Trouble with M201 and M566 settings

-

If you have set an acceleration for X and Y to 2000mm/s^2 in config.g, but to 500mm/s^2 in the slicer, then the sliced printed part will only be printed with an acceleration of 500mm/s^2.

I don't know Simplify3D that well anymore (too long ago) but in PrusaSlicer, just as an example, you can specify the acceleration, jerk and other values in the printer settings, which will then be used to print.

However, if the value in config.g is lower than that in the slicer, the value is taken from config.g.

Google Translate

-- Original Text --Hast Du in der config.g eine Beschleunigung für X und Y auf 2000mm/s^2 eingestellt, aber im Slicer auf 500mm/s^2, dann wird das geslicte Druckteil auch nur mit einer Beschleunigung von 500mm/s^2 gedruckt.

Ich kenne Simplify3D nicht mehr so gut (zu lange her) aber im PrusaSlicer, nur als Beispiel, kann man die Beschleunigung, den Jerk und andere Werte in den Druckereinstellungen angeben, mit der dann auch gedruckt wird.

Ist der Wert in der config.g allerdings niedriger wie der im Slicer, wird der Wert aus der config.g genommen.

-

@jered Are you aware that any G1 Xn Yn En move has to be in sync? That is to say the X axis move, the Y axis move and the Extruder move all have to start and end at the same time. A similar effect is with instantaneous speed change whereby the firmware will have to wait for the slowest instantaneous speed change threshold before applying any of them. I note in you config.g that your instantaneous speed change threshold for the extruders is a mere 2mm/sec (120mm/min). This will definitely slow the print down, especially when doing segmented curves or holes. I suggest you try setting the extruder jerk to a "silly high" value - it won't affect anything unless it's too low - I use 3600 (60mm/sec). Then with that out of the way, changes to X and Y jerk and acceleration will not be limited by the extruder settings.

-

I had a look around in the slicer, but did not find those settings. I don't mind having the config dictate the settings. They just seem to operate differently in the Duet controller vs what ever is in the Ender.

Maybe it will help if I include the config for the Ender. It is attached below. Note that it looks completely different than Duest's.

Ender config Configuration.h

Maybe its this one: Configuration.h

-

You can't just copy a Marlin configuration into an RRF configuration, that won't work.

You have to take the trouble to write down the values and transfer them to config.g.

But in such a case I would rather take an existing configuration of another user who has the same printer (RatRig printers are represented here) and adapt it and then copy it into the system directory of the Duet.

The best solution in such a case is the RepRapFirmware Configuration Tool.

Simply enter everything here as you have it and in the end a usable complete package of software and, if necessary, firmware comes out.It also seems that you have an older firmware on your Duet.

According to your config.g it is 3.3.

https://forum.duet3d.com/topic/30059/software-bundle-3-4-3-released/Google Translate

-- Original Text --Du kannst keine Marlin Konfiguration einfach in eine RRF Konfiguration kopieren, das funktioniert nicht.

Du musst Dir da schon die Mühe machen und Dir die Werte notieren und sie in die config.g zu übertragen.

Aber ich würde in so einem Fall eher eine bestehende Konfiguration eines anderen Users nehmen der den gleichen Drucker hat (RatRig Drucker sind hier einige vertreten) und diese anpassen und dann in das System Verzeichnis des Duet kopieren.

Die beste Lösung in so einem Fall ist aber das RepRapFirmware Configuration Tool.

Hier einfach alles so angeben wie Du es hast und am Ende kommt ein brauchbares Komplett Paket an Software und bei Bedarf + Firmware dabei heraus.Auch scheint es das Du eine ältere Firmware auf Deinem Duet hast.

Laut Deiner config.g ist es 3.3.Hier ist die aktuellste...

https://forum.duet3d.com/topic/30059/software-bundle-3-4-3-released/ -

@norder

Update must have came out recently as I updated a few weeks ago.Anyway, I know I can't copy configs between my machines, I was just looking at the accel and jerk setting compared to each other.

I will do another test to see what happens.

-

I was wondering about the jerk setting. If the number goes up vs moving closer to zero, how does the machine respond.

Does a higher setting slow down more?

-

I just realized, you answered this on my other post.

-

These setting are working, I just don't know why I can't get this machine to have very smooth movement like the Ender 5 I have.

Seems like, If I match the jerk and accel setting on the 2 machines, they should perform similarly.

I can tell it is making a difference in quality due to the threaded holes not being as good.

I will just keep tweaking this....

-

@jered said in Trouble with M201 and M566 settings:

I just realized, you answered this on my other post.

Where I wrote that the Z6 should be set to Z1200 and also all extruders to 1200mm/min?

Have you set the jerk values of Z and all extruders to 1200mm/min?

