My printer stops extruding randomly, what am I missing?

-

the filament gets stuck in the hotend somehow, creating a kind of plug (since when I finally pull the filament back I can see that the last 1-2cm which was in the hotend is thicker and breaks rather than bends) which blocks the nozzle to output anything.

In case of a clogging nozzle, try these steps to achieve a steady filament flow:

• reduce printing speed (drastically)

• reduce retractions to less than or about 1 mm

• increase hotend temp. to 210°C

• stop the part cooling fanPlease report back which of the measures helped. I'm curious

Bought the metal upgrade kit for the filament guide

Does this mean that you now have a full-metal hotend? Then, you might need to improve the cooling of the (hot end of the) hotend to avoid heat creep.

-

@infiniteloop I have a stock ender hotend, I think thats full metal as well but I'm not sure.

Okay, so, I have reduced the printing speed to half, reduced retractions, increased hotend temp to 210 and stopped the part cooling fans. All of that for naught. I'm started to think that there may be a problem with the file itself, but I remembered just now that this was an issue before too.

One thing tough, after I rebuilt my printer I've fitted a new duct for my hotend, but since I turend off part cooling I don't think that should have any effect.

Edit: Somthing just ran accross my mind…could this be caused by the ptfe tube not extending all the way down to the hotend tip? If yes, I’m an idiot…

-

I have reduced the printing speed to half, reduced retractions, increased hotend temp to 210 and stopped the part cooling fans. All of that for naught.

Sorry to hear that. Excluding most of the culprits should - in theory - eliminate clogging.

could this be caused by the ptfe tube not extending all the way down to the hotend tip?

If that's the case, it would be a perfect reason for a heat creep. Can you re-fit the tube and run a test print?

-

Sorry to hear that. Excluding most of the culprits should - in theory - eliminate clogging.

It was a fair advice, I would've ended up doing these steps anyway I think just out of sheer frustration.

If that's the case, it would be a perfect reason for a heat creep. Can you re-fit the tube and run a test print?

Yep, I'm in the process of doing exactly that right now, I'll be posting in a few with the results.

-

@infiniteloop

Okay, so... I have made so many amateur errors that I can't even comprehend how I made these mistakes.First thing is, that during the reassembly I forgot to tie the hotend down properly and it was wobbling like crazy (I have no idea how I didn't notice that before...), no wonder I had layers shifting all over the place

Second thing was that during reassembly I probably pulled a bit on the ptfe tube, which pulled it back like half a centimeter, which caused heat creep and got the filament stuck all the time.

I took the whole hotend apart and thats how I discovered the issue.

Moral of the story: after a major rebuild ALWAYS double, triple, quadruple check everything. Luckily I had a new ptfe tube which I could replace and nothing clogged/broke/strained to the point where its unusable. I'm printing a calibration cube just to be sure everything is in order.

-

I have made so many amateur errors that I can't even comprehend how I made these mistakes.

Don’t blame yourself for the errors - you can’t avoid all of them. I appreciate that you were conscious about the potential pitfalls, you were spot-on with the tube not extending all the way down. Glad you found it.

-

After two failed attempts (extruding stopped yet again at both cubes) and several bed calibrations, I THINK I finally know what the issue could be... It seems like the filament gets melted inside the ptfe tube (?!) which gets stuck and thus no extrusion.

I...wtf?

Is it possible that I just have a sh*t ptfe tube? Am I pushing the tube too far into the hotend? Am I not pushing it far enough?!

Is it possible that I just have a sh*t ptfe tube? Am I pushing the tube too far into the hotend? Am I not pushing it far enough?!I'm so bummed at the moment I can't even describe...

-

Am I pushing the tube too far into the hotend?

I don't think so, it must go straight down to the heat break. On your photo, the thickening in the filament indicates a potential gap: looks like the tube coupling looses grip. That's quite common if you have to remove the tube several times for a hot or cold pull. Either shorten the ptfe or replace it. If that doesn't help, replace the coupling.

-

@infiniteloop Seesh the coupling is done for. I can just pull the tube out with no resistance at all. I'll be ordering one asap, will post results when that arrives.

Thank you for the help, I'll update as soon as I can!

-

Seesh the coupling is done for. I can just pull the tube out with no resistance at all.

Yeah, that’s what you get when you’ve faced some serious trouble with the filament path. I’ve gone through that several times

. Order some ptfe as well: pulling these thickenings through the tube widens its diameter, which results in higher friction of the filament (due to unequal guiding). In my case, a cheap, fresh no-name tube worked better than the widened blue "wonder" tube it replaced.

