Progress goes boink - bad noises, no movement, what to replace?

-

Actually, it's not so much boink, probably more bok(it), bok(it), bok(it): https://vimeo.com/707224929 (that's a video, but it's the sound track that matters).

In another thread, I reported that I was getting 'Driver x error: phase B short to Vin' on my Fly E3 Pro in my sand table. Since moving the motor from driver 0 to driver 1 caused the error to also move from 0 to 1, it seemed to be the motor or cable.

Today I tried swapping cables around, and the error stayed on driver 1 (that is, driver 1 and motor X errors with either of the available cables), suggesting it's not a cable.

Then I tried swapping the drivers. I was previously using 0 or 1 for X and 3 for Y. I moved Y to 0 and X to 3. The error followed the motor (i.e. driver 3 which had been fine driving Y was now generating short to Vin when driving X). So I thought it must be the motor.

But I decided I'd roll back to RRF 3.3.0, just to see what it did.

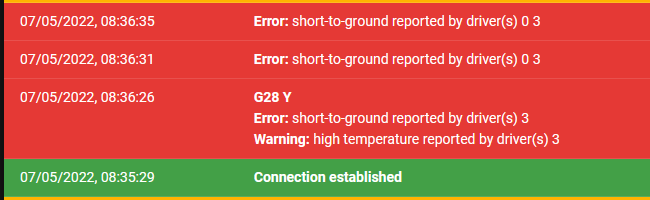

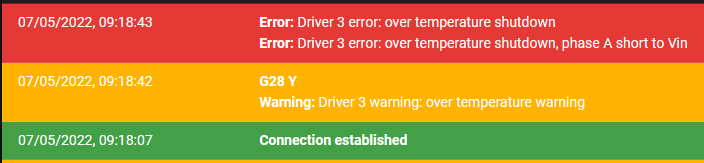

Now I have short-to-ground, high temperature and over temperature reported by variously both driver(s) 0 and 3, e.g.:

I also get the bok(it) noise (see video), at various tempos between that of the video or two or three times that speed, and an occasional mooing sound (as if an axis is driving against an end-stop, but the axis isn't at an endstop).

Emergency stop stops all the noises, but that seems to be the only thing that does.

Returning to RRF 3.4.0, I'm back to short-to-Vin (not short-to-ground), now have temperature shutdown but axis Y is working again. No more bok(it) noises, but now the motor makes a whooshing noise (sounds like a PC cooling fan running fast). Is it significant that 3.3.0 was all short-to-ground but 3.4.0 is always short-to-Vin ?

Motor and board are both about six months old, faultless until a week or two ago, the other motor which was OK until today is a couple of years old, but was in an extruder faultlessly for a year and in a 'bits box' for the rest of the time. PSU was new a week ago and installed yesterday while I had the table dismantled fault-finding (ie faults started before this PSU).

Something is borked, clearly. I'm now not sure whether it's the board or the motor (given that on different firmware versions I get errors on different drivers). I don't really want to replace both motors and the board and the wiring (and the PSU?) but I don't want to replace just one thing and have something else fry. Any opinions?

-

Well, I've solved this, by noticing that the fault occurs only after the 'idle hold' timeout. I can print any number of files as long as I follow the previous quickly enough, but if the M84 timeout occurs then the next time I attempt to move axis X I get a short to Vin. (This was pernicious, because when I was testing I'd print one after another and all would go ok, then I'd come back later to do something and it would fail!)

I did have a very very low idle current factor -

M906 X1000 Y1000 I5i.e. 5% of full. That's because my mechanism can't droop (it's X and Y only) so I didn't think I needed much hold current. If I increase the idle factor to a more normal value (I've actually set to 35%) then it can timeout fine and I can still print the next file.I have no idea why this behaviour started (I've had 5% for months and months), but setting idle current factor to a higher value seems to have stopped shorts being reported, and fortunately the only components I'd got round to replacing so far were cables ie not very costly).