Twin Z axis Motors and MBLA

-

@Dizzwold can you run G32 again before you run G29?

that is a decent dip in the bed though.

If you put a straight edge on the bed along the X axis can you see anything like the 1mm dip its showing?

What type of probe are you using? -

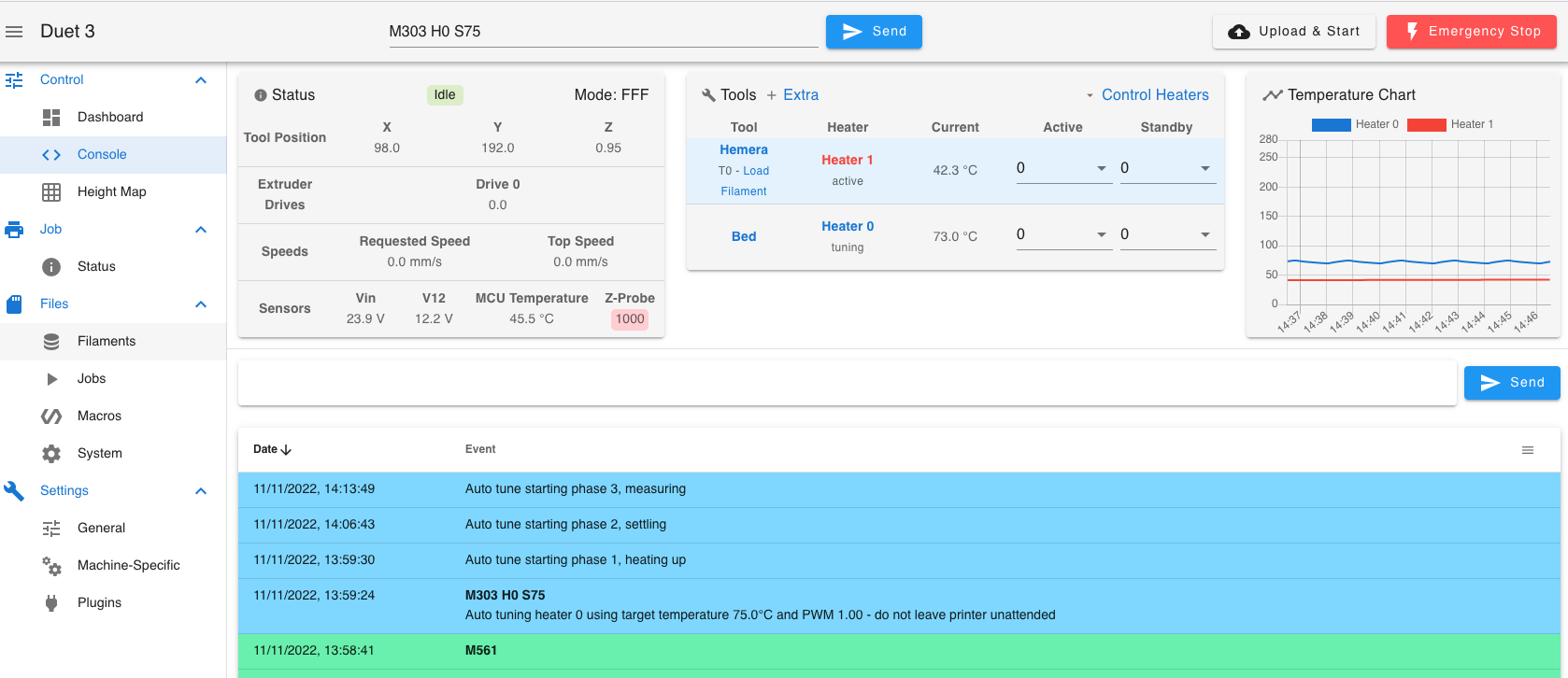

I'm waiting for the bed to cool down and do another PID tune.

