G32 Indicating config problems?

-

First time poster, Duet2 user since early 2017?? Pleased with the thoroughness of Duet products and the support it has! Thank you to all in advance (and sorry for the long post!)

Delta - Kossel XL with IR Probe running Duet2 wifi. Did not use the printer for a while and just got back into it. Updated all the firmware recently and basically re-wrote all the config files. Had a problem before with bed leveling and I'm trying to work that out (turns out my glass print bed is slightly curled).

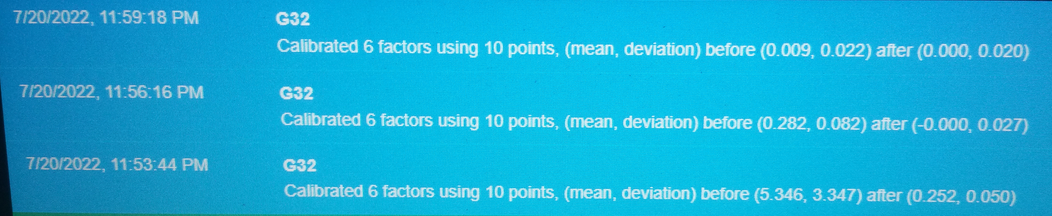

In the process of nailing that down, I came across an error that appears when running G32. At first I didn't realize what I was seeing... first run (G28 first) and then I'd get a higher reading and if I hit G32 again, (G28) and then get a much smaller reading. Trying again, the reading changes slightly, see image.

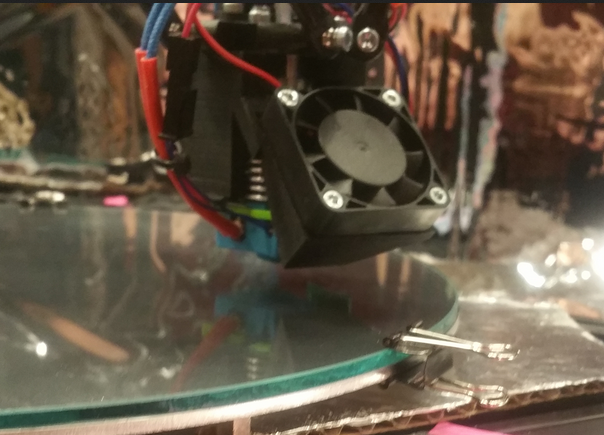

Now the crazy part. The very first run, the print head is closer to the center or maybe I should say a little further from the print bed edge. Bed is 280mm with configuration specifying 250mm usable. These print head/bed images are with me calling out 115mm radius, no offset for the IR probe. This appears to be about the correct distance from center.

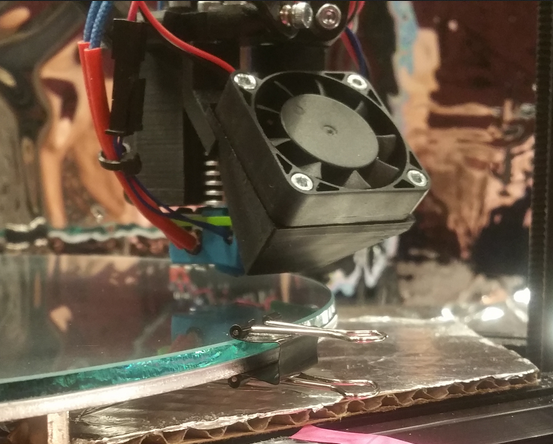

When I hit G32 again, the print head goes right to the edge. These pictures (above and below) are two of the 3 runs listed above. This is #2 or #3. The bed.g file homes (G28) every time before it runs the points specified. The X and Y coordinates displayed in the DWC are the same in both runs, X = 0.0 and Y = 115.0 but clearly they are positioned differently physically.

I have tried this with bed and hot end at temp, cold, from a power off, IR sensor offsets used, no offset, etc. This is repeatable. Clearly after the first run, the printer/Duet2 board makes an adjustment for or maybe "to" Z0 and the the G32 runs after that, uses this new measurement.