. Order some ptfe as well: pulling these thickenings through the tube widens its diameter, which results in higher friction of the filament (due to unequal guiding). In my case, a cheap, fresh no-name tube worked better than the widened blue "wonder" tube it replaced. -

@infiniteloop stock ender3 hotend has ptfe line go all the way to the nozzle, and with a bad heatsink fan and high retracts this can happen (plus clogs between the inevitably appearing gap between nozzle and tube when the cheap coupler gives out).

Alsp your after market tube is transparent and likely not proper PTFE, so it may not have the right inner and outer diameter.

Dont waste money on Capricorn tubes, not worth it. Get a nice after market all metal hotend (NF Smart or Phaetus Dragonfly BMS are decent choices), a replacement coupler for the filament feeder (or a whole new feeder), and normal ptfe tube).

Check the heatsink fan for proper operation.

With an all metal hotend reduce retract to 1mm or less. If you keep the ptfe lined one, keep retract at 4mm or less.

-

@oliof Not sure of what you want to tell me:

-

I have an all metal hotend, and it has its merits if you want to print ABS, Nylon etc. at high temperatures, but it’s overkill for PLA, not to mention the inherent problems with an all-metal design. But that’s OT.

-

You are right in that blue tubes may not be worth it, but my point was not to recommend crap ("not proper PTFE") instead. In the context of this thread, I just wanted to alert the OP of potential problems with a deformed tubing.

-

Thx for your recommendations on retraction settings. Due to the fact that I mainly use PETG, mine are different.

-

-

@infiniteloop i meant to mention OP, sorry.

-

Here is another vote for not using Capricorn tubing. I tried it one of my experimental multi-input hot ends and it was easily pushed out of the coupling by pressure build up within the hot end, whereas "generic" non-branded PTFE tubing did not suffer the same way. I'm not sure if that is due to the Capricorn being exactly the correct OD whereas the generic stuff might be a bit oversized, or whether the Capricorn is just a bit more "slippery". Either way, "generic" PTFE tubing was gripped better by the coupling than the expensive Capricorn tubing.

I did discover a way to fit PTFE tubing into a heat sink such that it'll never move but it's a bit extreme. There is a product called "Technicoll X-935" which is a two part cyanoacrylate and primer specially designed for gluing PTFE/PP/PE etc. Apply the primer/activator to one surface and the cyanoacrylate the other. BUT, you have about one second to get the PTFE into the heat sink. If you are not very fast, then the liner will be stuck part way inside and the only way it comes out is by drilling it out. This is the voice of experience talking...........

-

@oliof To be honest the tube came with the machine, I just dug it out of the box and changed the old one. I had my suspicions tho that it may be a crappier replacement, since the one which was fitted to the hotend looked different.

I bought a new coupler as @infiniteloop pointed out that it may be shot(which it absolutely was) and now I'm printing a calibration cube. I don't want to jynx it, but so far its seems to function normally again.

The cooling fan is a noctua 10x10 fan with a step down converter, which I don't think is an issue(but I've been wrong before sooo...)

I may buy a dragonfly if I have this issue again though since the coupling cost me 5€ and the dragonfly is around 40€ but would eliminate this kind of problem altogether.

Thank you for the tips!

-

@infiniteloop Alas, failiure. Around layer 40 it yet again got stuck inside the tube and couldn't move further down the hotend. I've had enough with this hotend, as @oliof said I'll try the dragonfly and see if this keeps occuring with that hotend also.

Deep breaths.