The bed is the original Tronxy 300 x330 (rolled Alloy) with the Tronxy TR Glass Sensor (Z probe), Inductive NPN with the Glass Bed that comes with the Probe;

https://www.tronxy3d.com/products/tronxy-black-tr-auto-leveling-sensor-lattice-glass-plate-500-500mm

It's usually quite reliable IMO, and even with the faulty board previously, it was never this off. -

Is there a way to run a log while running the bed pid, G32, G29?

-

@jay_s_uk

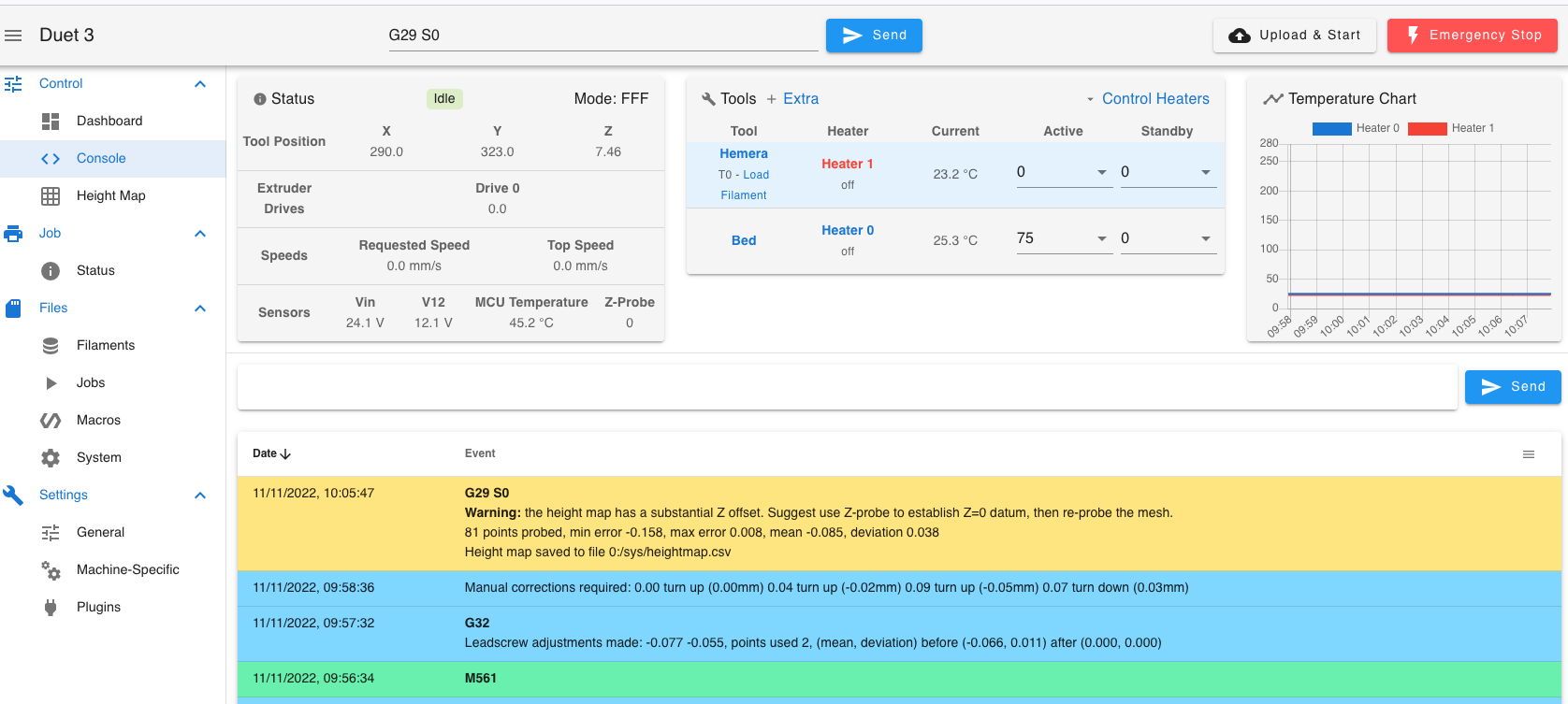

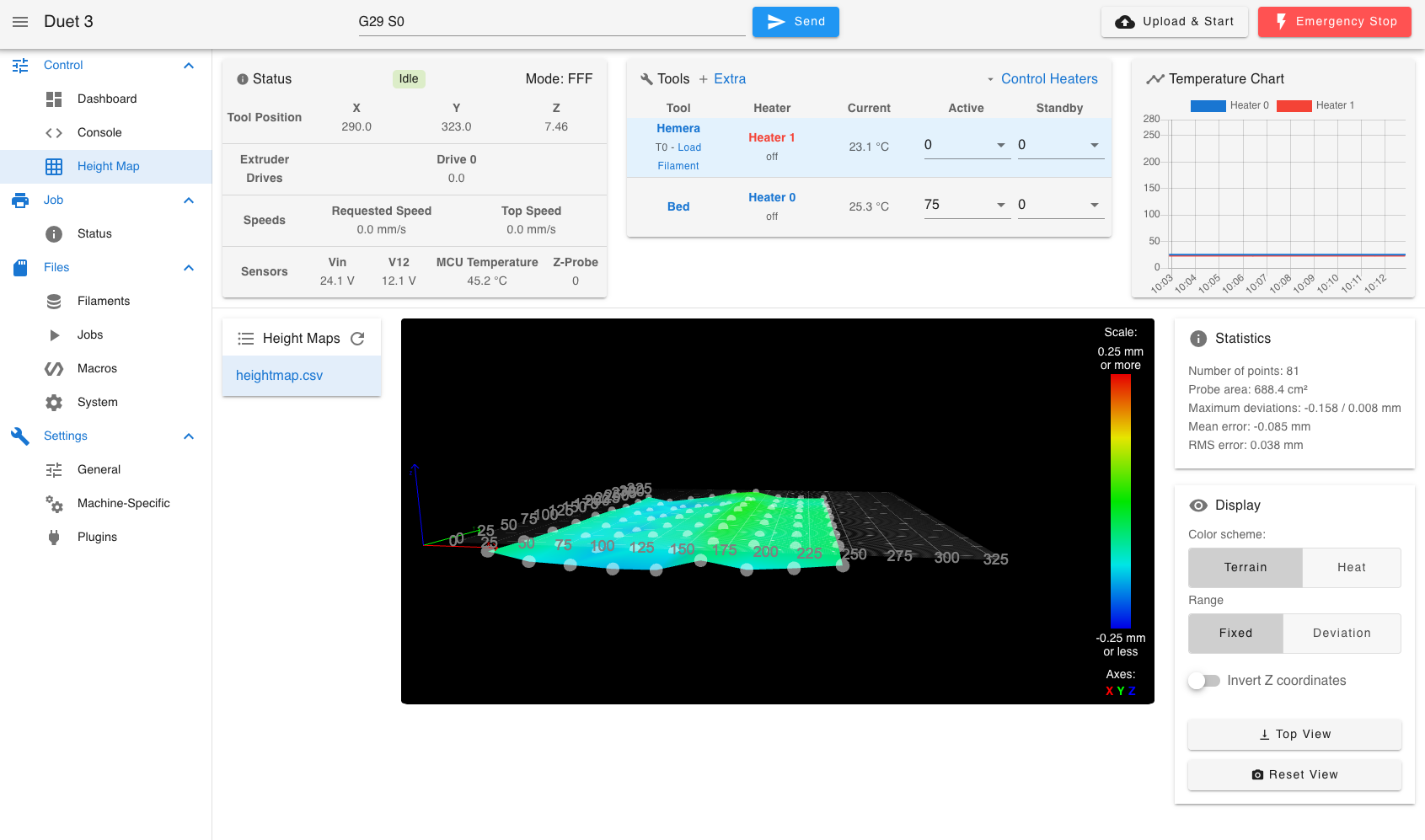

Okay, I've just done, with a Cold bed and nozzle M561, G32, G29, and got the following results. I've left the machine powered on over night thinking that the motors (Z axis) would hold position, but with the result it would look like this isn't the case. So I reset the Z=0 (G92 Z0, G30 S-1), and try again;

Yet, I now have this for the height map???

