Tweaking my firmware for a better print.

-

I have a 3d printer which I produced. The X and Y movements are with a 2.5mm pitch x 16mm ball screws.

I am not so happy with the print quality and get various blobs... I have looked around and tweaked but still not happy with the print quality. The same printer produced impeccable prints with just a Ramps/Arduino board but I believe it must be some adjustments I need to make in the firmware. Now some commands are placed in the 3d Slicer. I use simplify 3D and I have pasted the startup and end script. Any suggestions by you experts with duet 3D welcome. what I am not happy most is that I get a lot of blobs all over. I have checked the interpolation steps and they are as suggested in the forum. Many thanks in advance.; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-upM81 ; Pin PS ON (State is normally on but just in case it was put off by M code M80)

; PRESSURE ADVANCE

;M572 D0:1 S1.50:1.50

;placed pressure advance command in simplify 3d start script; GENERAL PREFERENCES

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"MENDELEVIUM 3D HULK TWIN TOOLS" ; set printer name; NETWORK SETTINGS

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; NOTE DRIVES S0 FORWARD S1 REVERSE

;DRIVES ORIENTATION

M569 P0 S1 ; X physical drive 0 goes backwards

M569 P1 S1 ; Y physical drive 1 goes forwards

M569 P2 S1 ; Z physical drive 2 goes backwards

M569 P3 S0 ; E0 physical drive 3 goes backwards

M569 P4 S1 ; E1 physical drive 4 goes backwardsM584 X0 Y1 Z2 E3:4 ; set drive

;MAPPINGS

;M350 X16 Y16 Z16 E16:16 I1 ; configure;MICROSTEPPING WITH INTERPOLATION SETTINGS

M92 X160 Y160 Z400.00 E297.80:297.80 ; set steps per mm;SETTING OF INSTANTANEOUS MAXIMUM SPEED CHANGES IN MM/MIN

M566 X1000.00 Y1000.00 Z100.00 E750.00:750.00;MAXIMUM SPEEDS IN MM/MIN

M203 X4000.00 Y4000.00 Z2000.00 E2400.00:2400.00;SET ACCELERATION IN MM/SEC SQUARED

M201 X500.00 Y500.00 Z20.00 E250.00:250.00;MOTORS MAXIMUM CURRENT

; NOTE 60 mm steppeprs max current 2.1A

; NOTE Board max current 2.4A

M906 X2100 Y2100 Z2100 E1200:1200 I30;SET IDLE TMEOUT

M84 S30;AXIS LIMITS OF MINIMUM TRAVEL

M208 X0 Y0 Z0 S1;AXIS LIMITS OF MAXIMUM TRAVEL

M208 X345 Y301 Z261.05 S0; ENDSTOPS

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstopM558 P1 I0 C"zprobe.in" H5 R0.2 F1000 X0 Y0 Z100 ; piezo inserted 12/12/22

;DEFINITION OF MESH GRID MOVED TO MACRO BED MAPPING

;M557 X15:215 Y15:195 S20;CONFIGURATION OF THERMISTORS

;HEATBED

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

;HOTENDS 0-e0

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

;Hotend 1-e1

M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp;MAPPING OF HEATER OUT PUT TO SPECIFIC SENSORS

;HEATBED

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0;MACHINE HEATERS

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2;AUTOTUNED M307

;HEATBED

M307 H0 R1.058 C224.9 D2.17 S1.0 V24.3 ; autotuned value;HOTEND 0

M307 H1 R2.407 C189.6:163.8 D4.90 S1.00 V24.3 ; autotuned value;HOTEND 1

M307 H2 R2.562 C179.0:165.4 D3.60 S1.00 V24.3 ; autotuned value;MAXIMUM HEATER TEMPERATURES

;S VALUE IS MAX PERMITTED TEMPERATURE

;HEATER 0-BED

M143 H0 S110 ; set temperature limit for heater 0 to 120C;HOTEND 0

M143 H1 S310;HOTEND 1

M143 H2 S310HEATBED MAPPING

M140 H0 ; map heated bed to heater 0; FANS TO COOL PART ON NOZZLE 1 & NOZZLE 2

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned off;WATER COOLER

M950 F2 C"fan2" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P2 S0 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools as per forum instruction

M563 P0 S"EXTRUDER 0" D0 H1 F0 ;TOOL 0 USES DRIVE 0 AND HEATER 1

G10 P0 S0 R0 X-16.5 Y0 ; set tool 0 axis offsets

M563 P1 S"EXTRUDER 1" D1 H2 F1 ; define tool 1

G10 P1 S0 R0 X16.5 Y0 ; set tool 1 axis offsets; FILAMENT MONITOR LASER WITH MICROSWITCH

; R Values may need setup according to different filaments

;TEMPORARY DEACTIVATED FILAMENT MONOTOR

;M591 D0 P6 C"e0stop" R1:600 E30 S1

;M591 D1 P6 C"e1stop" R1:600 E30 S1; MISCELLANEOUS

M575 P1 S1 B57600 ; enable support for PanelDue

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power lossSimplify 3d program startup script;-