Now, the original config.g file had the rod length shorter than actual length by about 6mm (I have the correct, measured length in there now) and I did need to replace the IR sensor a few years ago because I broke the original. How? When manually setting Z height, my readings have always been too low and I was trying to get them where the published numbers say. Example = IR Probe triggered height "should be" somewhere between 1.0 to 2.0mm and mine consistently measures at 0.33 to 0.4mm. From the top Home switch down to a paper shim on the glass is very repeatable. (Edit: saying that, I will try this before and after a G32 to see if there's a difference).

So I am probably overlooking something in the configuration - Homed Height, arm length - something - and any help would be greatly appreciated! Thank you for reading this!

-

if the same move changes the physical position of the effector, it's probably worth checking all the fasteners and connectors for mechanically loose joints.

-

@oliof That's a good thought but I've checked everything and this only seems to occur the first G32 after a power on or recovery from a machine stop/reset. Once its been run, it makes that system 'adjustment' and throws the parameters off. Likewise, in the first image above, running G32 repeatedly gets very close, consistent results -after- that first run.

-

Have you measured the probe trigger height at different points on the bed? The IR sensor can give varying results if the surface changes.

-

@phaedrux I will take a look tonight. I print on glass and under that I have a piece of black construction paper (with bulls eye rings for alignment). One of the things I've tried is lights out with the enclosure closed up. When running a mesh leveling, I believe that I've have seen a difference with lights on vs off.

I did check the Z height (not IR sensor) last night and found a difference when I measured after homing and at temp and that, plus a G32 command. Difference wasn't much, maybe 1.2mm?? Didn't record that change/difference. I'm going to adjust my overall starting height a little more tonight...

Side note- I measured 115mm from bed center and that is where the effector lands in the bottom picture above. So in the first run, its landing short, maybe 20mm... will measure that also.

Thank you phaedrux and oliof for replying.

-

@bilagain

I force my IR-Probe in the M558 command with the parameters A7 S0.007 R0.4 to only move to the next measuring point with a repeatability of at least 0.007mm.

He has 7 failed attempts before the MBL is aborted.

Before each measurement, the IR-Probe is given a time of 0.4 seconds to calm down.

The LED lighting is also interrupted before each measurement so that light scattering is avoided. In addition, an LED light is pulsed, which "can" also lead to errors.However, I do not use glass but a completely matt black magnetic GRP-FR4 pressure plate WITHOUT any imprints or logo.

It is the Blackprint from Printbay (www.printbay.eu) which I can recommend to anyone who has an IR-Probe.

As far as I know, it's a one-man operation...at least when I bought from him.

The record is several years old and indestructible.

They are also available for Delta printers.What is the measurement speed of your IR-Probe ?

Mine is at F60... I go up to F100 at most and my 0.9° stepper motors also increase the repeatability, which I could clearly see with the BLTouch that I used before the IR-Probe.Did you also clean and grease all the spindles after the long break ?

My M558 command line:

M558 C"zprobe.in" P5 H1.5 F60 T18000 A7 S0.007 R0.4P.S.:

line corrected (He has 7 failed attempts before the MBL is aborted.).

Because of a wrong letter, Google Translate translated the sentence into the opposite.

Good that I can speak a little bit of English.

Google Translate

----- Original Text -----Ich zwinge meinen IR-Probe im M558 Kommando mit den Parametern A7 S0.007 R0.4 dazu, erst bei einer Wiederholgenauigkeit von mind. 0,007mm zum nächsten Messpunkt zu fahren.

Dazu hat er 7 Fehlversuche bevor das MBL abgebrochen wird.

Vor jeder Messung bekommt der IR-Probe eine Zeit von 0,4 Sekunden um sich kurz zu beruhigen.

Die LED Beleuchtung wird auch vor jeder Messung unterbrochen damit Lichtstreuungen vermieden werden, zudem ist ein LED Licht gepulst, was auch zu Fehlern führen "kann".Ich nutze allerdings kein Glas sondern eine komplett mattschwarze magnetische GFK-FR4 Druckplatte OHNE jegliche Aufdrucke oder Logo.

Es ist die Blackprint von Printbay (www.printbay.eu) die ich jedem empfehlen kann der ein IR-Probe besitzt.

Soweit ich weiß ist es ein Ein-Mann-Betrieb... zumindest in der Zeit wo ich bei ihm gekauft hatte.

