Bed heater error

-

I am running out of ideas as to what could be causing a bed heater fault.

Error: Heater 0 fault: temperature rising too slowly: expected 0.85°C/sec measured 0.25°C/sec

I have done heater tuning a couple of times, both produced the same parameters. In both cases, the temperature climbed very consistently. Looking at the temperature graph when I start a print, the line appears to be nice and smooth yet I get the fault. I am wondering if there is anything else I could check or do that might point to the cause of this.

I have tried modifying the heater error detection with this command:

M570 H0 P10 T20

I don't really know how far I can tweak these before I risk major damage.

The error happens even if the bed is stationary (I was thinking that maybe the power lines for the bed (120V) might be flaky due to constant flexing but they are in a cable chain and with the bed not moving the likelihood of bad supply lines seems remote.

Is there any kind of diagnostic in RRF that could give me more information on why the fault is happening? Is there a way to set up a higher frequency of temperature measurements to maybe see what is happening?

The only thing that I have left to try is replacing the bed thermistor ... but as I said, the temperature curve looks smooth.

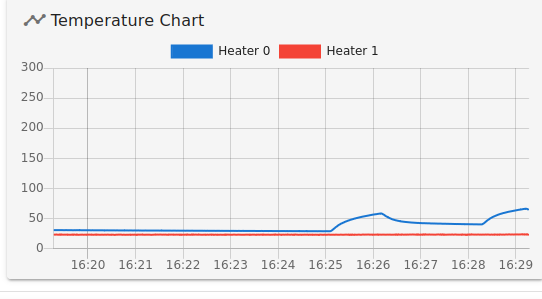

Anybody else run into this kind of a problem ?Here is the temperature chart from a few minutes ago. The first bit is when a fault is called, I then reset and tried again with no faults.

Duet2 wifi, DWC 3.4.0

-

Is it failing when the fan turns on?

What are the tuned values you are getting?

What is the size of the bed and wattage of the heater?

-

@Phaedrux, wattage is probably around 1500W, there is no fan (bed heater), the bed is 500 * 500

My current parameters are M307 H0 R1.151 K0.973:0.000 D1.80 E1.35 S1.00 B0

I am still running more tests - the latest was with a PT1000 sensor on top of the glass bed (not really a smart thing to do). The tuning took about 45 minutes because of the time it took for the heat to get to the top of the glass surface. Interesting part here is that after a cool-down I set the bed temperature to 70C and everything proceeded just as it should without a hickup. I only did a single heating run and I might just have gotten lucky that time.

I am now back to the bed mounted thermistor with the above parameters. The bed needs to cool off before I can run a heating cycle. This tuning run took a tad over 9 minutes.

I would replace the thermistor just for the heck of it if it didn't involve a major disassembling of the printer. The bed has to come off which then means tweaking the bed levelling screws and a very painful bed surface scan which, with this printer and the re-testing if the repeat measurements are not consistent, takes an average of 2 hours! If it needs doing, so be it .... but I need to be sure first.

I have adjusted the heater watchdog parameters to M570 H0 P30 T50 while I am experimenting. -

@jens55 I found that there is problem with having the temperature sensor at the junction between the heater and the underside of a large, thick bed. What happens is that when it starts to heat, the temperature at that point rises rapidly, the sensor "sees" that rise, so the heater switches off. Then there is a pause while the heat conducts through the rest of the plate. Eventually the temperature at the measurement point drops sufficiently for the heater to turn back on and the cycle repeats. The net result of that constant cycling is that it takes an awfully long time to heat the bed fully. My solution was to drill a 3mn diameter hole in the edge of the bed plate, as deep as possible, and as close to the top edge of the plate as possible, and fit the sensor in there. It cured all my problems.

-

@deckingman, interesting .... this printer has worked fine (as far as bed heat is concerned) for two or three years. The built-in thermistor went nutzoid after a year which is when I installed a second thermistor which then became the thermistor that called the shots. The thermistor is actually underneath the heat pad and not directly in contact with the heat bed.The original thermistor was left in place and gives me a second temperature line on the DWC graph.

While the aluminum bed is not thick enough for me to feel comfortable drilling into the side, there are some re-enforcing rib sections which I could be used for the new sensor if needed.