M81 ; AUTO OFF FUNCTION IS SWITCHED OFF AND LATCHING RELAY IS ON (NORMALLY CLOSED)

G28 Z0 X0 Y0

M106 P0 S0 H-1

M106 P1 S0 H-1

M115 U3.1.0

M83

M140 S90 T0 ;BED temp set

M104 S220 T0 ; EXTRUDER 0 TEMP HEAT

M109 S220 ; Wait until temperatures stabilize

M105

G21

G90

M83

G0 Z299

G0 Y0 X0 F3000

G29 S1; APPLY BEDMESH MAPPING

G0 Z10 F1000

G1 Z0.15 F1000

G92 E0

G1 Y100.0 E25 F400.0

G1 Y200.0 E20 F800.0

G1 Y270 E15 F400.0

G1 Y290 E2 F600

G1 Z25 F300

M106 P2 S255 H-1

M572 D0 S1.25 ; PRESSURE ADVANCE

G0 Z5END SCRIPTS

G91 ;relative position set

G1 Z10 F1000

G1 E-20 F150 ; retarct 20mm of filament to avoid burningM140 S0 ; turn off bed

M104 S0 ; turn off extruder

M109 S50 ; wait for extruder temp to reach cooldown

M106 P0 S0 H-1 ;Cooling FAN 0 Switch off

M106 P1 S0 H-1 ;Cooling FAN 1 Switch off

M106 P2 S255 H-1 ; WATER COOLING HEAD SWITCHED OFFG90 ; Absolute position set

G28 Z0

G91 ;realtive mode

G1 Z-5 F500 ; Z axis lowered 5mm from max

G90 ; absolute mode returned

M84 ; disable motors

M80 ; Auto Off or work ready alarm activated -

Can you share your slicer settings and some photos of what you're actually seeing?

