I could use some help

-

@mac said in I could use some help:

@fcwilt thank you for considering my concern. I’ll remove the ^ after I get up.

Here is what woke me up this morning.

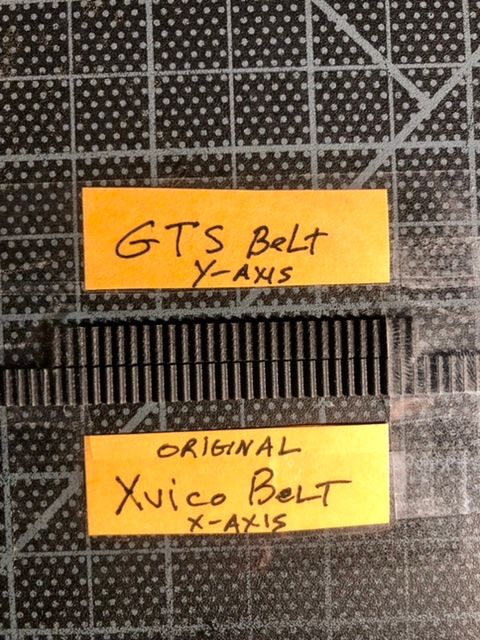

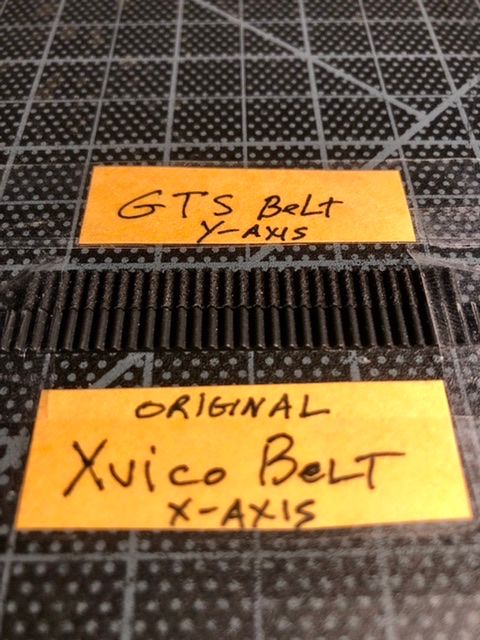

Hopefully the GTS belt is not adding to our problems.

But these belts around my neck in my bad dream were my brain chewing on DWC’s statement that 452mm’s is 350mm’s. Then I realized that now, DWC thinks that the distance from the rear Y-endstop to the front of the printer (and possibly a few mm’s more) is 220mm’s. If DWC thought that 226mm’s was 220mm’s X 2, that would be 452mm’s? We have the steps set at 100, correct? If we were to change that number to 50, or 200, what would be the impact?

Also, by the labeling on those 2 belts, I wanted to imply that the X-axis still has the original belt from the XVico on it.

Maybe I should change that to a GTS belt?

And the Z-screw, it looks like what was on my Anet. Do we have the steps for Z correct?

Frankenstein’s Cinderella is giving me nightmares.

Mac

Hi mac,

Hope you are feeling better.

Don't worry about the belts for now. It is very unlikely they are part of the problem.

The Z axis in on my list of things to check.

Right now I want to get Y working, then get X working and then Z working.

Frederick

-

@fcwilt It's almost 7 AM, but I can't start working until my wife gets up around 8. Is 8:30 a good time for you?

-

@fcwilt here are the results: I discovered that my wireless mouse and the printer aren't really communicating. Sometimes, the bed moves the whole 10mm's, sometimes it turns half or less of that. So it isn't click, pulley turns, bed moves 10mm's, it's more like click, nothing happens, click, the pulley turns 3 mm's, click, the pulley doesn't do anything, click, it turns 10mm's.

So I turned off the wireless mouse, and plugged a USB mouse into my keyboard.

I'm going to do the test again, from the beginning.

-

@fcwilt Test no. 2, same results with a wired mouse. I'm clicking the same way every time, and that's not working every time. Maybe the wifi is wonky?

Status isn't reporting anything.

-

@fcwilt so here's some bad news: I'm experimenting with the code (G1 H1 Y-XX FXXXX). I used 2600 for the F, because that "speed?" worked last night? No change, really. The signal's going to the printer are having a hard time getting there, or, the printer's having a hard time understanding and acting on them?

So then I changed the code to: G1 H2 Y-20 F2600

The bed slides towards the rear like it's on ice.

And here's some more bad news: Status is displaying the position of the bed. Y is at -160 now.

The end-stop fully compressed.

Mac

-

@fcwilt more bad news: I went to the Dashboard. There, Display is showing me the position of the bed. (So maybe, when you're in the CONSOLE, that information isn't available?).