-

@Dizzwold It's a bit hard to see if that step is in the X or Y axis. If it is in the Y axis so the first half of the entire probe is one level and the second half is another, then that may be due to lost steps in Z movement. If the step is in X, so that it happens as the head scans left/right then I'd be checking that nothing is "pulling on the print head" like a bowden tube or wiring and causing movement.

-

Hi,

Oh dogs balls, that could be my hotend cable chain, rather the nylon cable braid around it.

The idea of the cable braiding was to stop the cable chain inverting inwards and blocking the path of the carriage.

-

@jay_s_uk @gloomyandy @Phaedrux

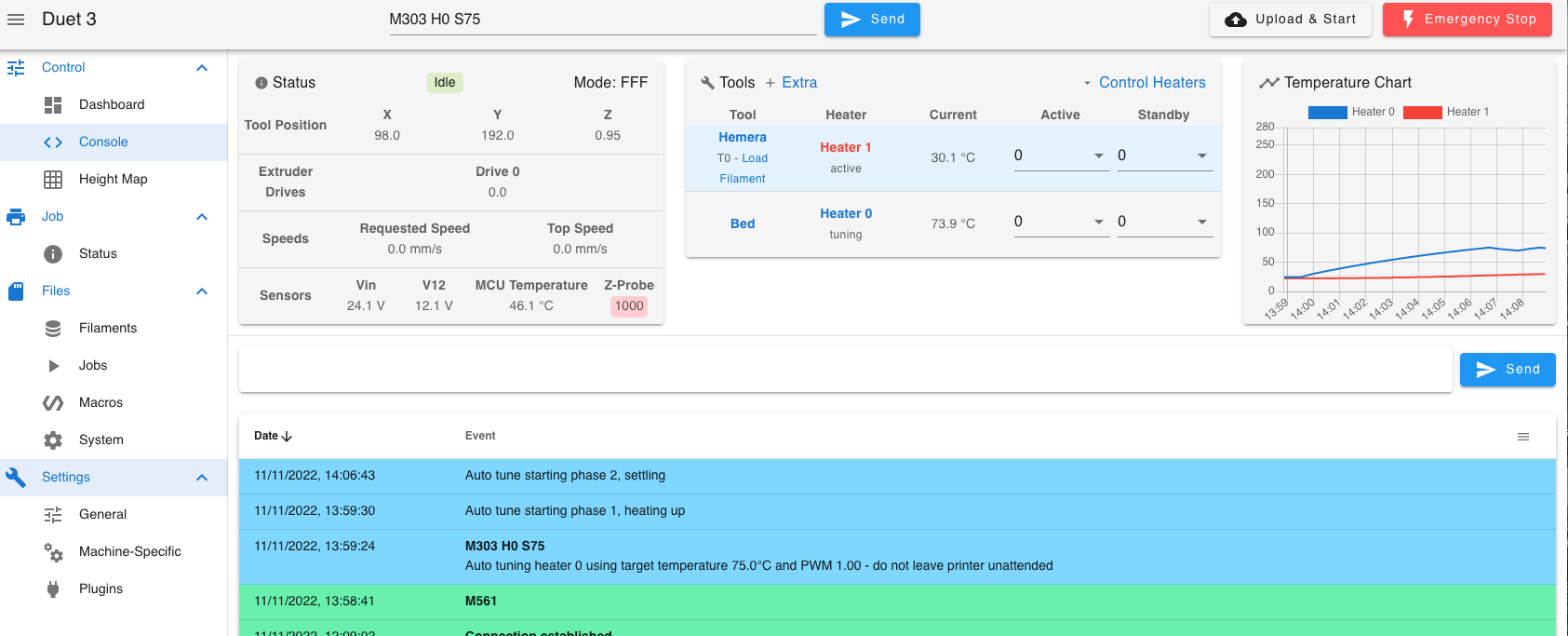

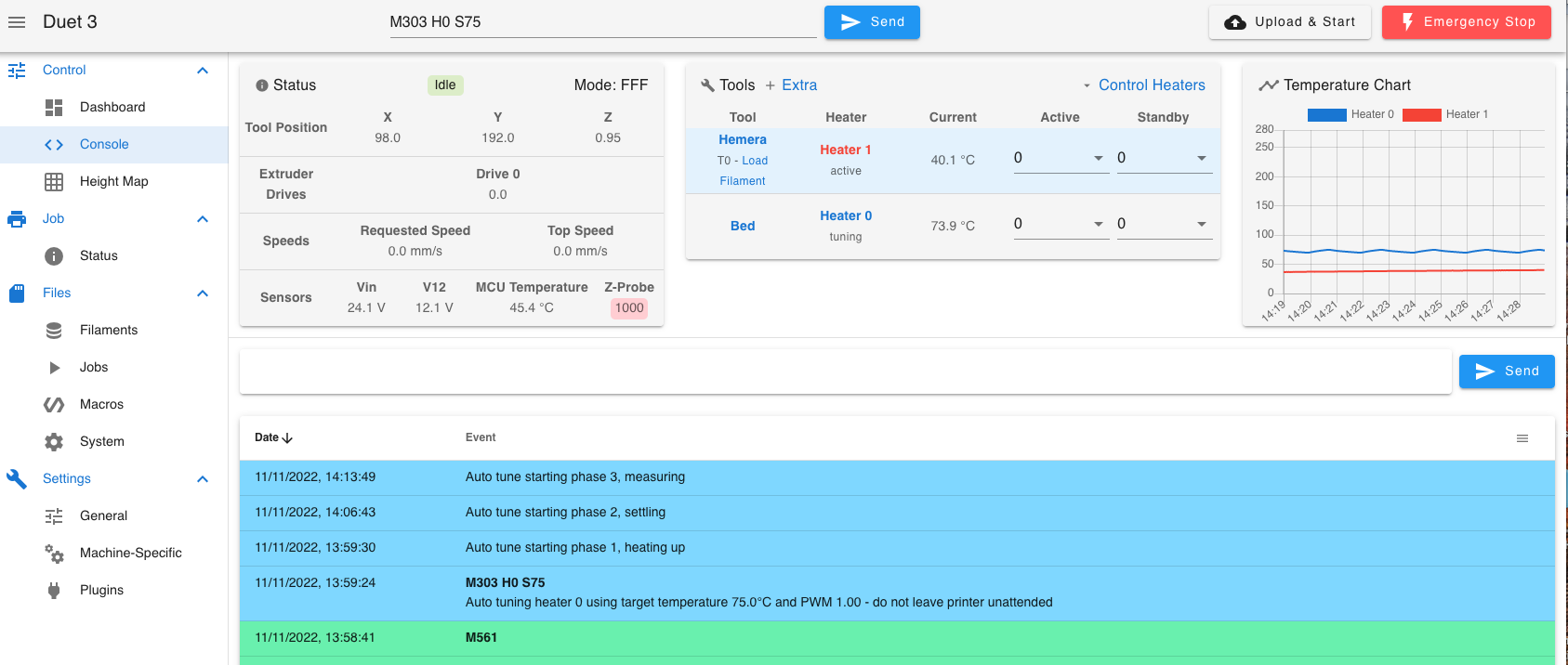

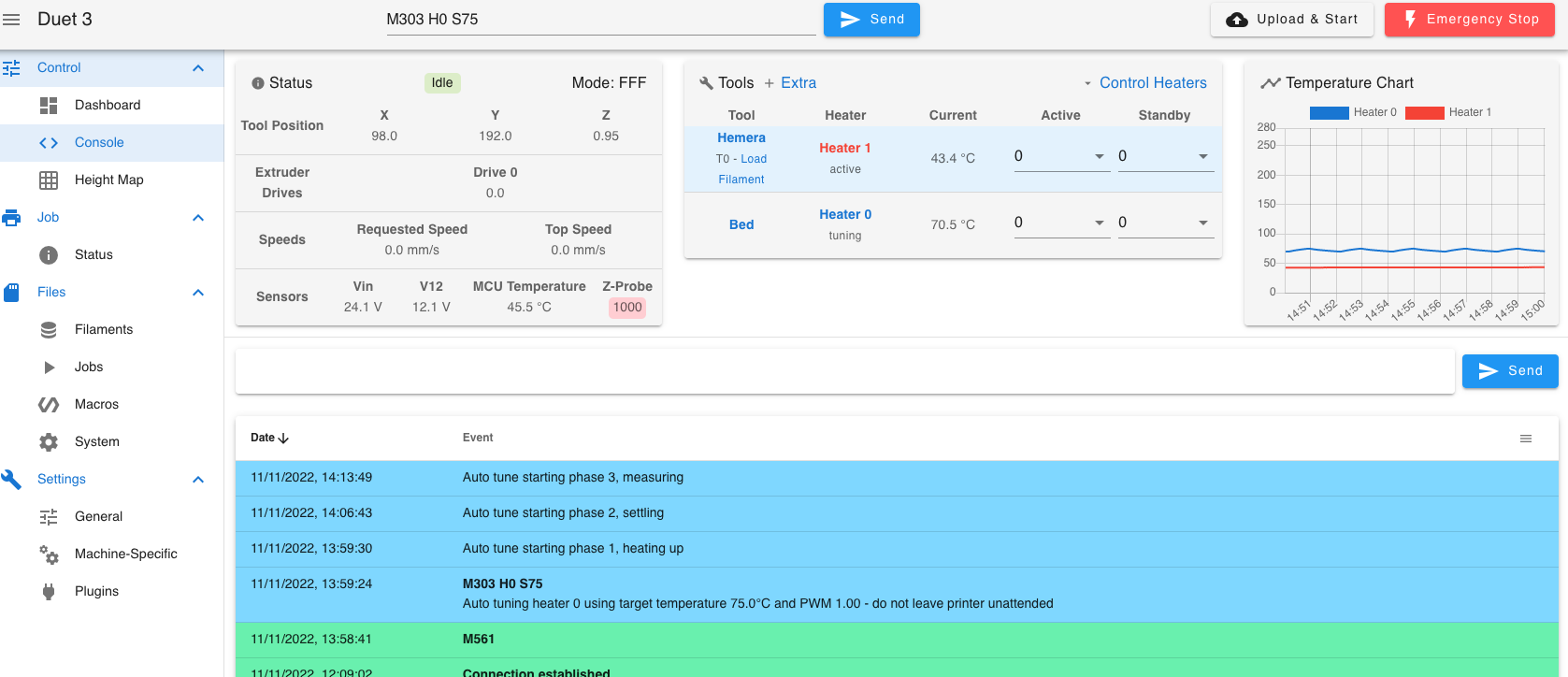

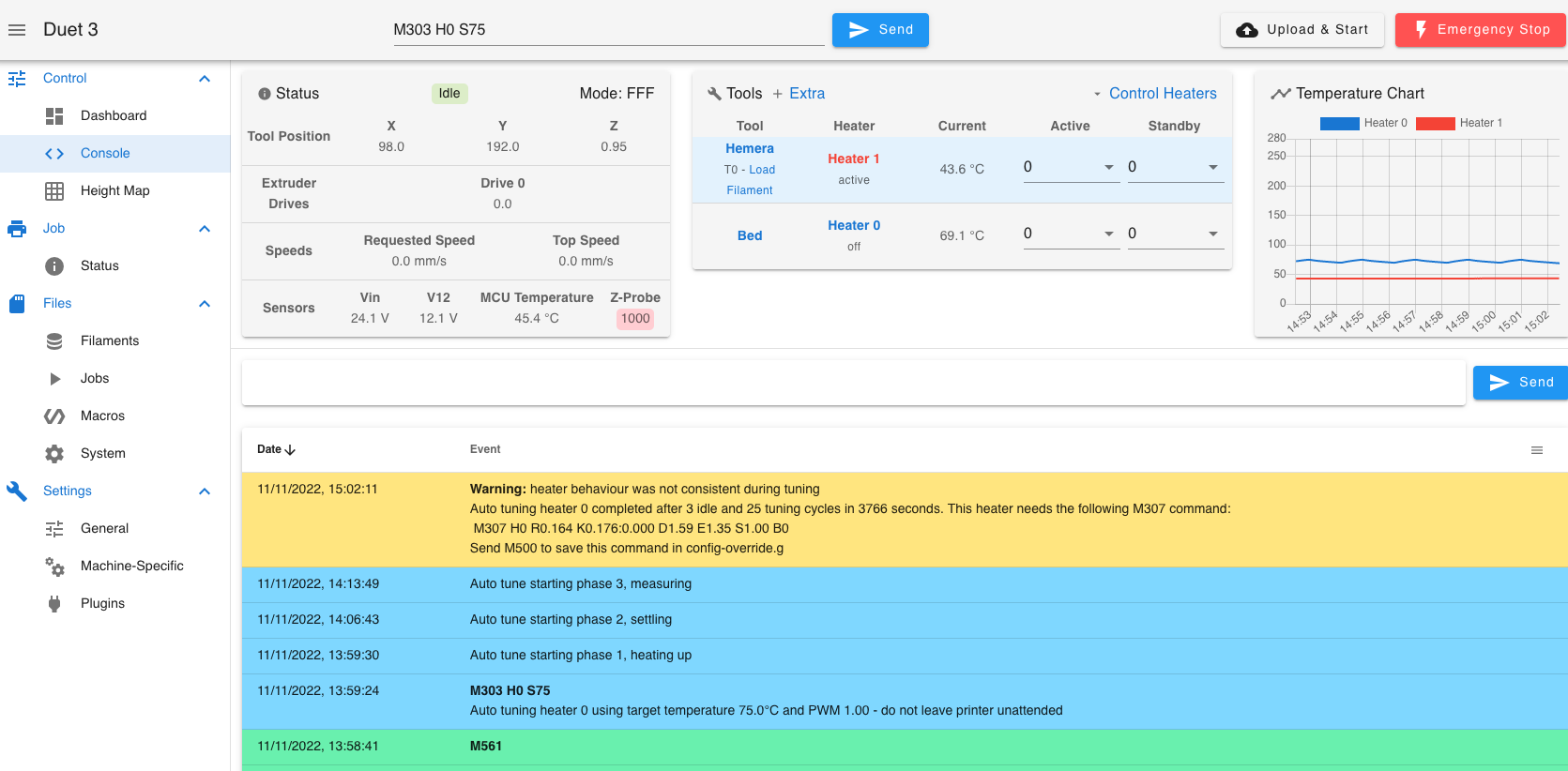

I've done another Bed PID, and got a similar warning message.

The graph raised and fell between 69.9 and 75.1;

-

If you save those values and use them are you able to set a temp for the bed and have it reach it and maintain it?

-

For the bed, just about. I don't think it will go much higher than that, bearing in mind this is the stock Tronxy heater and bed.

Cant wait to get the parts printed for the cast tool plate.

I was having a problem that now I'm printing, that I was having to add around 0.5mm in babysteps.

I've figured out why this was.

I was setting Z Probe height with G31 in config.g with the Tool position /nozzle height shown, hence to 0.5mm. -

@Dizzwold said in Twin Z axis Motors and MBLA:

Tronxy heater and bed.

Well 70c for that bed heater is probably the limit.