Weak torque only during head travel

-

Hello,

When the print head is stationary, with the motor switched on, moving the head by hand requires 4kg of effort (effort according to X or Y, measured with a dynanometer).

On the other hand, when the head is printing or simply making a controlled movement, it takes between 0.5 and 1kg of effort to make the print head "derail".

4k of resistance is fine for me. 0.5 to 1kg is so low that as soon as the nozzle comes into contact with a small print defect, it "derails" for no reason (layer shifting).

Any idea why the motors get all weak (torque) during printing? While outside of printing they have a normal torque.

I tried to many thing but the problem still here... Imo, the problem come frome my config file but i don't know what can fix this problem.

I work on a Ratrig with Duet 3mini 5+ (TMC2209 drivers) and my motors are Nema 17.

Here is my config.g file :

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"GigaRat" ; set printer name M669 K1 ; CoreXY G21 ; Set Units to Millimeters ; Network M552 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 D2 ; physical drive 0.0 goes forwards M569 P0.1 S1 D2 ; physical drive 0.1 goes forwards M569 P0.2 S1 D2 ; physical drive 0.2 goes forwards M569 P0.3 S1 D2 ; physical drive 0.3 goes forwards M569 P0.4 S1 D2 ; physical drive 0.4 goes forwards M569 P0.5 S1 D2 ; physical drive 0.5 goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E0.5 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.154 Y80.154 Z798.56 ; set steps per mm M906 X1000 Y1000 Z800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M566 X400.00 Y400.00 Z6.00 E120.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X10800.00 Y10800.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z100.00 E3600.00 ; set accelerations (mm/s^2) ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X295 Y272 Z280 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; configure active high endstops M574 Y2 S1 P"io3.in" ; configure active high endstops M574 Z1 S2 ; configure Z-probe endstop for low end on Z M671 X-4.5:150:304.5 Y-4.52:305:-4.52 S5 ; define positions of Z leadscrews or bed levelling screws M557 X20:280 Y20:280 P5 ; define 5x5 mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out5 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C ;; Run Bed PID Tune!! Bellow is an example for a 300x300 bed M307 H0 A303.1 C356.7 D1.4 S1.00 V24.0 B0 ; Fans M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 C"Hotend Fan" S0 H1 T45 L255 ; set fan 0 name and value. Thermostatic control turned on for Hotend M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 C"Layer Fan" S0 H-1 L255 ; set fan 1 name and value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M950 H1 C"out1" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 ; set the maximum temperature in C for heater ; EVA 2 / BMG / E3D V6 M92 E409 ; set extruder steps per mm, 0.9 angle/step (LDO Pancake) M906 E800 ; set extruder motor current (mA) and idle factor in per cent M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.060000e-8 A"Hotend" ;; Run Heater PID Tune!! M307 H1 A751.5 C196.6 D4.7 S1.00 V23.9 B0 ; Z-Probe ;; Inductive Probe ; M558 P5 C"!io3.in" H5 F400 T5000 ; set Z probe type to unmodulated and the dive height + speeds ; G31 P500 X-30 Y-15 Z0.20 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ;; BLTouch M950 S0 C"io2.out" ; Create a servo pin on io7 M558 P9 C"io2.in" H5 F240 T10800 A5 ; set Z probe type to unmodulated and the dive height + speeds G31 P25 X24.5 Y-46 Z3.5 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ; Pressure Advance M572 D0 S0.035 ; PanelDue M575 P1 S1 B57600 ;Température Chambre M308 S2 P"temp2" Y"thermistor" T100000 B4725 A"Chambre" ;M950 F2 C"out5" T2 ; create fan 0 on pin out3 and set its frequency ;M106 P2 T40:60 H2 ; set fan 0 name and value. Thermostatic control turned on for Hotend T0Thanks !

-

@aodrennn I would check to make sure your motor currents are close to what they should be. Do you have a part number and/or datasheet for your stepper motors?

