Independent bed leveling excessive mesh bed deviation

-

Hi all,

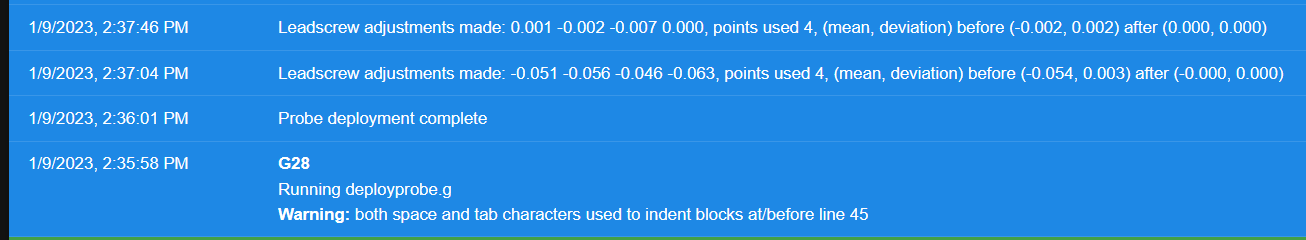

I'm having an issue with my new machine where there is a low area on the max end of the x axis. I am using 4 point independent leadscrew bed calibration. These are the results from the my calibration. My machine is set up to run the independent leadscrew calibration everytime it home, and G32 is run twice to make sure it is accurate.

According to these results, my bed should be very level. However, I still have first layer height issues.

Here is my heightmap from a 100 point mesh bed compensation with a euclid probe.

As you can see, there is a low spot, on the max end of the x axis.

I am using an e3d 300x300 high temperature heated bed, with a glass plate on top, and 2 swiss clips holding it in each corner. I have multiple glass plates. This plate that I'm currently using was used on a previous printer for hundreds of prints without any issues.

I decided to try a different glass plate to see if I would achieve the same result.

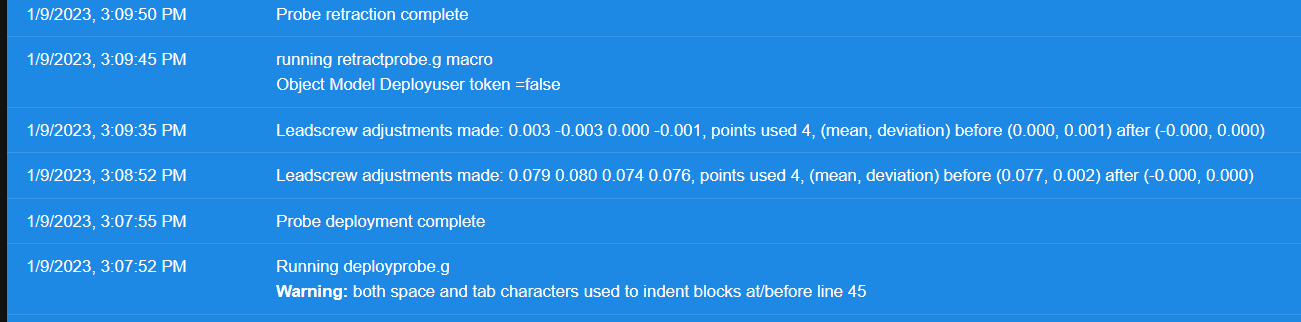

Here are the results from the independent bed leveling during homing.

And here is another mesh bed compensation with the new glass plate installed.

Ase you can see, there is still a massive low spot on the high end of the x axis. Any idea for what could be happening? Do I need to change my probe points for independent bed leveling? Is there a sag in the linear rail on the side that is low?

Thanks.

-

Is something pulling at the print head?

@Surgikill said in Independent bed leveling excessive mesh bed deviation:

Is there a sag in the linear rail on the side that is low?

You tell me.

-

@Phaedrux I have a wire loom and there might be a possibility of it pushing down on the print head, I can try to relieve it as much as possible.

I think it's the linear rail though. I pulled it off and took the carriage off the rail. Laying it on edge on a piece of ground granite, one side has a large bend in the center, I can fit a 4 thou piece of paper under it with room to spare. If I flip it over and put it on the same spot on the granite and try the paper again, it will only fit under the rail at the ends, and not in the middle.

-

@Phaedrux Any idea how I can mount that rail straight? I contacted the company I bought it from and basically got told I was mounting it wrong, and I need to pretty much compress the rail into straightness. I tried to do that with some printed jigs, and now I'm at 0.144mm total extreme spread.

I also checked the slab of granite I was using with a set of parallels, and it looks to be within about 0.001" across the surface, which isn't great, but it's good enough to show a >4 thou variance in the rail.

-

I'm no expert on linear rails unfortunately. Though I do know that typically in industry when rails are used the surface they are mounted to must be flat to begin with.

I think you're on the right track though, if you know how the rail bends, you can try and force a counter bend with shims.