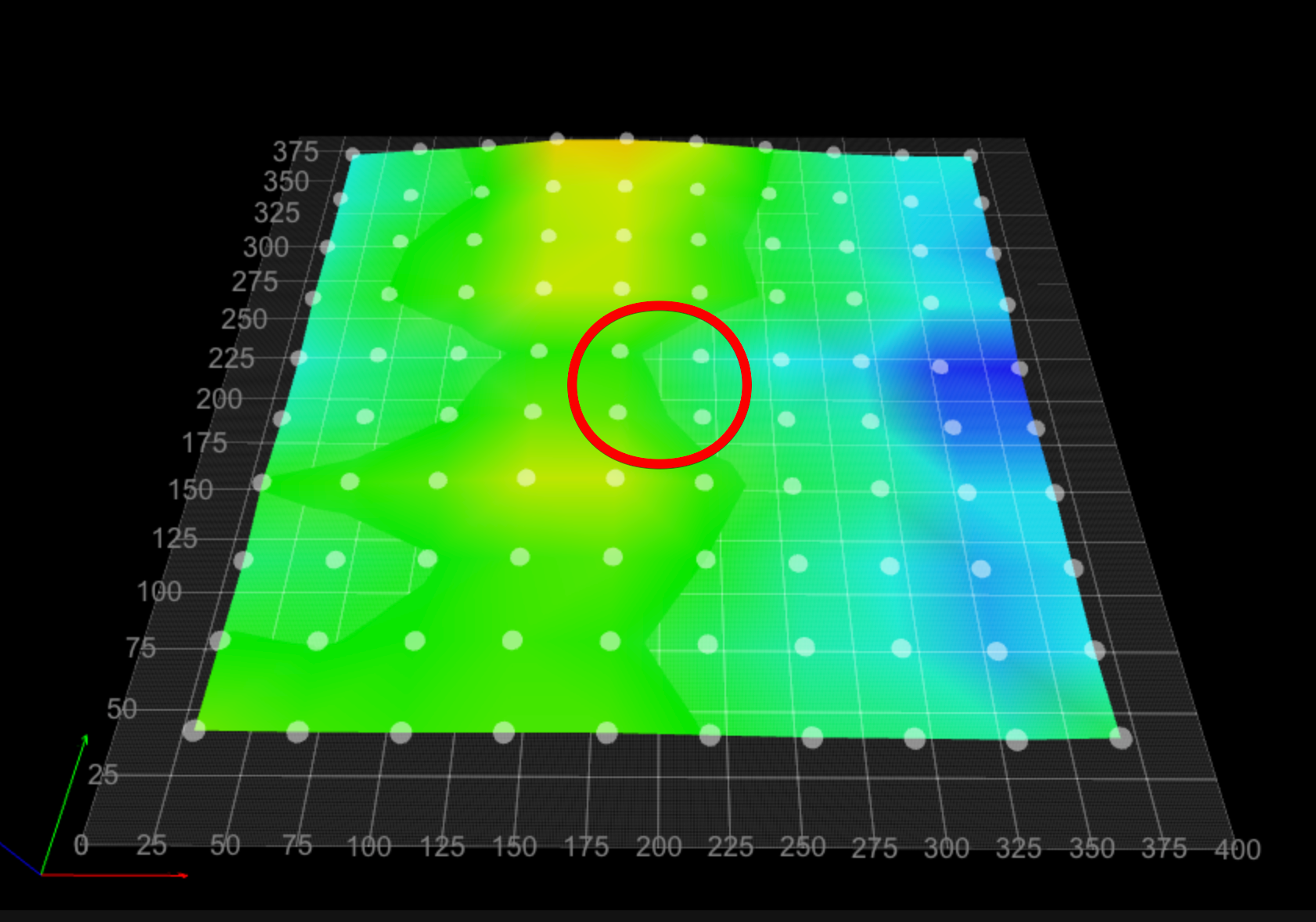

Looking at the height map one can see some minor differences between those areas, why isn't those compensated better?I'm running a 0.5mm nozzle, 0.3mm layer and a 0.6mm width on the first layer.

Number of points: 100

Probe area: 1145.4 cm²

Maximum deviations: -0.104 / 0.060 mm

Mean error: -0.013 mm

RMS error: 0.035 mm

-

@Reine Does the heightmap show the real height differences?

It looks to me as if there are magnets underneath, messing with the sensor. (right-center it is most obvious) -

@o_lampe It's a large magnetic, stick-on sheet, no individual magnets in the aluminum bed.