If so, is the printer now behaving as desired?In order to set a smooth pressure movement using jerk, it is quite sufficient to do it only on the X and Y axes.

Always remember, 480mm/min is just 8mm/s.I also have a jerk of 8mm/s (480mm/min) on mine and the beginning and end of each printed swath is gently accelerated and decelerated.

With a jerk of 20mm/s, the acceleration and deceleration is very hard, which is not necessarily reflected in the print image, but it puts more stress on the hardware and it hurts to watch. The movements go from round to square and from soft to hard.You have to find the right or most comfortable one for you and your printer.

I prefer a round, almost even pressure movement to these extreme high-speed pressures ala Vez3D (Benchy Speed Challenge).

Interesting... but I don't have to have it.

Google Translate

-- Original Text --Da wo ich geschrieben habe das Z6 auf Z1200 und auch alle Extruder auf 1200mm/min eingestellt werden sollten ?

Hast Du die Jerk Werte von Z und allen Extrudern auf 1200mm/min gestellt ?

Wenn ja, verhält der Drucker sich jetzt wie gewünscht ?Um eine weiche Druckbewegung mittels Jerk einzustellen, reicht es vollkommen aus es nur bei der X und der Y Achse zu machen.

Bedenke immer, 480mm/min sind gerade einmal 8mm/s.Ich habe bei mir auch ein Jerk von 8mm/s (480mm/min) und der Anfang und das Ende jeder gedruckten Bahn wird sanft beschleunigt und abgebremst.

Bei einem Jerk von 20mm/s ist das Beschleunigen und Abbremsen sehr hart, was sich nicht unbedingt im Druckbild widerspiegelt, aber die Hardware wird dadurch mehr belastet und es tut einem schon weh beim zugucken. Die Bewegungen gehen von rund zu eckig über bzw von weich zu hart.Man muss das richtige bzw angenehmste für sich und seinen Drucker herausfinden.

Eine runde, fast gleichmäßige Druckbewegung mag ich lieber als diese extremen Highspeed Drucke ala Vez3D (Benchy Speed Challenge).

Interessant... aber muss ich nicht haben.

-

@jered said in Trouble with M201 and M566 settings:

I was wondering about the jerk setting. If the number goes up vs moving closer to zero, how does the machine respond.

Does a higher setting slow down more?

Is was about higher number vs lower number for the jerk setting.

Anyway, I am just messing with the x and y. I have the x and y set to 250mm/m currently, for the jerk setting. It is still not as smooth my ender which has a setting of 600mm/m.

I even put the accel to 250mm/s and still ......

-

@jered

You should see Ender at work.

Maybe you have the time and desire to film the two printers at work so that you can get a better idea and suggest something about it? -

So I put the M566 to 0 and M201 to 10 and didn't notice any change. At this setting the machine should have never reach full speed. Right? The part is small.

-

@norder

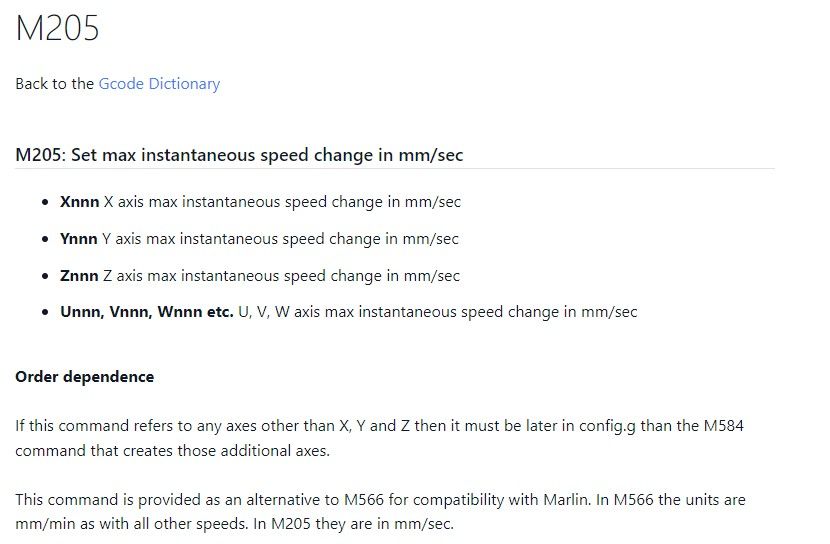

Should I be using the M205 command instead of the M566?Just found this on the internet.

Or is just one command is different units?

-

@jered

I'm just a normal Duet user and not an expert on anything... although...

I mean, I don't know every M command and M205 is new to me.I wonder... why ?

You can easily convert mm/min to mm/s by simply dividing the value by 60.Although I like mm/s better because it gives me a better idea of the speed.