-

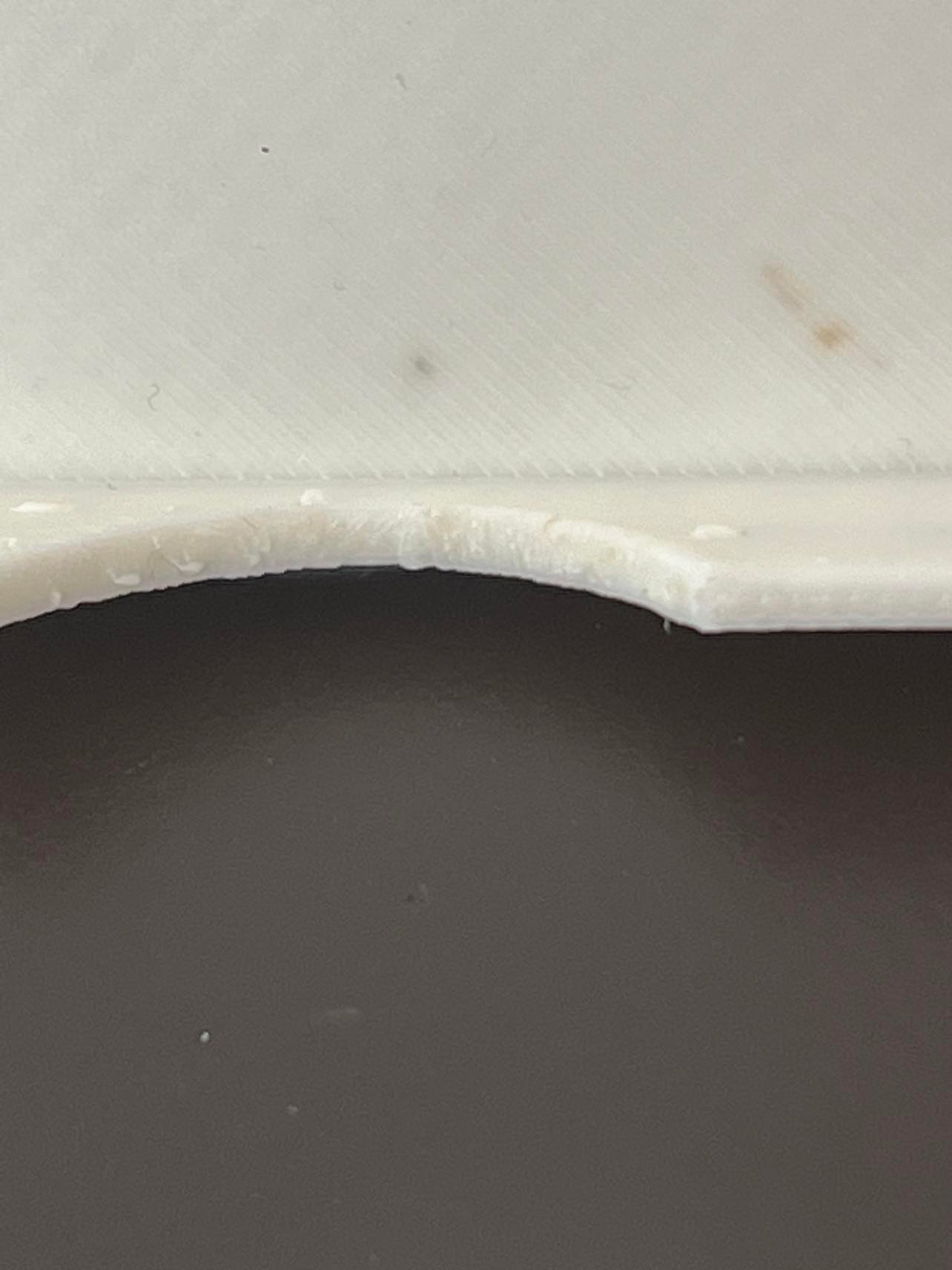

These were worse since I already had cleaned off the sides a bit...

-

I would say that looks like over extrusion.

-

@Phaedrux the material does not look great but the blob pieces all over are what is bothering me more.