Anyways, the bed is at 87 right now. That's the 18" mark (the 457mm mark).

The jog selections for Home Y are available.

Mac

-

@fcwilt I'm using G1 H2 Y-20 F2600 to send the bed back to the Y-endstop. The transmission rate is working very well. The foot of the bed (underneath it, on the mounting hardware for the bed), is depressing the endstop. Status is reporting -220.0.

The Home Y jog buttons are active. However, a single click on Y+50 sends the bed all the way to Y= 0.0, which is at the front of the bed.

Mac

-

@mac said in I could use some help:

@fcwilt more bad news: I went to the Dashboard. There, Display is showing me the position of the bed. (So maybe, when you're in the CONSOLE, that information isn't available?).

Anyways, the bed is at 87 right now. That's the 18" mark (the 457mm mark).

The jog selections for Home Y are available.

Mac

Hey Mac,

As to what the DWC reports: It means nothing until the axis is homed. Yes the display changes as you issue Y movement commands but the DWC has no reference as to where the bed was before the move.

Do you have a part number for the X, Y and Z steppers? It may be printed somewhere on the stepper itself.

In your config.g file: The M906 commands which set the currents for the steppers: Where did you get those values?

Thanks.

Frederick

-

@fcwilt I think what we've learned from this experiment is: G1 H1 Y-20 F2600 doesn't communicate with the board / printer very well, and G1 H2 Y-20 F2600 seems to have no problem communicating with the board / printer?

-

@mac said in I could use some help:

@fcwilt I think what we've learned from this experiment is: G1 H1 Y-20 F2600 doesn't communicate with the board / printer very well, and G1 H2 Y-20 F2600 seems to have no problem communicating with the board / printer?

Hi Mac,

The particular command issued would not in anyway affect communication with the board.

The configuration of the board may be preventing the commands from being performed correctly.

Did you do the test I asked for? The one using a series of G1 H1 Y-10 commands to move the bed until it reach the endstop.

Do you remember that list of steps I posted?

Thanks.

Frederick

-

-

-

-

@mac

Thanks, Mac.

That is just what I needed to know.

Did they come with the printer or are the new items you installed?