-

@Reine I think there are multiple possible reasons, not only a firmware reason or extrusion settings, like difference between behaviour of Z probe and nozzle like offset, backlash, probe not vertical etc.

Without more information like which probe you use, your printer type and how Z axis moves, how the bed is fixed, config settings, firmware version and controller, filament type and temperature used, if bowden which retraction settings are used, it will be difficult to help finding the reason. You can check with M122 whether bed compensation is active while printing also.

-

This post is deleted! -

@Herve_Smith I'm sure that the answer is an adhesive.

-

This post is deleted! -

@paralepsis said in Why isn't this compensated by ABL?:

@Herve_Smith I'm sure that the answer is an adhesive.

The question is: No airbubbles?

That's why I asked earlier about magnets under the sheet. There are some obvious bulges in your heightmap... -

@Reine I'm a bit confused by all of this. Your title asks the question why isn't ABL compensating. The simple answer is that Automatic Bed Levelling (ABL) is for making a flat bed level. Therefore it won't compensate for flatness errors. The height map indicates that the bed isn't flat, in which case Mesh bed compensation (MBC) would be a better tool to use.

We might have a better chance of understanding what might be amiss, if you posted your entire config.g file. -

@deckingman FWIW, and I'm just guessing, but the fact that we have the height map makes me think he's using MBC and just misused terminology. I say this in part b/c I was confused by ABL vs. MBC when I first started using RRF also. But @Reine can confirm...

-

this was discussed in depth on the Unofficial RatRig discord and it came down to not being ABL related but too aggressive Pressure Advance settings. Now with lower Pressure Advance, it works fine.

-

@oliof That's interesting, do you come to any conclusion as to why it only seemed to impact one half of the disc?

-

@gloomyandy the other half of the disc has too much material which isn't easily seen on the photos above. We could rule out backlash in the motion system. It also was highly improbable that this was due to ABL since the error followed the extruded lines. So the only remaining possible factor was PA which was at .08 for a very short path direct feed -- about 4 times as much as I have on a very comparable setup (same hotend assembly for the most part -- EVA2/3 -- and same filament feeder family -- mellow libra vs hextrudort).

Reducing PA to 0.04 made the error go away, here is the photo of the same sample print after adjusting

-

@oliof It certainly seems like a PA problem but maybe something else is going on as well...

Looking at this photo: https://forum.duet3d.com/assets/uploads/files/1690535511899-e31ff3fa-4a28-4d62-ad6a-b245b7a7dee1_1_102_a.jpeg

It seems that the infill lines run right/left and left/right, but it looks like the lower half has too much material and the upper not enough. However I would have expected that a high PA value would have resulted in over extrusion at the start of the line and under extrusion at the end of the line and too little at the end. Given that I assume the extrusion switched direction after each line I'd expect the gaps to be evenly distributed around the disc. It looks like this may be the case in the upper half, but not the lower. But who knows perhaps there is some slight offset with the way the infill lines overlap (or not) the perimeter or something that gives this effect? Or maybe my interpretation of what is happening is just wrong?

-

@gloomyandy your guess is as good as mine, but reducing PA to more common numbers helped fix this issue. So that either was a red herring, or the whole system changed somewhere inbetween the OP didn't share with us. For me, the giveaway that it's not the ABL was that the extrusion is super even except for the starts and ends of the test print, and the error follows the form of the sample test rather than the rectangular grid of bed compensation.

-

Sorry for the delayed replay guys, as previously mentioned this was also discussed and mostly resolved in the RRF channel on the unofficial RatRig Discord.

@Herve_Smith I'm using this flex plate, and as mentioned it's fastened with adhesive. https://ratrig.com/3d-printers/accessories/heaters-surfaces/flexplate-set-pei-410-x-410-mm.html

@deckingman I could very well have meant MBC, tbh that's a term I haven't heard before you mentioned it. I referred to ABL as I thought that was the entire system that scanned, mapped and compensated for the bed topography.

My setup is as follows:

RatRig VCore 3.1 400- Duet 6HC / 1LC

- VzBot CNC Toolhead

- VzBot Hextrudort

- VzBot Goliath

- My own adaptor to make it work https://www.printables.com/model/507786-duet-1lc-mount-for-vzbots-ratrig-printhead

- 0.5mm nozzle

- RatRig "SuperPinda" sensor

- CPAP fan

I was running v3.4.5 when this was reported and are now running v3.4.6.

Here are my main config files:

config.g

bed.g

config-override.g