Powering a printer and PID tuning issues

-

Hello.

I am setting up a duet 2 ethernet and duet 5 board for a 3D printer build. It has Nema 23 stepper motors driving ball screws on the x (600mm), y and y' (300mm0, and two z (500mm) axis. Dual extruder with BL touch, BMG direct drives to mosquito high temp hotends.

I did my best to spec out what is needed based on the motherboard outputs. But I am having the following issues.

The power supply used is a 24V 50A psu, but the temperature tuning is not able to achieve the temperature that is required. 250 deg C. So the autotuning keeps canceling itself. For both hotends and for the bed heater. The bed heater is 24V 400W.

Why is this happening? I have tried making M307 have a long dead time so it can reach temp, but still is not working.

Any help is appreciated!

Config file below.; General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"djtprint" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X400.00 Y400.00 Z400.00 E420.00:420.00 ; set steps per mm

M566 X900.00 Y900.00 Z120.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z2000.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1400 Y1400 Z1400 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X600 Y300 Z500 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"duex.e2heat" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

;M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C;M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M308 S1 P"spi.cs1" Y"rtd-max31865"

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 D60 B0 S1.00 V24 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C;M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp

M308 S2 P"spi.cs2" Y"rtd-max31865"

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

;M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H2 T45 ; set fan 2 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@djthuma i'd be surprised if you could get a 400w 24v bed to 250 degrees.

you've not given any details about the hotend setup -

@jay_s_uk The bed i'm only trying to max at 100 C.

But that still has trouble reaching 90 +.The hotends are setup as.. nema17 motor, bondtech bmg direct drive extruder with a mosquito magnum hotend with the high temp heater and pt100 temp sensor.

-

This calculator will give you a good estimate of the time required for the bed to reach a specific temperature. A 300x600mm bed will probably need a lot more than 400W to get to 100C. I use a 750W line powered heater for my printer's 300x300 bed. It heats to 100C in about the time it takes the hot end to get to print temperature.

Why are you using relatively expensive, and probably very loud, DC power to generate bed heat?

-

@djthuma said in Powering a printer and PID tuning issues:

The hotends are setup as.. nema17 motor, bondtech bmg direct drive extruder with a mosquito magnum hotend with the high temp heater and pt100 temp sensor.

Slice seem to offer a 50W heater at 24V. Is that correct?

Do you get sensible temperatures from the PT100 sensors?

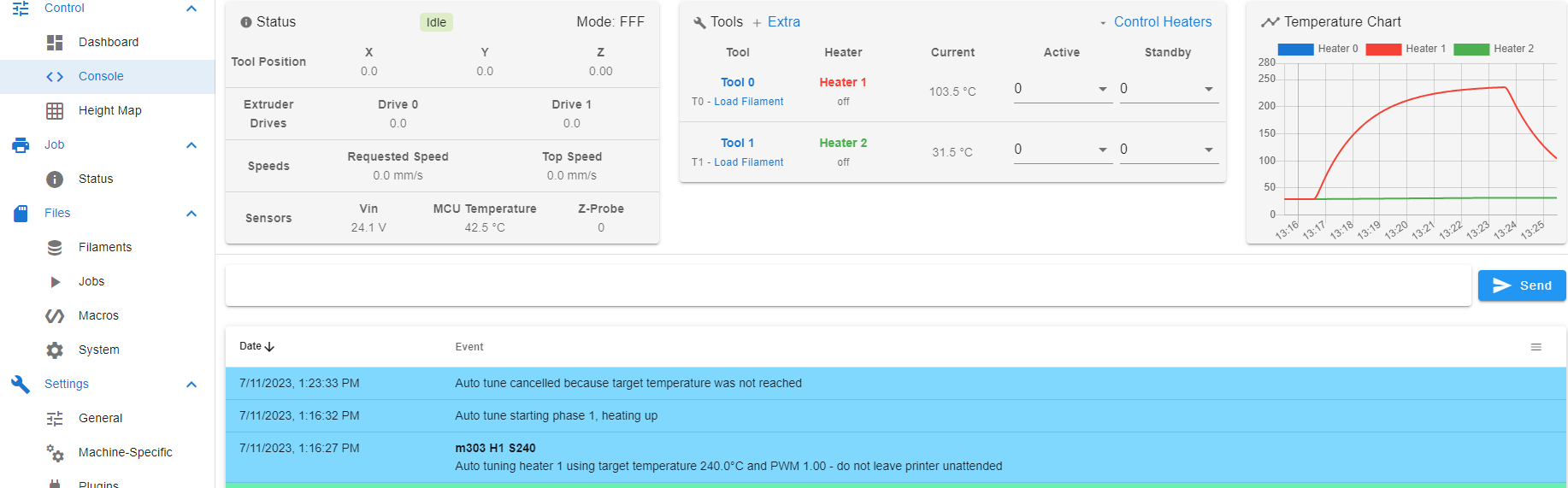

Post a screen shot of the temperature graph while tuning the hotend and/or bed.As other have said, for the bed, it's going to struggle to get to 100C, will probably take 15 minutes at least. It's also drawing 16A, which is at the limit of what a Duet can safely supply (if you're using the on board connectors, fine if you're using a solid state relay), so make sure the wiring is very good, that the connectors aren't heating up, and that the fuse hasn't blown.

Ian

-

@droftarts Yes. I am using a 50W 24V heater. The PT100 sensors work well and I have the config setup to have a pt100 as the active sensor for each of the extruders.

-

@mrehorstdmd I am using a DC psu for the motherboards.

And I am using the attached terminals for the 24V output to the bed heater. -

I even tried to shut off the Bed as an active heater so it wouldn't try to use any voltage in sensing the bed. It cancels everytime even at 240 deg C.

-

@djthuma that is a heater that is struggling to get to the required temperature. Can you check the resistance of the heater? For a 50W heater on 24V, it should be around 11.5 ohms. Check the heater mounting in the hotend. Does it have a fan blowing on it?

Ian

-

@djthuma Bed heaters are happy to generate heat from AC power, allowing you to use a smaller, cheaper, quieter 24V supply for the rest of the printer. Power to a line-powered bed heater is switched using an SSR connected to the heater pins on the Duet board.

If you already have the 24V heater and power supply, insulating the underside of the bed may allow the low powered heater to eventually get it up to print temperature, but will also extend its cool-down time.