Frederick

-

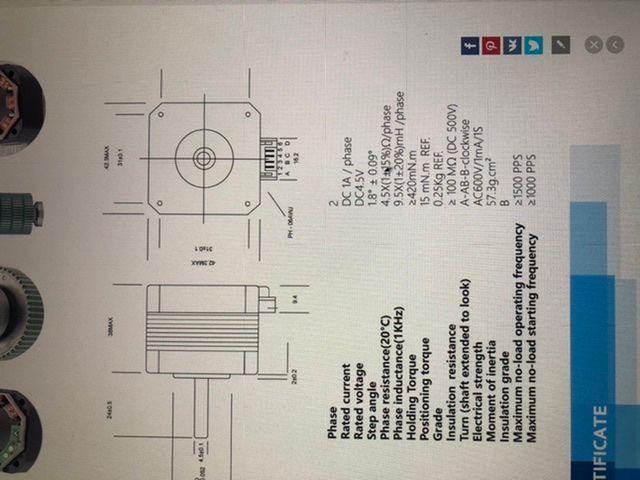

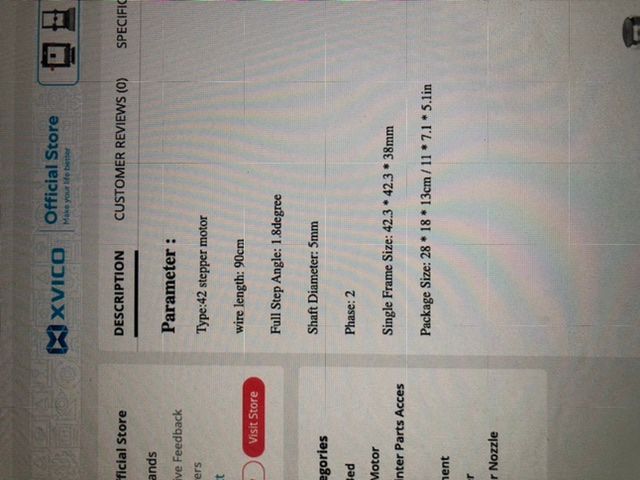

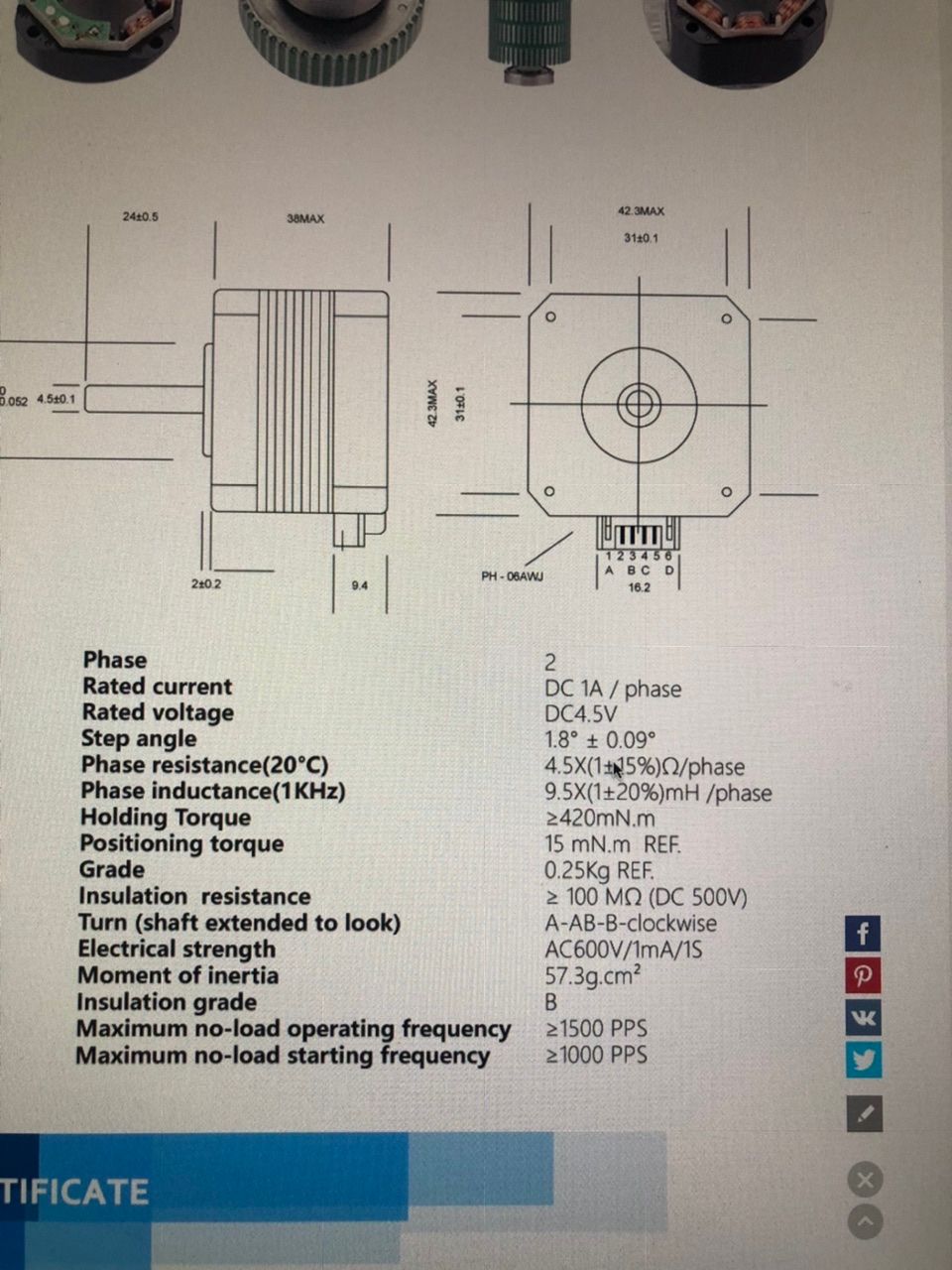

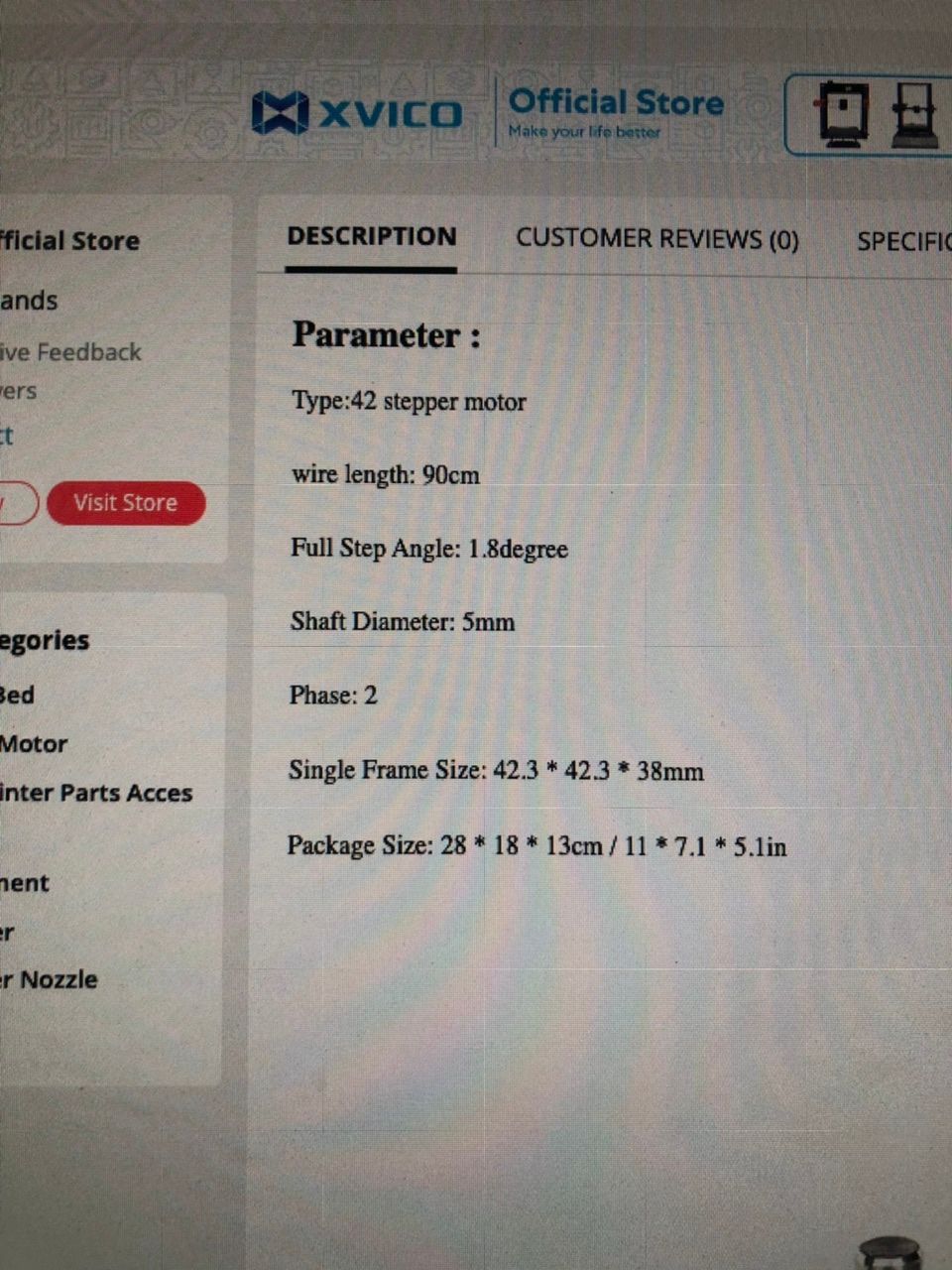

@fcwilt the motors that came with the printer are painted black. there is no information on them. I'm trying to think if I still have the literature? (I'll work on that). The pictures I just posted (twice), are based on googling Xvico motors, Alienexpress. That's what I found, those pictures match my motors to a T, although the wiring that came with mine is colored differently.

-

@mac said in I could use some help:

@fcwilt the motors that came with the printer are painted black. there is no information on them. I'm trying to think if I still have the literature? (I'll work on that). The pictures I just posted (twice), are based on googling Xvico motors, Alienexpress. That's what I found, those pictures match my motors to a T, although the wiring that came with mine is colored differently.

Well steppers with very different characteristics can all look the same as it is the wiring on the sides that makes the difference.

So backing up to the question about the M906 current settings for the existing steppers - where did those value come from?

Thanks.

Frederick

-