Die Platte ist schon einige Jahre alt und unkaputtbar.

Es gibt sie auch für Delta Drucker.Wie hoch ist die Messgeschwindigkeit von Deinem IR-Probe ?

Meine liegt bei F60... ich gehe maximal bis F100 und meine 0,9° Stepper Motoren erhöhen auch die Wiederholgenauigkeit, das konnte ich damals bei dem BLTouch den ich vor dem IR-Probe nutze, eindeutig feststellen.Hast Du auch alle Spindeln nach der langen Ruhepause gereinigt und gefettet ?

Meine M558 Kommandozeile:

M558 C"zprobe.in" P5 H1.5 F60 T18000 A7 S0.007 R0.4 -

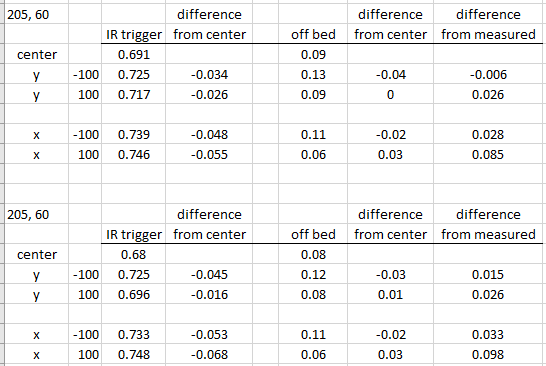

@phaedrux Sorry for the delayed reply. Looks like you are correct. Different measurements at different locations and they are not the same. Close but not identical.

Ok. So I ran through measuring nozzle heights and then IR trigger heights five times. In brief, I heated up my printer to 205 & 60C bed, ran G28 then G32 twice and then started measuring and recording.

Took center measurement first and then went out 100mm and measured. First the IR reading ( G30 S1 from about Z15 = "IR Trigger" height ) and then manually down to the same piece of paper every time ( "off bed" ). I was curious so I used excel to do the math from the IR Trigger point to the measured spot difference. Did the same for the off bed measurement. The last column, "difference from measured" is IR difference minus off bed difference. Not sure if helpful but I was looking for a trend indicator.

Side notes. IR trigger height has changed vs my original post - new nozzle and adjusted. On the first G32, the print head only moves out 90mm and begins to measure. Its configured for 115mm. Every G32 after that, until a reset/power off/etc, moves 115mm. I also know that the effector does NOT move in a flat plane until the G32 command is run. Its movement is high in the middle and about 10mm low at the outside edge of the print bed. I don't know if both these are normal or not.

-

@norder Thank you for your reply. I apologize for my delayed response.

I did clean everything up, gave it a few drops of thin or very thin oil where needed and made sure everything moved freely and easily.

Thank you for the suggestion on the print bed. I looked at them when you posted and may just go that direction.

I like what you've done with your M558 probe code with adding multiple times to probe each spot, the tolerance and then probe recovery time. Here's what mine is currently set for. This is the one generated by the config wizard:

M558 P1 C"zprobe.in" H5 F120 T6000

I have not had a chance to add in some of the things you've identified yet - my wife is finally better from c19 so hopefully soon. I am wondering if those settings - slowing down, multi probe and time delay - will make a difference in the readings I am getting ( see post above ). Hopefully I can make this changes tomorrow and give it a test! Will post my results.

-

@bilagain

You don't have to apologize, but it's nice of you.

As the saying goes... "Take your time and not life".

I re-read my previous comment and noticed an error.

In the German text it was only one letter that was wrong, but Google then reversed the translated sentence into the opposite.

I just corrected the comment, see P.S.:Google Translate

----- Original Text -----Du musst Dich nicht entschuldigen, aber es ist nett von Dir.

Wie sagt man hier so schön... "Nimm Dir Zeit und nicht das Leben".

Ich habe meinen vorherigen Kommentar noch einmal durchgelesen und dabei ist mir ein Fehler aufgefallen.

Im deutschen Text war es nur ein Buchstabe der falsch war, aber Google hat dann den übersetzten Satz ins Gegenteil umgekehrt.

Ich habe den Kommentar gerade korrigiert, siehe P.S.:Im deutschen Text habe ich nur den einen Buchstaben korrigiert !