-

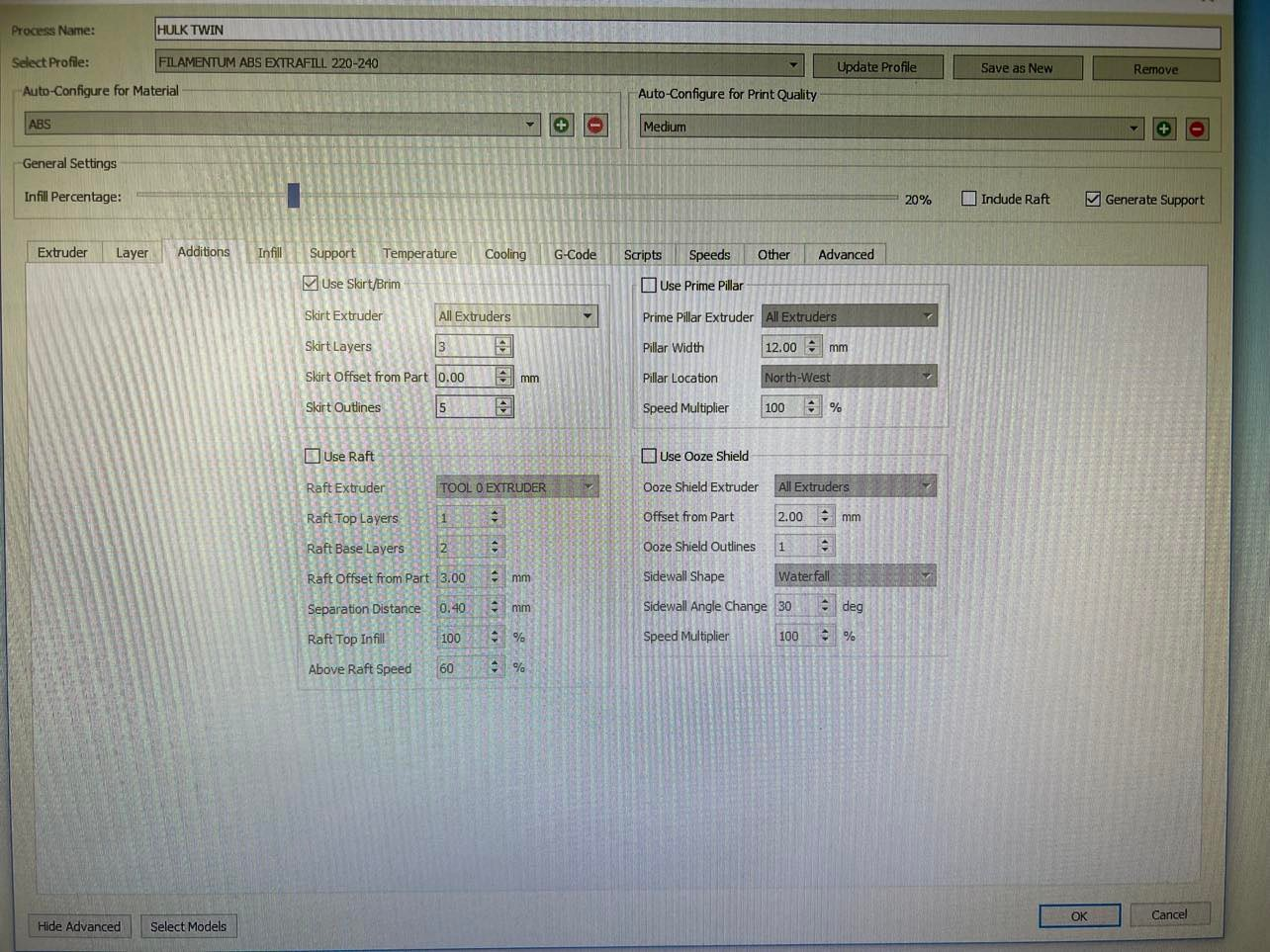

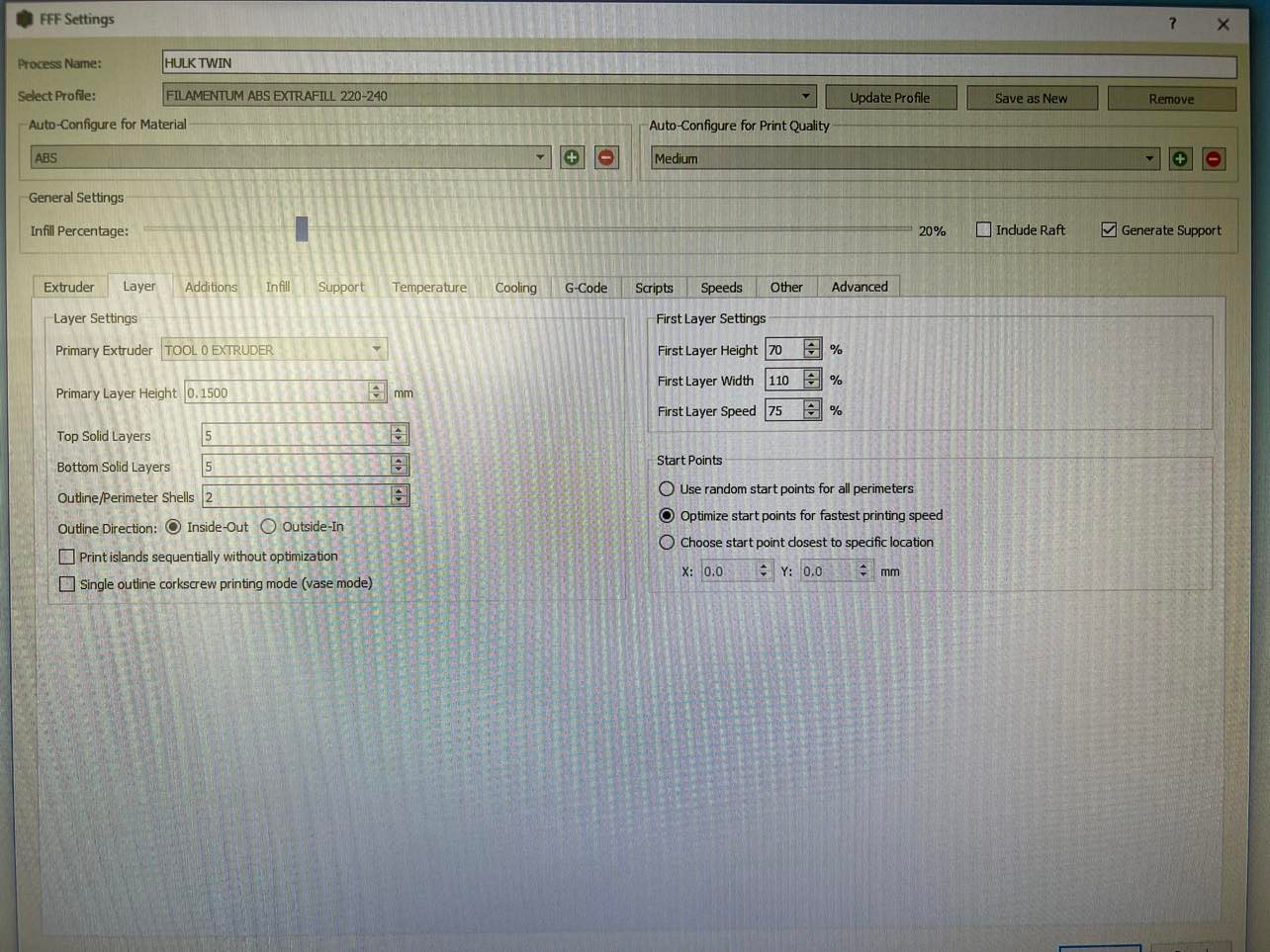

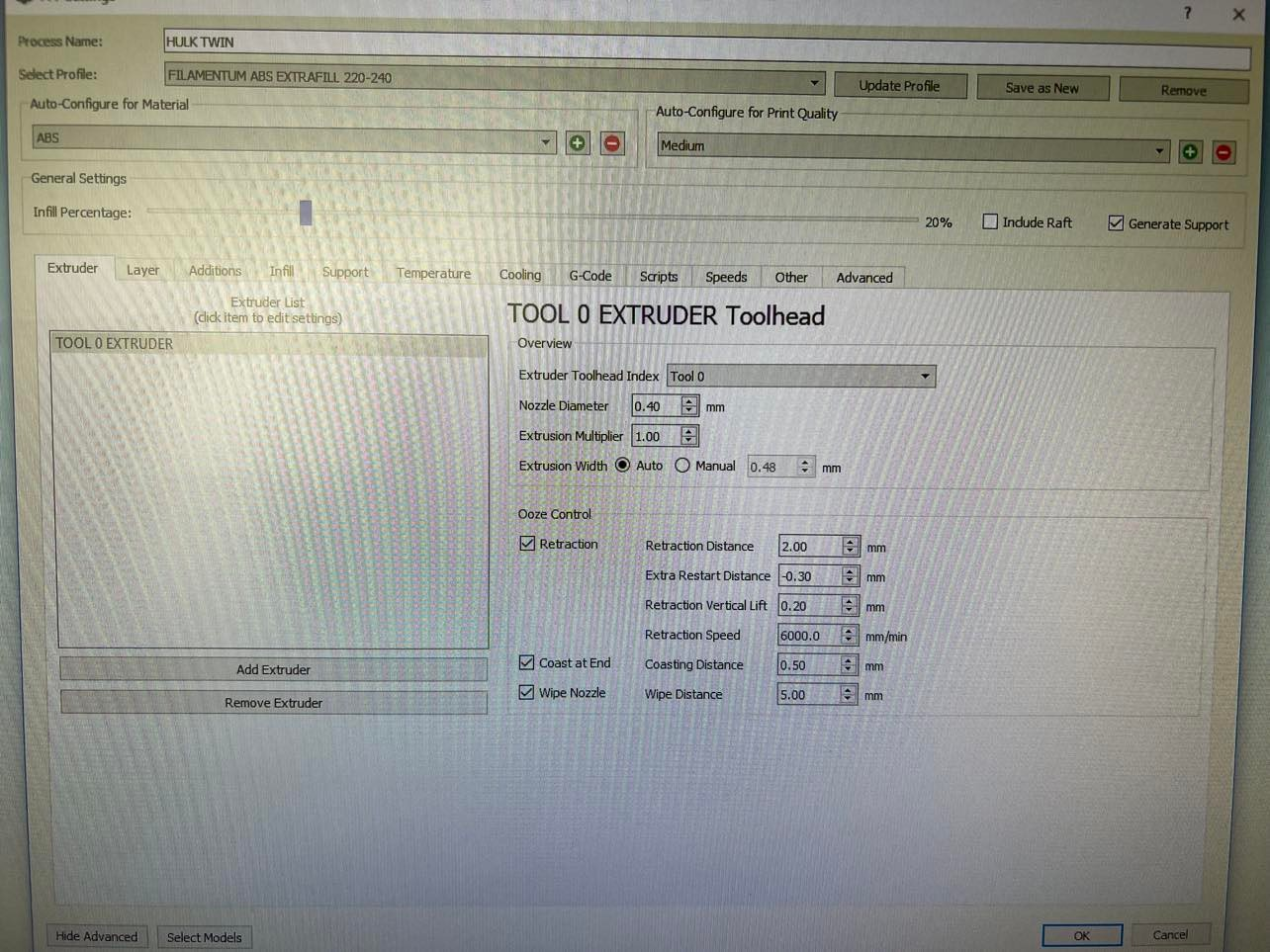

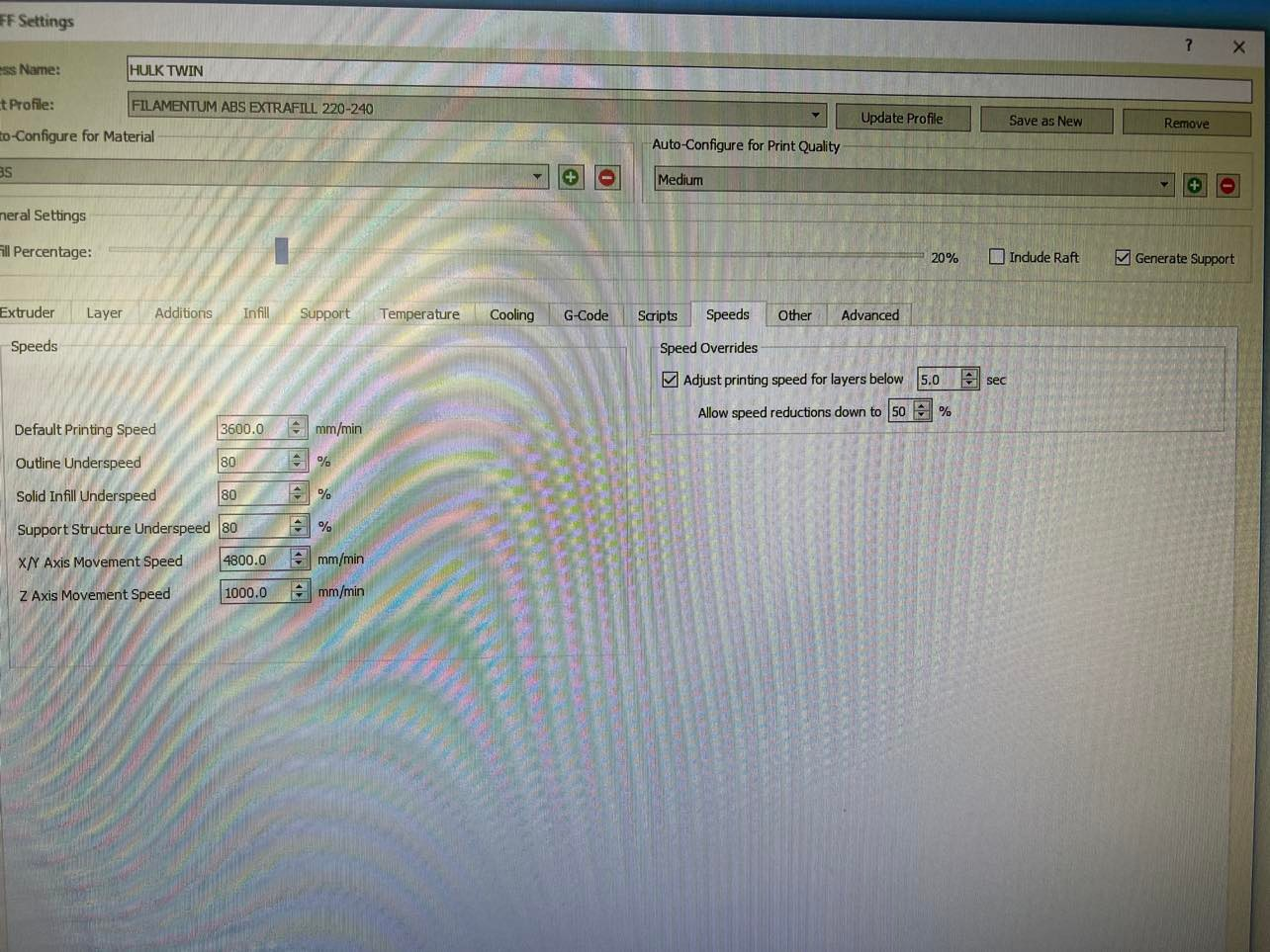

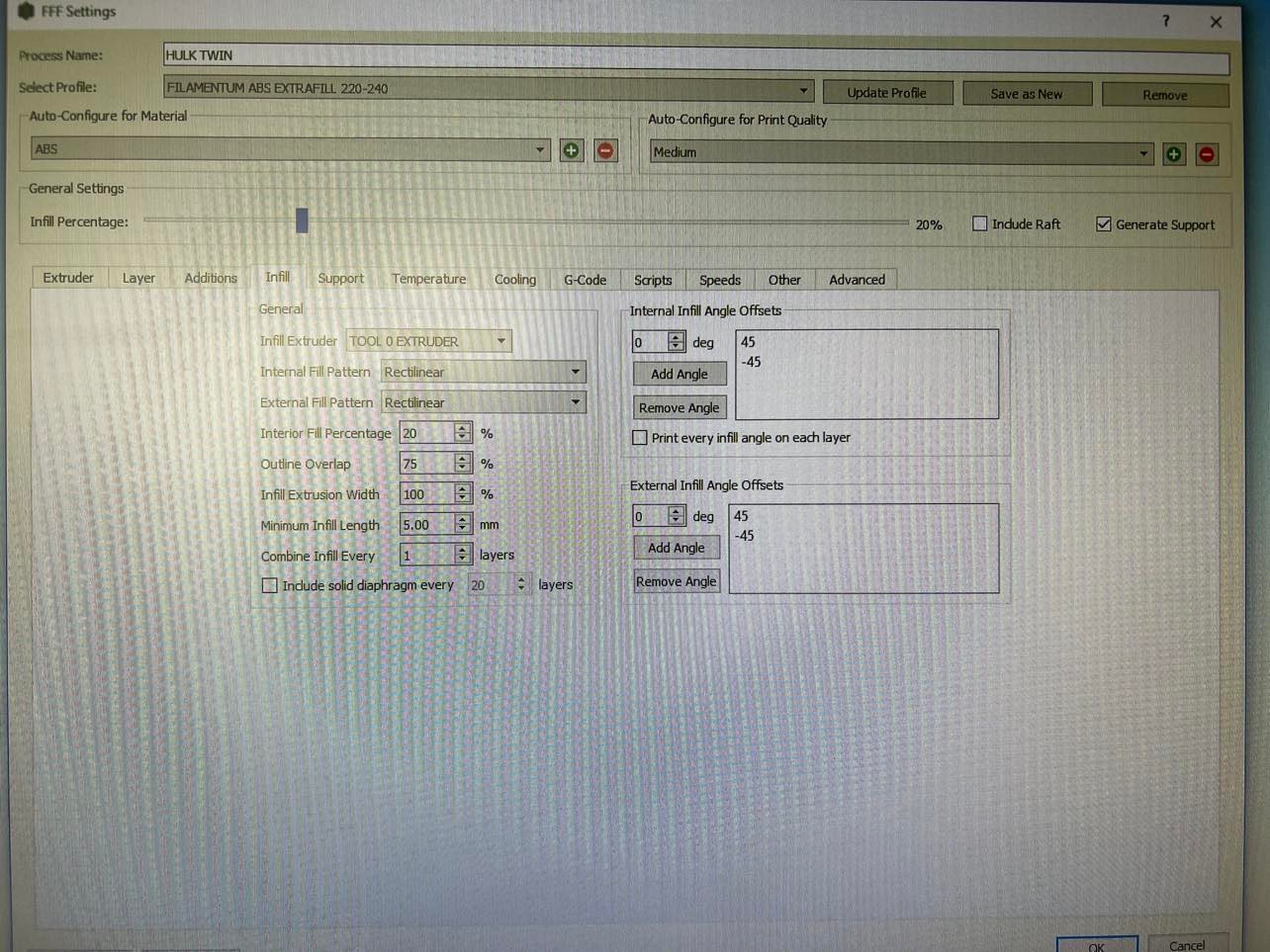

