Homing crashes

-

Why do you have a Y move in your X homing code?

Why do you have a X move in your Y homing code?

Frederick

-

@fcwilt

I home to the front left corner. If I home y without moving I will strike the z axis lead screw or fan. -

@trublu89 said in Homing crashes:

@fcwilt

I home to the front left corner. If I home y without moving I will strike the z axis lead screw or fan.That suggests your axis limits may be wrong. You should not have to worry about the position of Y when homing X or the position of X when homing Y.

Could you post one or more pictures show what the problem is?

Frederick

-

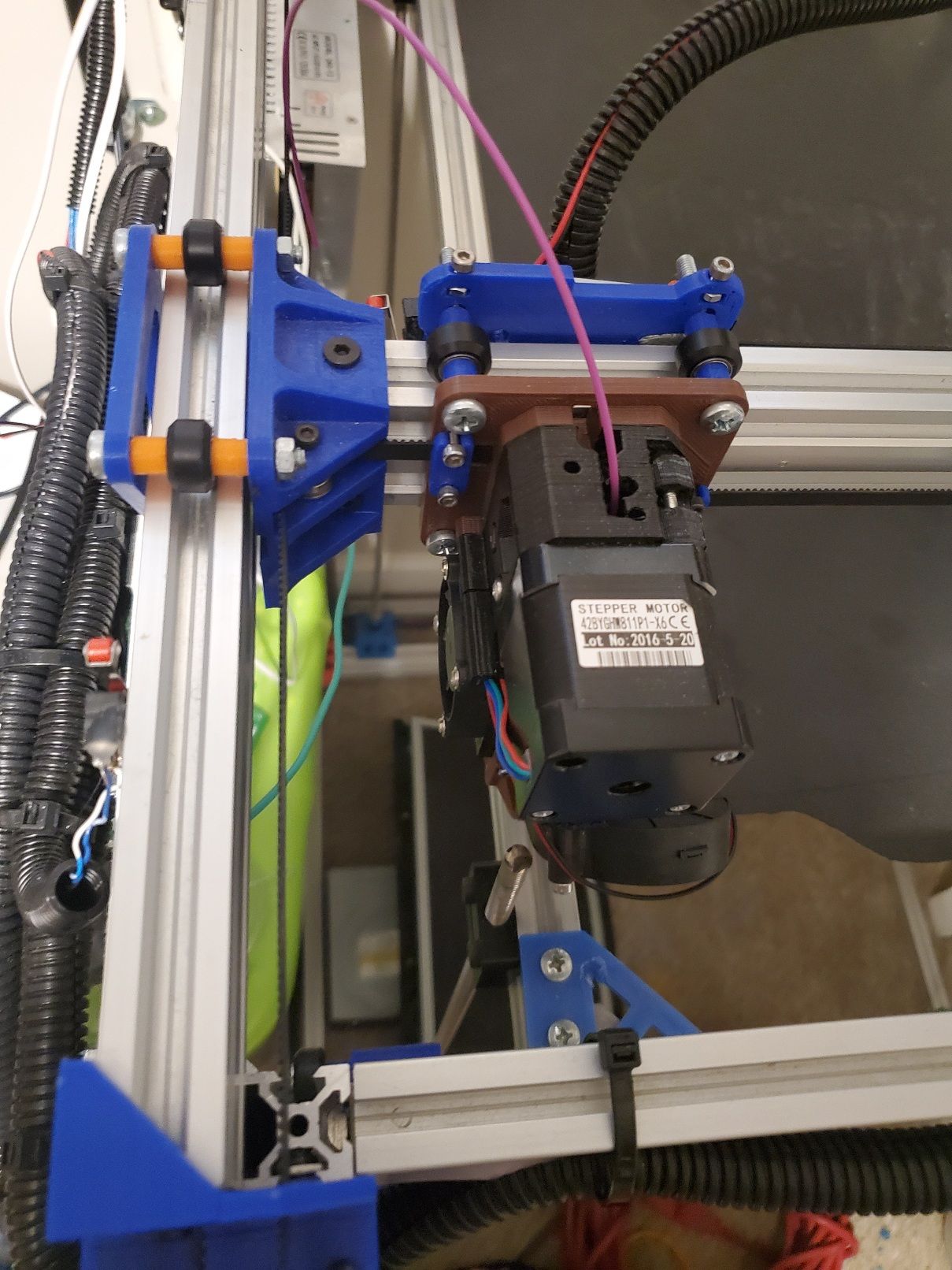

Attached is where I home to. So I should move my limit switches?

-

Wow, that is a lot of hardware in the way.

Do the axis min/max setting prevent hitting that lead screw during normal printing operations?

I don't know what the best solution is for you. Just for reference my endstop sensors are all positioned so there is no risk of hitting other parts of the printer during homing.