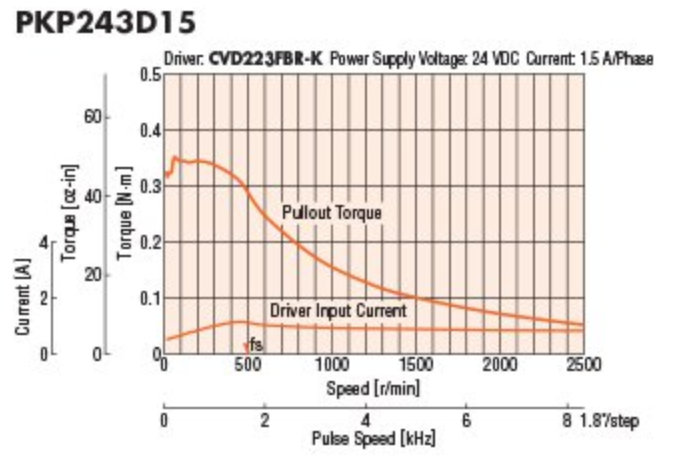

What you're experiencing isn't entirely surprising - stepper motors have a torque curve - relating rotational speed to pullout torque. Different motors can have very different torque values at a given speed. Here is a random chart for a Nema17 motor.

As speed increases, torque decreases. If you move at very fast speeds, you may find that small obstructions (infill lines, print defects, etc) will cause the motor to stall out or miss steps.

If you haven't already, I would check out one of the stepper motor sections of the documentation: https://docs.duet3d.com/User_manual/Connecting_hardware/Motors_choosing . You'll want to double check that with your power supply, steps/mm, motor choices, you can hit the speeds you want without sacrificing too much torque.

-

I kept the config.g from ratrig so I did not change the currents in the motors because I expected that they were corrects and I don't find someone with the same problem.