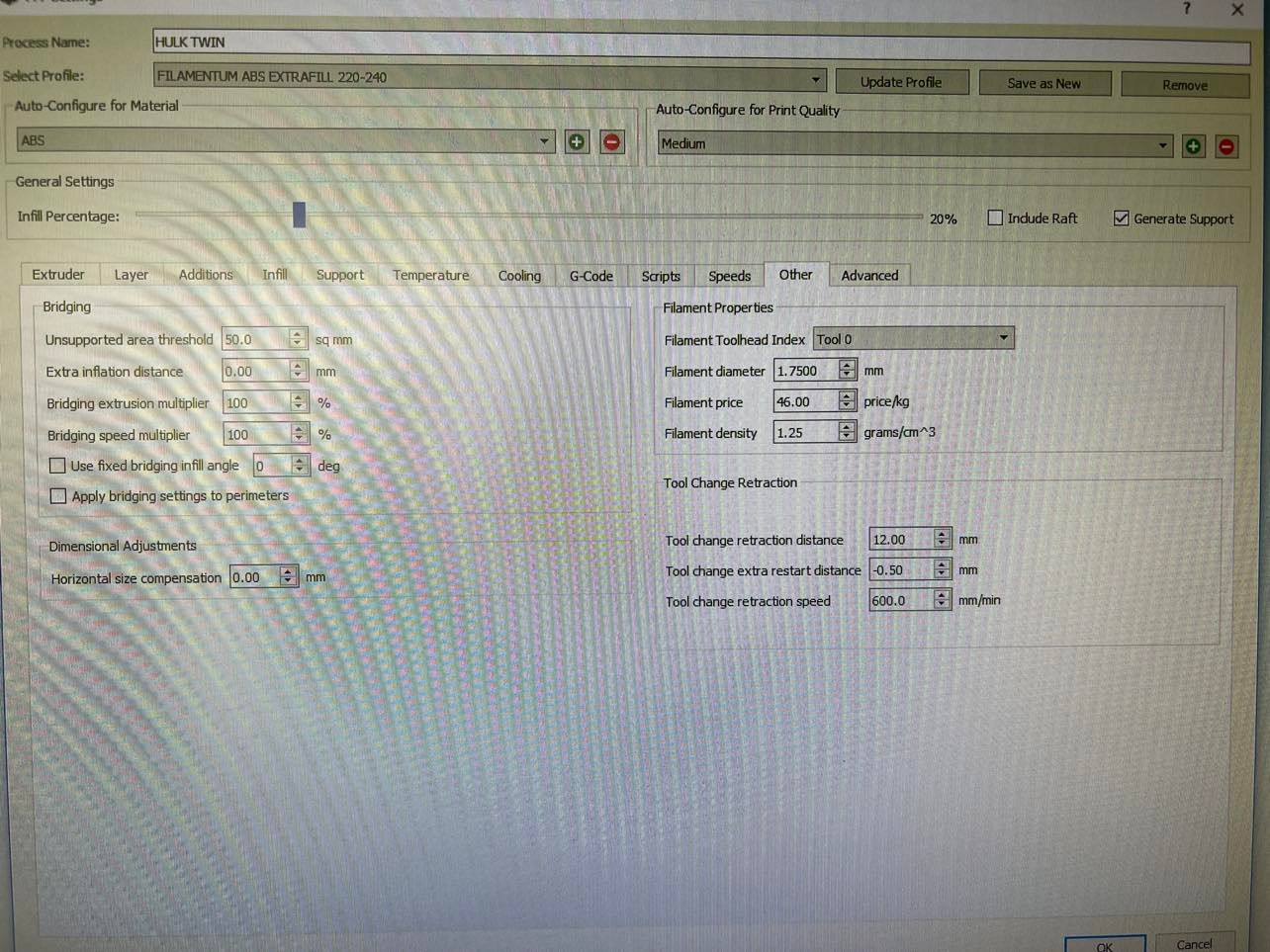

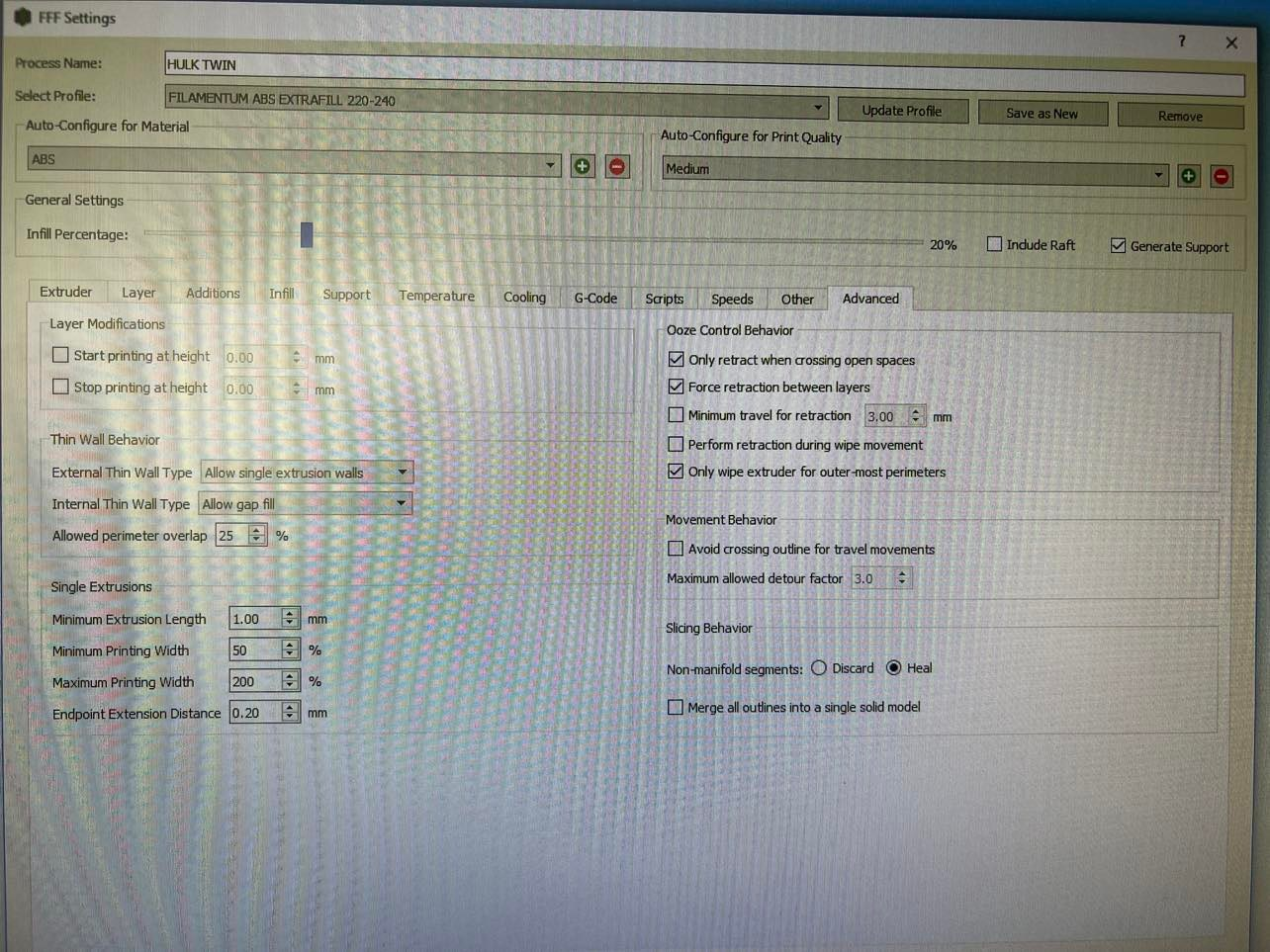

@Phaedrux have yo taken a look at the slicer settings? the machine has a bowden extruder

-

@mendelevium Things to try. 1. I have never seen such a high pressure advance setting (S1.25). Are you sure that's right? Try reducing or even disabling it just to see what difference it makes. 2. Do the blobs coincide with retractions? If so,look at your retraction settings but note that there is an interaction between PA and retraction so do the PA first. Using firmware retraction wil enable you to change settings "on the fly". 3. You haven't specified what filament you are using. Have you printed a temperature tower to ascertain the correct value to use for your machine! If not, do so. 4. If the blobs are seemingly random, try another reel of filament but do (3) first. 5. Try an extrusion multiplier of 0.95 or even 0.90 just to see if that helps.