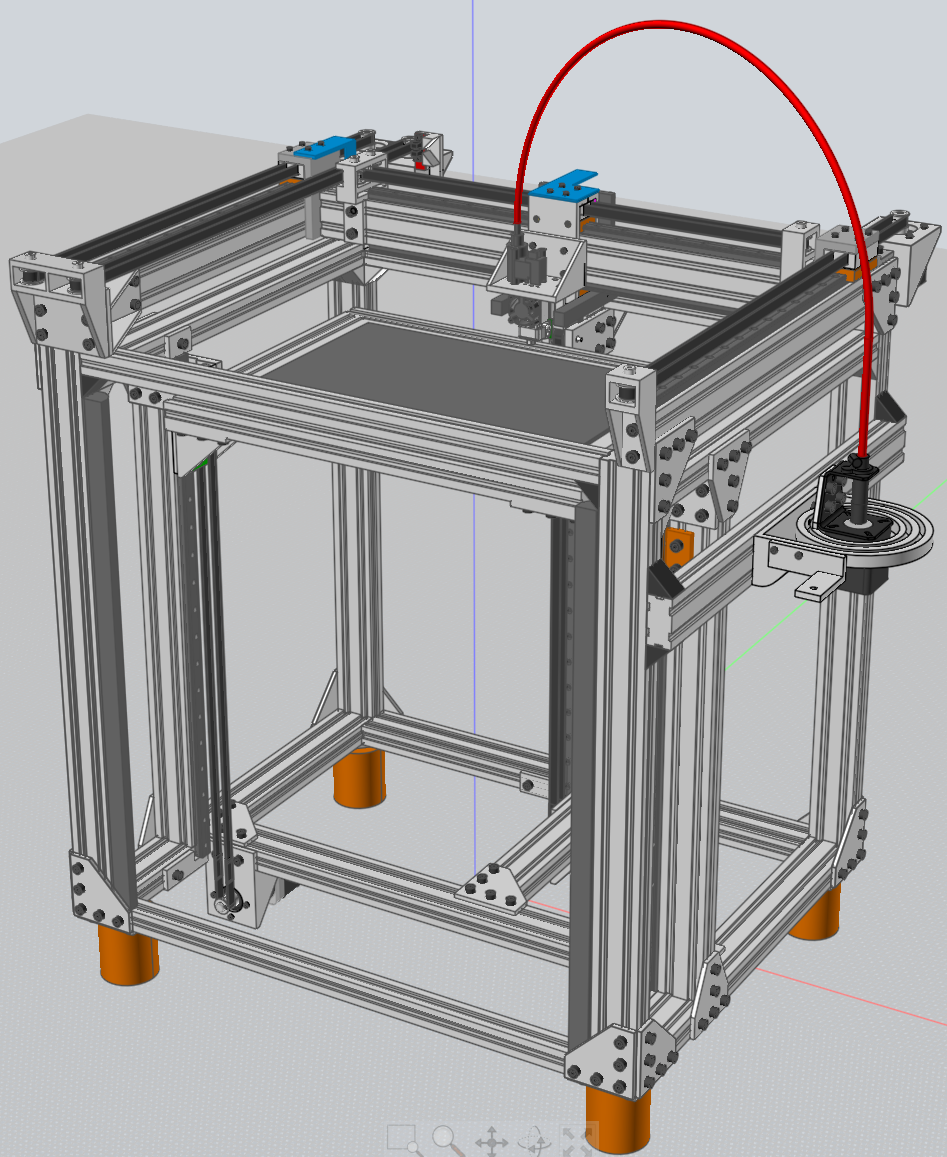

One possibility would be to re-design the extruder mount to use a Zesty Nimble remote drive extruder. This system puts the stepper on the frame and drives the geared extruder via a flexible cable.

Here is one of my printers using a Nimble. On this printer to reduce the strain on the drive cable the stepper is mounted on a gimbal but that is optional.

Frederick

-

@fcwilt

I'm kinda stuck with what I have right now. Maybe I can reduce the size of the bed by moving y back. That should clear hitting the fan or lead screw. -

@trublu89 said in Homing crashes:

@fcwilt

I'm kinda stuck with what I have right now. Maybe I can reduce the size of the bed by moving y back. That should clear hitting the fan or lead screw.I have had to re-position the bed during printer design to resolve problems like yours.

Frederick

-

@fcwilt

Originally it was a 3 lead screw system but the weight causes it to fall so I recently added the fourth and haven't been able to begin calibrating of dialing in the 1.2 nozzle. -

@trublu89 said in Homing crashes:

@fcwilt

Originally it was a 3 lead screw system but the weight causes it to fall so I recently added the fourth and haven't been able to begin calibrating of dialing in the 1.2 nozzle.What was the lead of the lead screws?

There are a number of solutions to beds that fall that don't involve adding another lead screw.

One is using lead screws with a smaller lead. A common lead is 8mm but you can purchase lead screws with 4, 2 or 1. But you can run into speed problems with small leads.

Another is using a geared stepper motor or a pair of pulleys to obtain the same result, such as a 20 tooth pulley driving a 100 tooth pulley.

On the printer I posted I used stepper motors with integral 5:1 planetary gear boxes and the bed stays put as needed.

Frederick

-

@fcwilt the standard 8mm from open builds.

I had a stepper motor with gearbox never thought to use that.