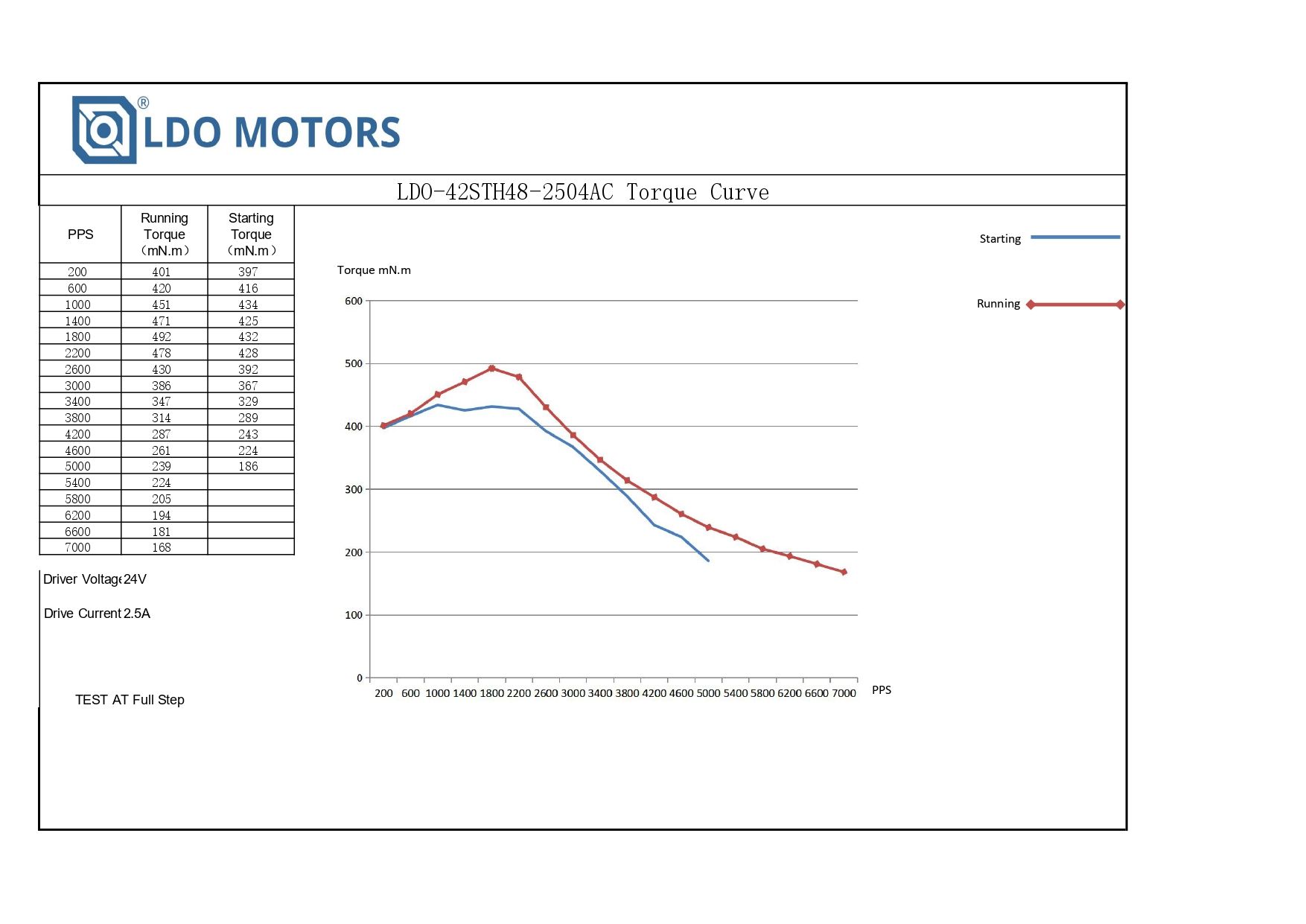

So here is the curve from the datasheet of my motors.

Most of the time, the print speed is around 120 mm/s and 250 mm/s for travelling.So I change in my config.g M906 X1000 Y1000 Z800 I30 to M906 X1500 Y1500 Z1000 I30.

I'm a little bit scared about overheating my drivers (TMC2209), should I cool my motherboard ?

-

@aodrennn said in Weak torque only during head travel:

Most of the time, the print speed is around 120 mm/s and 250 mm/s for travelling.

Er, you've configured the maximum speed for X and Y to 10,800 mm/min which is 180mm/sec so you won't be seeing that 250mm/sec travel speed.

I'm a little bit scared about overheating my drivers (TMC2209), should I cool my motherboard ?

The drivers are good for 2Amps (2.8A peak) and the duet boards use thick copper traces, and the drivers do have over temperature warnings and will shut down if they get very hot. So it usually isn't necessary to actively cool the drivers but it depends on a number of factors such as does the board have plenty of free air around it or is it in an enclosure?

-

@deckingman

In fact, I never changed that point in the config.g lol, thank you for pointing this out to me.Thanks for all informations ;))

-

@deckingman

The motherboard is outside the printer chamber so I think it's okay. But it cost nothing to put a fan on the motherboard so I think I'll do that. -

@aodrennn said in Weak torque only during head travel:

@deckingman

The motherboard is outside the printer chamber so I think it's okay. But it cost nothing to put a fan on the motherboard so I think I'll do that.It's a wise precaution if you are able to do it easily. You can configure a fan to run thermostatically too. Unfortunately the driver chips don't report actual temperatures - just a digital "high" if the temperature get too hot. In the past I have stuck a small bead thermistor onto a driver chip with a small dab of epoxy and used that, or you could use the MCU temperature, or you could just have the fan run whenever power is applied which is the simplest option.

For info, I run 1.8 Amps on my XY drivers and 2.3 Amps (Nema 23s) on my UV gantry with no active cooling of the boards and the driver chips barely get above ambient even when throwing my 3Kg extruder (UV) gantry around at up to 350mm/sec. But that's with a 6HC main board and 3HC expansion boards (different drivers to yours).

-

@deckingman

Yeah I think I'll use MCU temperature to control the fan.

Thanks for all it gaves me ideas and orders of magnitudes.