If I'm printing at 30mm/s or at 50mm/s then I can roughly guess when I see it.So judging by the description for the M205 command, it does the same thing as M566 just in a seconds format.

I'm just wondering... is there also a mm/s command for the maximum speed (M203) which is also calculated in mm/min?

And since the M203 command usually comes directly after the M566 command in the config.g, I ask myself... isn't that a trip on your own because you have two different formats one below the other?So nothing should change for you whether you enter M566 Z480 or M205 Z8 in config.g, because according to the description for the command, the result is the same.

In the end it's more of a "matter of taste"!?

Google Translate

-- Original Text --Ich bin ja auch nur ein normaler Duet Nutzer und kein Experte von irgendwas... obwohl...

Ich will damit sagen, ich kenne nicht jeden M Befehl und M205 ist für mich neu.Ich frage mich... wozu ?

Denn mm/min kann man doch sehr einfach in mm/s umrechnen, dazu einfach nur den Wert durch 60 teilen.Obwohl mm/s mir besser gefällt, weil ich mir so die Geschwindigkeit besser vorstellen kann.

Wenn ich mit 30mm/s drucke oder mit 50mm/s, dann kann ich das in etwa schätzen wenn ich es sehe.Also nach der Beschreibung für den Befehl M205 zu urteilen, macht er das gleiche wie M566 nur in einem Sekunden Format.

Ich frage mich gerade... gibt es auch einen mm/s Befehl für die maximale Geschwindigkeit (M203) der ja auch in mm/min gerechnet wird ?

Und da der M203 Befehl meistens direkt nach dem M566 Befehl in der config.g kommt, frage ich mich... stellt man sich so nicht selber ein Bein, weil man zwei unterschiedliche Formate untereinander stehen hat ?Demnach sollte sich also bei Dir nichts ändern, ob Du jetzt M566 Z480 oder M205 Z8 in die config.g einträgst, denn nach der Beschreibung für den Befehl ist das Ergebnis das gleiche.

Am Ende ist es wohl eher eine "Geschmackssache" !?

-

@jered said in Trouble with M201 and M566 settings:

Just found this on the internet.

You write you have the command "found on the internet".

For GCodes, you should use the GCodes for RepRap firmware, not any you find on the web.

The following page lists and describes all of the GCodes for the Duet.

If you come across a GCode on the net, then check what it does in a Duet and whether the Duet understands or knows it at all. -

I am still not satisfied with the M201 command. I changed it to 1 and still I can not see any difference in performance. It appears that this setting does nothing. That being said, I need this to work.

I have literally tried at least 50 different values for this setting and can not see that it is having an effect.

To account for this setting not doing what I think it should, I have had to greatly reduce my print speed to 50mm/s to get a good quality of print.

I am very bummed that this very expensive 3d printer is getting its ass kick by my cheap Ender 5 in quality of print.......

If I make these same changes on my cnc machine, the difference is VERY noticable. But not here.

-

How are you sending the command?

Does your sliced gcode file include M201 commands from the slicer?

If you send M201 by itself, what does it report the current values as? -

@Jered said in Trouble with M201 and M566 settings:

If I make these same changes on my cnc machine, the difference is VERY noticable. But not here.

That's likely because your CNC machine does not have an extruder. Therefore it's only X and Y moves that need to be synchronised. Whereas your printer needs to have extruder moves start and end in sync with the X and Y axes moves. Because you have capped the speed of the extruder by having very low accelerations and instantaneous speeds, then the X and Y axes will be slowed to keep in sync with the (slow) extruder. So you can change X and Y as much as you like but unless you also raise the thresholds for "E", then in order to maintain synchronisation, the X and Y acceleration and jerk will be capped by the low extruder settings.

I explained all this to you in my earlier post.

-

@Jered

I already wrote to you in another thread that you should set the jerk values for Z and all extruders to 1200mm/min.

Because 6mm/min for Z and 120mm/min each for the extruder is too slow.Please post...

-

Your current config.g

-

A GCode of a printed part.

-

A screenshot of your printer settings in your slicer

This might help to solve your problem faster.

Google Translate

-- Original Text --Ich hatte Dir in einem anderen Thread auch schon geschrieben dass Du die Jerk Werte für Z und alle Extruder auf 1200mm/min stellen solltest.

Denn 6mm/min für Z und je 120mm/min für die Extruder ist zu langsam.Bitte poste...

-

Deine aktuelle config.g

-

Ein GCode eines Druckteil.

-

Ein Screenshot Deiner Drucker Einstellungen in Deinem Slicer

Dieses könnte helfen Dein Problem schneller zu lösen.

-

-

I wonder if there is a problem with the M201 setting using the 1XD boards. I am using these boards for x y and z.