-

I'll try the dragonfly…

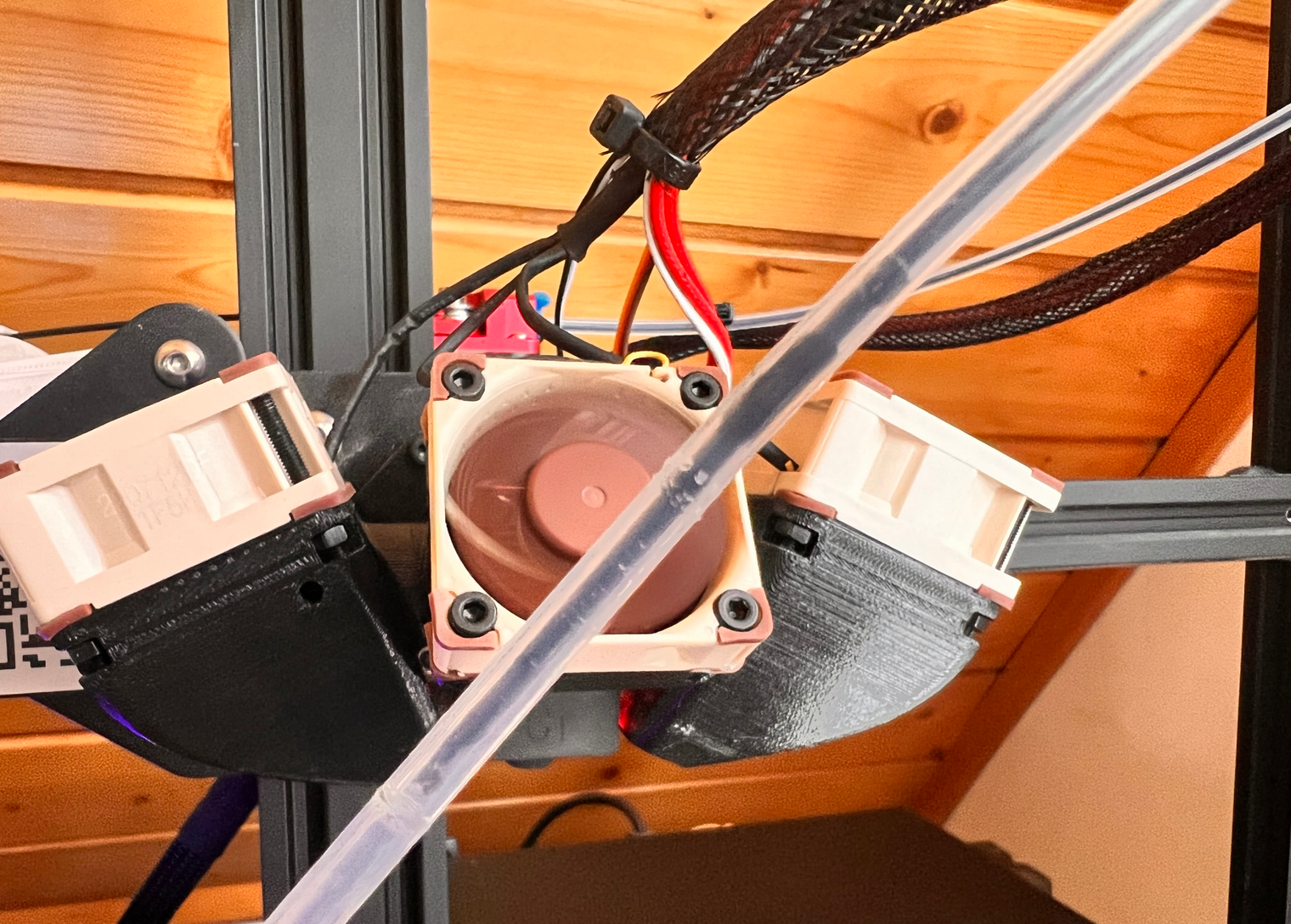

The dragonfly is certainly fine, hopefully it can eliminate your problem. With your current setup, there would just be two suspects left: nozzle too cold or hotend too hot. However, if you ran your test without the part cooling fan, we can exclude the nozzle from the equation. OTOH, the Noctua should well do its job to cool the hotend. My best guess is that the air flow might be less than optimal - from your photo, I can’t spot the details. With the dragonfly, that’s all obsolete, but maybe you keep an eye on this potential problem when you print your next fan duct. Good luck, and keep us informed of your progress. Hope to see some perfect benchy soon, not another cabriolet version

-

@infiniteloop I will look into the issue a bit further during this week, I have ordered the dragonfly, but that will only arrive on the next week. Until then, who knows, maybe I find the offending factor and can eliminate it. I will be back with updates and hopefully with a complete benchy!

-

@re_tour said in My printer stops extruding randomly, what am I missing?:

@infiniteloop I will look into the issue a bit further during this week, I have ordered the dragonfly, but that will only arrive on the next week. Until then, who knows, maybe I find the offending factor and can eliminate it. I will be back with updates and hopefully with a complete benchy!

After two failed attempts I let the hotend cool to see why the filament gets stuck and guess what! The ptfe tube has no molten pla in it. So whatever happens, it happens below the ptfe tube. Since the thermistor and the heater are working fine, I can only guess theres clogging...which is just not possible, I already changed the nozzle and saw no sign of residual pla in the entire hotend which could cause clogging.

If the issue will be the same with the dragonfly there may be some petrol and cigarette lighter involved in the following troubleshooting step.

-

So whatever happens, it happens below the ptfe tube.

I already changed the nozzle and saw no sign of residual plaBetween these two parts, the heat break should do its miraculous work. But, as you state:

I can only guess there’s clogging...

Exactly. Usually, a hotend simply works. If it doesn’t, we can only hypothesise what goes wrong. Some time ago, I spent weeks figuring out that the chemistry of a certain PETG filament slowly built up unflamable debris in the hotend - I couldn’t even torch it (and believe me: I had enough petrol and cigarette lighters at hand). So: strange things happen.

That’s not to say your case is similar. You just encounter a similar mess. So, hopefully, you can resolve the issue with an exchange of the hotend. Anyway, the ultimate way is follow one hypothesis after the next, to take one step at a time. At the end, we know better.