attempting to extrude with no tool selected - SOS

-

hey lovely community,

I have this error. I can print normally but I now I installed a tool switch and I think it has to be solved in this case.; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Mon Aug 02 2021 16:15:35 GMT+0200 (Mitteleuropäische Sommerzeit) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M552 s1 M550 P"Black Flamingo" M587 S"AndroidAPebc3_EXT" P"hhhhhhhh" G4 S4 M574 C1 S3 M574 C0 Z0 M915 P0.5 C S0 F0 R1 ; Drives ;closed loop M569.1 P20.0 T2 C5 R69 I0 D0 H10 ; Configure the 1HCL board at CAN address.20quadrature encoder 128 steps/motor full M569.1 P21.0 T2 C5 R69 I0 D0 H10 ; Configure the 1HCL board at CAN address.21quadrature encoder 128 steps/motor full step. M569.1 P30.0 T2 C5 R100 I0 D0 H10 ; Configure the 1HCL board at CAN address.21quadrature encoder 128 steps/motor full step. M569 P20.0 D4 S0 ; Configure the motor on the 1HCL at can address 20 as being in closed-loop drive mode (D4) and not reversed (S1) M569 P21.0 D4 S1 ; Configure the motor on the 1HCL at can address 21 as being in closed-loop drive mode (D4) and not reversed (S1) M569 P30.0 D4 S0 ; Configure the motor on the 1HCL at can address 21 as being in closed-loop drive mode (D4) and not reversed (S1) Other drives; open loop; M569 P0.0 S0 ; physical drive 0.0 goes forwards M569 P0.1 S0 ; physical drive 0.2 goes forwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 M569 P0.5 S0 M569 P100.0 S1 ; physical drive 0.2 goes forwards M569 P110.0 S1 ; physical drive 0.2 goes forwards M584 X30.0 Y20.0:21.0 Z0.0:0.1:0.2:0.3 C0.5 E100.0:110.0 ; set drive mapping M350 X32 Y32 Z128 E16:16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z5120.00 C91.022 E409.00:409.00:409.00 ; set steps per mm M566 X600.00 Y600.00 Z60.00 C3000 E1000.00:1000.00:600.00 ; set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z500.00 C10000 E6000.00:6000.00:6000.00 ; set maximum speeds (mm/min) M201 X1600.00 Y1600.00 Z500.00 C550 E2500.00:2500.00 ; set accelerations (mm/s^2) M906 X1700 Y1700 Z2300:2300:2300:2300 C600 E1000:1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S300 ; Set idle timeout M671 X-140:-140:990:990 Y-140:990:990:-140 S20 ; leadscrews at front left1 and n´back2. back rigth3 and front4 ; Axis Limits M208 X0 Y-100 Z0 S1 ; set axis minima M208 X860 Y860 Z850 S0 ; set axis maxima ; Endstops M574 X2 S1 P"^30.io1.in" ; configure active-high endstop for high end on X via pin ^io3.in M574 Y2 S1 P"^20.io1.in+21.io1.in" ; configure active-high endstop for high end on Y via pin ^io1.in ; Z probe M558 P5 C"0.io1.in" H8 F2000 I0 T5000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds M558 K1 P5 C"0.io2.in" H8 F2000 I0 T5000 ; create probe #1 for use with M585, active low G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height; Z probe M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters M557 X50:700 Y50:700 S65 ; define mesh grid ;Tool Switch M558 K1 P5 C"0.io2.in" H8 F2000 I0 T5000 ; create probe #1 for use with M585, active low G31 P200 X0 Y0 Z0 ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 R0.243 C586.2 D33.87 S1.00 V0 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 M143 H0 S120 M308 S1 P"100.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as PT1000 on pin 121.temp0 M950 H1 C"100.out0" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 R1.553 C487.8 D10.35 S1.00 V0 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 M308 S2 P"110.temp0" Y"thermistor" T100000 B4138 ; configure sensor 2 as PT1000 on pin 121.temp0 M950 H2 C"110.out0" T2 ; create nozzle heater output on out1 and map it to sensor 2 M307 H2 B0 R1.553 C487.8 D10.35 S1.00 V0 ; disable bang-bang mode for heater and set PWM limit M143 H2 S250 ; set temperature limit for heater 1 to 250C ; set temperature limit for heater 1 to 250C ; Fans M950 F0 C"100.out1" Q500 ; create fan 0 on pin 100.out1 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M563 P0 D0 H1 ; tool uses extruder 0, heater 1 M950 F1 C"100.out2" Q500 ; create fan 1 on pin 100.out2 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M563 P0 D0 H1 F1 ; tool uses extruder 0, heater 1 M950 F2 C"110.out1" Q500 ; create fan 2 on pin 101.out1 and set its frequency M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off M563 P1 D1 H2 ; tool uses extruder 0, heater 2 M950 F3 C"110.out2" Q500 ; create fan 3 on pin 101.out2 and set its frequency M106 P3 S1 H2 T45 ; set fan 3 value. Thermostatic control is turned on M563 P1 D1 H2 F2 ; tool uses extruder 1, heater 2 ; Magnete M950 F8 C"0.out8" Q500 CMagnet0 ; create magnet 0 on pin out9 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F9 C"0.out7" Q500 CMagnet1 ; create magnet 0 on pin out9 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F10 C"21.out0" Q500 CMagnet2 ; create magnet 0 on pin out9 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F11 C"21.out1" Q500 CMagnet3 ; create magnet 0 on pin out9 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X-9 Y-39 Z-3.65 ; set initial tool 0 active and standby temperatures to 0C G10 P0 R0 S0 M563 P1 D1 H2 F2 ; define tool 1 ; set initial tool 0 active and standby temperatures to 0C G10 P1 X-8.4 Y-39.2 Z-4 G10 P1 R0 S0 ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0