Thanks! -

@deckingman, I have a light bulb in parallel with the heat bed power to see when the heater switches on. Watching that shows it being constantly powered up until it gets in the general area of the temperature set point. Now just because the heater is powered, doesn't mean it is generating full power and I have not yet come up with a reasonable method of verifying current draw.

As I have mentioned, I monkeyed around with the failure point parameters without much success. My next try was to increase the dead zone parameter from 1.8 to 10 to see what happens - no change. I read somewhere that in the bang-bang mode, the failure detection works differently so I tried that - again, no change.

Since the error message always claims that a much higher heating rate is expected than what is actually measured at the point of failure, I am now working on changing the 'R' parameter from R1.151 to a lower figure. It's very tedious because it takes forever for the bed to cool enough to run a test. At R0.8 I still get the failure but at R0.6 I seem to be able to heat the bed without failure.I noticed that the rate of temperature rise slows down quite noticeably as the bed heats up. I am now thinking that maybe the tuning mechanism samples the heating rate when the bed is cold and as it heats up and with the heating rate slowing down, maybe that confuses the works? This could also involve the fact that the thermistor is attached to the underside of the heat pad as per your previous comment.

I will need to run through a number of heating cycles to verify that this is adjustment to 'R' is reliable.I wonder if the 'Powers To Be' could comment on the side effects (if any) of telling the Duet that the heating rate is slower. I am especially curious about any implications to safety. I am also curious if my guess of the 'R' factor being determined when the bed is cold is correct and if there is a mechanism to also sample and adjust the heating rate at a higher temperature.

BTW, looking at the temperature graph shows a much steeper slope (heating rate) at the start of the heating cycle and, as the temperature goes past about 50C, things seem to slow down considerably. -

@jens55 Hmm, curious. I just had a look back through all my various configs but I don't seem to have heater tune post-dating RRF 3.4. So mine all have a "C" parameter rather than the newer K and E parameters. I can't say that I ever noticed any change in the temperature graph similar to that which you describe so I'm just wondering if your issues stem from the change in tuning algorithm? Do you happen to have an M307 for that same heater from RRF 3.3 that you could try? It might not be much helps as my bed is smaller than yours at 400 x 400 x 10mm thick (and insulated) and the heater is 800W (I think), but here is my M307 using RRF 3.2 if you want to try it - M307 H0 R0.104 C2186.5 D28.16 S1.00 V0 B0. Note that the dead time is 28 seconds because of where the sensor is in relation to the heater pad so you might want to drop that down to suit your own setup.

-

@deckingman, I don't have an old config file but the thing that immediately jumps out is the 'R' figure of 0.104!!!

Here I was getting concerned about my R of 0.6 when the 'tuned' value was 1.151 !!!

My bed is 3.5 mm thick (no kidding, insulated) with a 4 mm plate of glass for the build plate and when I did the tuning with the PT1000 sitting on top of the glass plate I got an R value of 0.221. I can only imagine how long it takes for your build plate to heat up with an R value of 0.104 (visions of an hour or more .... <shudder>). -

@jens55 From ambient of around 20 up to 60 or so for PET-G takes about 15 minutes. To get from Ambient to 90 or so for ABS etc takes about 25 minutes. My "pre-print" macro pre-heats the bed to about 15 degrees less than print temperature, then it homes the axes, heats the nozzle, purges it and wipes it so there isn't any extra waiting around in addition to heating the bed. And the bed is flat, level and stays that way, so I don't do any form of software/firmware levelling or mesh compensation which otherwise add some time. And of course, being so thick and insulated it takes forever to cool. So it's only the first print of the day that has to wait that long for the bed to heat. After that, I slide out the (6mm) glass plate, insert another and I'm good to go again in short order. Overall, it's not too bad. If I know I'm going to be printing something, I tend to fire up the printer and start heating the bed while I'm making my first coffee of the day. So it's ready to go by the time I'm washed and dressed

I don't know enough about the various parameters of the heater model and how they interact or how they compare between firmware version - it used to be A, C and D, then it was R C and D, now it's R D and K/E - can't keep up

-

I am happy to reoprt that three out of three bed heat-ups were successful!

Barring any warnings about safety or other implications, I am calling this issue fixed.