@fcwilt the specs for the motors are in the lower picture, 600 V/1mA.

-

Motor specs:

Phase: 2, Rated current DC 1A / phase Rated voltage DC4.5V, step angle 1.8 degrees + or - 0.09 degrees phase resistance (20 degrees C) 4.5X(1 + or = 15%) ohm / phase Phase inductance (1 KHZ) 9.5X (1 = or - 20%) mH / phase Holding Torque more or less 420 nM.m Position torque 15 mN.m REF. Grade: 0.25Kg REF. Insulation resistance more or less 100 M ohm (DC 500V) Turn (shaft extended to look) A-AB-B-clockwise Electrical strength AC600V/1mA/1S Moment of inertia 57.3g.cm squared Insulation grade: B Maximum no-load operating frequency more or less 1500 PPS Maximum no load starting frequency, more or less 1000 PPS -

-

@mac said in I could use some help:

@fcwilt you must be gone.

I'm going to go look for the box the Xvico came in.

Mark

I was outside filling up the hot tub.

The specs you posted are reasonable as those steppers are but 38mm in length.

And if they are the steppers that came with the printer then my theory as to what is wrong is looking very good.

Still when you get a chance run the test I posted about using G1 H1 Y-10 moves repeatedly until the endstop is activated.

Until I know the result of that I cannot describe the next test to try.

Thanks.

Frederick