thanks to your help

R.G.

-

@index4d said in attempting to extrude with no tool selected - SOS:

; Z probe

M558 P5 C"0.io1.in" H8 F2000 I0 T5000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds

M558 K1 P5 C"0.io2.in" H8 F2000 I0 T5000 ; create probe #1 for use with M585, active low

G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height; Z probe

M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters

M557 X50:700 Y50:700 S65 ; define mesh grid;Tool Switch

M558 K1 P5 C"0.io2.in" H8 F2000 I0 T5000 ; create probe #1 for use with M585, active low

G31 P200 X0 Y0 Z0You've got some problems here. Are you trying to define two probes? Or what are you meaning with tool switch?

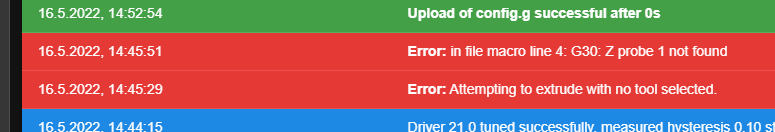

When are you getting those errors?

-

@phaedrux

tool switch = is a z prob for tools.I´m getting this error when selecting tool.

-

I'm not exactly sure what you're trying to accomplish without more detail but the way you've got M558 setup right now isn't correct for multiple probes.

Review the M558 wiki entry

https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m558-set-z-probe-typeYou've got M558 K1 P5 commands twice. Remove one.

The first M558 command will require a K0 to define it as the first probe. And then any time to configure or call a probe you need to specify which probe you mean to call by including K0 or K1 -

@index4d said in attempting to extrude with no tool selected - SOS:

I´m getting this error when selecting tool.

Post your tool change files as well. And your homing files.

And can you explain the overall goal of what you're trying to do?

-

error - can´t post

-

@index4d but I can post that there is an error... funny

-

Try again.

-

-

@phaedrux

strange errors....

I wanted to install a tool switch like in this thread. I thougth I have to solve problem ´´ attempting with no tool......´´.

Before it was never a problem, I´m not sure if it´s a problem for the tool switch. -

In that thread they used a switch as an endstop instead of another probe.

-

@Phaedrux ok yes I know but I don´t care.

It´s a thing to measure the z heigth. -

@phaedrux said in attempting to extrude with no tool selected - SOS:

I'm not exactly sure what you're trying to accomplish without more detail but the way you've got M558 setup right now isn't correct for multiple probes.

Review the M558 wiki entry

https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m558-set-z-probe-typeYou've got M558 K1 P5 commands twice. Remove one.

The first M558 command will require a K0 to define it as the first probe. And then any time to configure or call a probe you need to specify which probe you mean to call by including K0 or K1Have you taken this post into consideration yet?